Patents

Literature

69results about How to "Improve roll stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle control

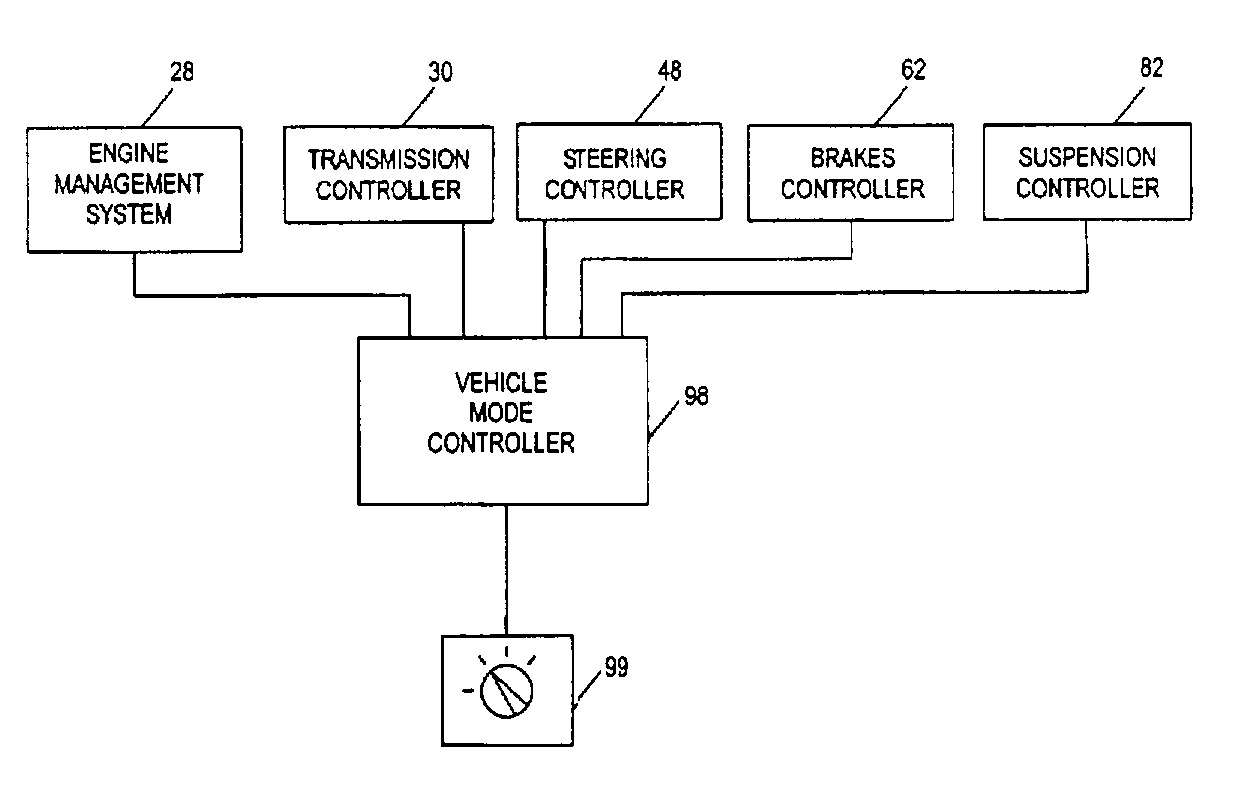

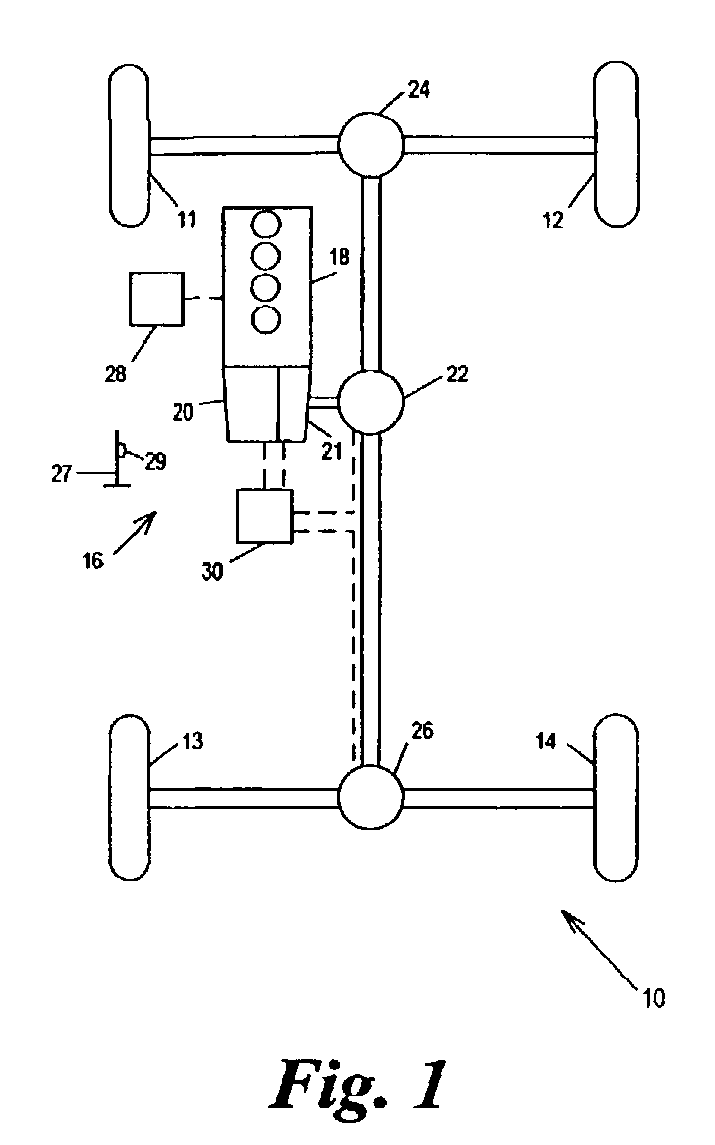

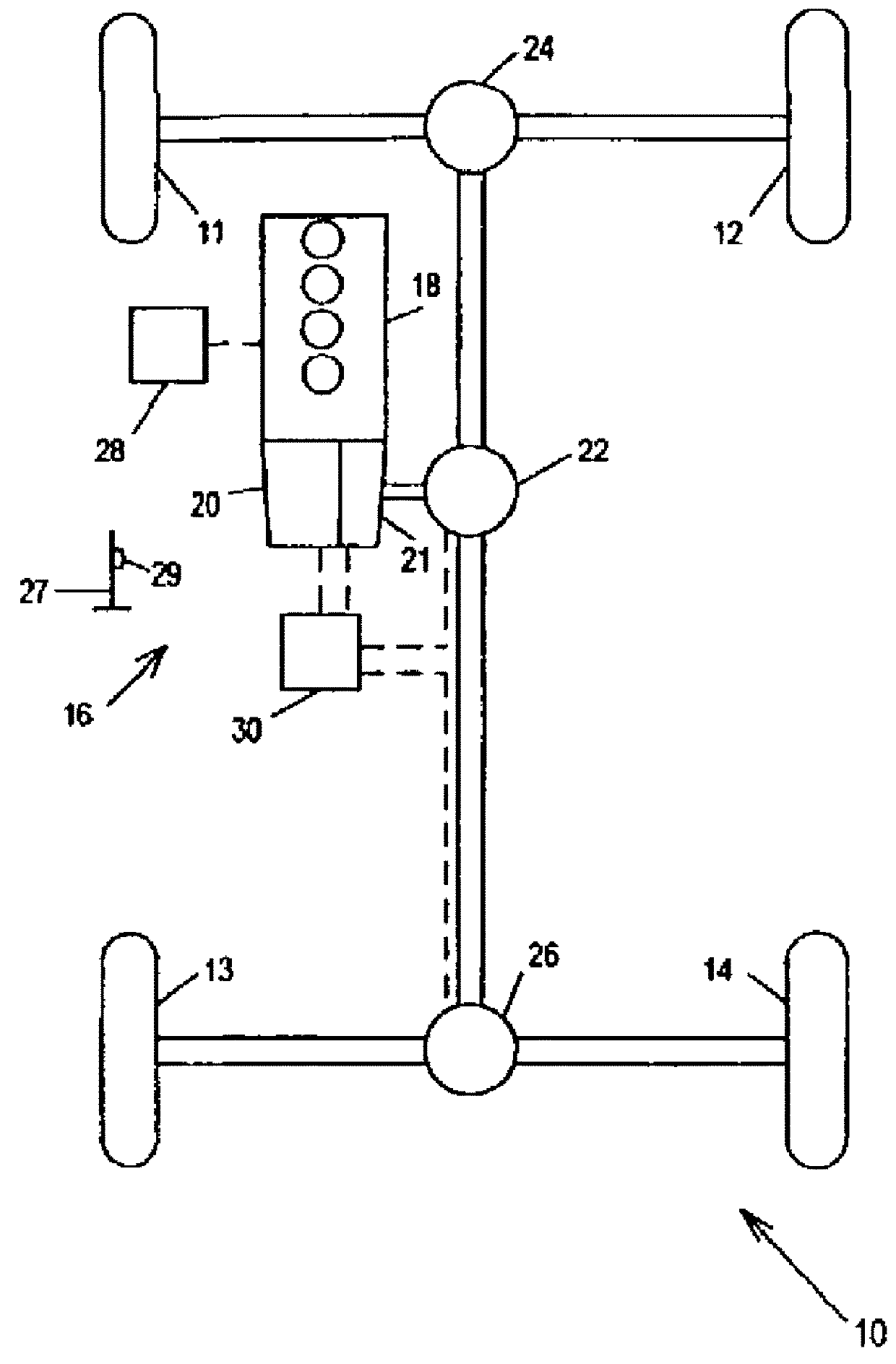

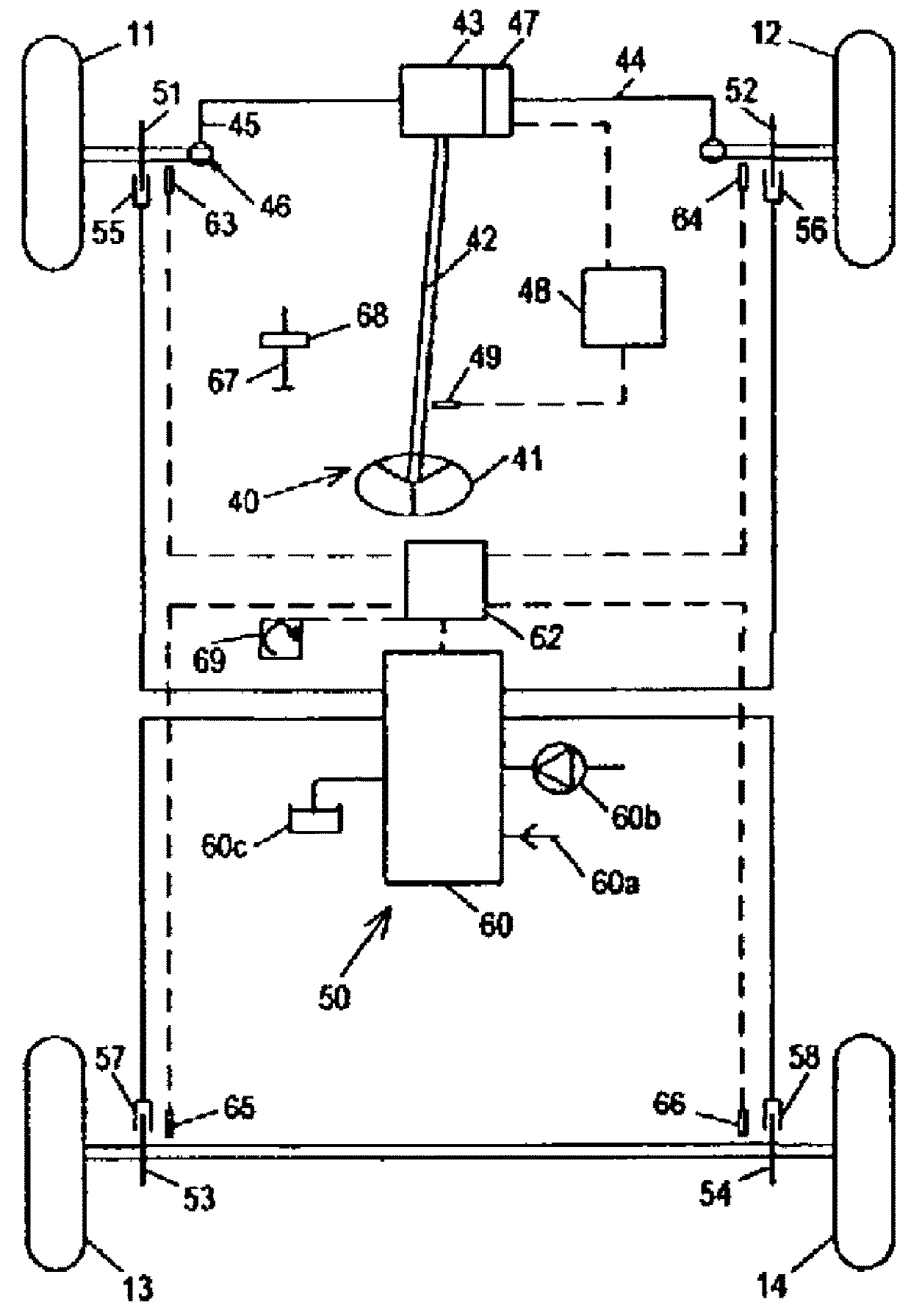

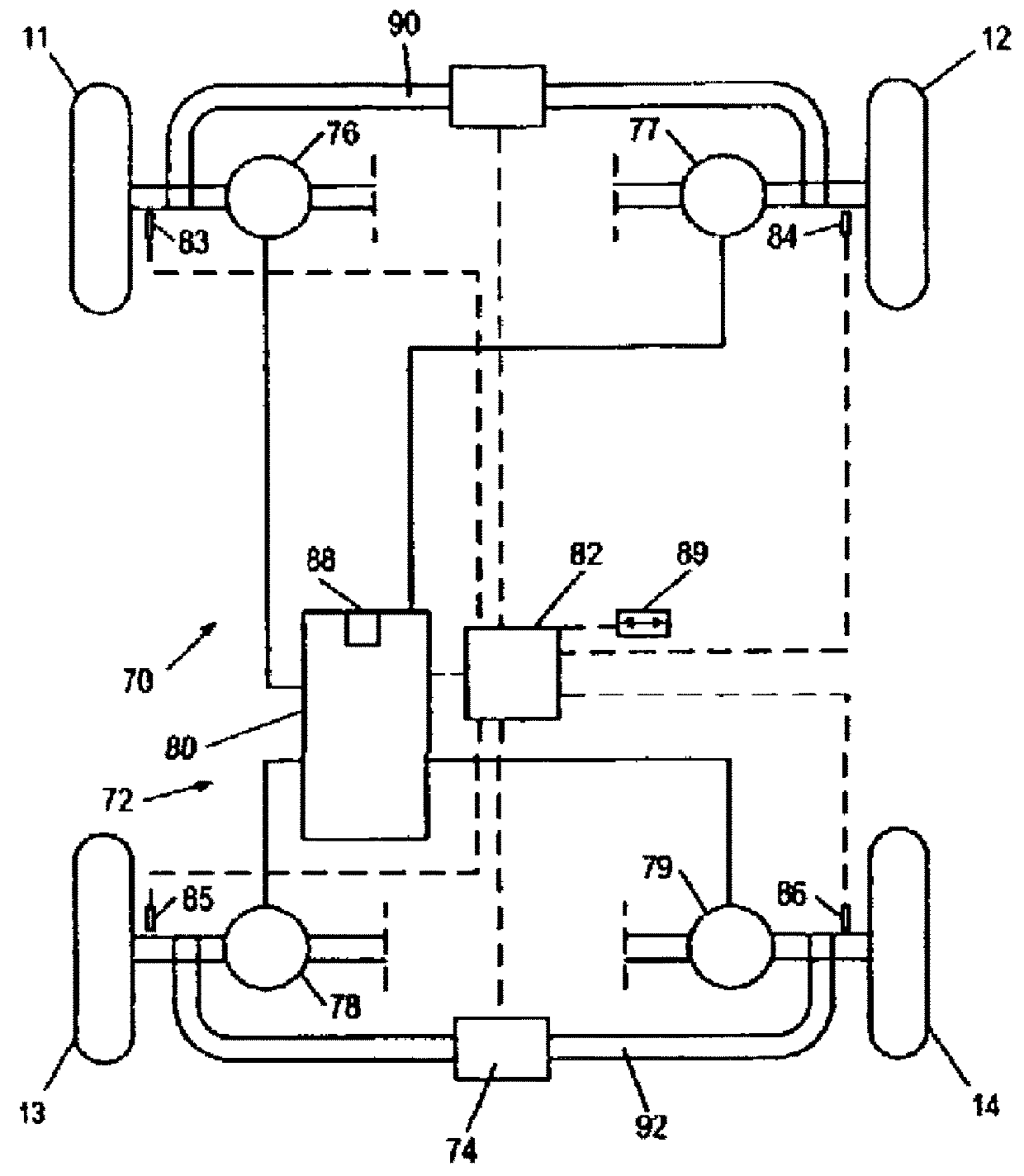

ActiveUS7349776B2Improved vehicle controlEasy to controlBrake system interactionsDigital data processing detailsControl systemMode control

A vehicle control system has a plurality of subsystem controllers including an engine management system 28, a transmission controller 30, a steering controller 48, a brakes controller 62 and a suspension controller 82. These subsystem controllers are each operable in a plurality of subsystem modes, and are all connected to a vehicle mode controller 98 which controls the modes of operation of each of the subsystem controllers so as to provide a number of driving modes for the vehicle. Each of the modes corresponds to a particular driving condition or set of driving conditions, and in each mode each of the functions is set to the function in mode most appropriate to those conditions.

