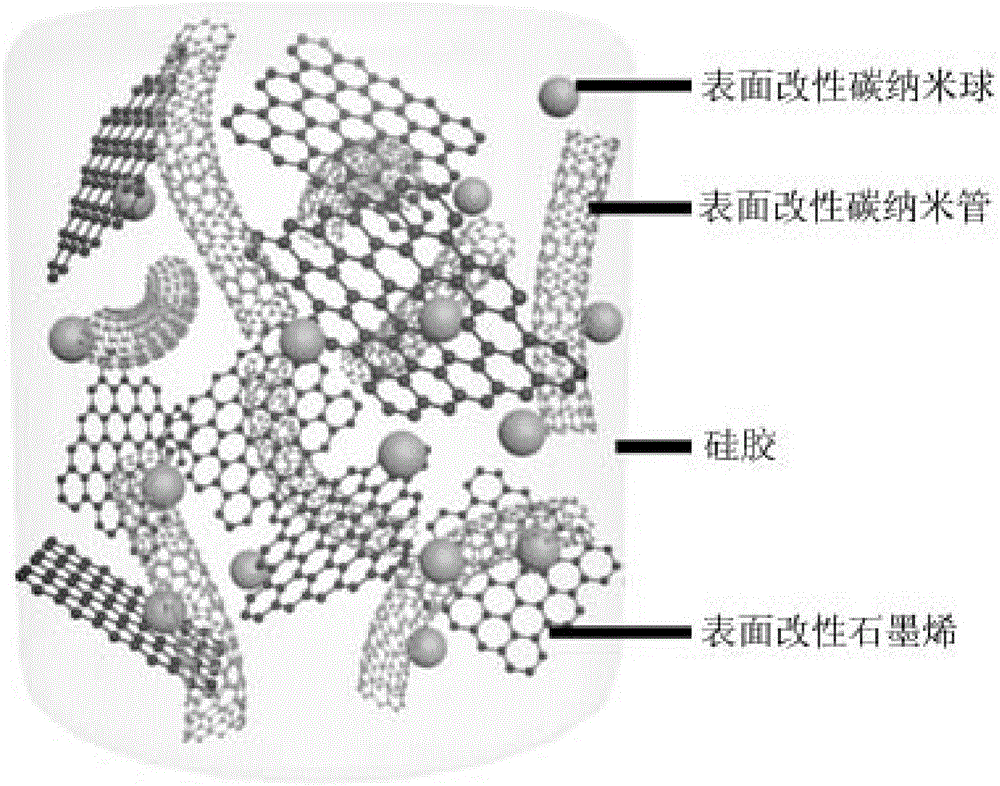

Point, line, surface three-dimensional carbon material composite heat-conduction silica gel and preparation method thereof

A three-dimensional, heat-conducting silica gel technology, applied in the field of heat dissipation, can solve the problems of poor dispersion of graphene materials, difficulty in forming a heat-conducting network, and no solution, etc., and achieve low cost, enhanced dispersion, and excellent balance between thermal conductivity and insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a point, line, surface three-dimensional carbon material composite heat-conducting silica gel and a preparation method thereof. The method includes the following steps:

[0074] (1) Preparation of surface-modified graphene

[0075] Graphene was prepared with reference to Example 1 and Example 2 in CN103771404A, and the yield of prepared graphene was greater than 95%. Among them, the yield of graphene with 5-10 layers is greater than 80%, the yield of graphene with less than 5 layers is lower than 10%, and the sheet diameter is 5-50 μm;

[0076] 100g of the prepared graphene is packed into a ball mill jar and mixed with 200ml of ethanol for ball milling, the ball milling speed is 300 rpm, and the graphene powder is collected after ball milling for 1 hour and dried for subsequent use;

[0077] The graphene after taking out 10g ball milling is dissolved in 500ml concentrated nitric acid (mass fraction is 55%) and carries out surface functionalizat...

