High efficiency cement composite grinding additive and preparation method thereof

A technology of grinding aid and cement, which is applied in the field of cement, can solve the problems of insignificant cement strengthening effect of grinding aid, little effect on cement early strength and late strength, etc., so as to prevent over-grinding phenomenon and reduce cement sieve allowance , Outstanding effect of grinding aid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

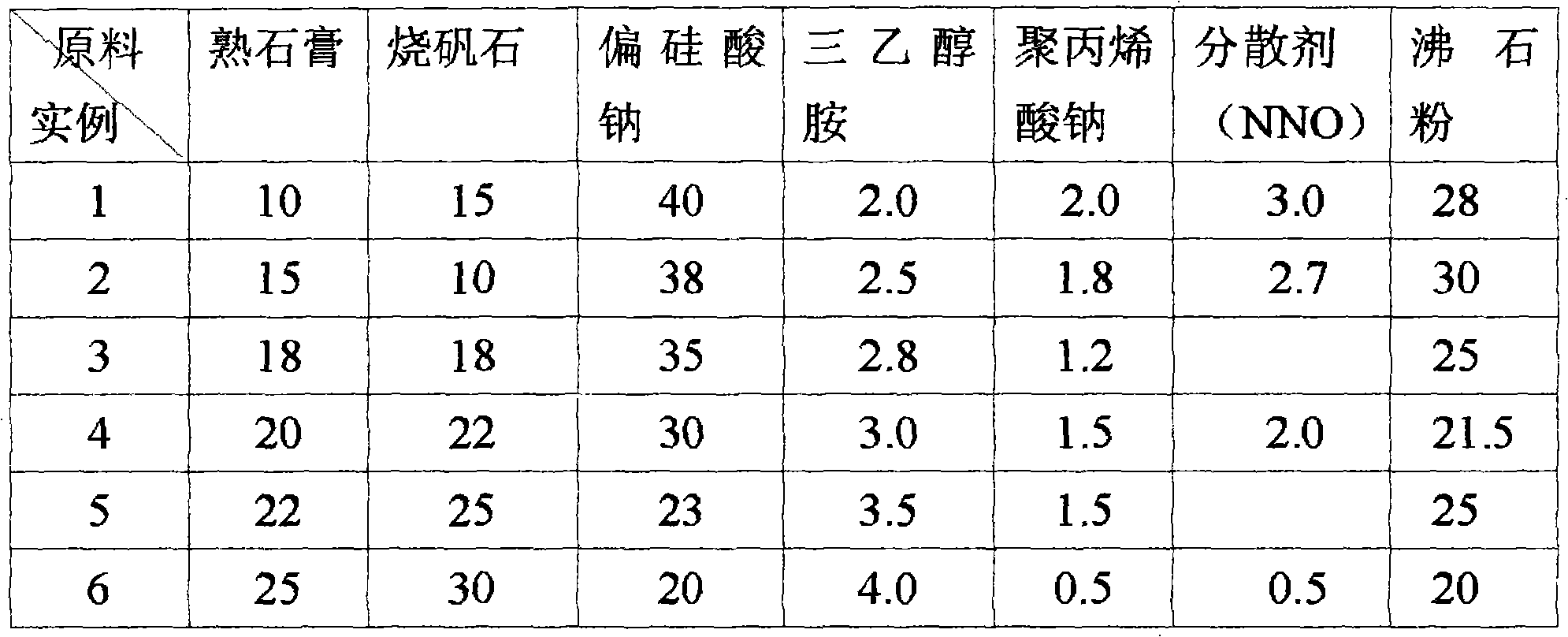

[0028] Table 1 The batching example of high-efficiency cement composite grinding aid (mass percentage%)

[0029]

[0030] Note: The zeolite powder in Table 1 can be replaced by any of fly ash, slag, and perlite powder.