Owner:JAGUAR LAND ROVER LTD

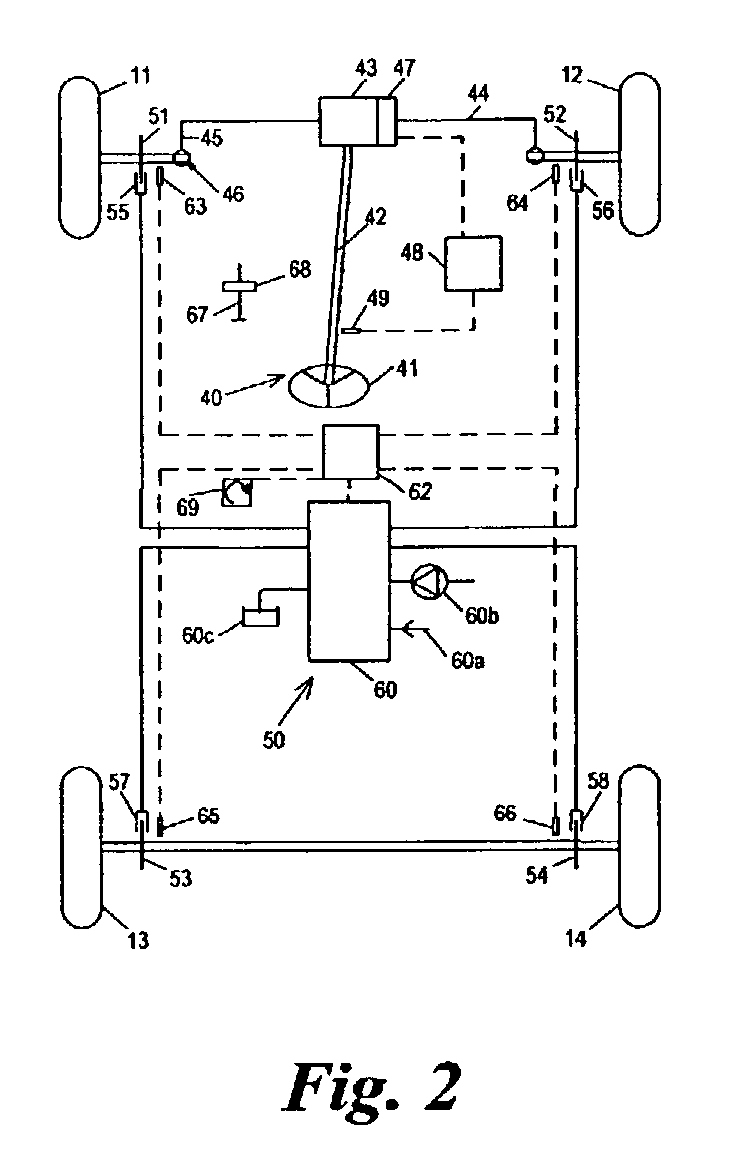

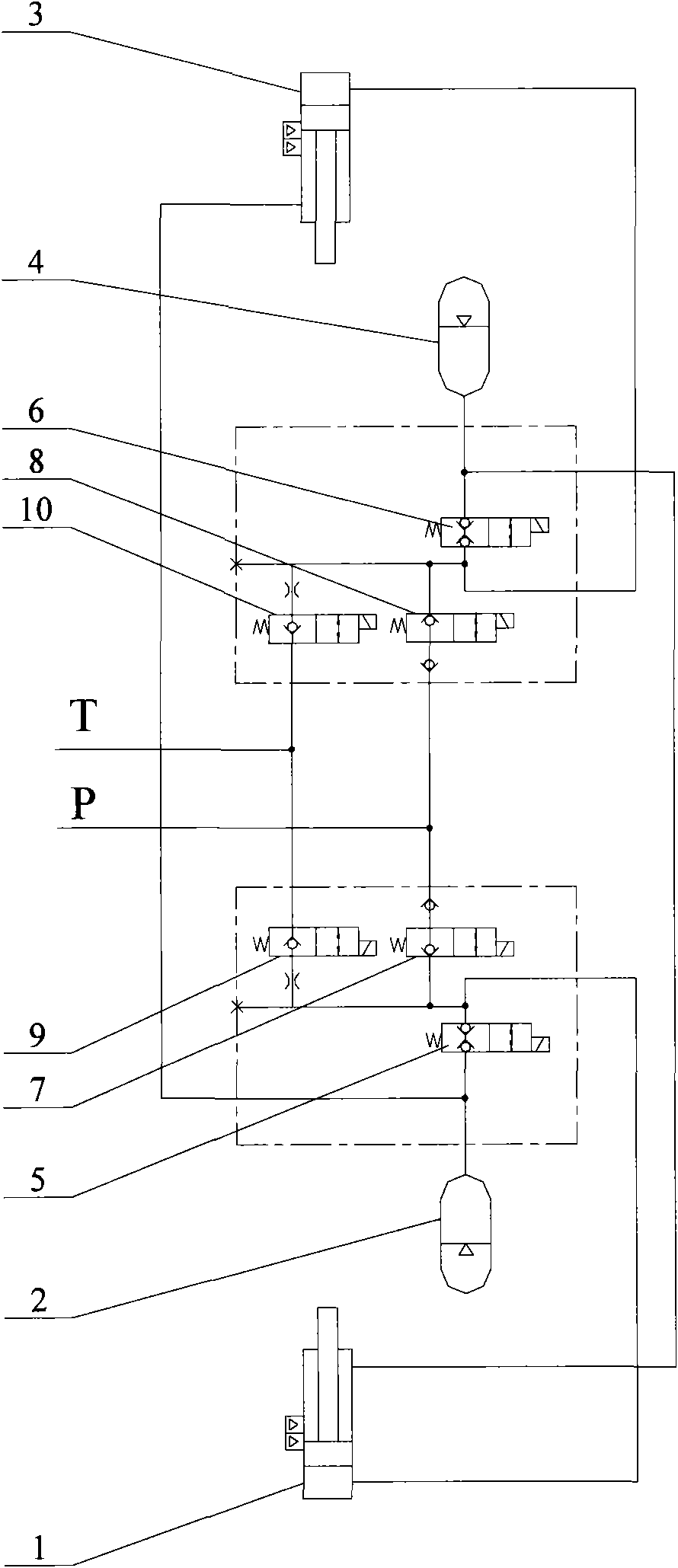

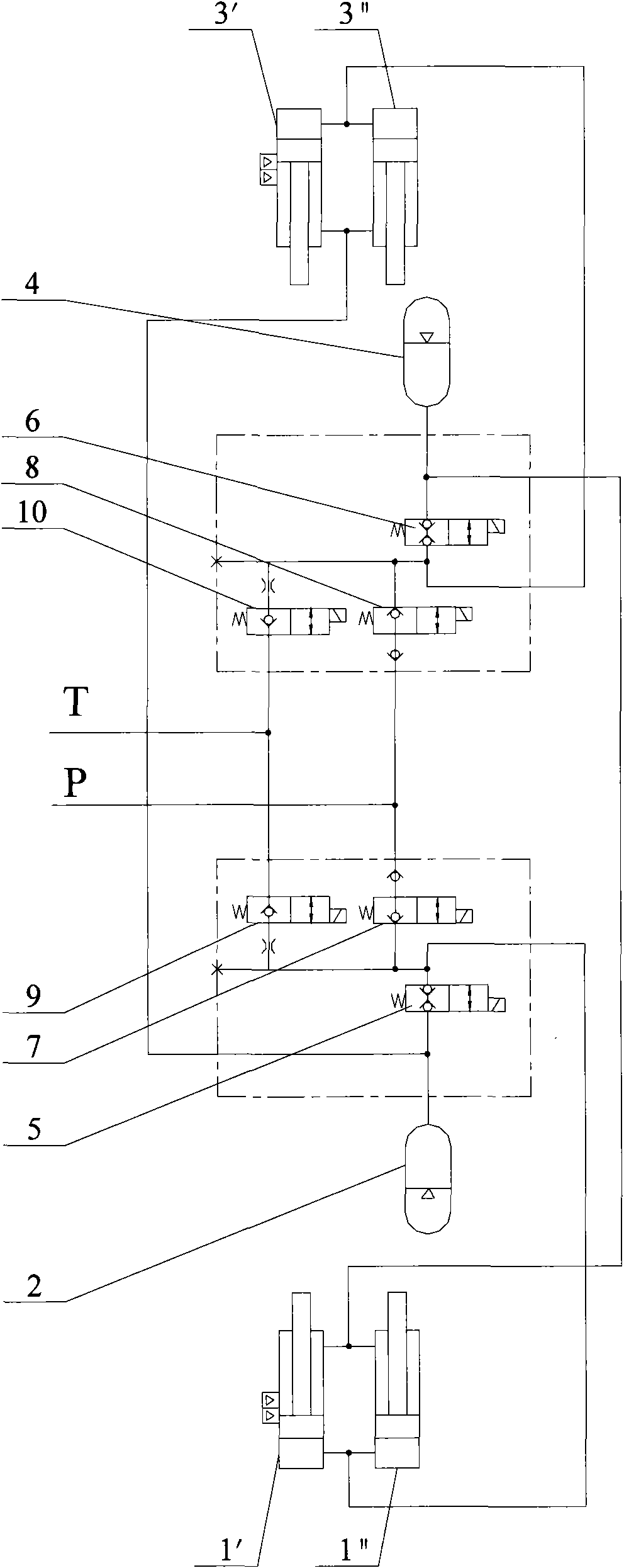

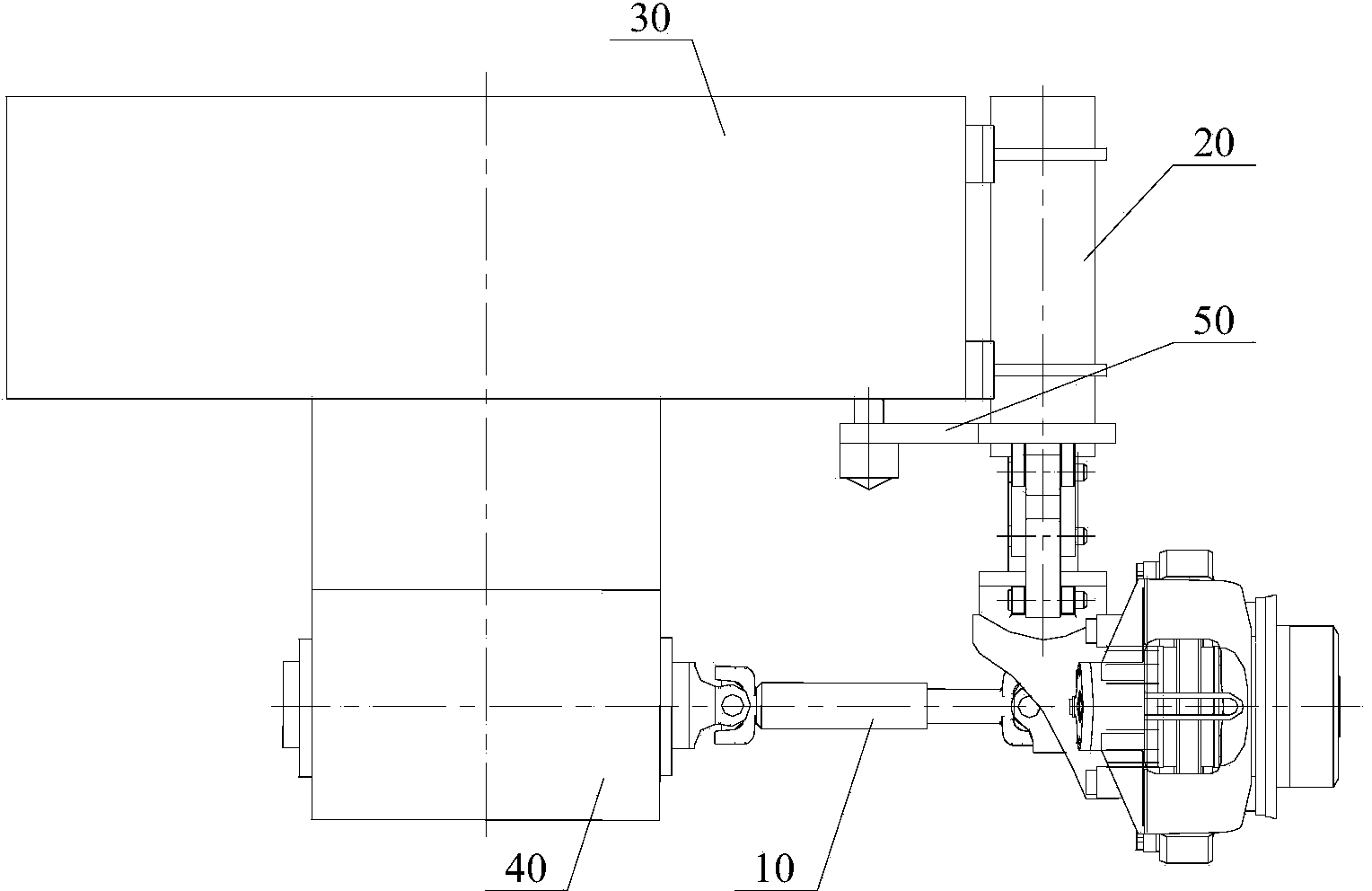

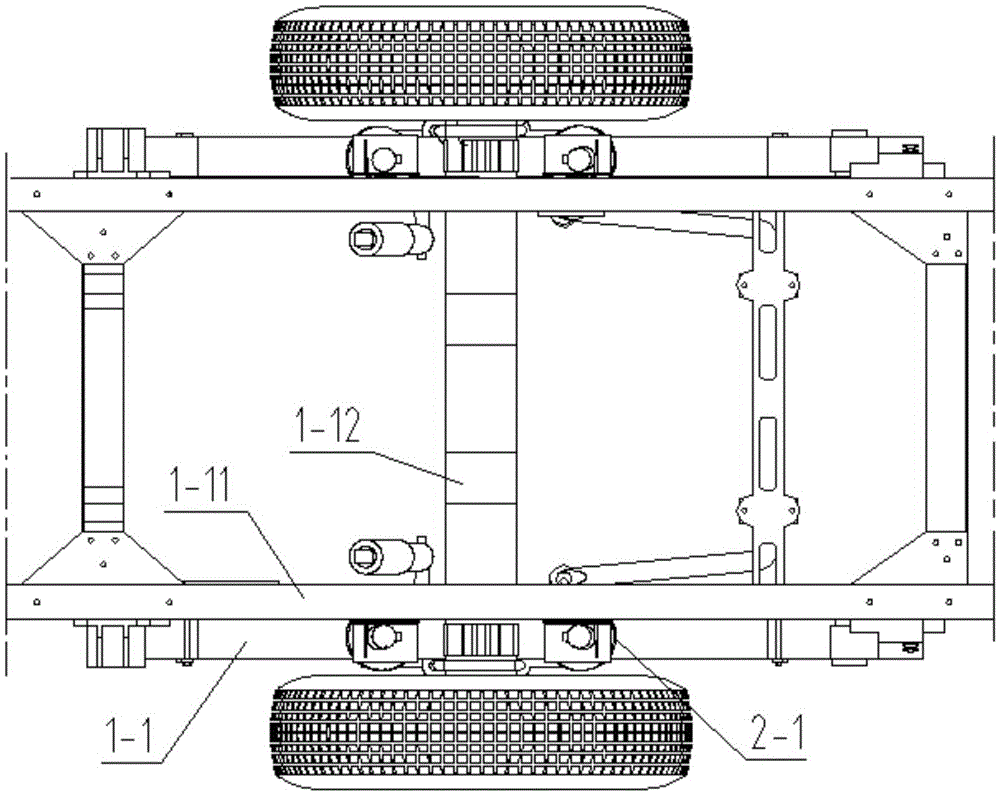

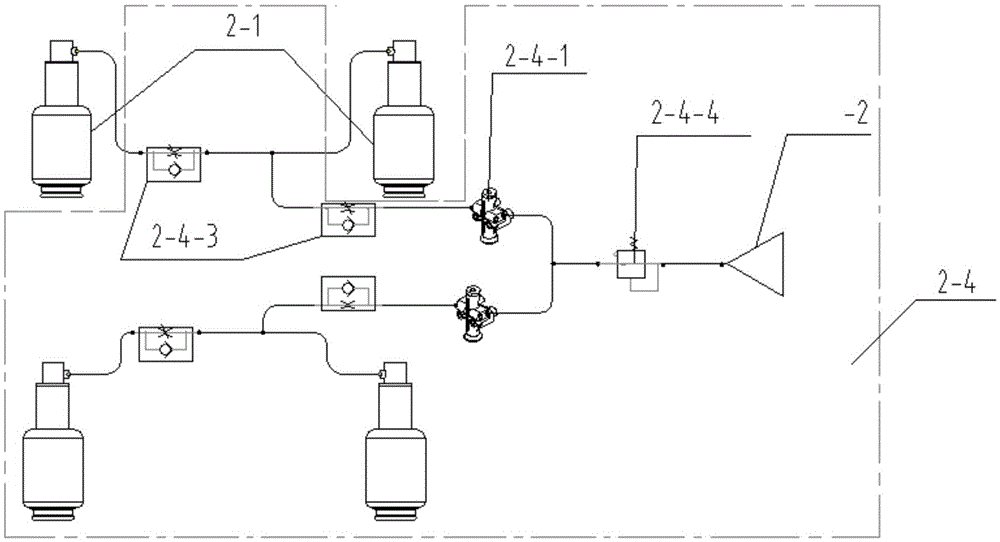

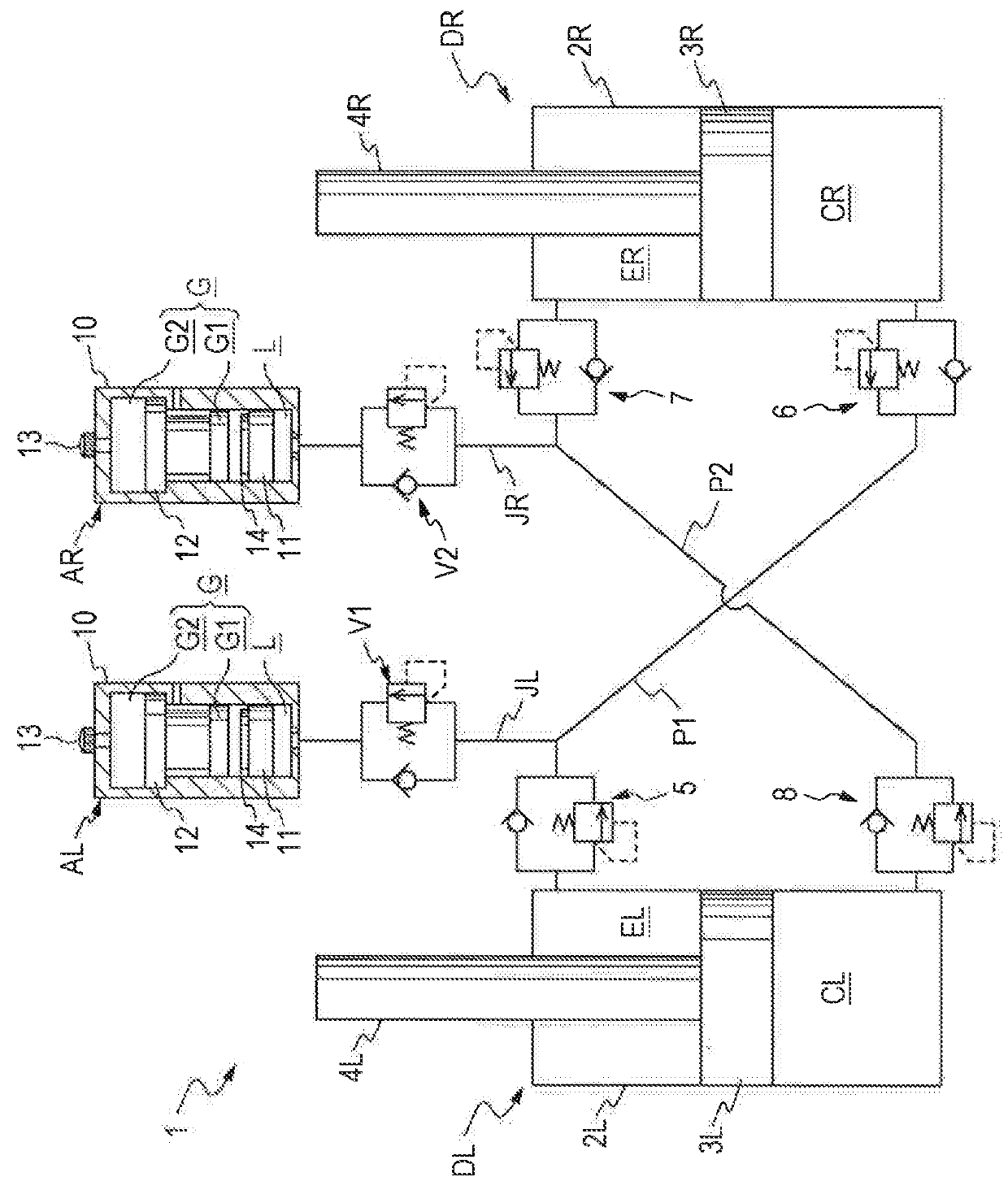

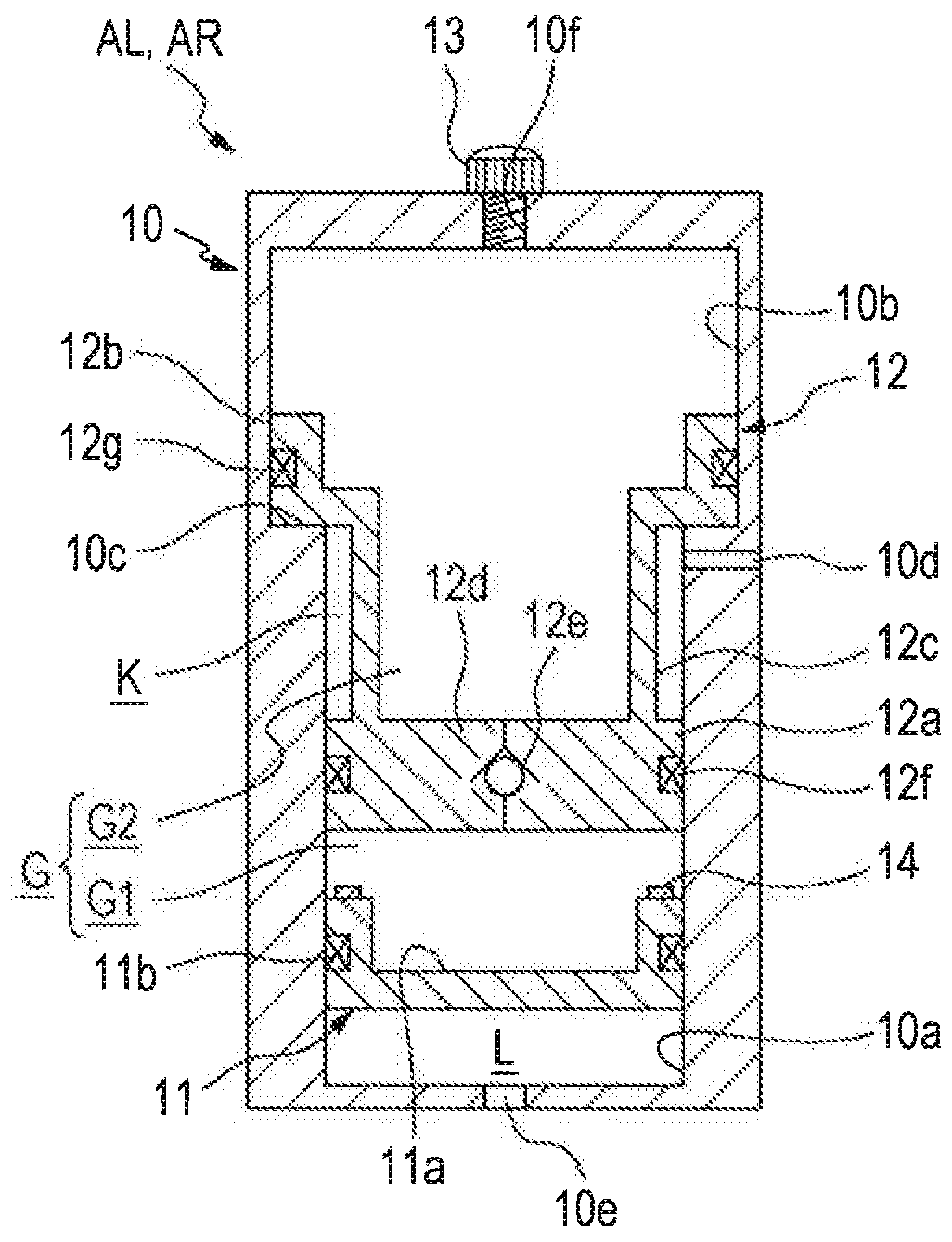

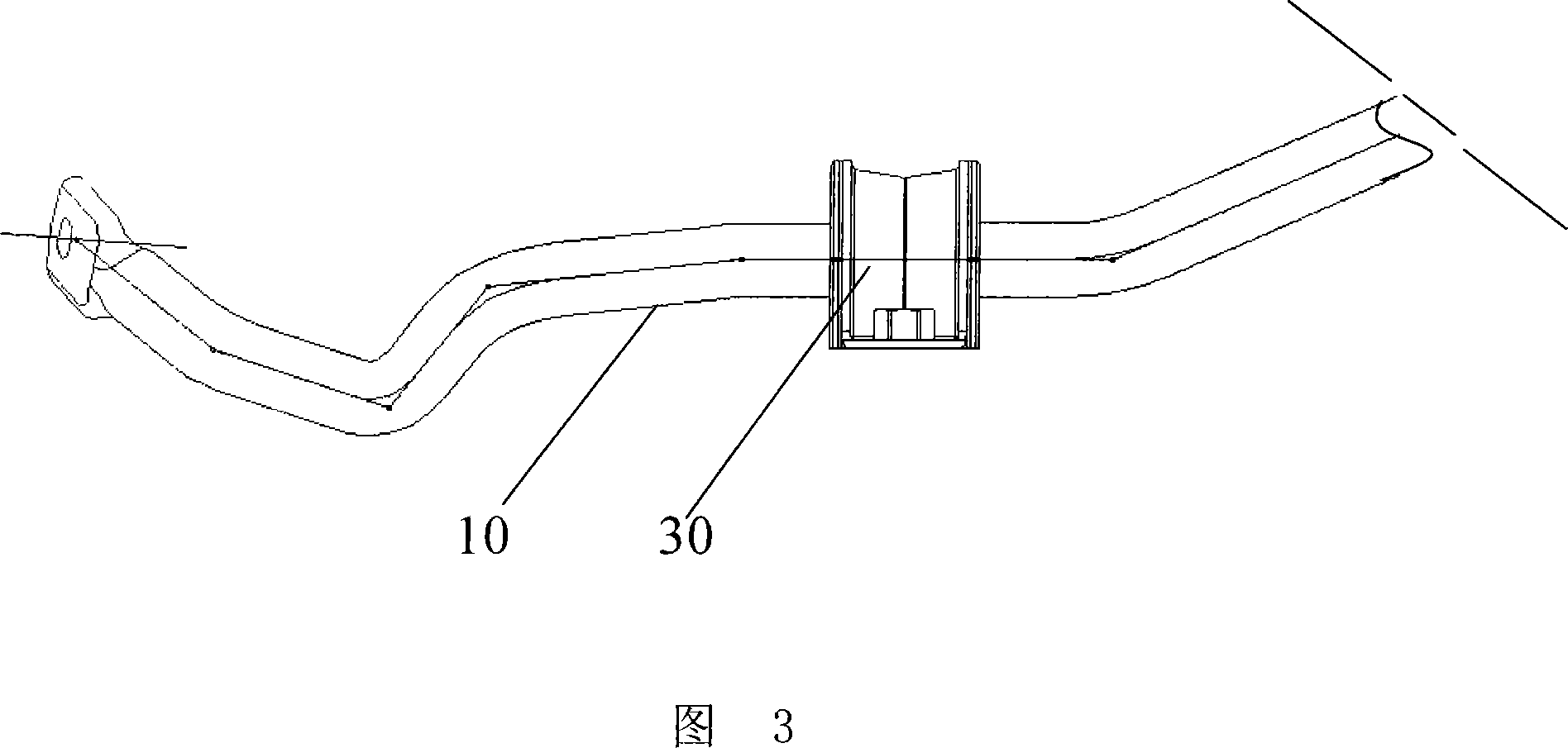

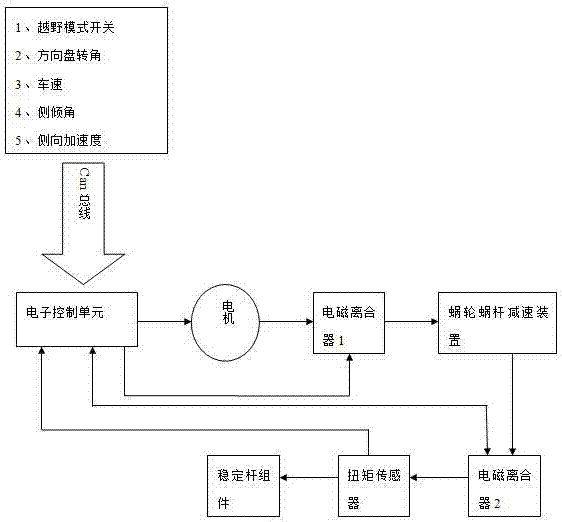

Hydro-pneumatic suspension control loop, multi-axle vehicle hydro-pneumatic suspension system and crane

ActiveCN101618669AImprove mobilityImprove roll stiffnessResilient suspensionsHydropneumatic suspensionAutomotive engineering

The invention discloses a hydro-pneumatic suspension control loop. The design key point of the invention comprises that: a communication relationship between a suspension oil cylinder rodless cavity and an energy accumulator at the same side is controlled by a two position two-way valve to realize rigid and flexible conversion of a suspension system; each suspension oil cylinder rod cavity is communicated with an energy accumulator at the opposite side so as to obtain relatively strong side tilting rigidity; and communication relationships between a pressure oil line and the suspension oil cylinder rodless cavity and between an oil return oil line and the suspension oil cylinder rodless cavity are controlled by a two position two-way valve, respectively so as to control the lifting of a vehicle body. In the multi-axle vehicle hydro-pneumatic suspension system provided by the invention, all the middle axle hydro-pneumatic suspension control loops and rear axle hydro-pneumatic suspension control loops form a lifting control group so as to level the vehicle body. The hydro-pneumatic suspension control loop provided by the invention has reasonable and reliable design and higher comprehensive performance of the suspension system, and is suitable for a multi-axle vehicle, particularly for a multi-axle construction crane. The invention also provides a crane using the hydro-pneumatic suspension control loop.