Embodiment 1 and comparative example 1

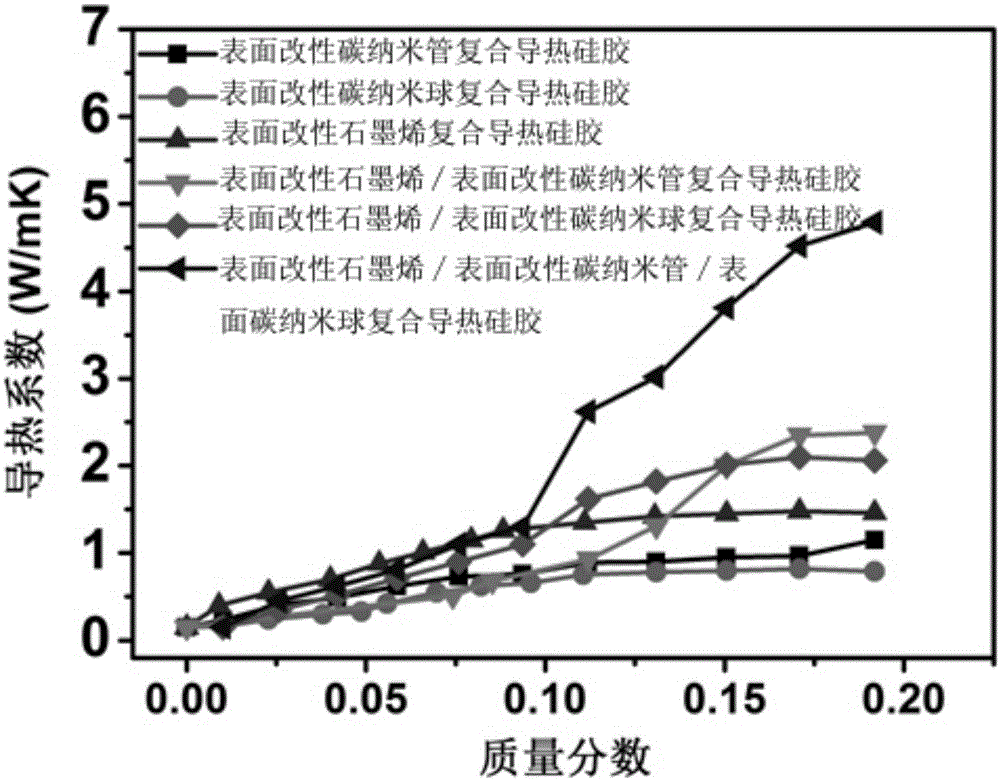

[0106] Embodiment 1 and comparative example 1 performance test of heat-conducting silica gel

[0107] According to the laser flash method, the thermal conductivity of the point, line and plane three-dimensional carbon material composite thermal silica gel obtained in Example 1 is 4.79W / m.k, and the thermal conductivity of the surface-modified graphene composite thermal silica gel obtained in Comparative Example 1 is 1.46W. / m.k, the thermal conductivity of the obtained surface-modified carbon nanotube composite heat-conducting silica gel is 1.15W / m.k, the thermal conductivity of the obtained surface-modified carbon nanosphere composite heat-conducting silica gel is 0.79W / m.k, the obtained surface-modified graphene / surface-modified The thermal conductivity of the carbon nanotube composite thermally conductive silica gel is 2.38W / m.k, and the thermal conductivity of the obtained surface-modified graphene / surface-modified carbon nanosphere composite thermally conductive silica gel...

Embodiment 2

[0112] This embodiment provides a point, line, and surface three-dimensional carbon material composite heat-conducting silica gel and a preparation method thereof, the method including:

[0113] (1) prepare surface-modified graphene by the same method of embodiment 1;

[0114] (2) Preparation of surface modified carbon nanotubes

[0115] 30g carbon nanotubes are dissolved in 1000ml concentrated hydrochloric acid (mass fraction is 35%) and carry out acidification treatment, then filter with filter paper and repeatedly wash with deionized water until the pH value is equal to 7, collect surface modified carbon nanotube powder and bake dry processing standby;

[0116]50g of carbon nanospheres were dissolved in 1000ml of concentrated sulfuric acid (mass fraction is 95%) for acidification, then filtered with filter paper and repeatedly washed with deionized water until the pH value was equal to 7, the surface modified carbon nanotube powder was collected and baked dry processing s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com