Preparation and use method of fly ash based mineral polymer

A technology of mineral polymers and application methods, which is applied in the preparation and application fields of fly ash-based mineral polymers, can solve the problems of waste of soil and cultivated land, consumption of fuel and energy, and low activity of kaolin, so as to save energy and avoid Good effect on pollution and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The raw materials for preparing the fly ash-based mineral polymer in the present invention are fly ash and activator solution.

[0026] Selection of fly ash raw materials:

[0027] The present invention requires that the fly ash of the second grade or above is selected as a raw material, and its chemical composition is mainly Al with a mass percentage of 25-40%. 2 o 3 , 35-60% SiO 2 , also contains less than 8% CaO.

[0028] Preparation of stimulant solution:

[0029] The activator solution used in the present invention is a silicate solution or a water glass solution, wherein the silicate solution can be a sodium silicate solution or a potassium silicate solution, and the concentration of the solution is 2mol / L-5mol / L; the water glass solution The main components are sodium silicate or potassium silicate, and monomeric silicon oxide, with a solid content of 25-40% and a modulus of 1.0-1.5.

[0030] The preparation and application method of the fly ash-based minera...

Embodiment 1

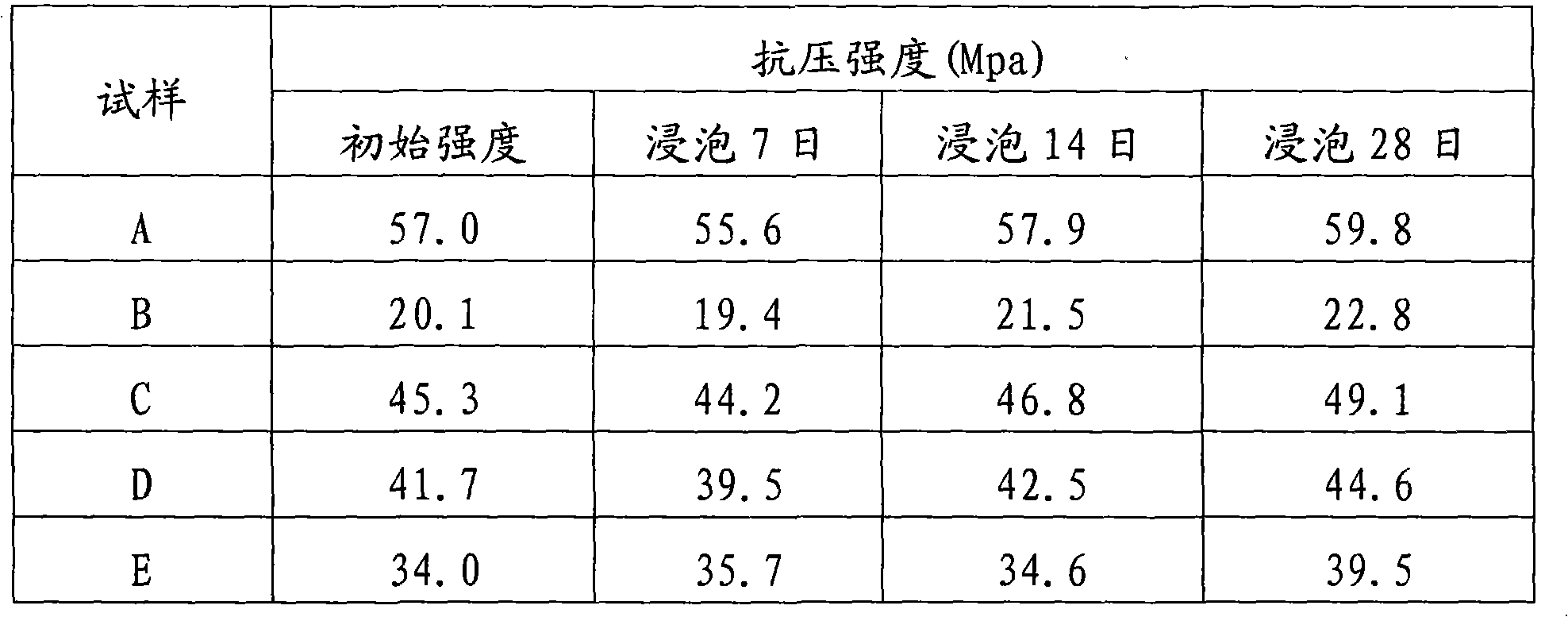

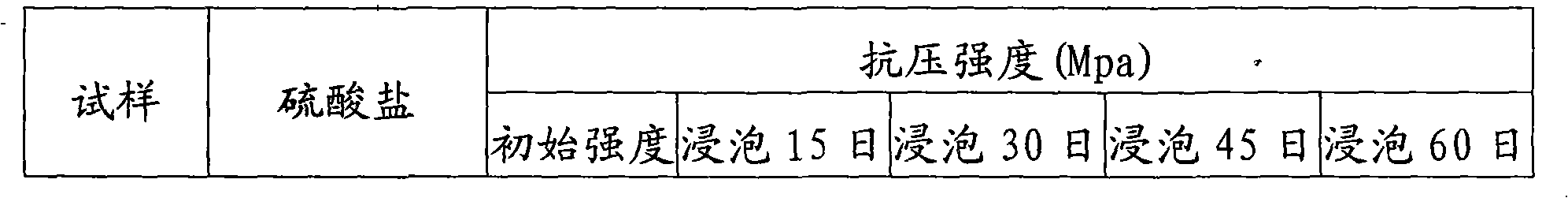

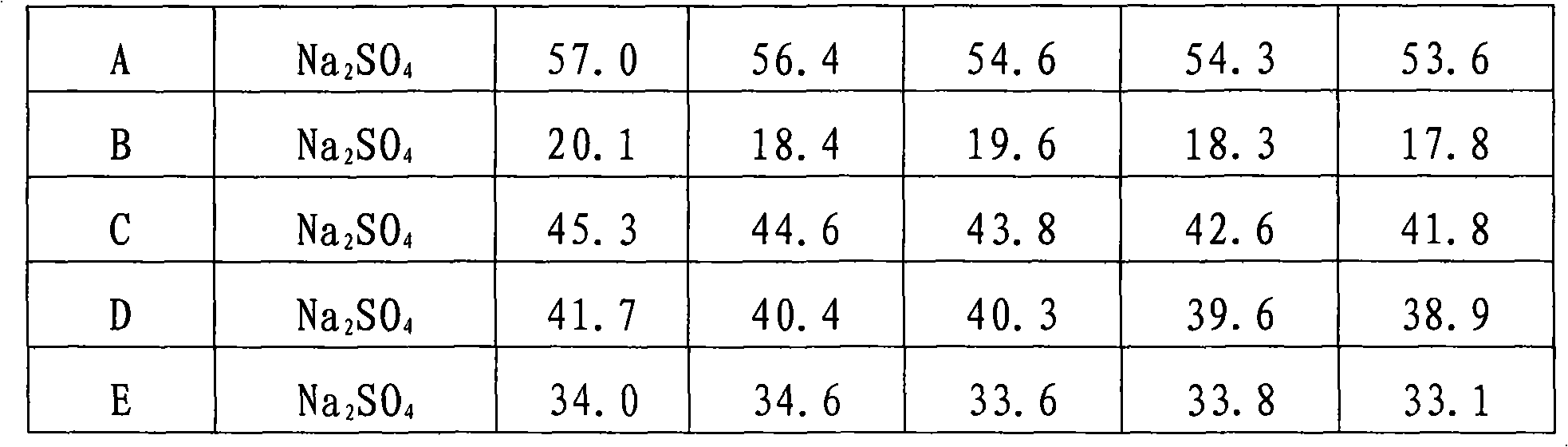

[0038] With 5mol / L K 2 SiO 3 The solution is used as an activator, using primary fly ash (calcium content 3.04%) as a raw material, and the liquid-solid volume mass ratio is 0.3L / kg, mixed and stirred to reach a standard consistency, and the molded product, after 7 days of steam curing at 50 ° C, is resistant to The compressive strength reaches 57.0MPa. It is tested in accordance with relevant cement standards. The long-term durability of the product (resistance to sulfate, hydrochloric acid corrosion, alkali-aggregate reactivity, etc.) meets industry standards.

Embodiment 2

[0040] at 2mol / L K 2 SiO 3 The solution is used as an activator, using secondary fly ash (calcium content 4.40%) as a raw material, and the liquid-solid volume mass ratio is 0.3L / kg mixed and stirred to reach a standard consistency. After 7 days of steam curing at 65°C, the molded product is The compressive strength is up to 20.1MPa, tested in accordance with relevant cement standards, and the long-term durability of the product (resistance to sulfate, hydrochloric acid corrosion, alkali-aggregate reactivity, etc.) meets industry standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com