Owner:XUZHOU HEAVY MASCH CO LTD

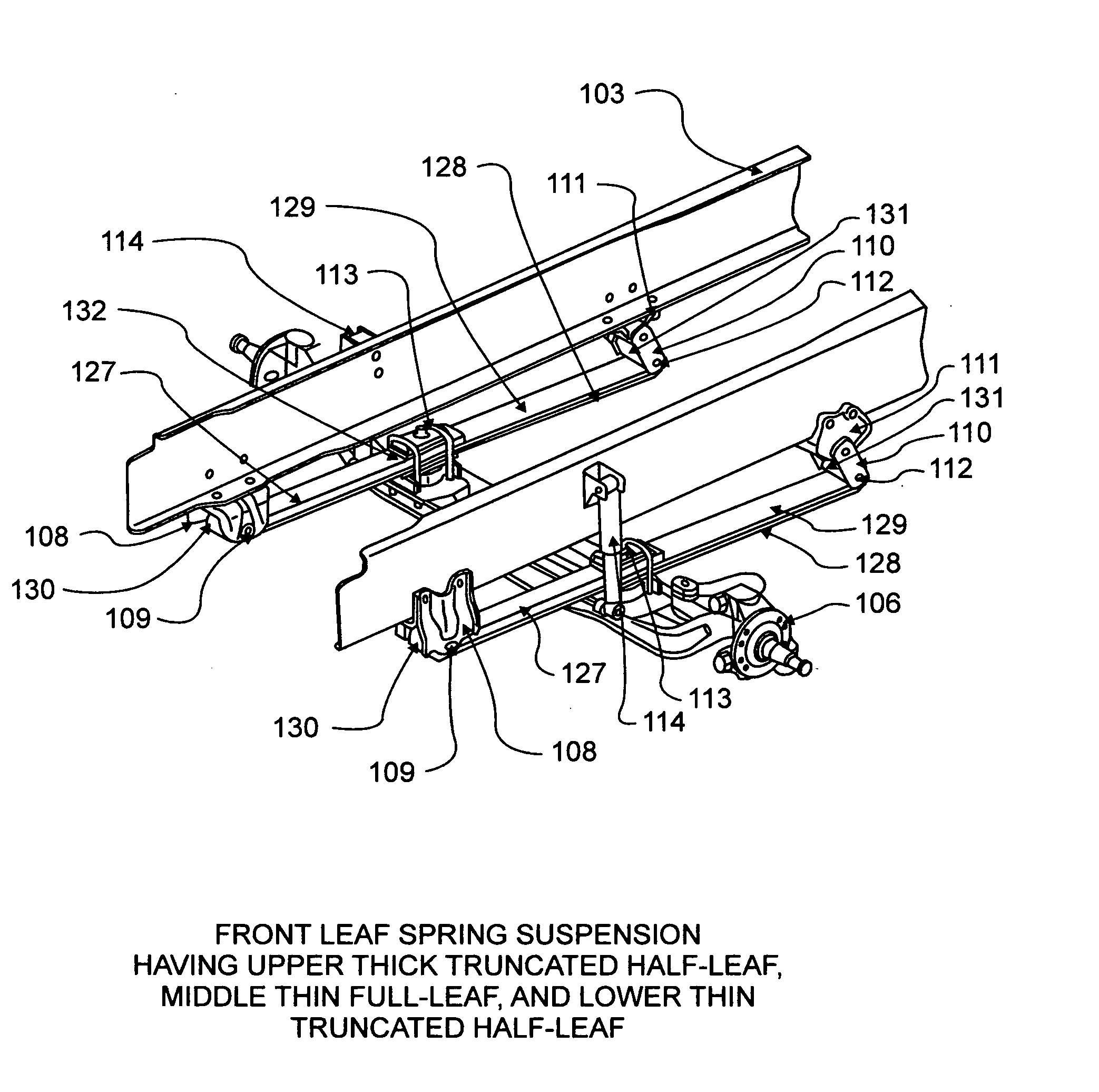

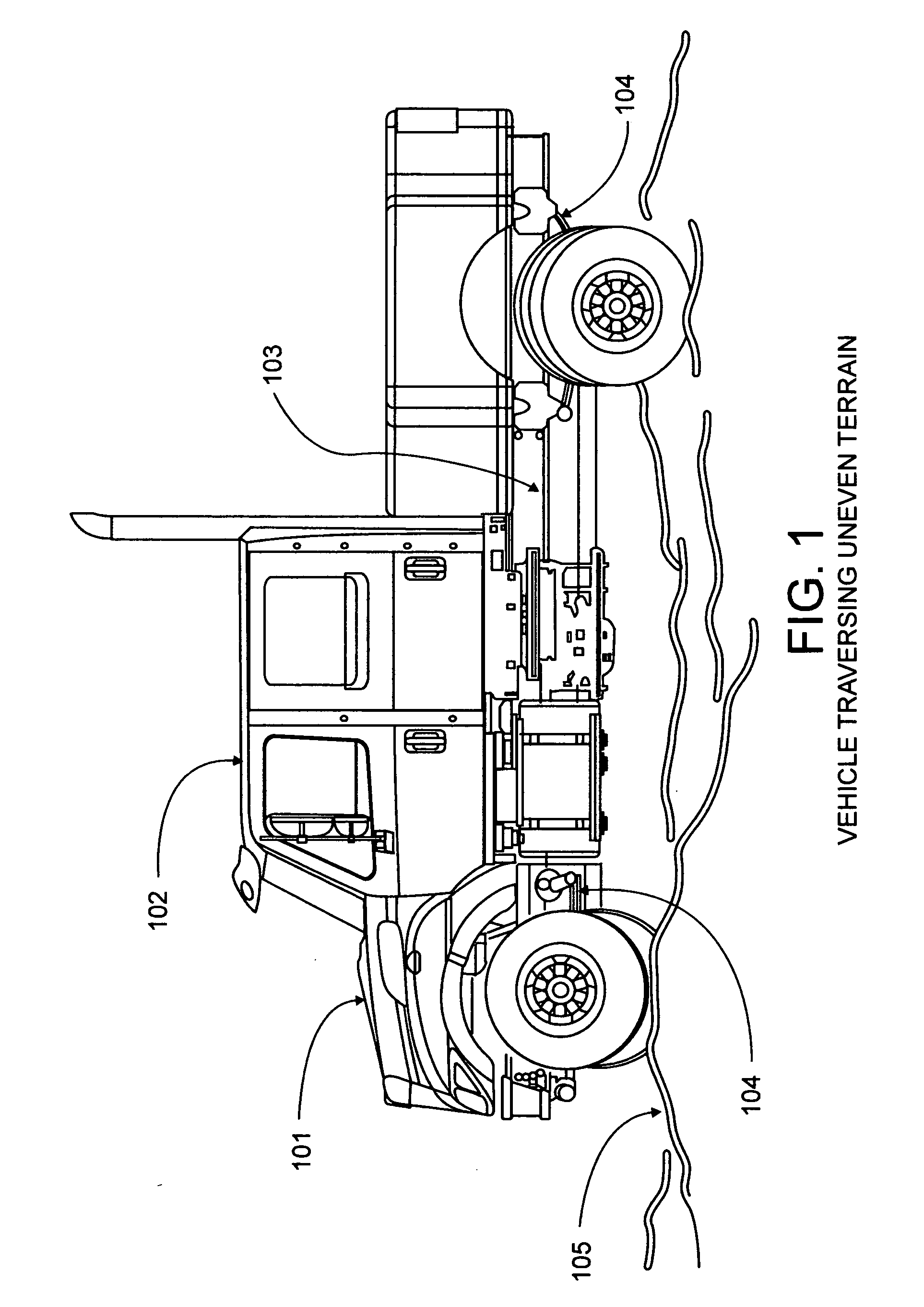

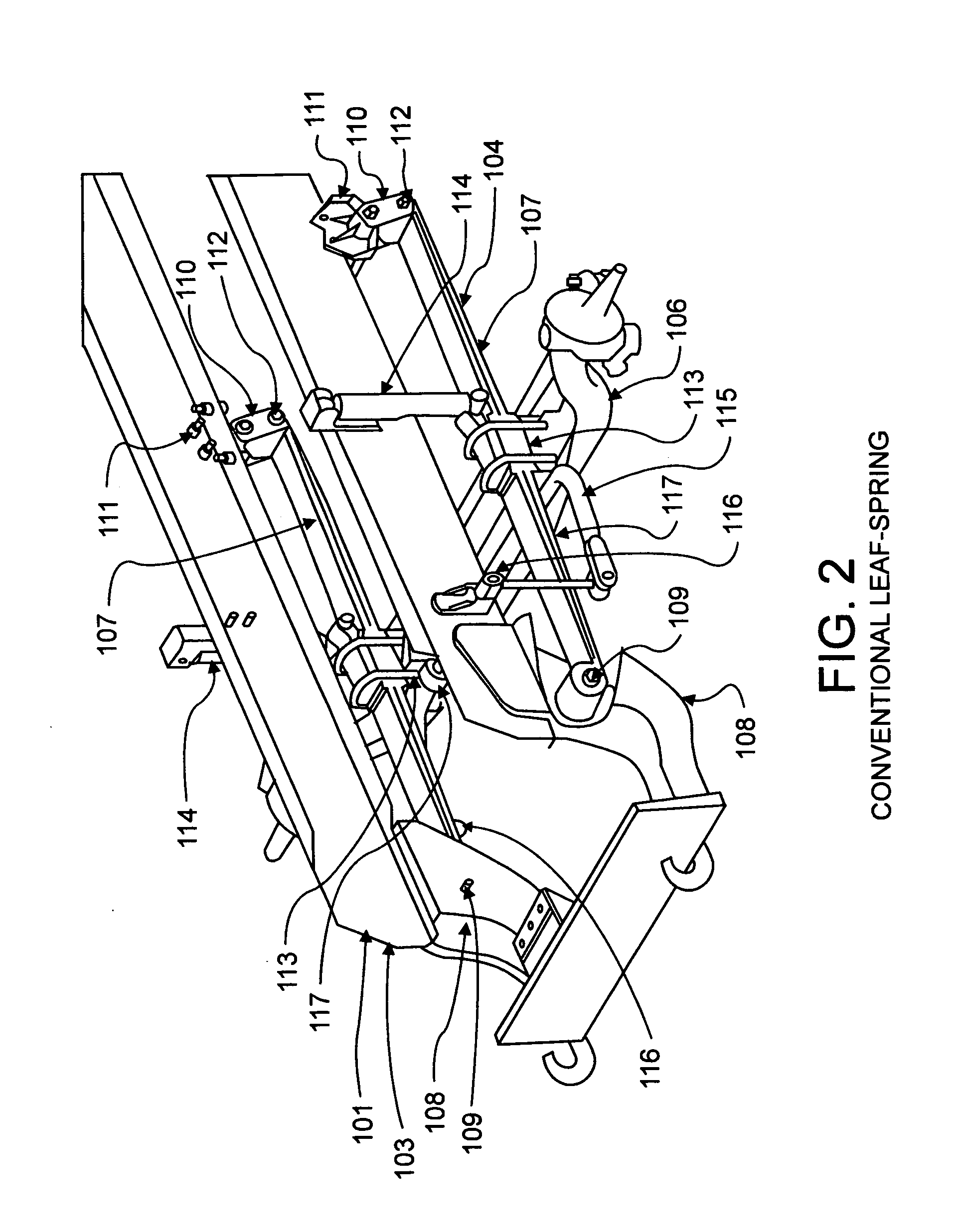

Leaf spring with high auxiliary roll stiffness

InactiveUS20070262547A1Robust and simple to manufacturePositive attributeLeaf springsInterconnection systemsEngineeringBending stiffness

A vehicle suspension provides increased auxiliary roll stiffness by utilizing spring assemblies having a thick truncated half-leaf, a thin full-leaf, and a thin truncated half-leaf located opposite the thick truncated half-leaf. The thick truncated half-leaf increases the torsional rigidity of the spring assembly in order to increase the leaf twist sub-component of auxiliary roll stiffness and increases the bending rigidity of half of the spring assembly in order to increase the axle torsion sub-component of auxiliary roll stiffness. The thin full-leaf provides structural integrity, and the thin half-leaf allows tuning of the overall vertical spring rate of the suspension and limits the leaf stresses in the thin full-leaf.