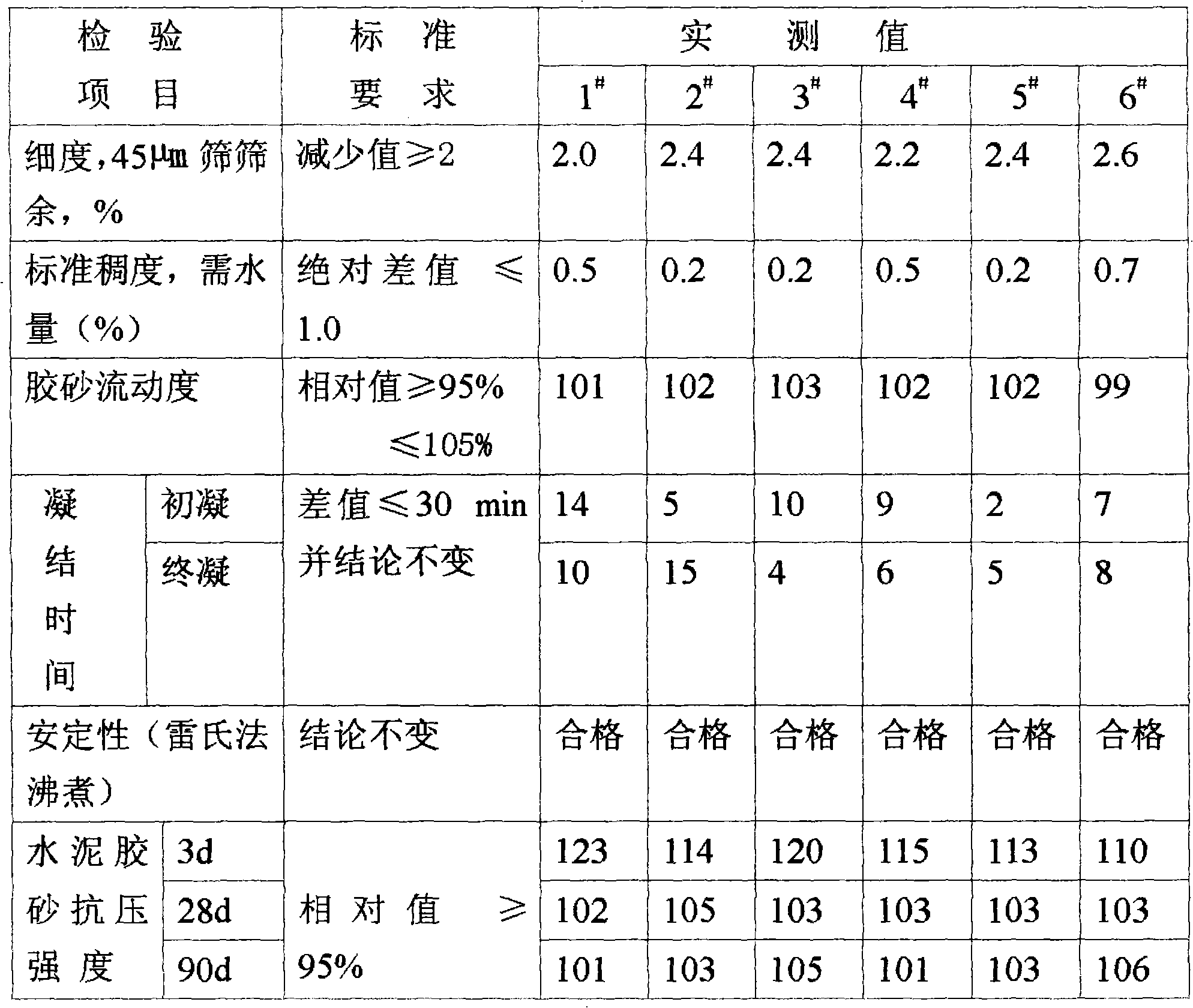

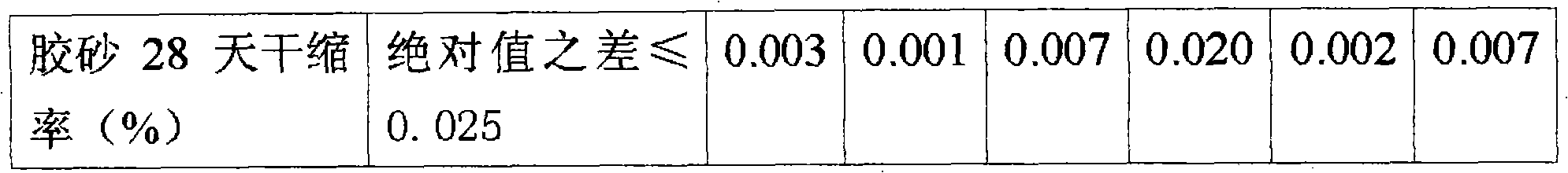

[0031] The various technical properties of the grinding aid of the invention meet the requirements of the national building material industry standard JC / T667-2004 "Cement Grinding Aid". 6 groups of grinding aids with different proportions (1 # ,2 # 、3 # 、4 # 、5 # 、6 # ) performance testing results are transcribed as follows, see Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com