Owner:INT TRUCK INTPROP LLC

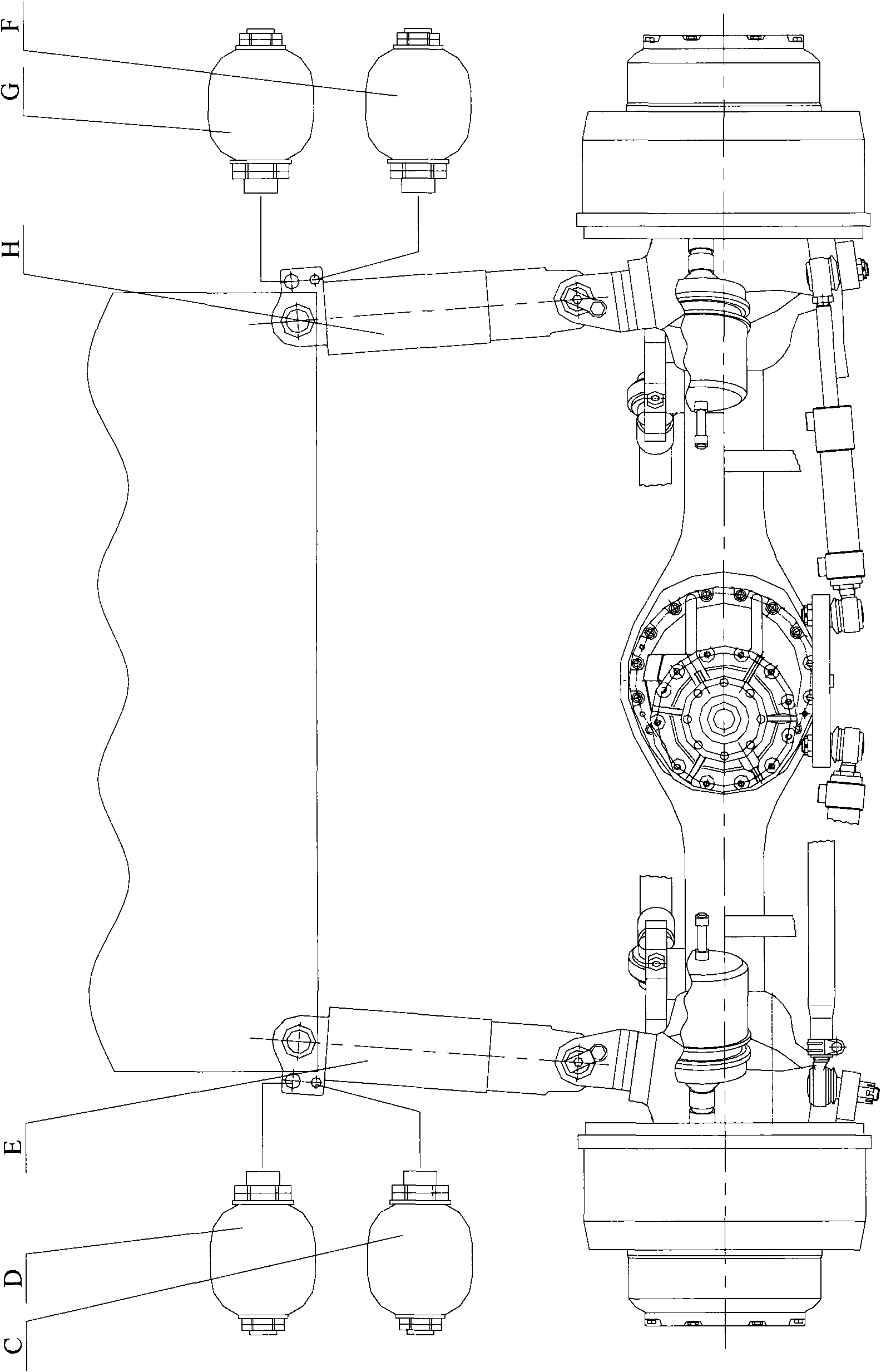

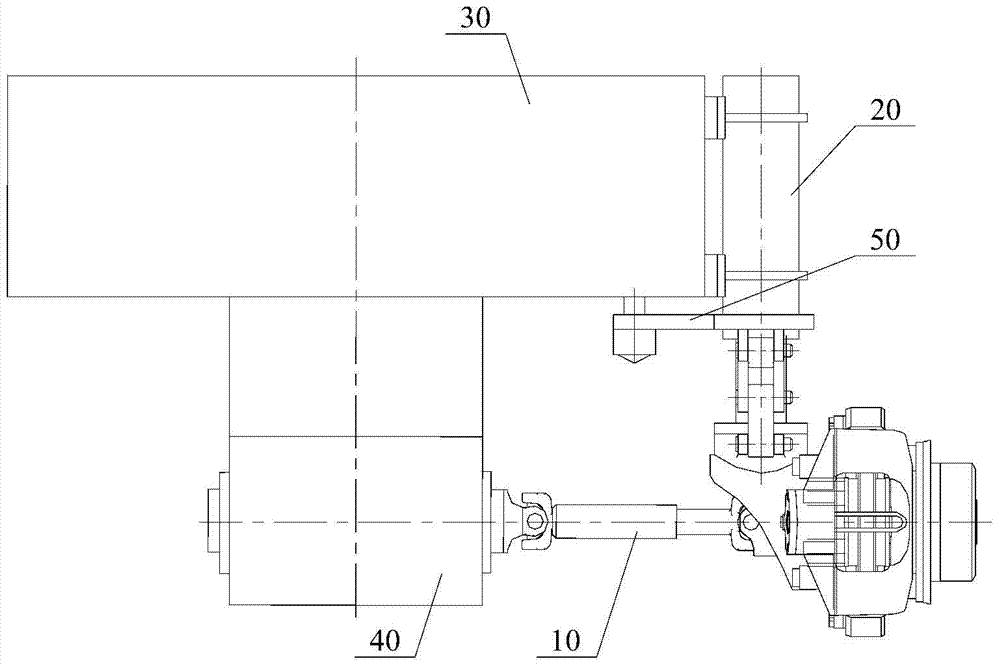

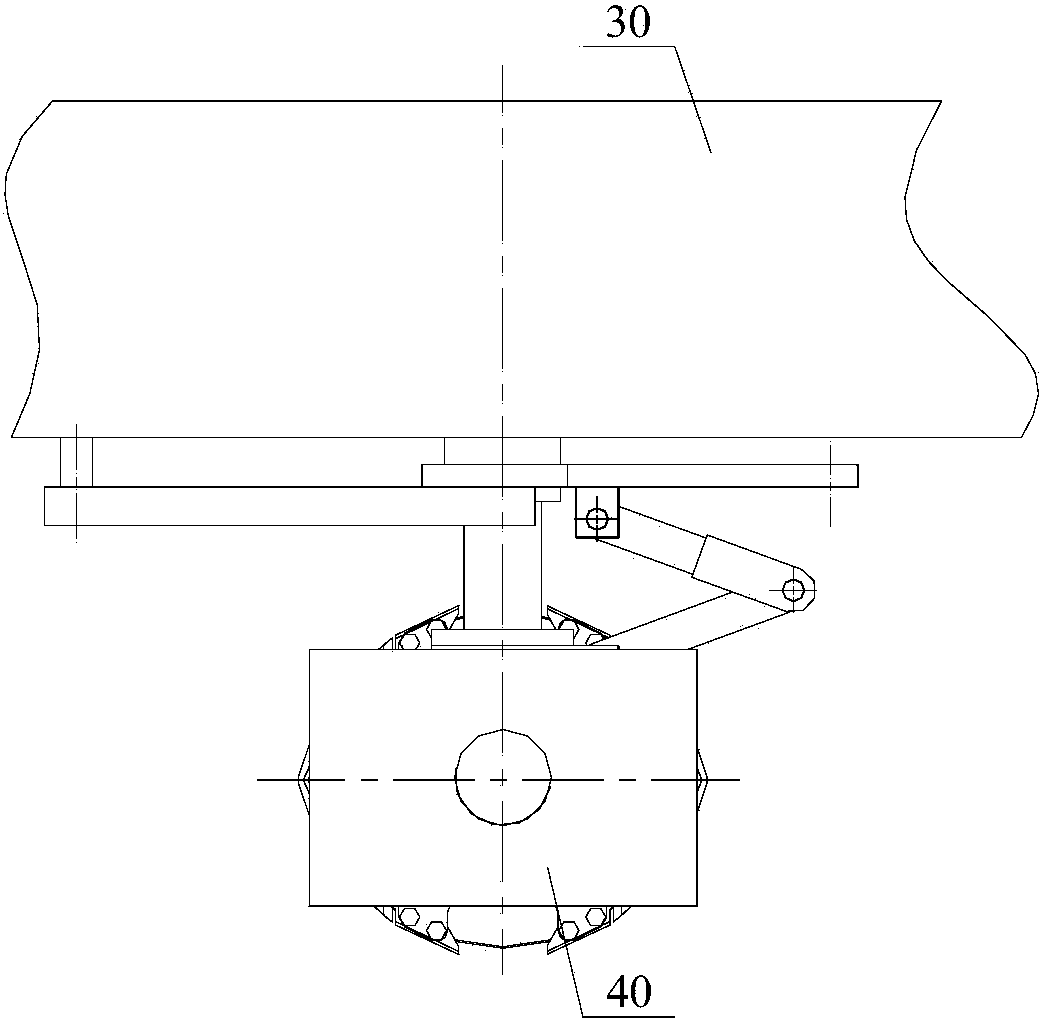

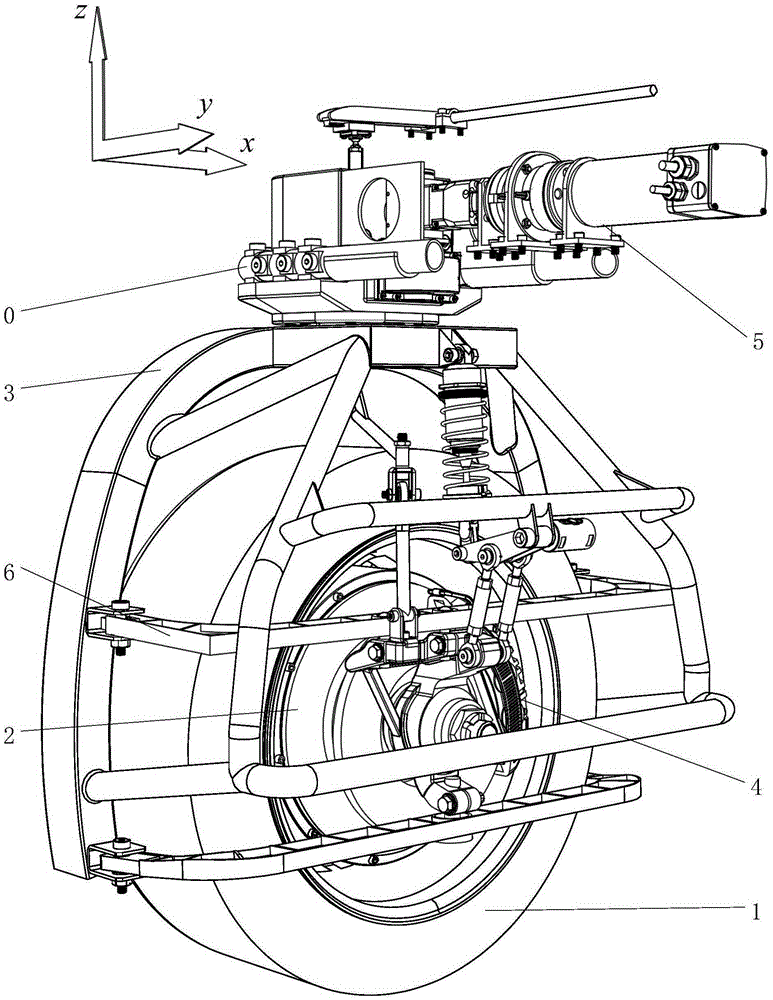

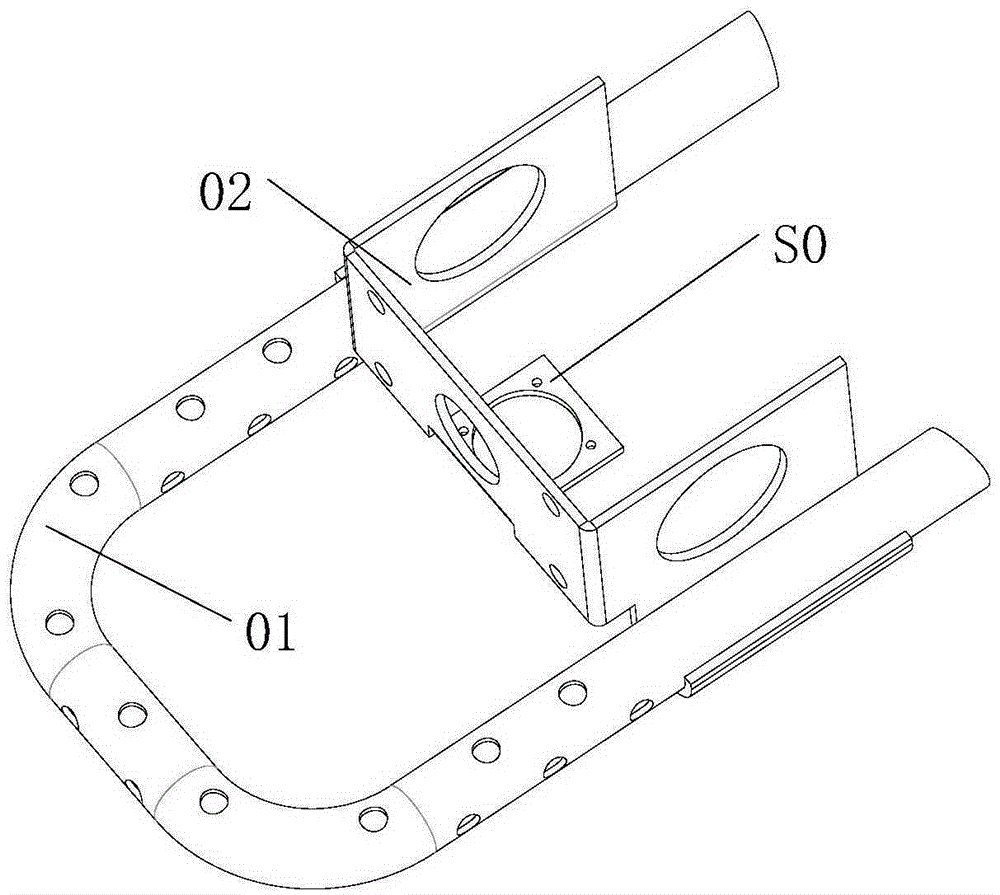

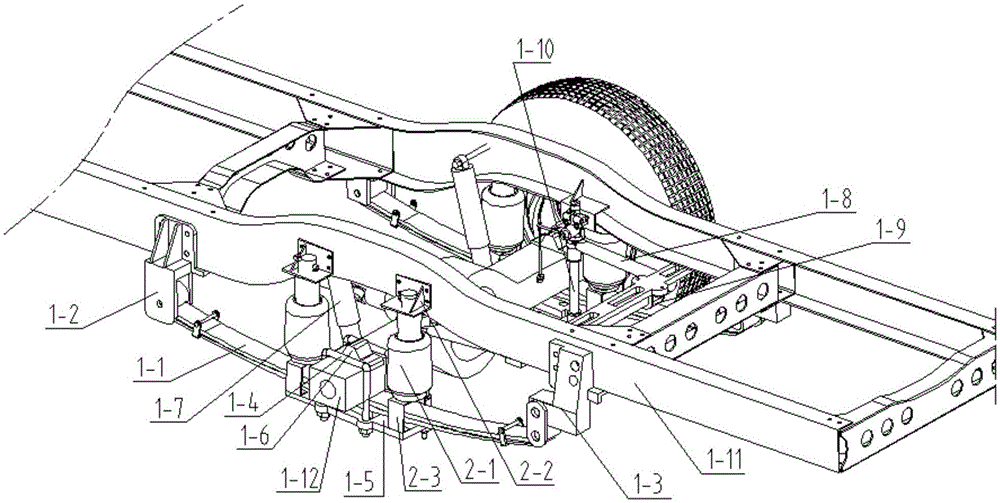

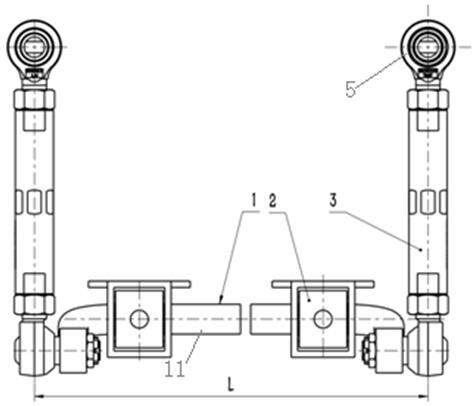

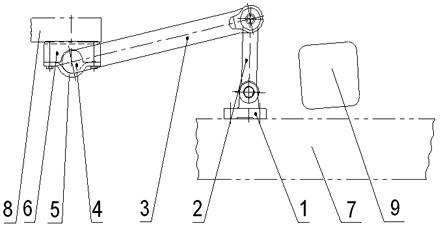

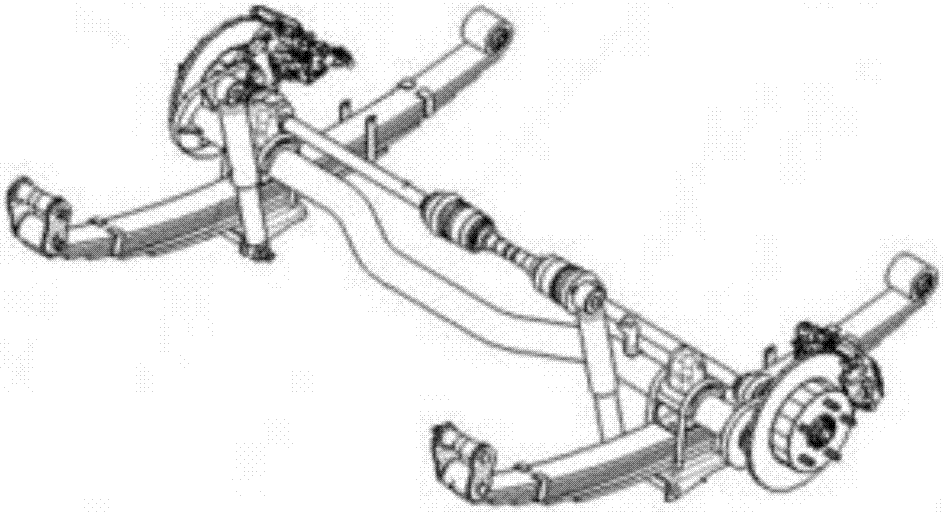

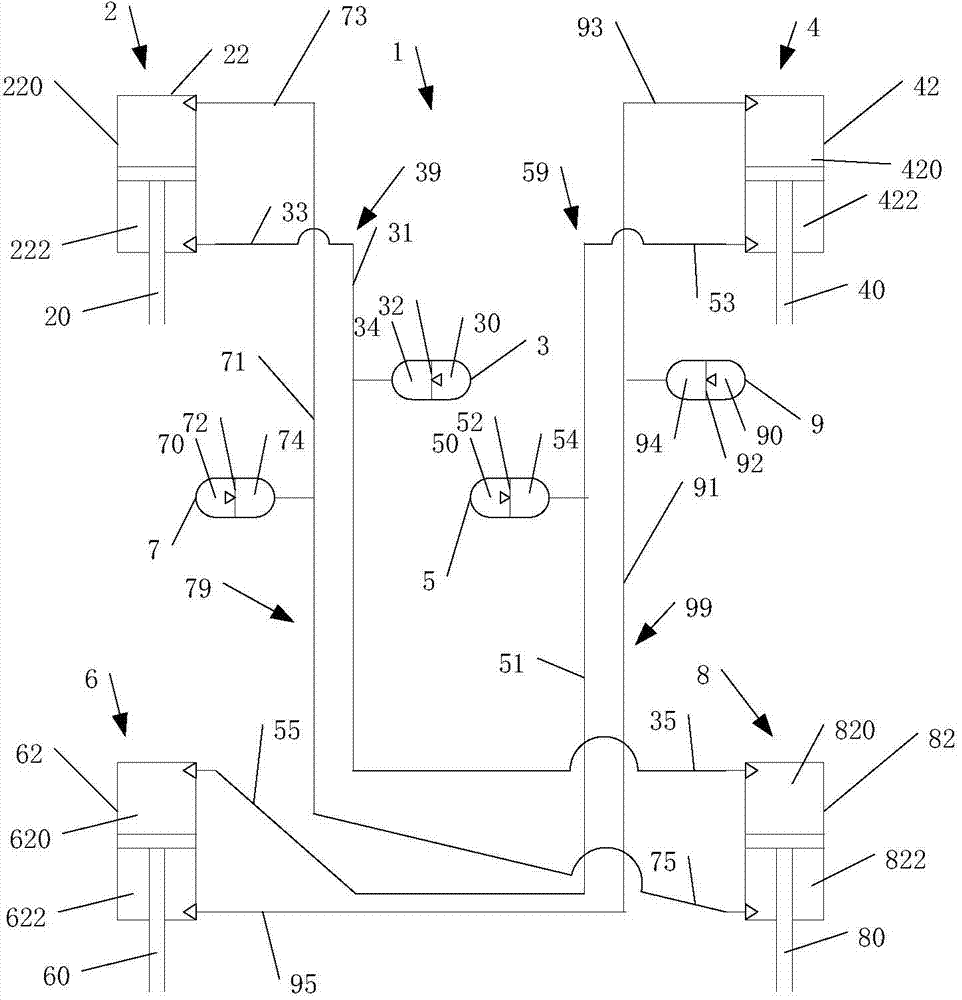

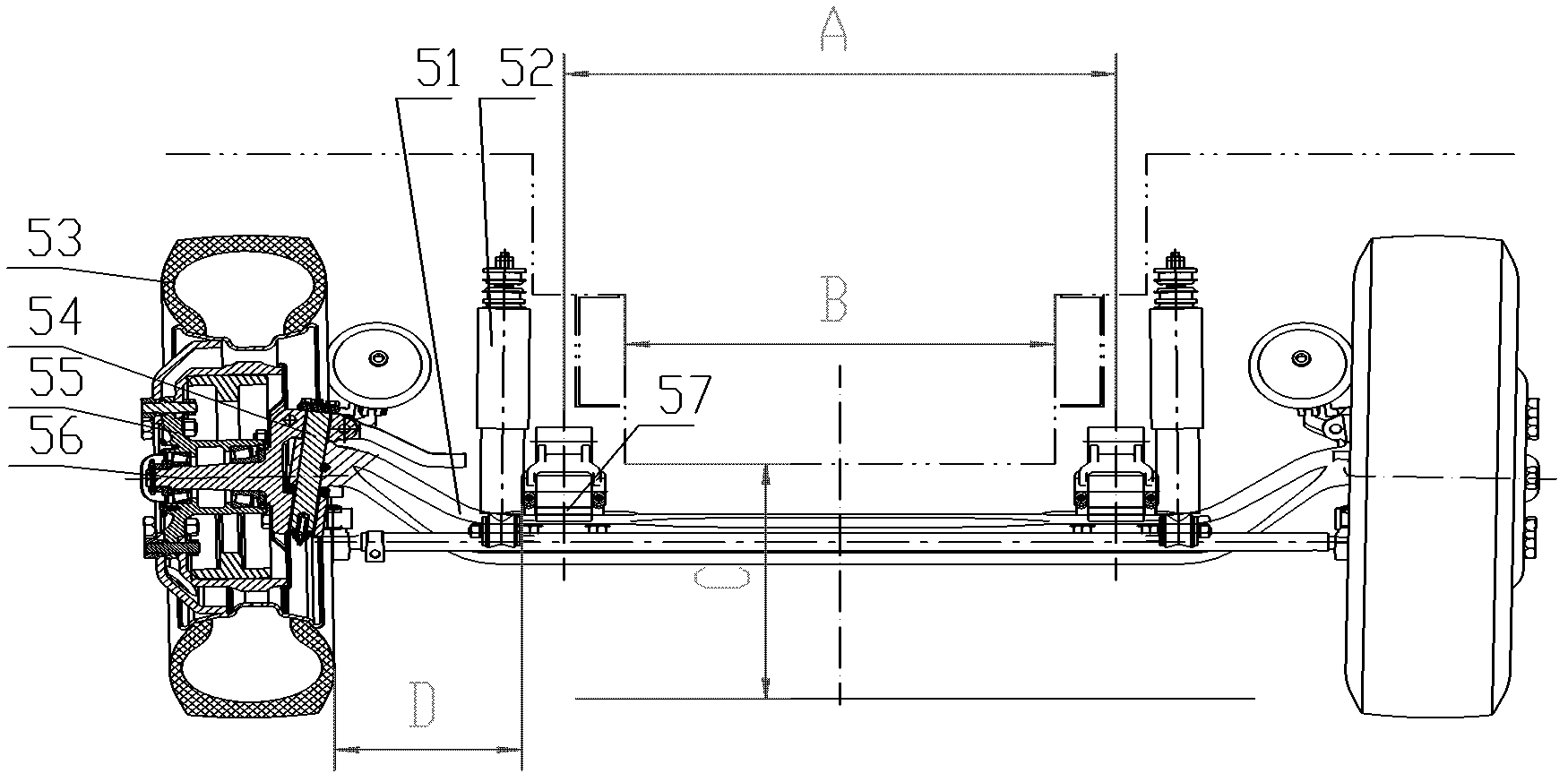

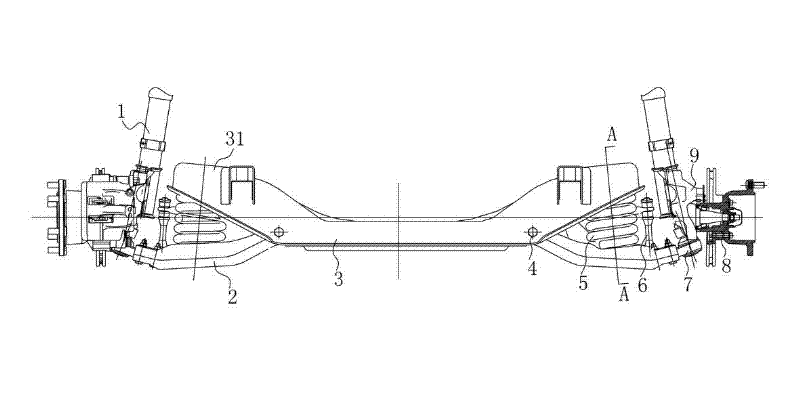

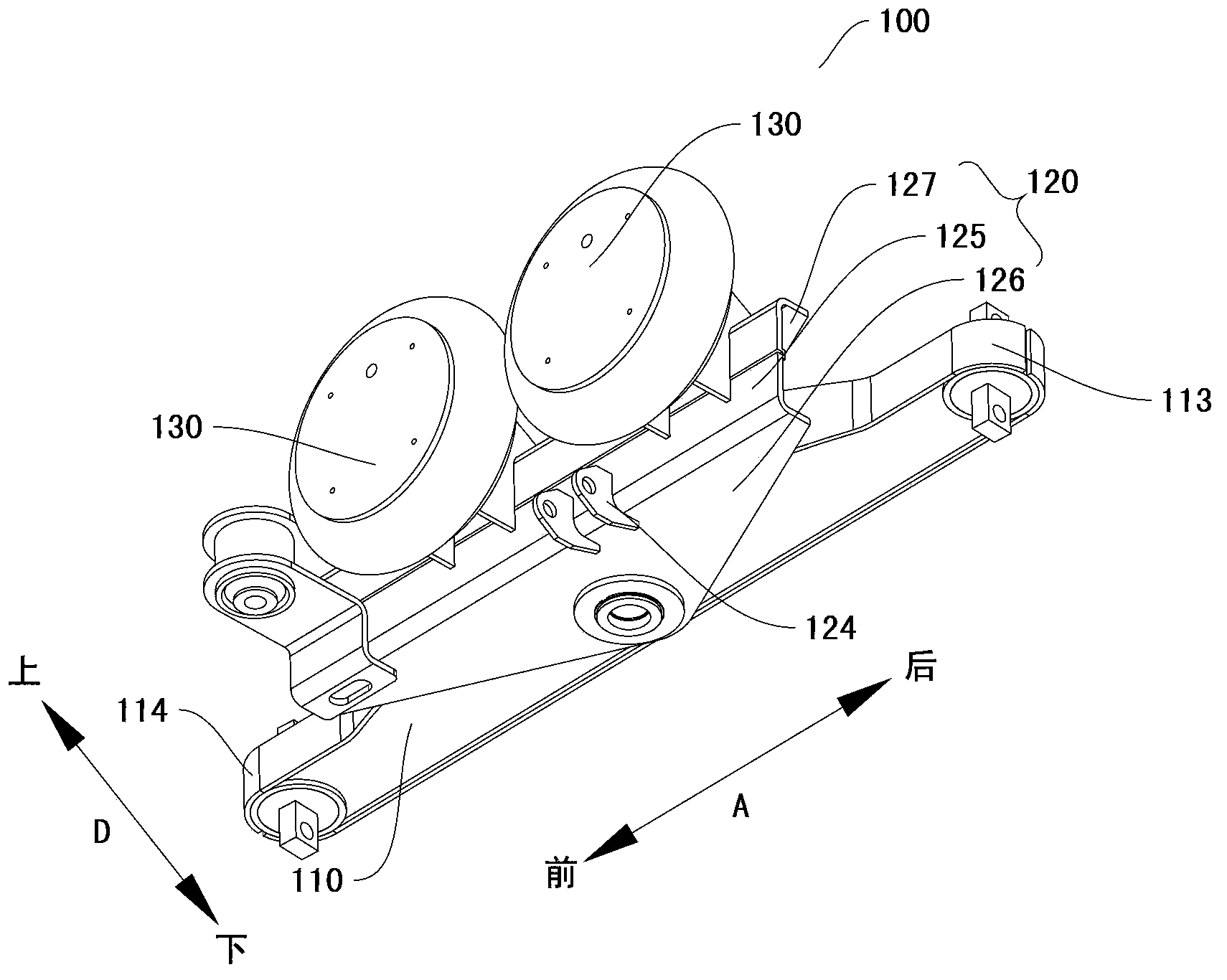

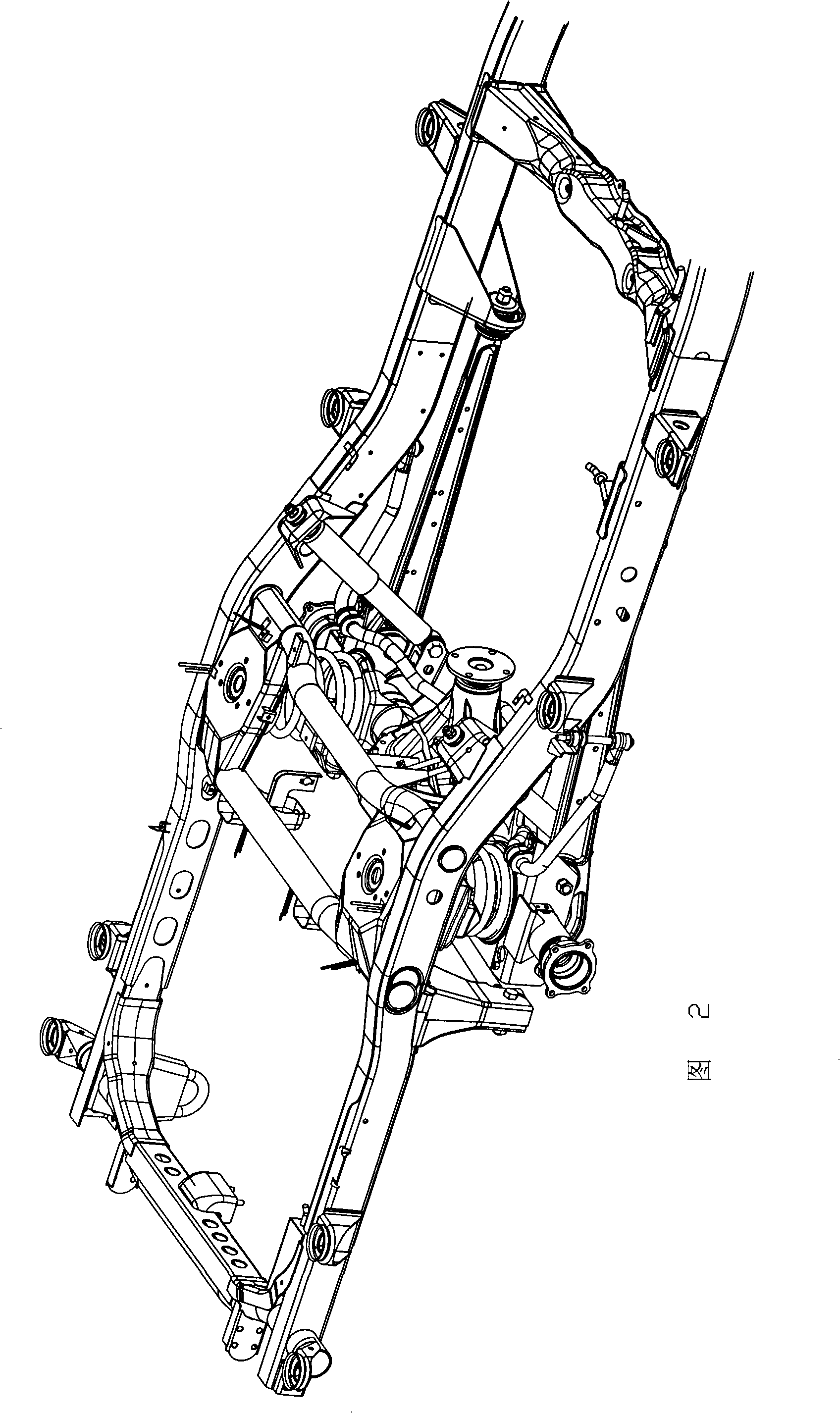

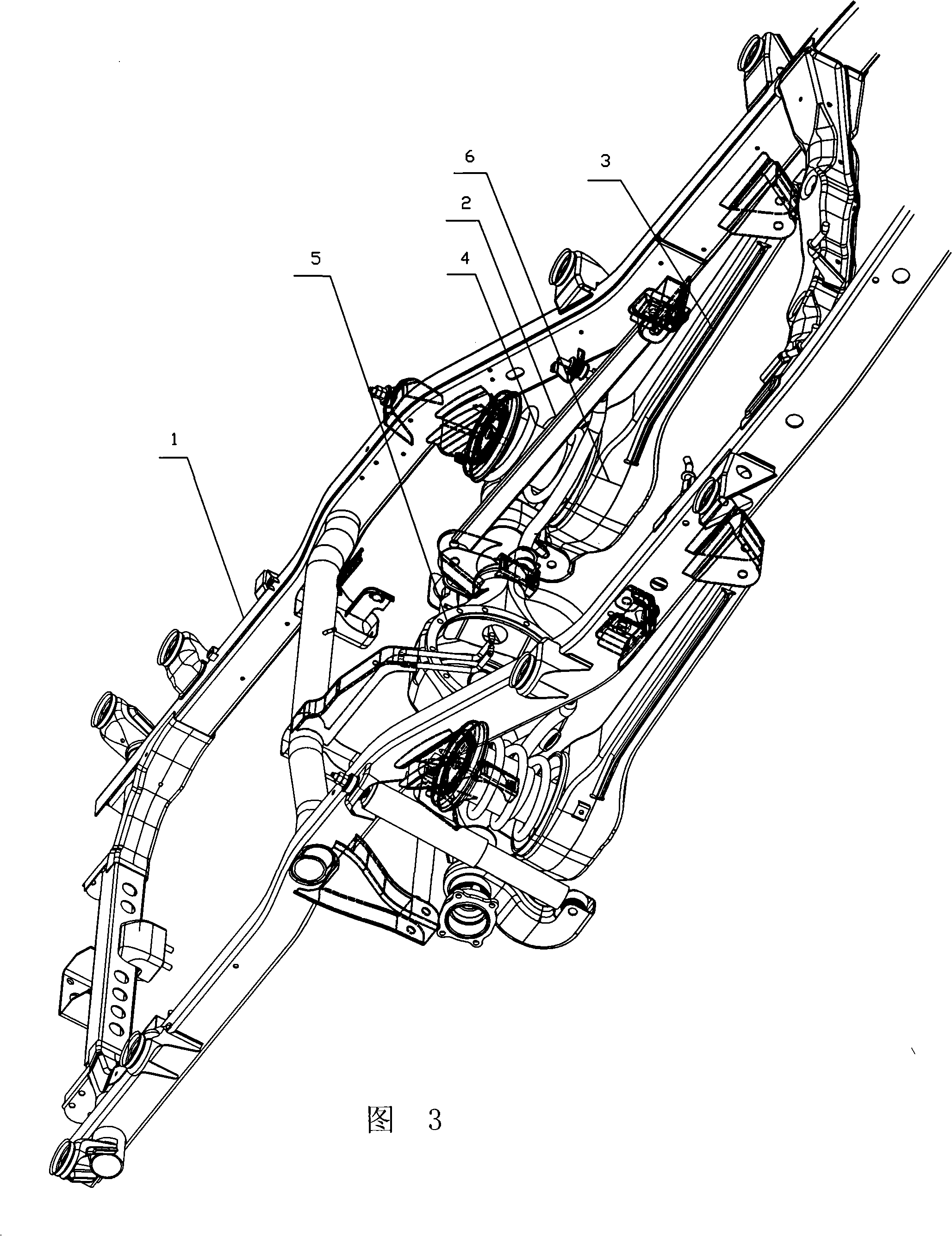

Independent suspension system and crane with same

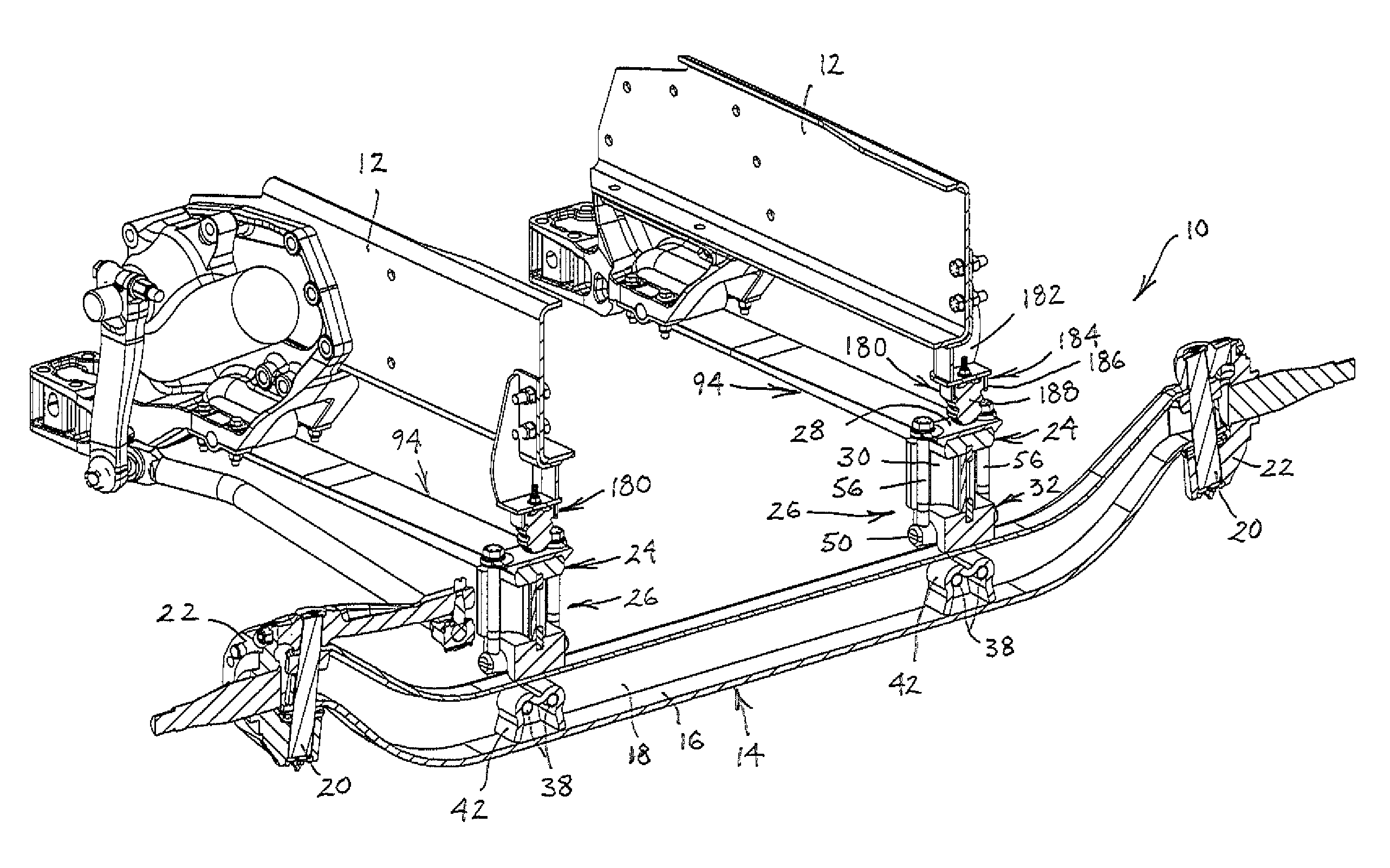

ActiveCN103522865AImprove reliabilityReduce unsprung massInterconnection systemsIndependent motionVehicle frame

The invention discloses an independent suspension system. Two suspension oil cylinders are arranged between wheel edges of wheels on two sides and a frame respectively, and a steering mechanism drives the wheels on the two sides to perform steering. Two upper V-shaped swing rods and two lower V-shaped swing rods are arranged corresponding to the wheels on the two sides. Rod connection end portions of the two upper V-shaped swing rods are hinged to the upper portions of the wheel edges of the wheels on corresponding sides through spherical hinges respectively, and rod separation end portions of the two upper V-shaped swing rods are hinged to fixing members fixed below the frame along the lateral direction. Rod connection end portions of the two lower V-shaped swing rods are hinged to the lower portions of the wheel edges of the wheels on corresponding sides through spherical hinges respectively, and rod separation end portions of the two lower V-shaped swing rods are hinged to the fixing members fixed below the frame along the lateral direction. By means of the independent suspension system, possible frustrating effects caused by the suspension oil cylinders can be avoided, mutual independent motion of the wheel on the left side and the wheel on the right side can be achieved reliably, adhesion conditions of the ground are fully utilized, and control stability of the complete machine is improved. On the basis, the invention further comprises a crane with the independent suspension system.

Owner:XUZHOU HEAVY MASCH CO LTD

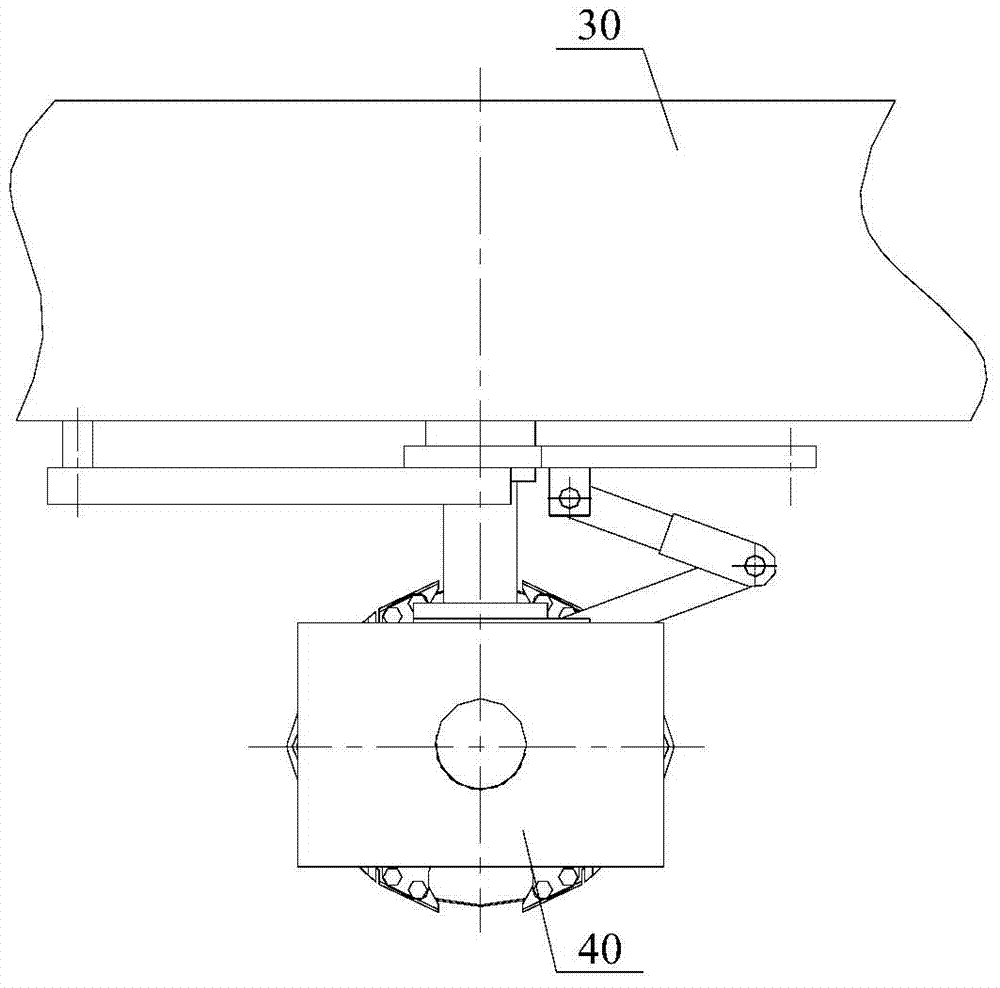

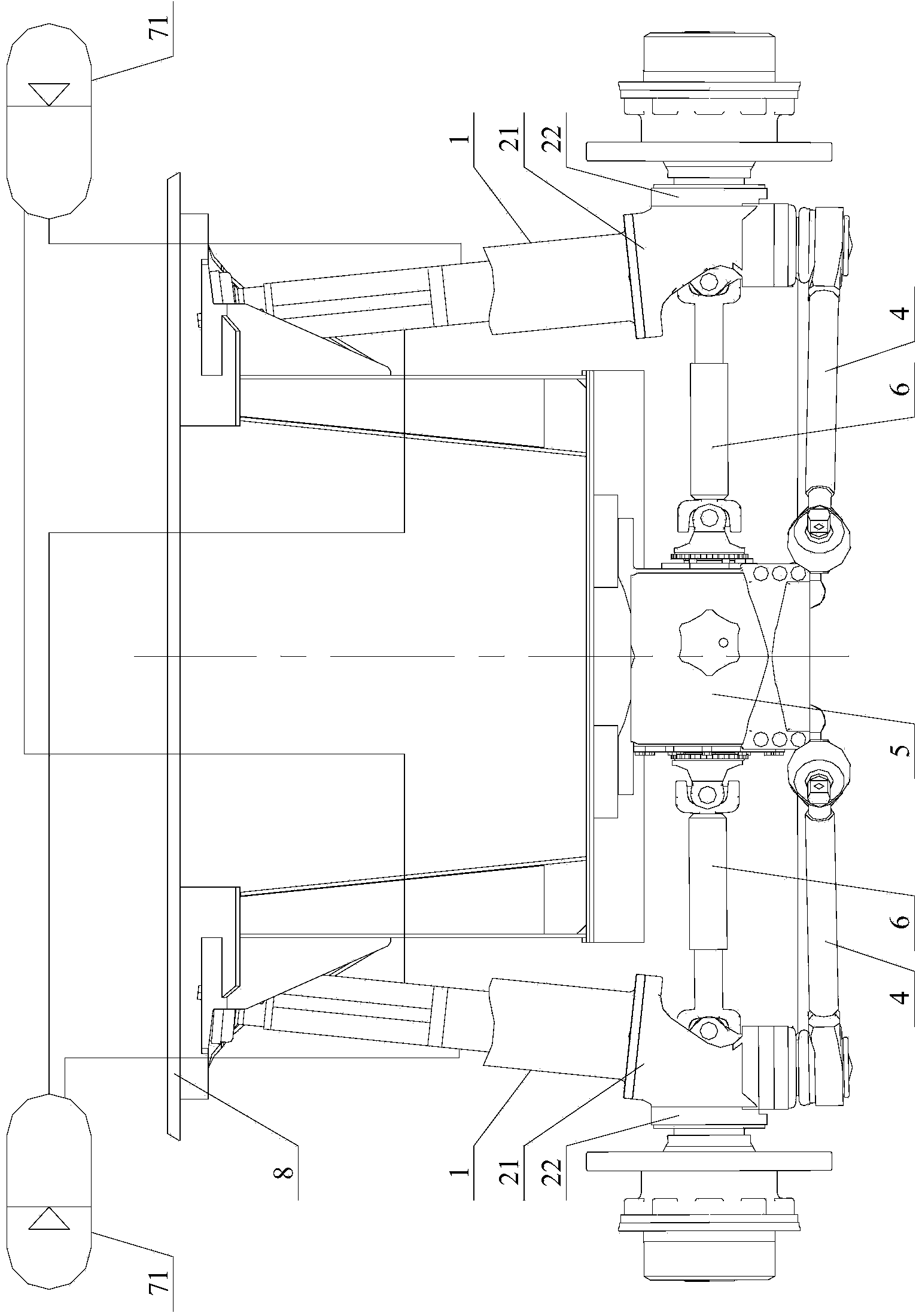

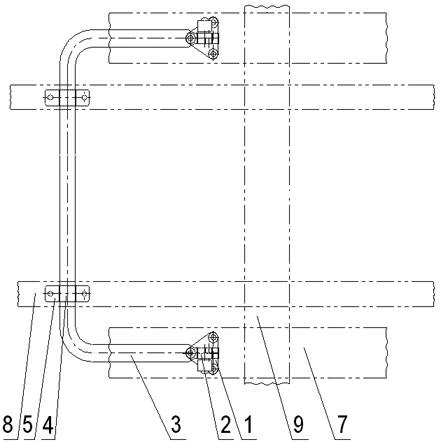

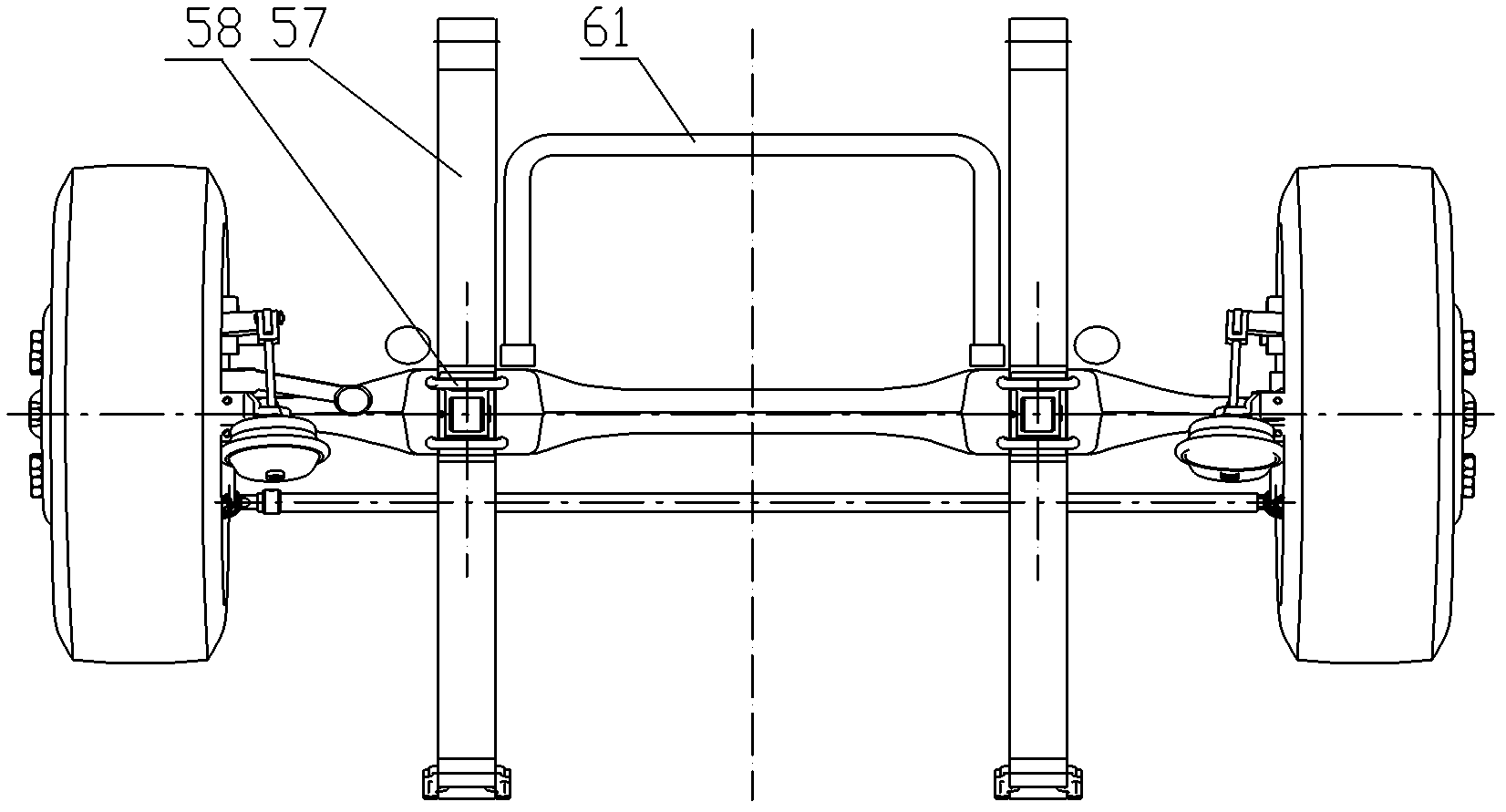

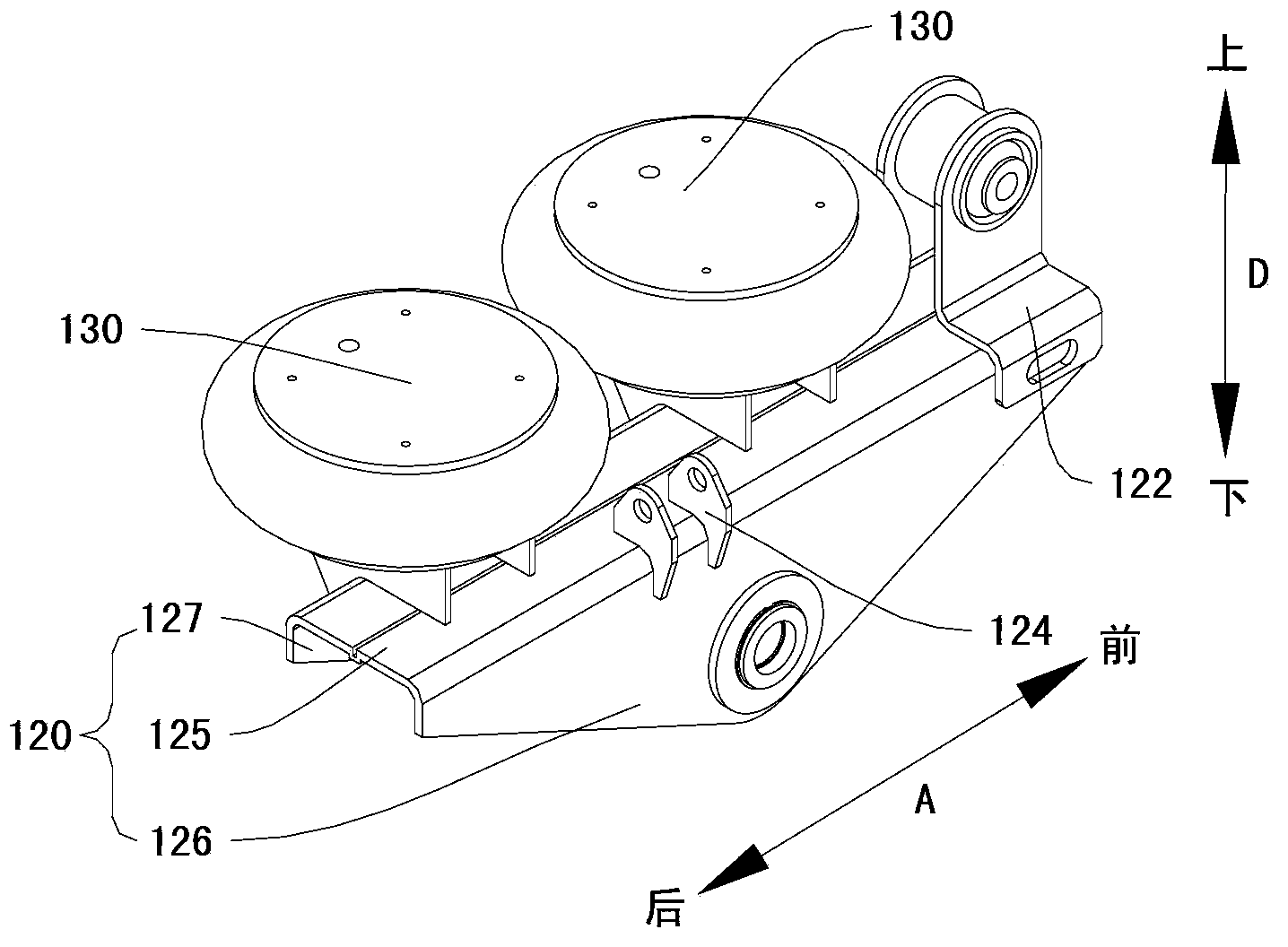

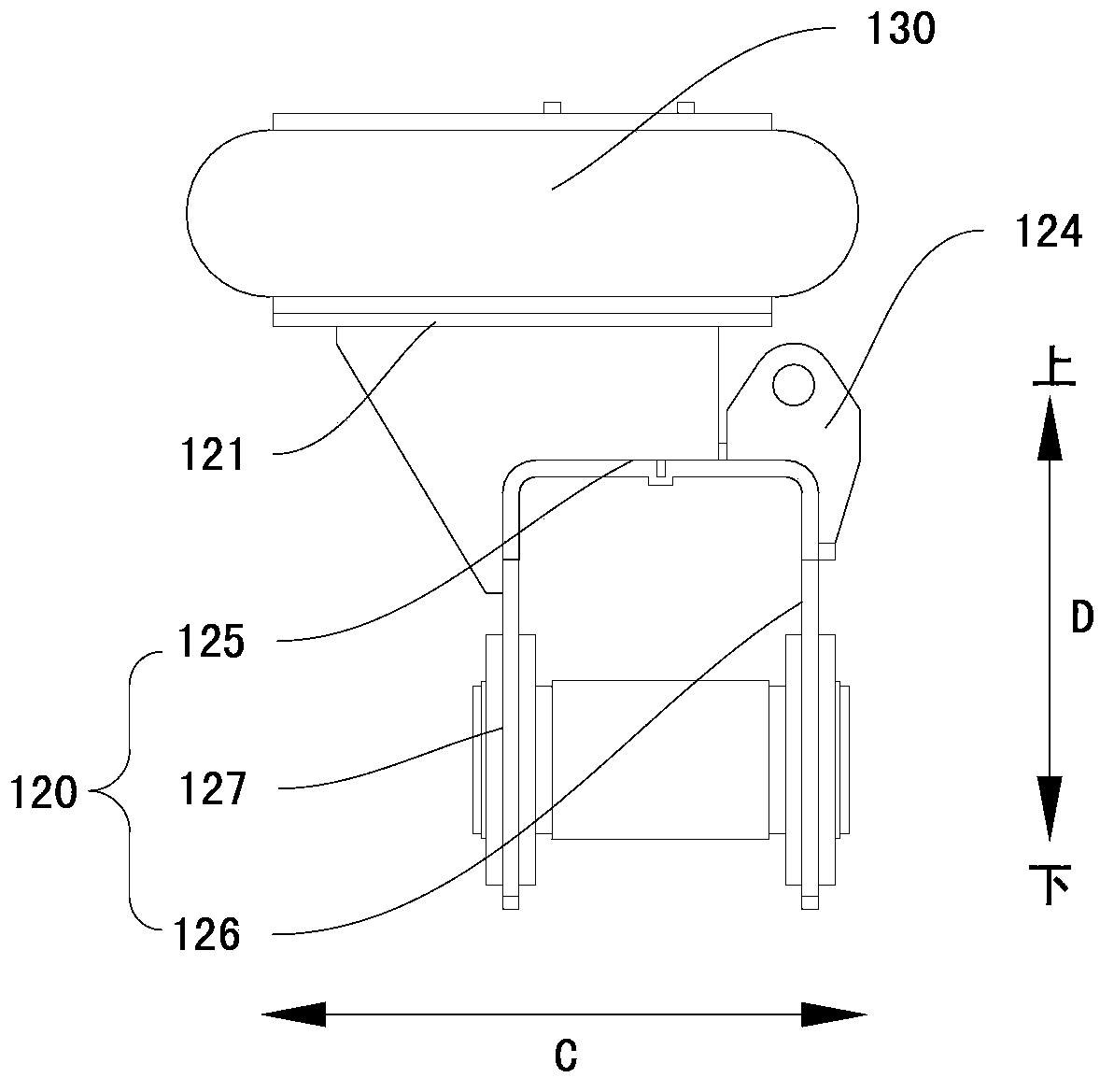

Independent suspension system and crane with same

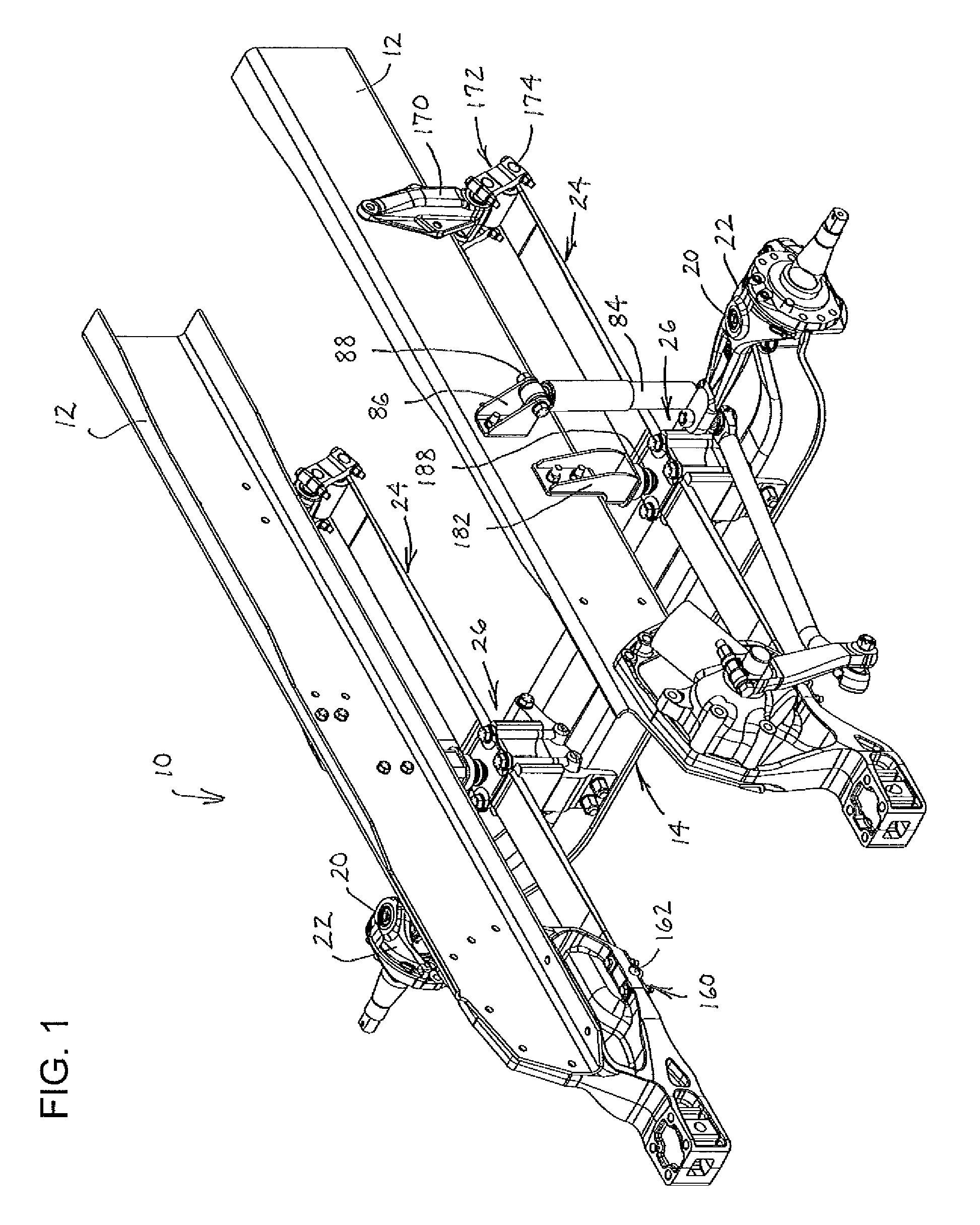

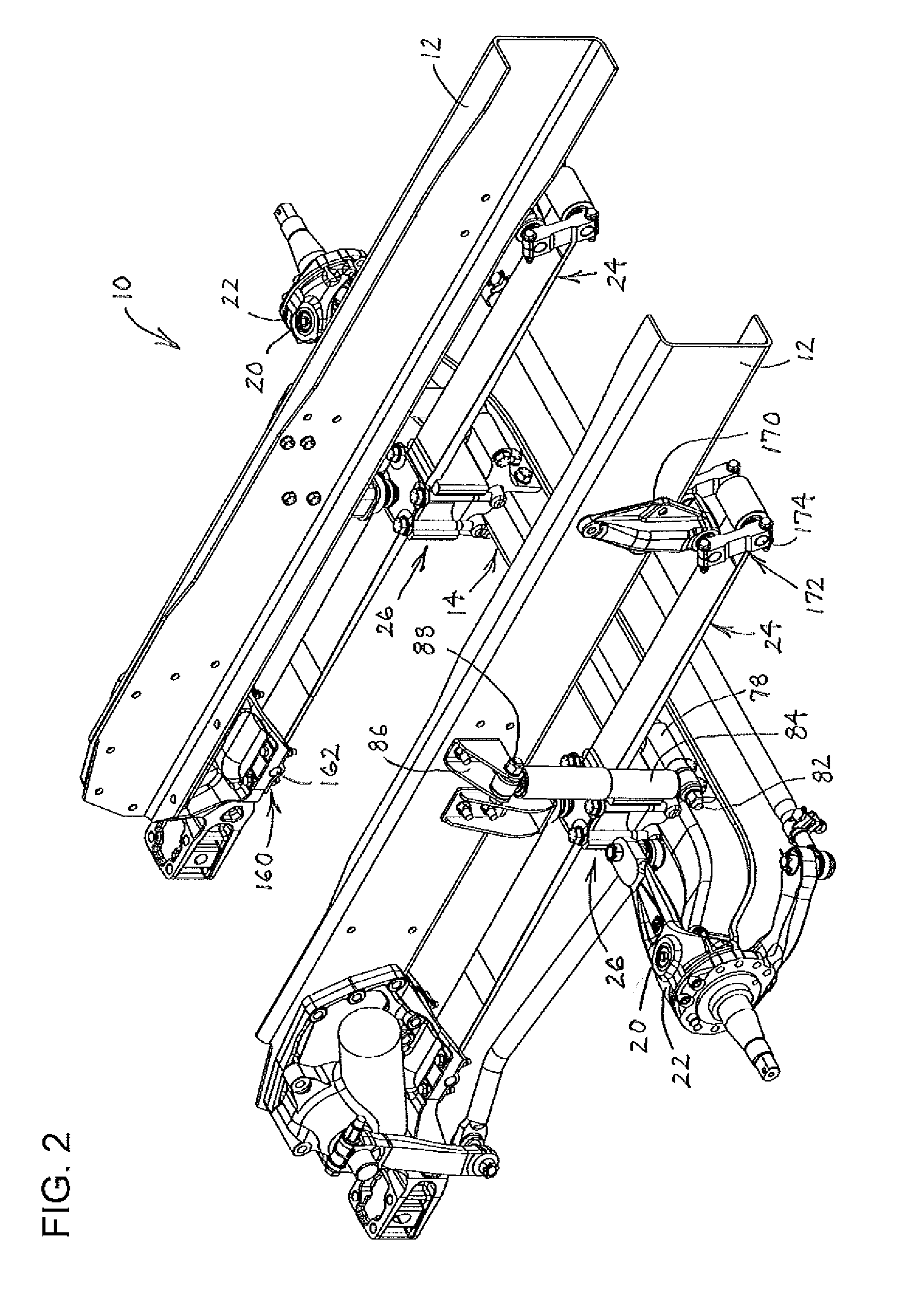

ActiveCN103738136AMeet the design requirementsReduce the effect of lateral forceAuxillary drivesSteering linkagesVehicle frameReduction drive

The invention discloses an independent suspension system which comprises two suspension oil cylinders arranged between the edges of wheels on two sides and a frame respectively, a steering mechanism used for driving the wheels on the two sides to make a turn under the drive action of a power-assisted steering oil cylinder, and two swing rods corresponding to the wheels on the two sides, wherein one end part of each swing rod is hinged to the edge of the wheel on the corresponding side through a spherical hinge, and the other end part of the swing rod is hinged to fixing members fixed below a main speed reducer in a front-rear direction through two spherical hinges respectively. Through the structural improvement, tires mounted on the wheel edges can be positioned, the tire motion in the moving process of a crane is guaranteed to meet the design requirement, and the possible destructive influence of the suspension oil cylinders can be completely avoided, so that the wheels on the left and right sides can reliably and independently move; the adhesion conditions of a road surface are fully utilized, so that the control stability of the complete crane can be improved. Based on the independent suspension system, the invention further provides the crane with the independent suspension system.

Owner:XUZHOU HEAVY MASCH CO LTD

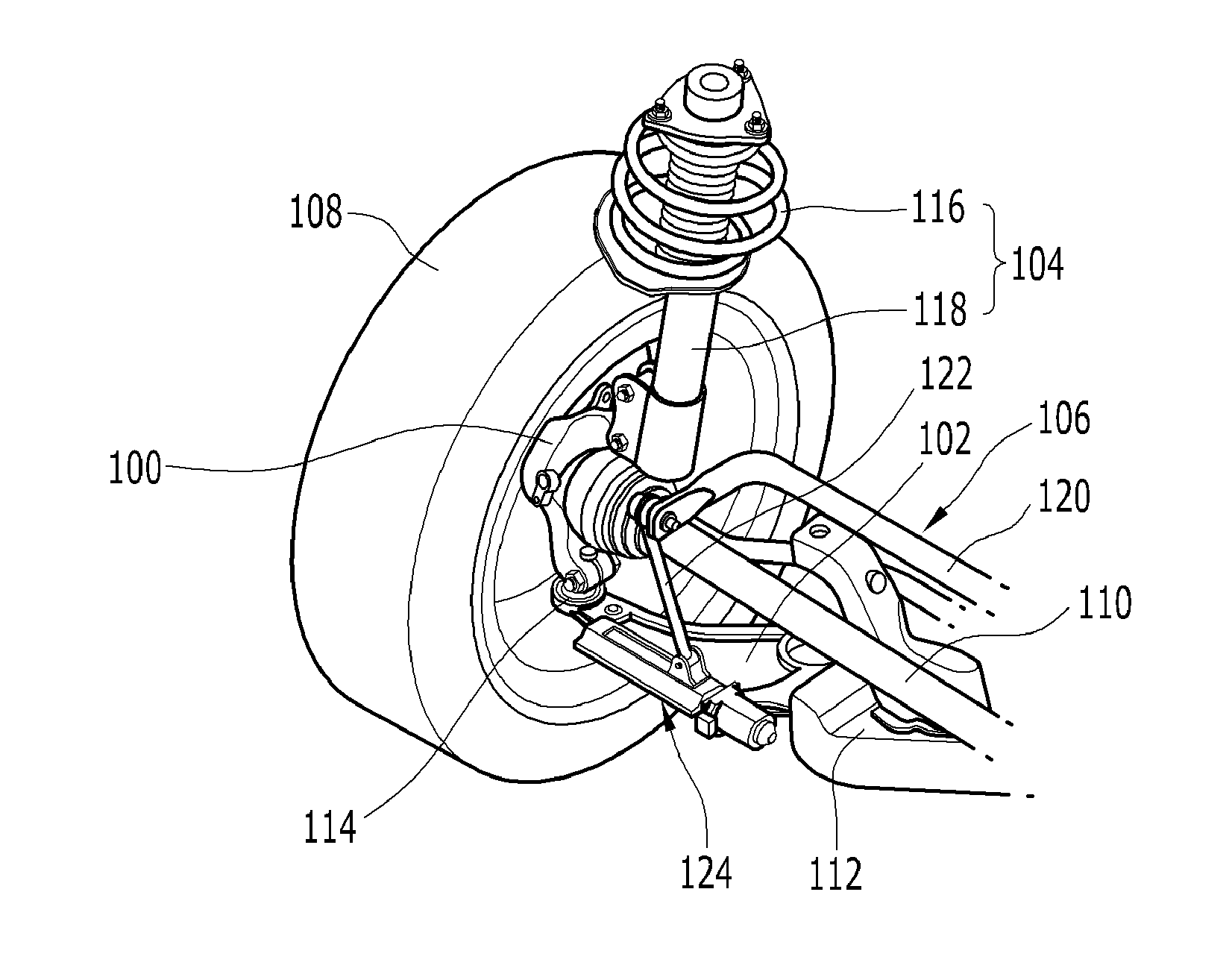

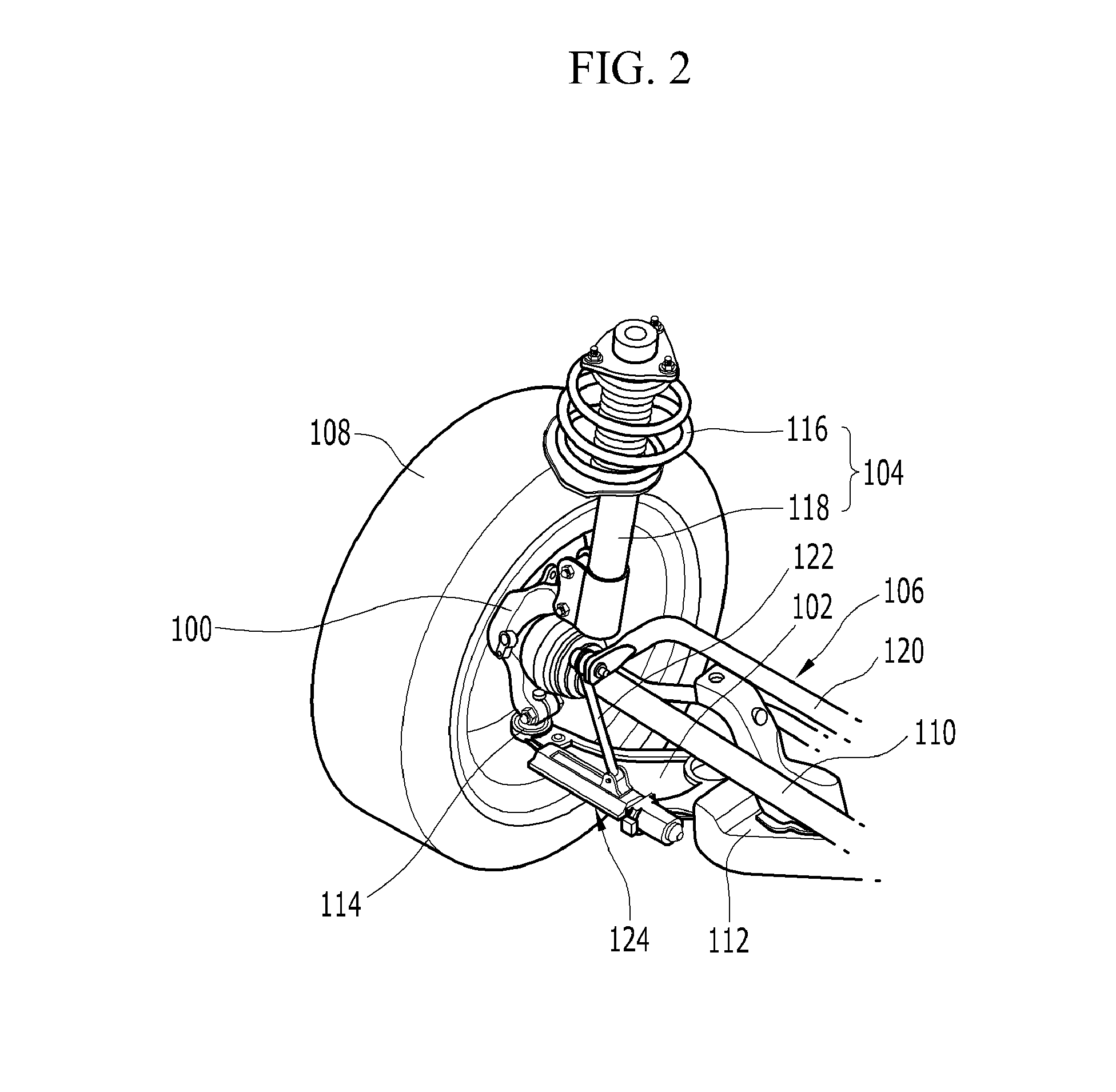

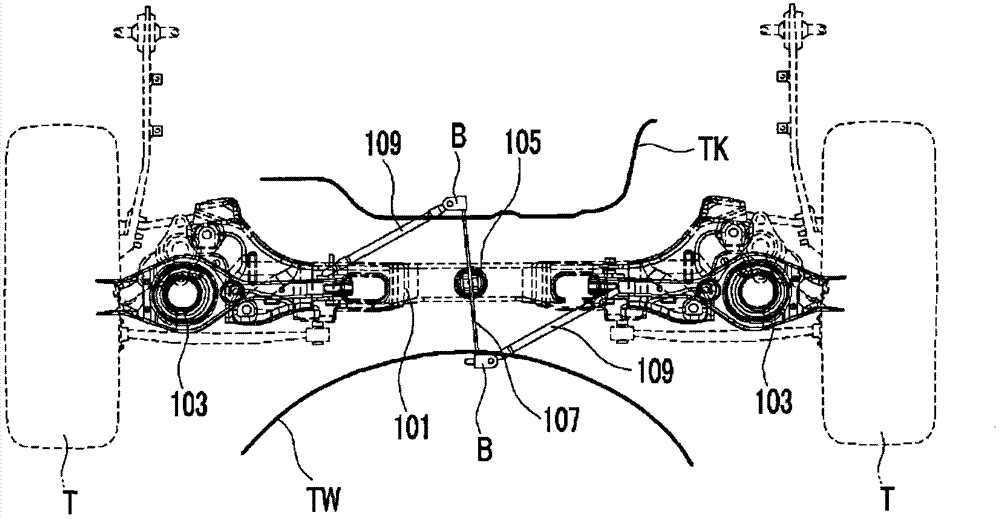

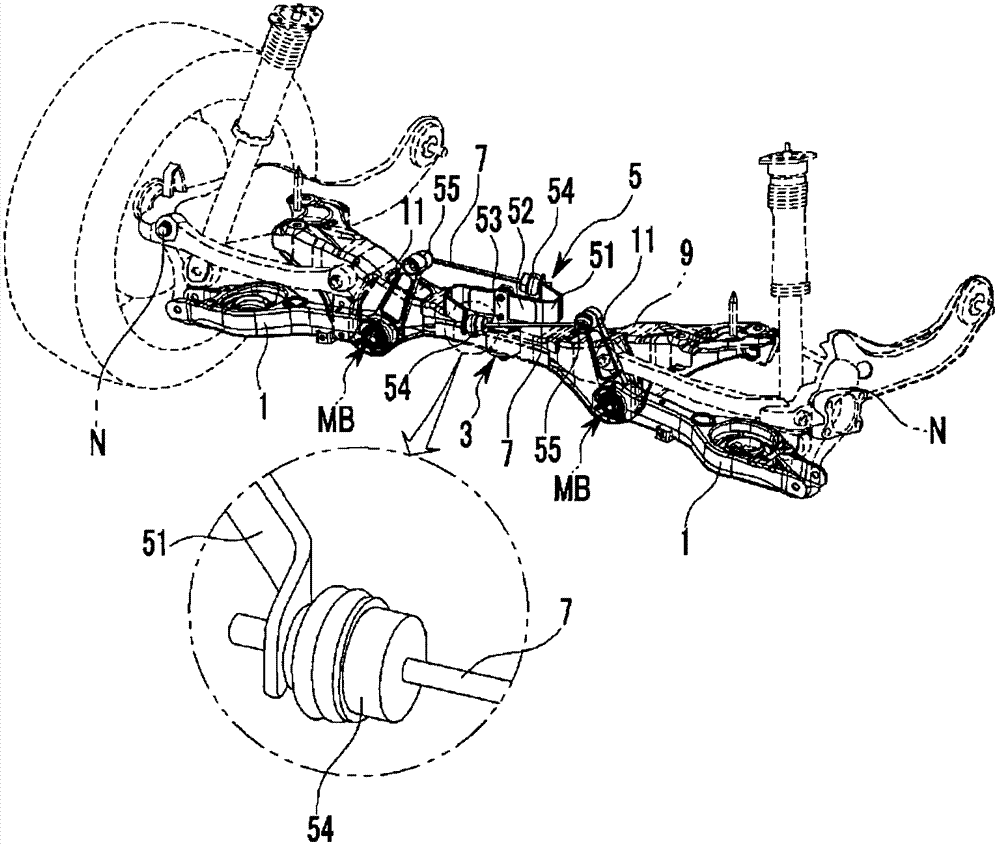

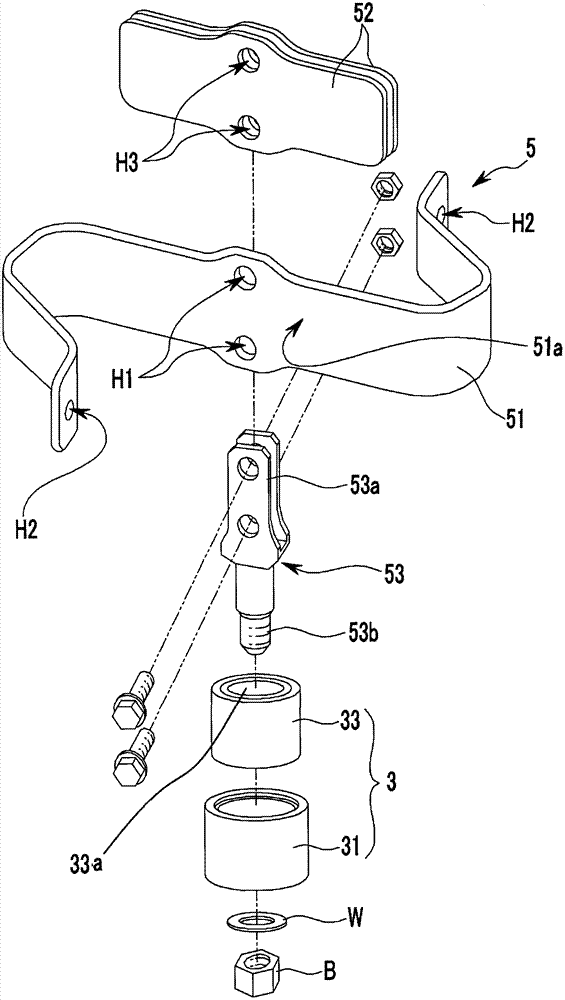

Active roll control system for vehicle

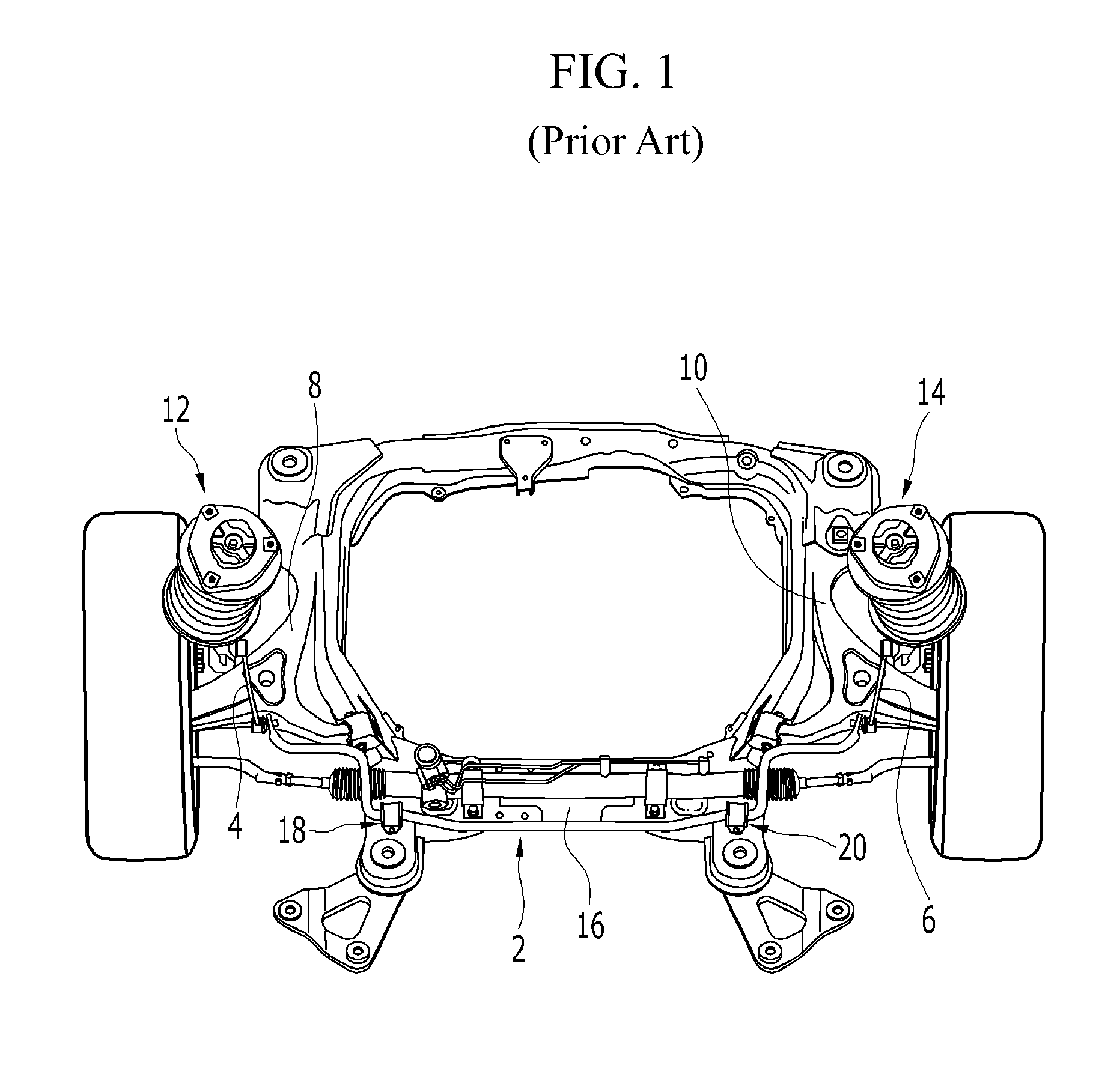

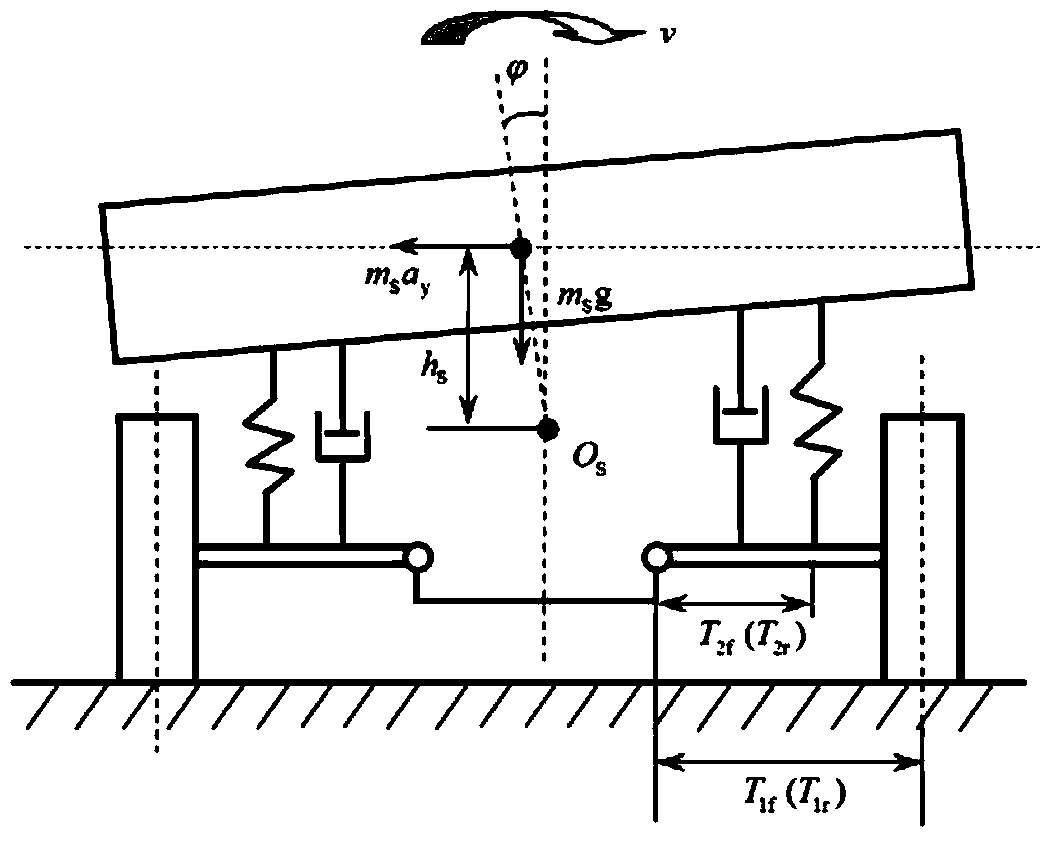

ActiveUS8398092B2Improve stabilityImprove roll stiffnessSteering partsInterconnection systemsVehicle frameControl system

A roll control system improves stability in turning by actively controlling roll stiffness in accordance with traveling conditions of a vehicle. The active roll control system for a vehicle suspension includes a stabilizer bar of which the middle straight portion is fixed to a sub-frame by a mount bush and both ends are connected with a lower control arm by a stabilizer link to suppress roll of the vehicle body, in which a roll control mechanism is disposed between a lower end connecting portion of the stabilizer link and the lower control arm to increase roll stiffness by increasing a lever ratio of the stabilizer bar, if needed.

Owner:HYUNDAI MOTOR CO LTD

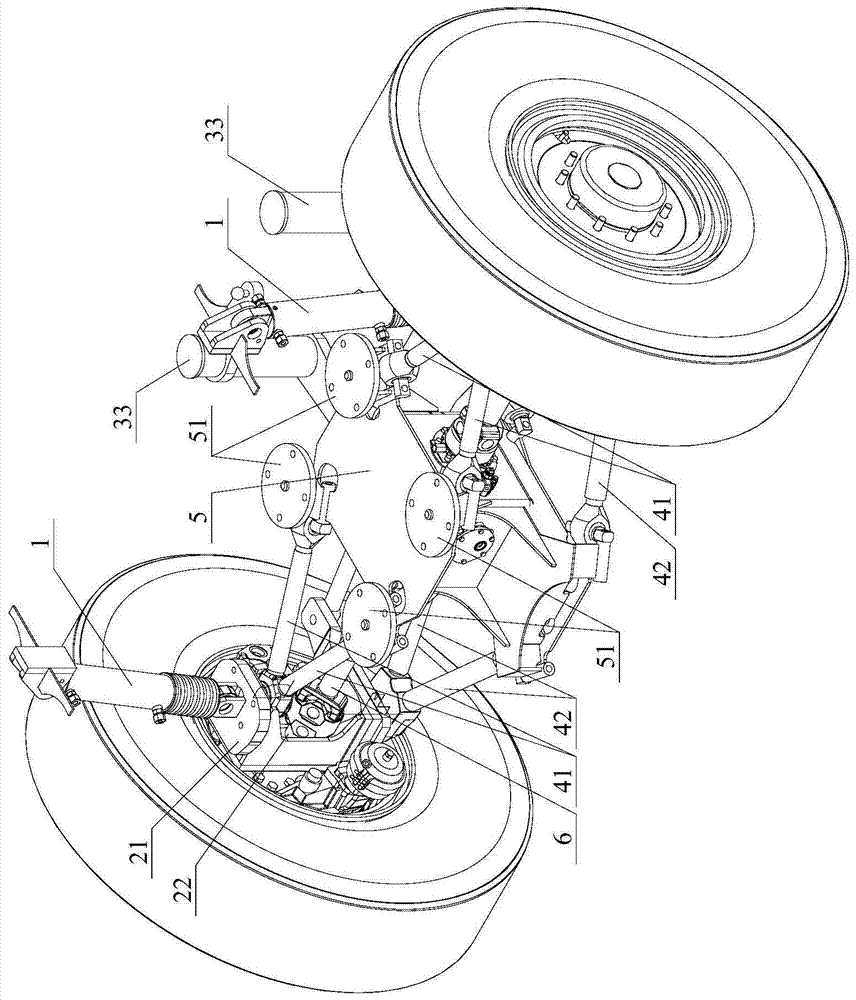

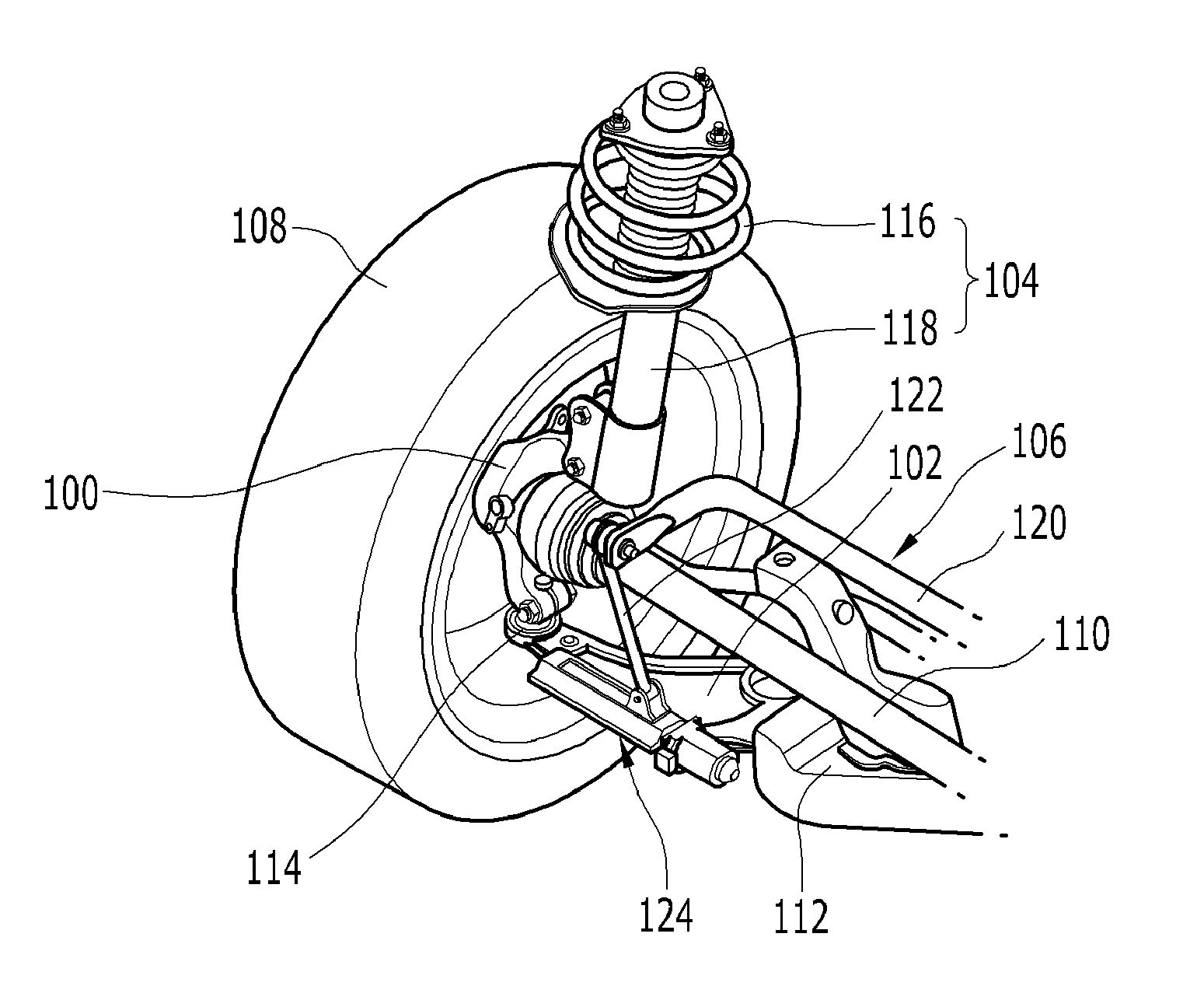

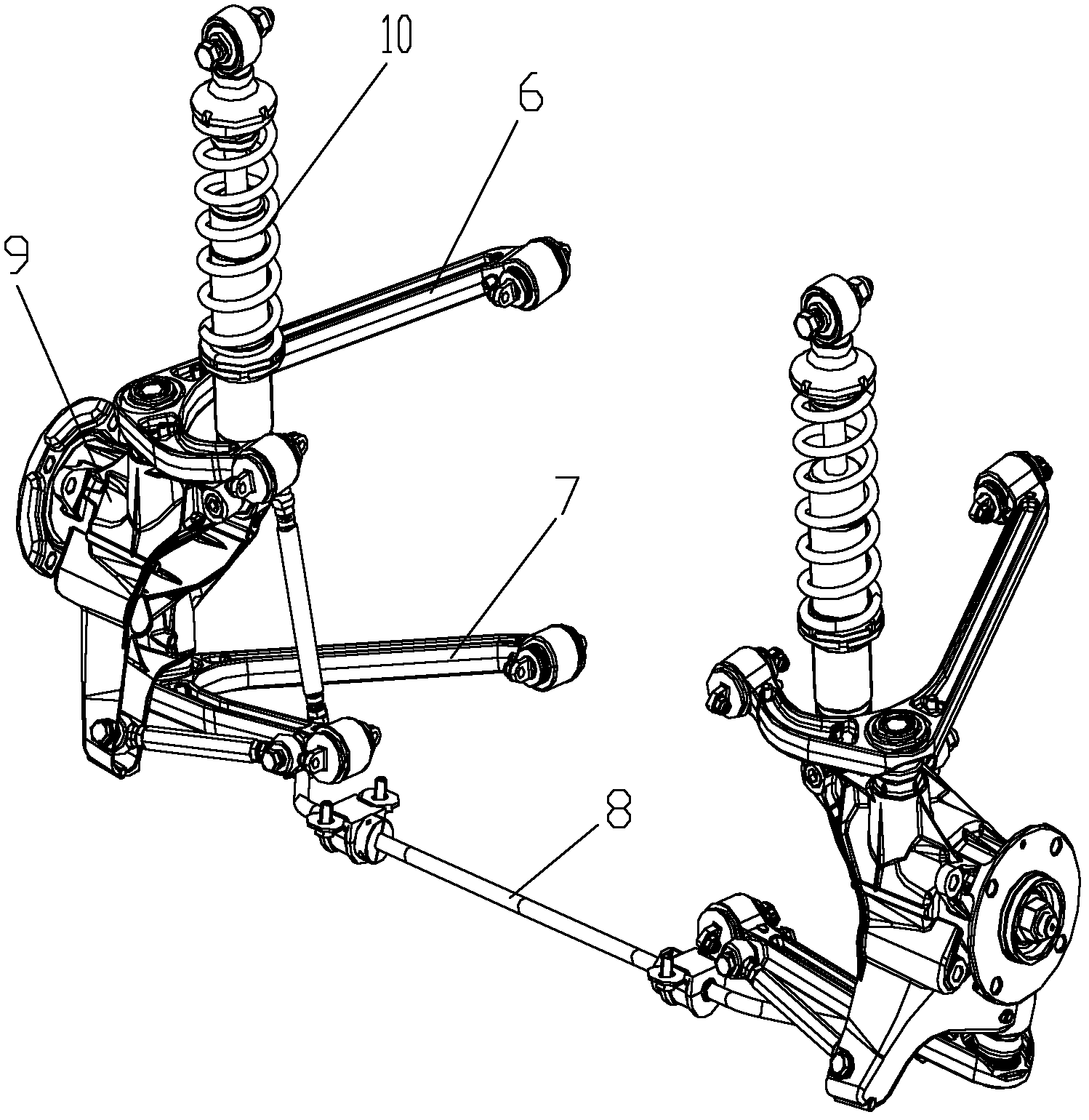

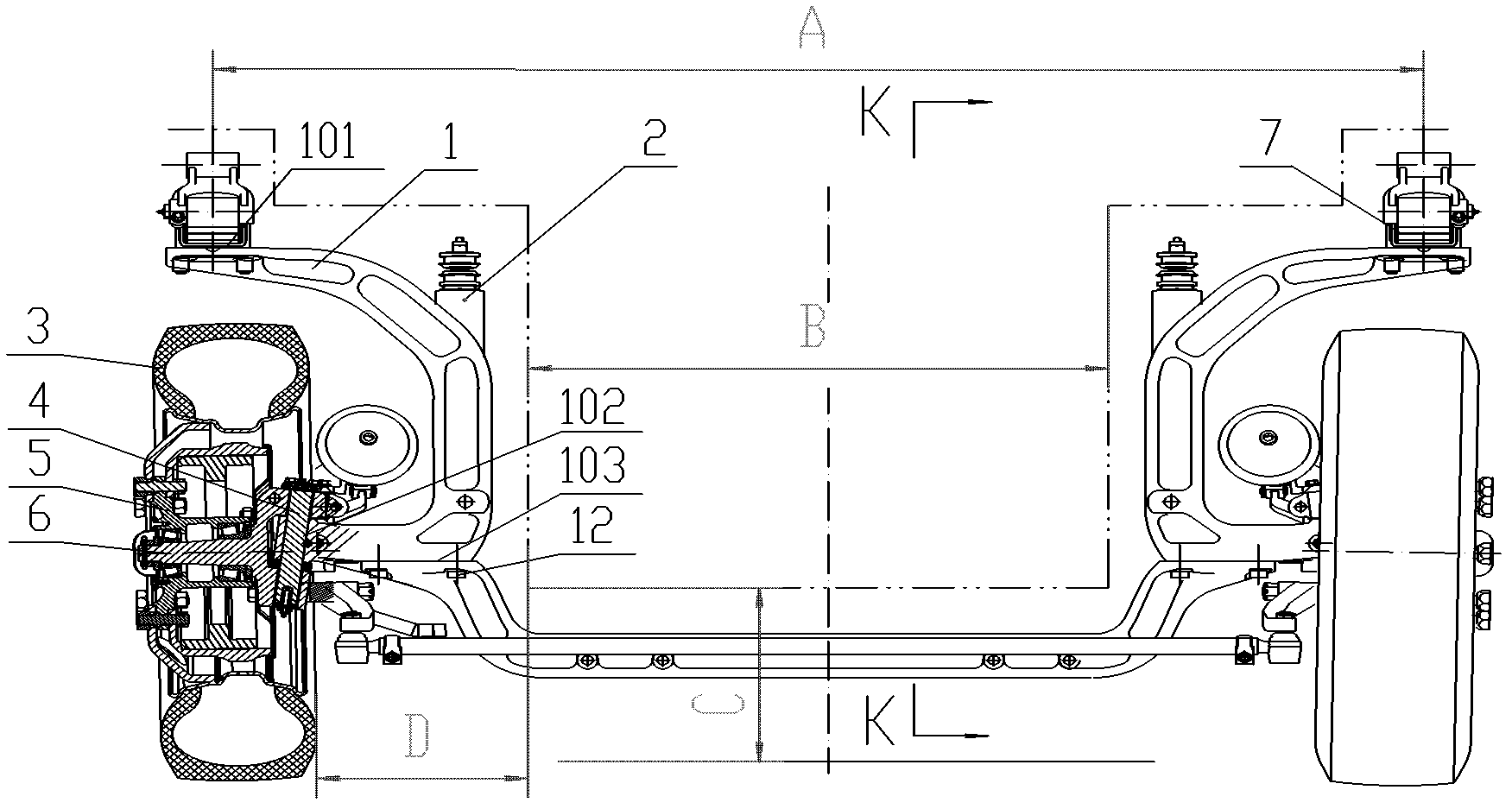

Suspension system and steering system for distributed driving and independent steering electric automobile

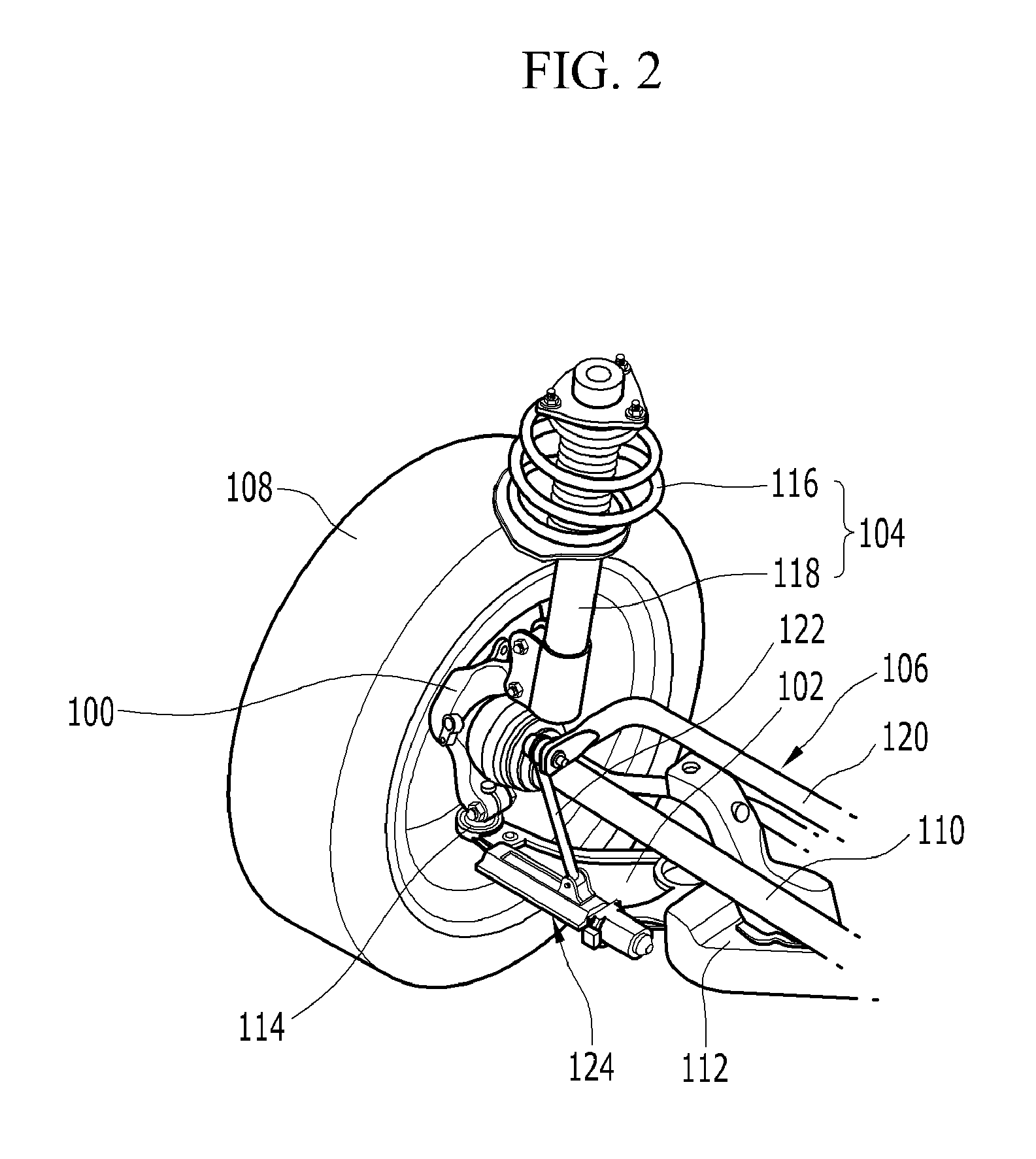

ActiveCN105415996AImprove groundingReduce wearElectrical steeringPivoted suspension armsDouble wishbone suspensionGround state

The invention discloses a suspension system and steering system for a distributed driving and independent steering electric automobile. The suspension system and steering system is fixed to an automobile body through an installation support and comprises wheels, a hub motor, a wheel support, a brake, a steering system body and a double-cross-arm suspension system. The steering system body is installed on the installation support of the automobile body, the wheel support is connected with the output end of the steering system, the double-cross-arm suspension system is installed on the wheel support, and the movement of the double-cross-arm suspension system does not interfere with the movement of the steering system body. By means of the suspension system and steering system, the double-cross-arm suspension system with a lateral stabilizer is integrated while each wheel can have large steering angular capability, so that the grounding state of tires is improved, the attachment limit is increased, friction of the tires is reduced, and the side lurch rigidity of the automobile is increased; thus, the control stability is improved, and the whole system is easy to calibrate.

Owner:JILIN UNIV

Active Roll Control System for Vehicle

ActiveUS20120049480A1Improve stabilityNot been characterized extensivelySteering partsInterconnection systemsVehicle frameControl system

A roll control system improves stability in turning by actively controlling roll stiffness in accordance with traveling conditions of a vehicle. The active roll control system for a vehicle suspension includes a stabilizer bar of which the middle straight portion is fixed to a sub-frame by a mount bush and both ends are connected with a lower control arm by a stabilizer link to suppress roll of the vehicle body, in which a roll control mechanism is disposed between a lower end connecting portion of the stabilizer link and the lower control arm to increase roll stiffness by increasing a lever ratio of the stabilizer bar, if needed.

Owner:HYUNDAI MOTOR CO LTD

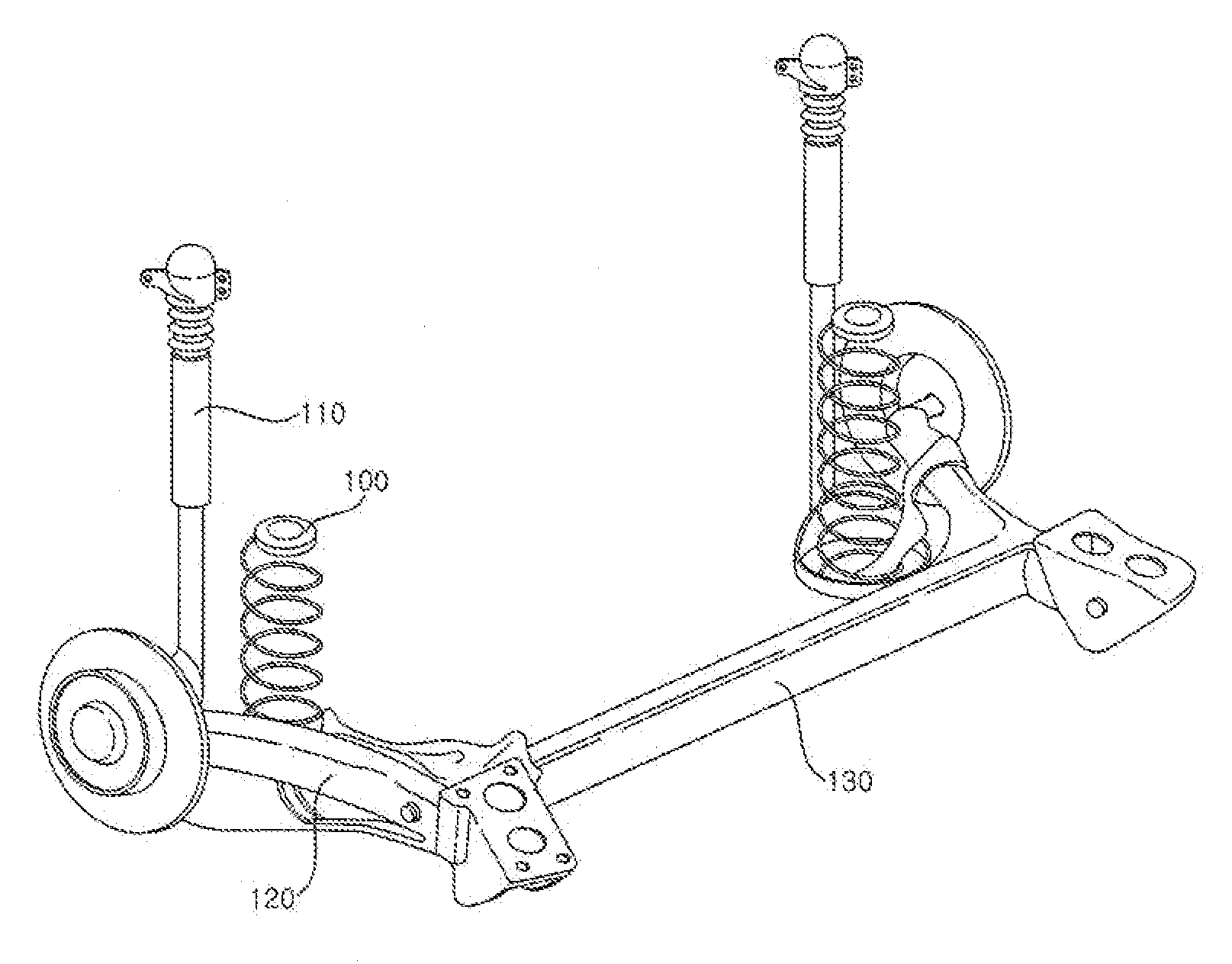

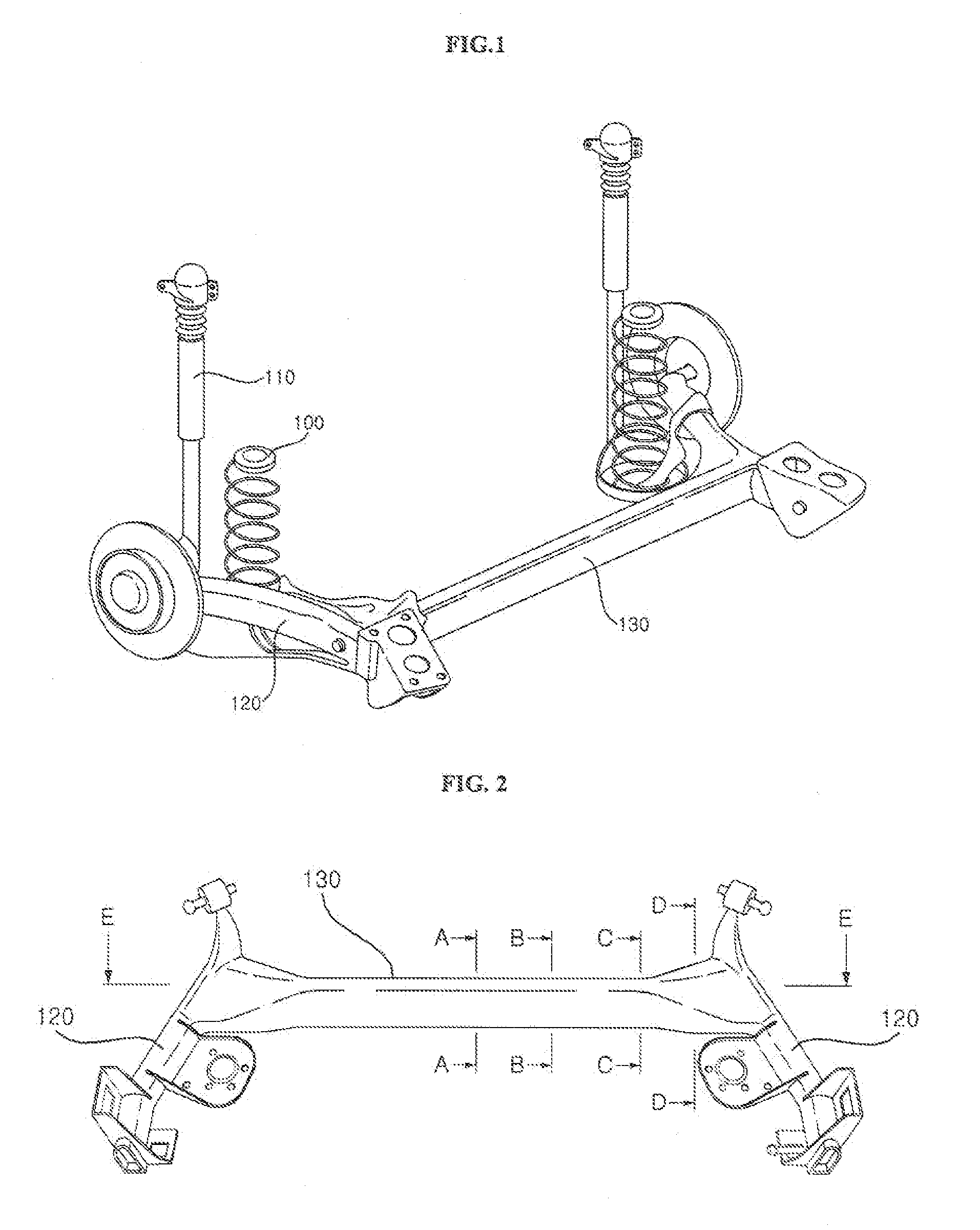

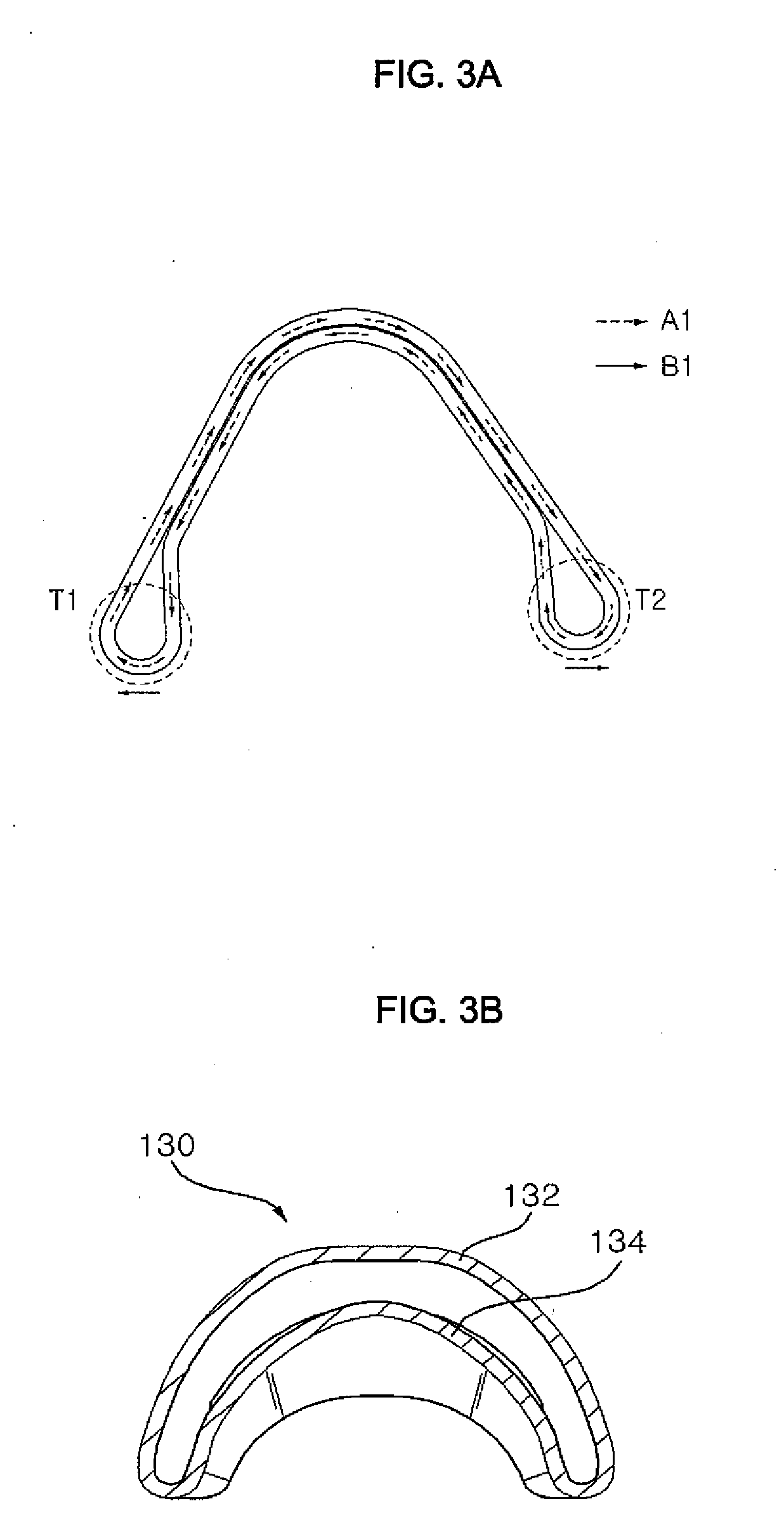

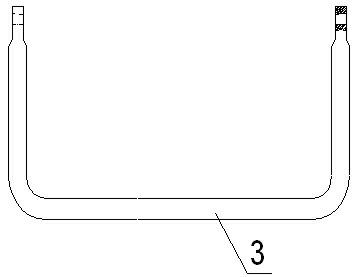

Torsion beam of suspension

ActiveUS20090020974A1Improve roll stiffnessIncreased durabilityInterconnection systemsResilient suspensionsEngineeringFront and back ends

There is provided a torsion beam of a vehicle suspension in which a upper portion and the lower portion of the torsion beam are bent in the front-to-rear direction alone of the vehicle along the longitudinal axis of the torsion beam, and a pair of tails is rounded at both front and rear ends of the torsion beam of the vehicle and formed different from each other in size, a rear tail of the pair of tails which is formed at the rear portion of the vehicle is larger than a front tail formed in the front portion of the torsion beam, the upper and lower portions of the torsion beam are gradually apart from each other with at least two predetermined slopes as they goes from the middle portion to both distal end of the torsion beam. Therefore, roll stiffness is increased and durability is improved.

Owner:HYUNDAI MOTOR CO LTD +1

Suspension System Having A Leaf Spring

ActiveUS20140035248A1Light weightImprove roll stiffnessInterconnection systemsResilient suspensionsEngineeringLeaf spring

Suspension systems, leaf springs and methods of providing a leaf spring in a suspension system are disclosed. The suspension systems, leaf springs and methods of providing a leaf spring in a suspension system allow use of a lighter weight leaf spring while providing customized roll stiffness and vertical spring rate that are complemented by a bumper that engages the leaf spring assembly when compressed to at least a preselected position.

Owner:HENDRICKSON USA L L C

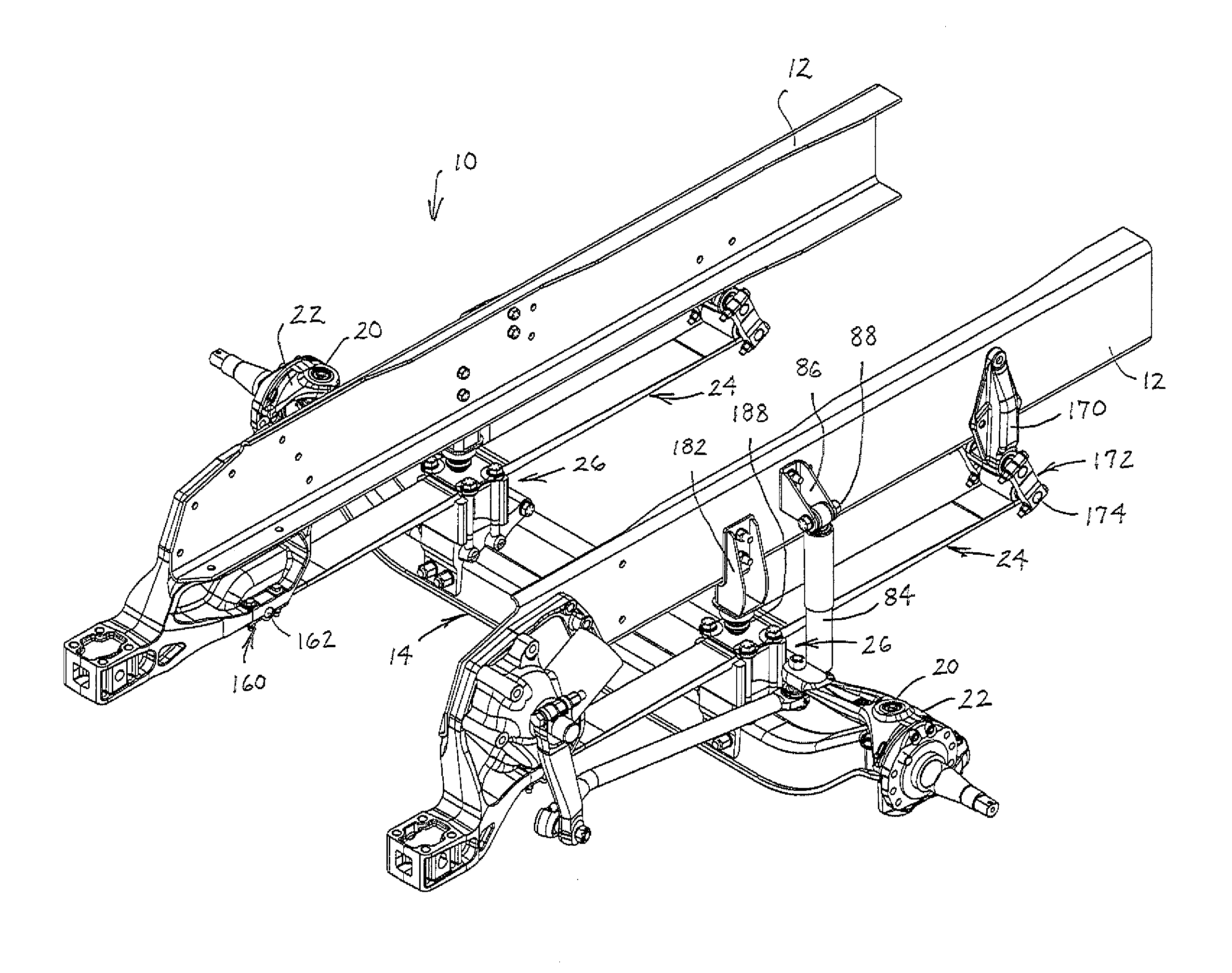

Front suspension

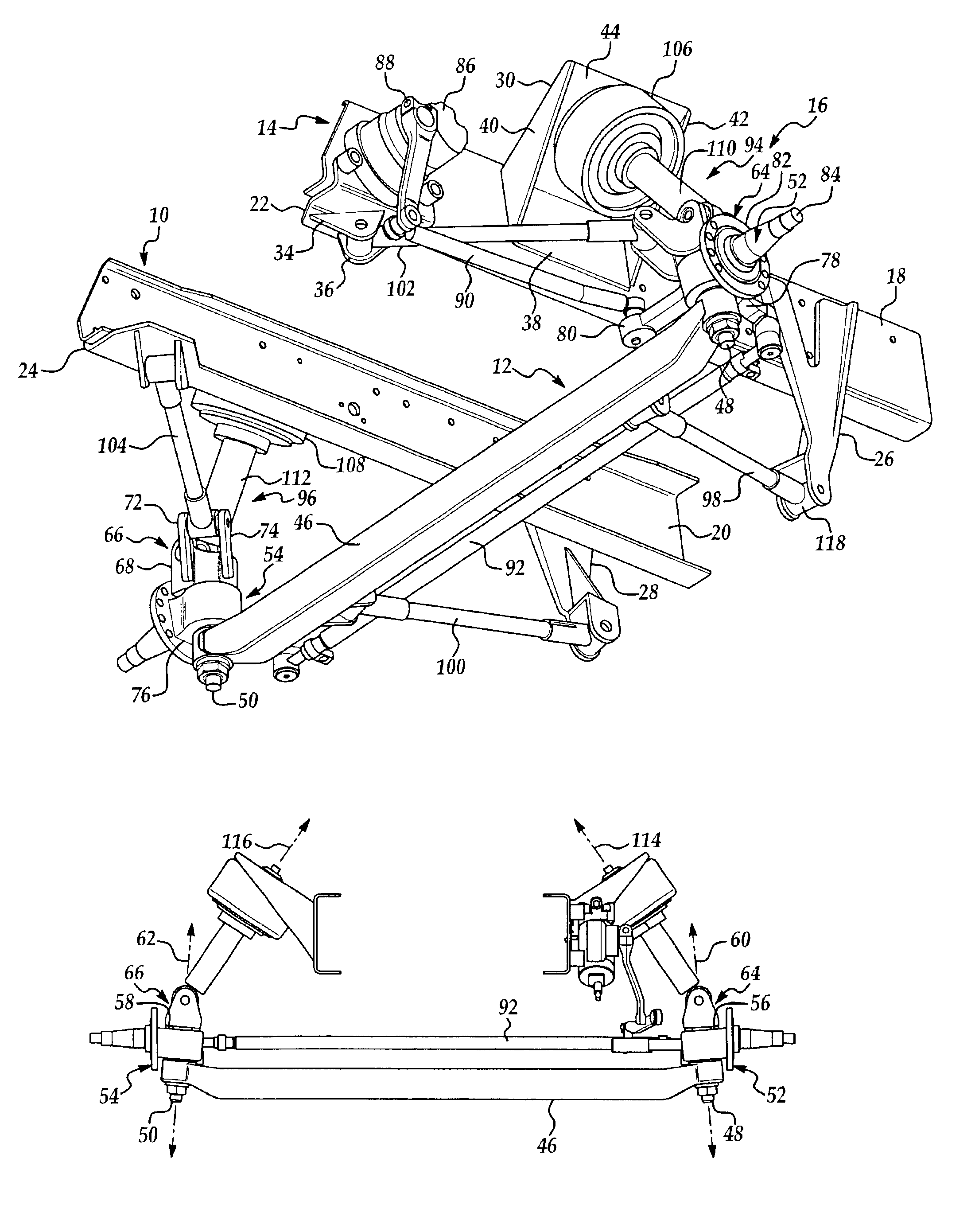

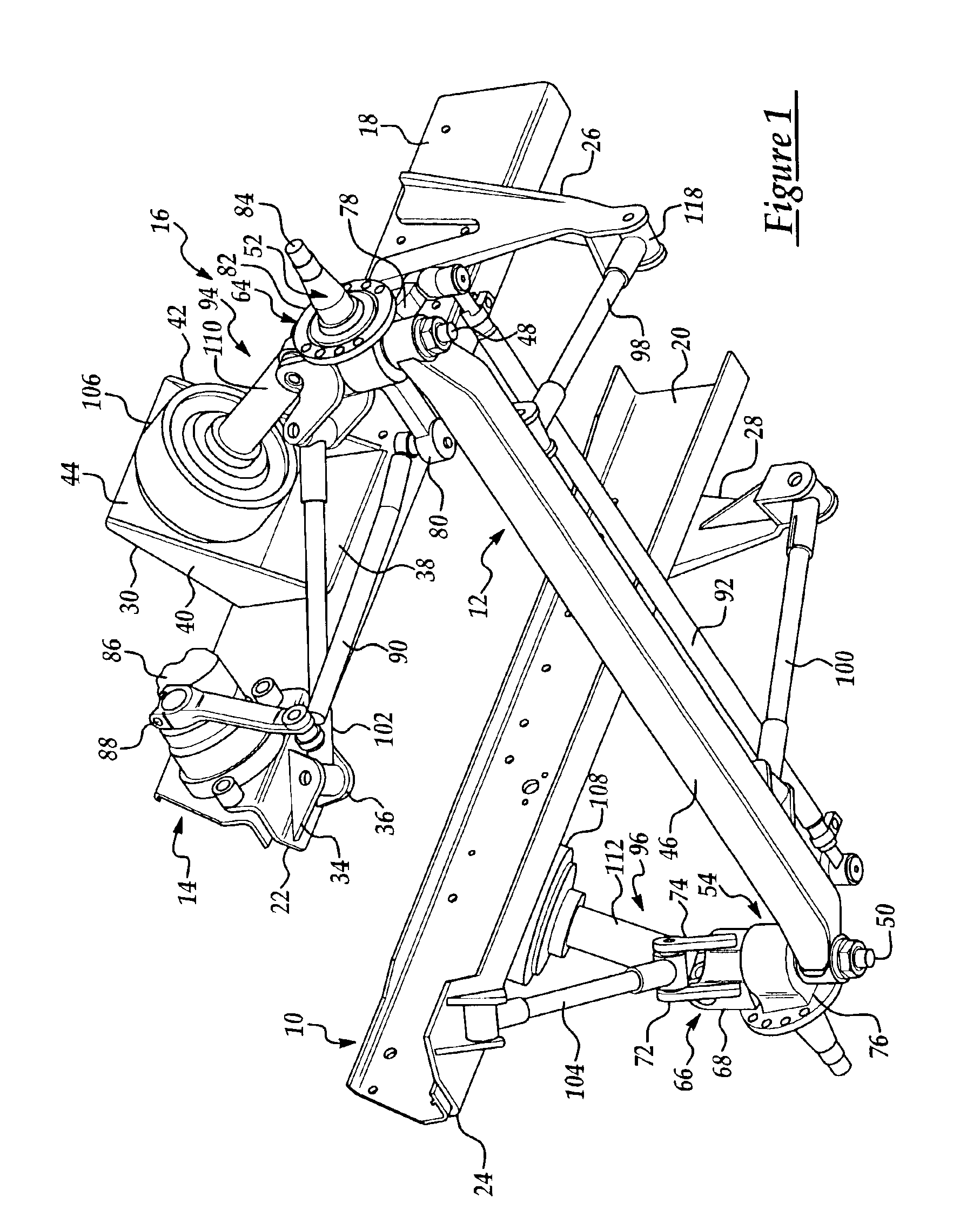

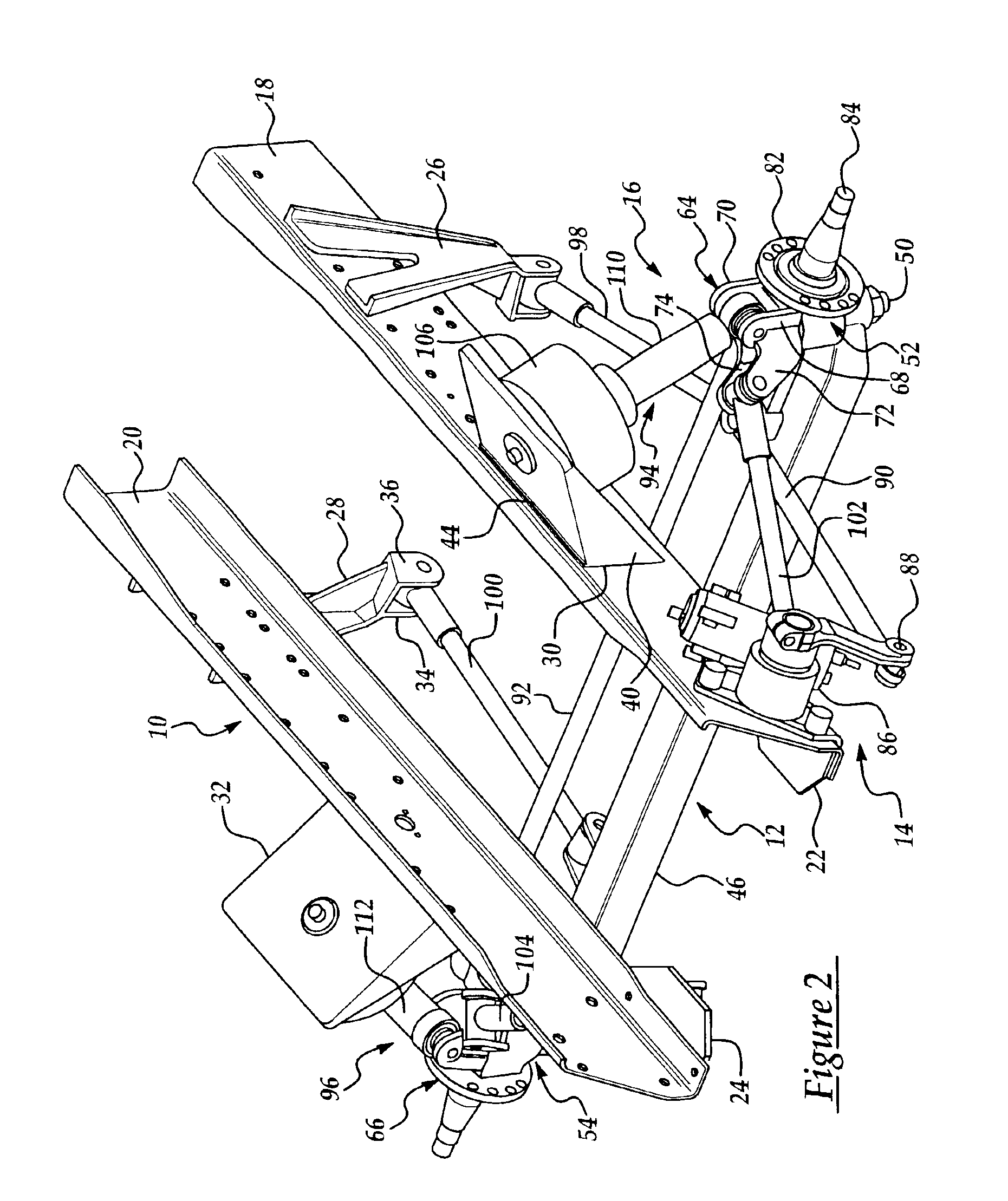

InactiveUS6866277B2Improve roll stiffnessReduces the bending momentUnderstructuresResilient suspensionsVehicle frameShock absorber

A suspension for coupling a steer axle assembly to a vehicle frame is provided that moves one or more of the spring reaction points outboard to increase roll stiffness and enable the use of a lighter axle. In one embodiment of the invention, the suspension includes a spring coupled to the vehicle frame and a shock absorber having a first end coupled to the spring and a second end coupled to a component of the steer axle assembly, such as the kingpin, at a location outboard of a longitudinal frame rail of the vehicle frame.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

Suspension system having a leaf spring

ActiveUS9050873B2Improve roll stiffnessReduce chanceInterconnection systemsResilient suspensionsEngineeringLeaf spring

Suspension systems, leaf springs and methods of providing a leaf spring in a suspension system are disclosed. The suspension systems, leaf springs and methods of providing a leaf spring in a suspension system allow use of a lighter weight leaf spring while providing customized roll stiffness and vertical spring rate that are complemented by a bumper that engages the leaf spring assembly when compressed to at least a preselected position.

Owner:HENDRICKSON USA L L C

Vehicle control

ActiveUSRE46828E1Improve controlEasy to controlDashboard fitting arrangementsExternal condition input parametersManagement systemEngineering

A vehicle control system has a plurality of subsystem controllers including an engine management system 28, a transmission controller 30, a steering controller 48, a brakes controller 62 and a suspension controller 82. These subsystem controllers are each operable in a plurality of subsystem modes, and are all connected to a vehicle mode controller 98 which controls the modes of operation of each of the subsystem controllers so as to provide a number of driving modes for the vehicle. Each of the modes corresponds to a particular driving condition or set of driving conditions, and in each mode each of the functions is set to the function in mode most appropriate to those conditions.

Owner:JAGUAR LAND ROVER LTD

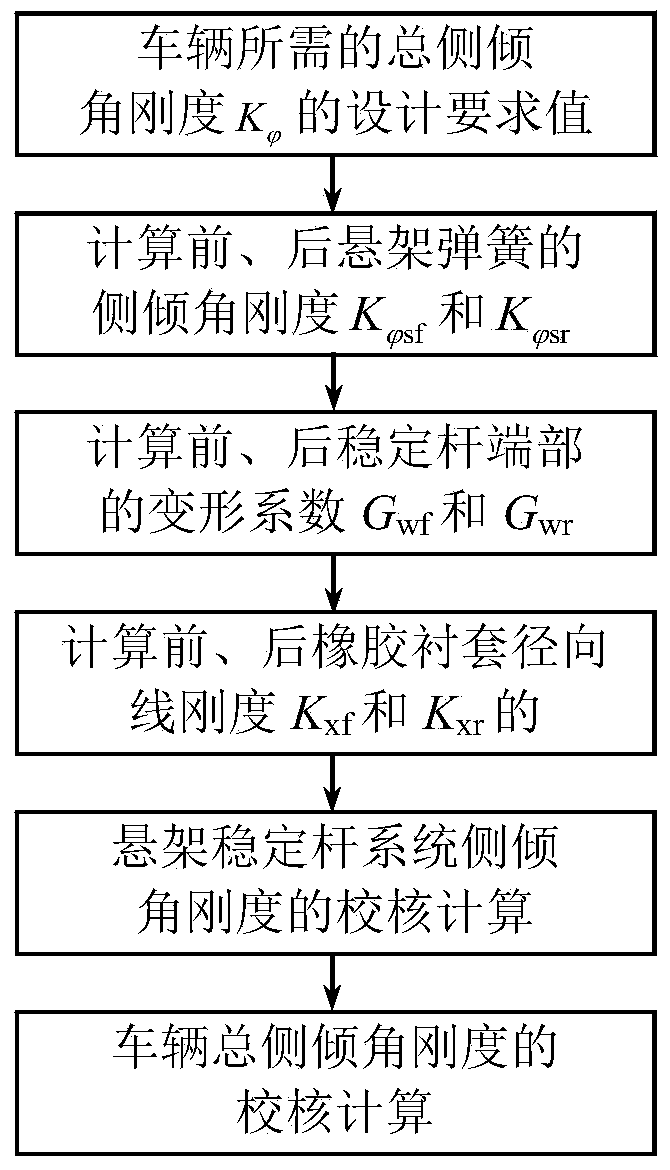

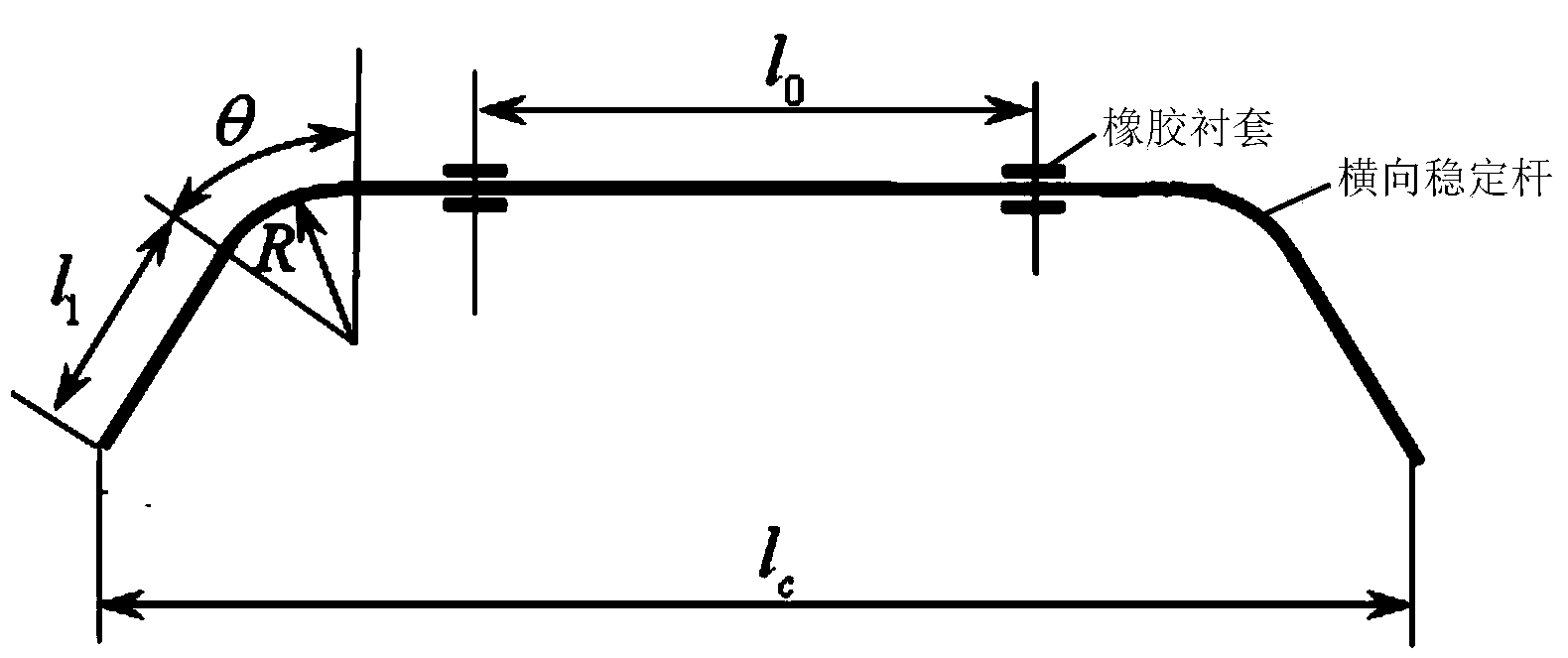

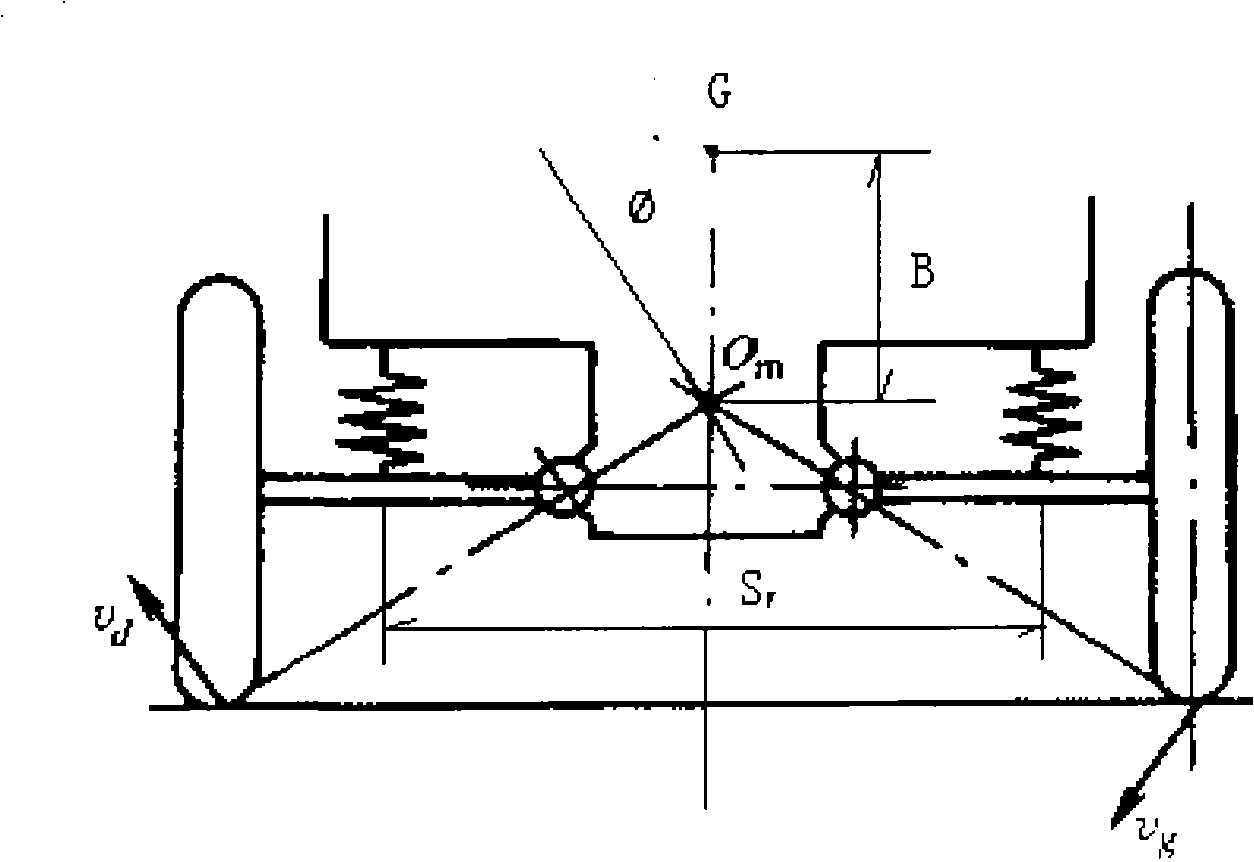

Vehicle suspension roll angle rigidity checking method

InactiveCN104182597AImprove roll stiffnessSatisfy the design requirement valueSpecial data processing applicationsRolling angleSoftware

The invention relates to a vehicle suspension roll angle rigidity checking method and belongs to the technical field of vehicle suspensions. Previously, a roll angle rigidity analysis checking and calculating method is not given. With the method, the roll angle rigidity of a front suspension and a rear suspension and the total roll angle rigidity of a vehicle are checked and calculated according to vehicle and suspension parameters, structure and material characteristic parameters of a designed stabilizer bar and a designed rubber bushing, the deformation coefficient GW of the end of the stabilizer bar, and the analysis calculation formula of the radial rigidity Kx of the rubber bushing. An accurate and reliable vehicle roll angle rigidity checking and calculation value can be obtained with the method, the design level and the design quality of a vehicle suspension and stabilizer bar system and driving smoothness and driving safety of the vehicle can be improved; meanwhile, design and experiment cost can be reduced with the method, product development speed can be increased, and reliable technical support is provided for development of stabilizer bar CAD software.

Owner:SHANDONG UNIV OF TECH

Vehicle double withbone arm type independent suspension system

InactiveCN102431405AImprove roll resistanceImprove roll stiffnessInterconnection systemsResilient suspensionsGround contactCamber angle

The invention discloses a vehicle double withbone arm type independent suspension system which comprises a front suspension assembly and a rear suspension assembly, wherein the front suspension assembly is provided with a front horizontal swinging arm assembly, the front horizontal swinging arm assembly comprises a front upper horizontal swinging arm and a front lower horizontal swinging arm, the rear suspension assembly is provided with a rear horizontal swinging arm assembly, and the rear horizontal swinging arm assembly comprises a rear upper horizontal swinging arm and a rear lower horizontal swinging arm; in the invention, the projection dimensions of the front upper horizontal swing arm and the rear upper horizontal swing arm in the transversal horizontal level respectively smaller than the projection dimensions of the front lower horizontal swing arm and the rear lower horizontal swing arm in the transversal level, the running stability of the automobile is improved, the inclinations and shakes of the vehicle body are reduced, and the lateral stiffness is high; the camber angle of a wheel can be changed automatically during the up-and-down motion, the tread changes can be reduced, the side slippage of the wheel can be avoided, and the abrasion of a tire is reduced; the vehicle double withbone arm type independent suspension system is self adaptive to road surfaces, the ground contact area of a tire is large, the grounding performance is good, and the vehicle is guaranteed to have an excellent running stability; and the left and the right wheels can jump independently and are prevented from mutual influences, the inclinations and shakes of the vehicle body are reduced, and the riding comfort is enhanced.

Owner:LONCIN MOTOR

Anti-roll system for vehicles

ActiveCN103158468ACurb rollImproved ride/steering stabilityLeaf springsInterconnection systemsVehicle frameEngineering

Owner:HYUNDAI MOTOR CO LTD

Air spring and plate spring composite suspension system

ActiveCN105480041AExcellent variable stiffness characteristicsImprove riding performanceInterconnection systemsResilient suspensionsVehicle frameAir spring

The invention relates to an air spring and plate spring composite non-independent suspension system. The suspension system is formed by assembling of a plate spring, a plate spring front end lifting lug, a plate spring rear end spring lug, a U-shaped bolt, a plate spring pressing plate, a buffer block, a vibration absorber, a horizontal stabilized bar, a stabilized bar mounting bracket, a vehicle frame mounting bracket, a stabilized bar pull rod, a vehicle frame, a wheel axle, an air spring, an air spring upper mounting bracket, an air spring lower mounting bracket and an air spring height regulating mechanism. According to the air spring and plate spring composite suspension system disclosed by the invention, the respective advantages of the air spring and the plate spring are utilized, so that the respective defects can be overcome, and the smoothness and the roll stiffness of the suspension system are improved.

Owner:浙江孔辉汽车科技有限公司

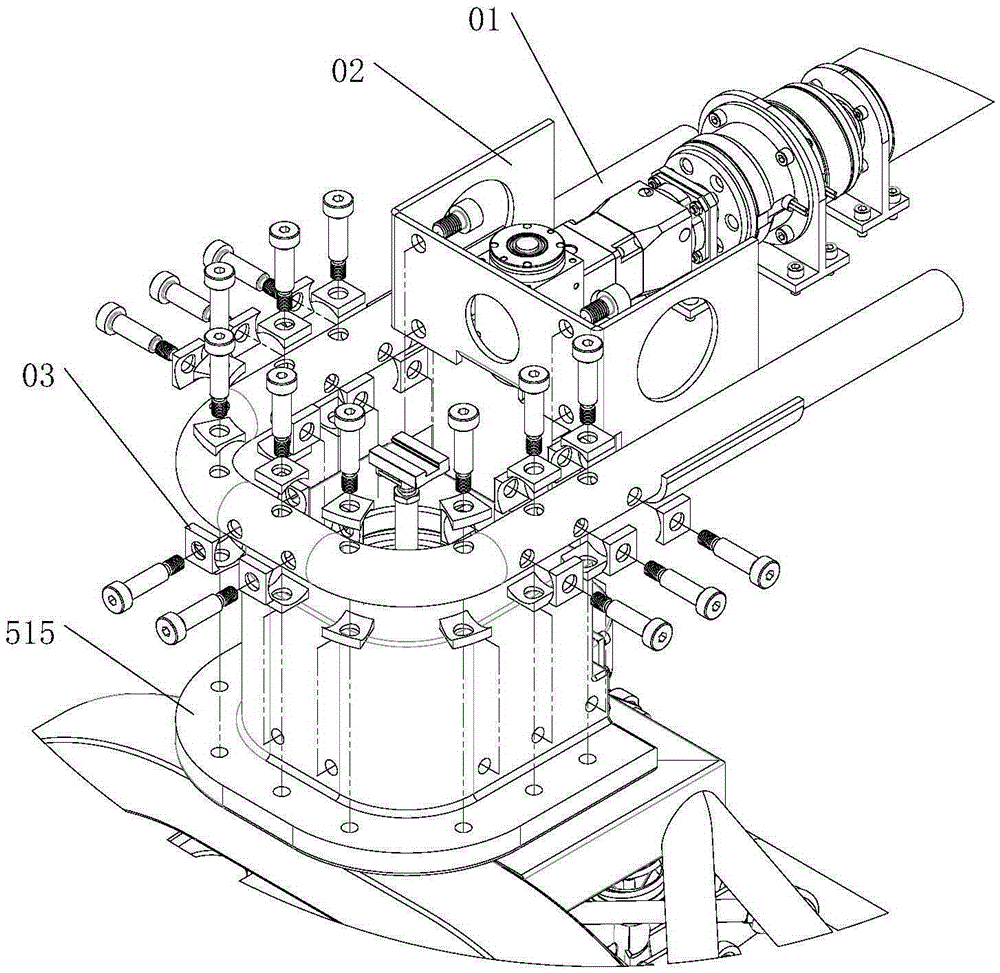

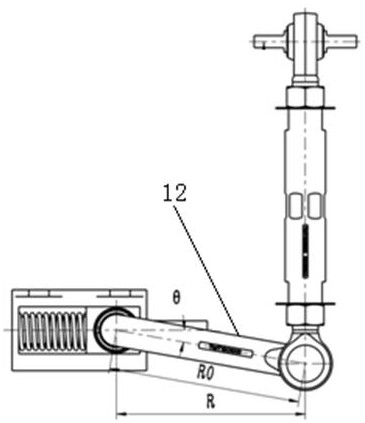

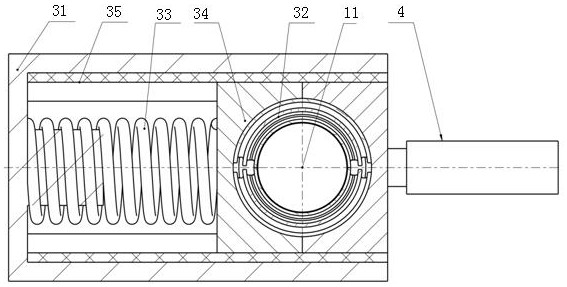

Active control type variable-rigidity anti-side-rolling torsion bar device and variable-rigidity method thereof

ActiveCN112046527AAchieving Kinetic PerformanceReduce overturning coefficientBogie-underframe connectionsLow speedBogie

The invention discloses an active control type variable-rigidity anti-side-rolling torsion bar device and a variable-rigidity method thereof. The device comprises a torsion bar, a supporting base assembly connected with a bogie and a connecting rod assembly hinged to a vehicle body, wherein the torsion bar comprises a torsion bar shaft and a rotating arm arranged at the end of the torsion bar shaft, the supporting base assembly is arranged on the torsion bar shaft in a sleeving mode, the connecting rod assembly is hinged to the free end of the rotating arm, the anti-side-rolling torsion bar device is characterized in that the effective arm length of the device is R, and the supporting base assembly is connected with a hydraulic system and can drive the torsion bar and the connecting rod assembly to move synchronously along with driving of the hydraulic system, so that the effective arm length R of the anti-side-rolling torsion bar device is changed. According to the device, active control over the side rolling rigidity is achieved, the requirement for the excellent riding comfort of passengers in the high-speed running process of a vehicle can be met, the overturning coefficient and the derailment coefficient of the vehicle passing through a parking lot line and a turnout at a low speed are reduced, and then the safety and reliability of the vehicle are improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Lateral stabilization system applied to rear air suspension

InactiveCN102555725AImprove roll stiffnessReduce impactInterconnection systemsVehicle frameEngineering

The invention relates to the field of the bus, in particular to a lateral stabilization system applied to a rear air suspension. The lateral stabilization system applied to the rear air suspension comprises stabilizer bar supports, a stabilizer bar assembly, a connecting block, a connecting plate, a rubber bearing and suspender assemblies and is characterized in that stabilizer bar supports are respectively fixed on bracket beams at two sides of a rear axle by bolts; two sets of suspender assemblies are respectively hinged with two ends of the stabilizer bar assembly; the middle of the stabilizer bar assembly is connected with the connecting block by the rubber bearing and the connecting plate; the connecting block is fixedly connected to the frame; and two ends of the suspender assemblies are both in ball pin structures. In the invention, the lateral stabilization system applied to the rear air suspension, which has a simple structure, effectively increases the sidesway rigidity of the suspension, improves the stability of a vehicle and ensures the vehicle to run safely, is provided.

Owner:SHAANXI EUROSTAR AUTOMOBILE

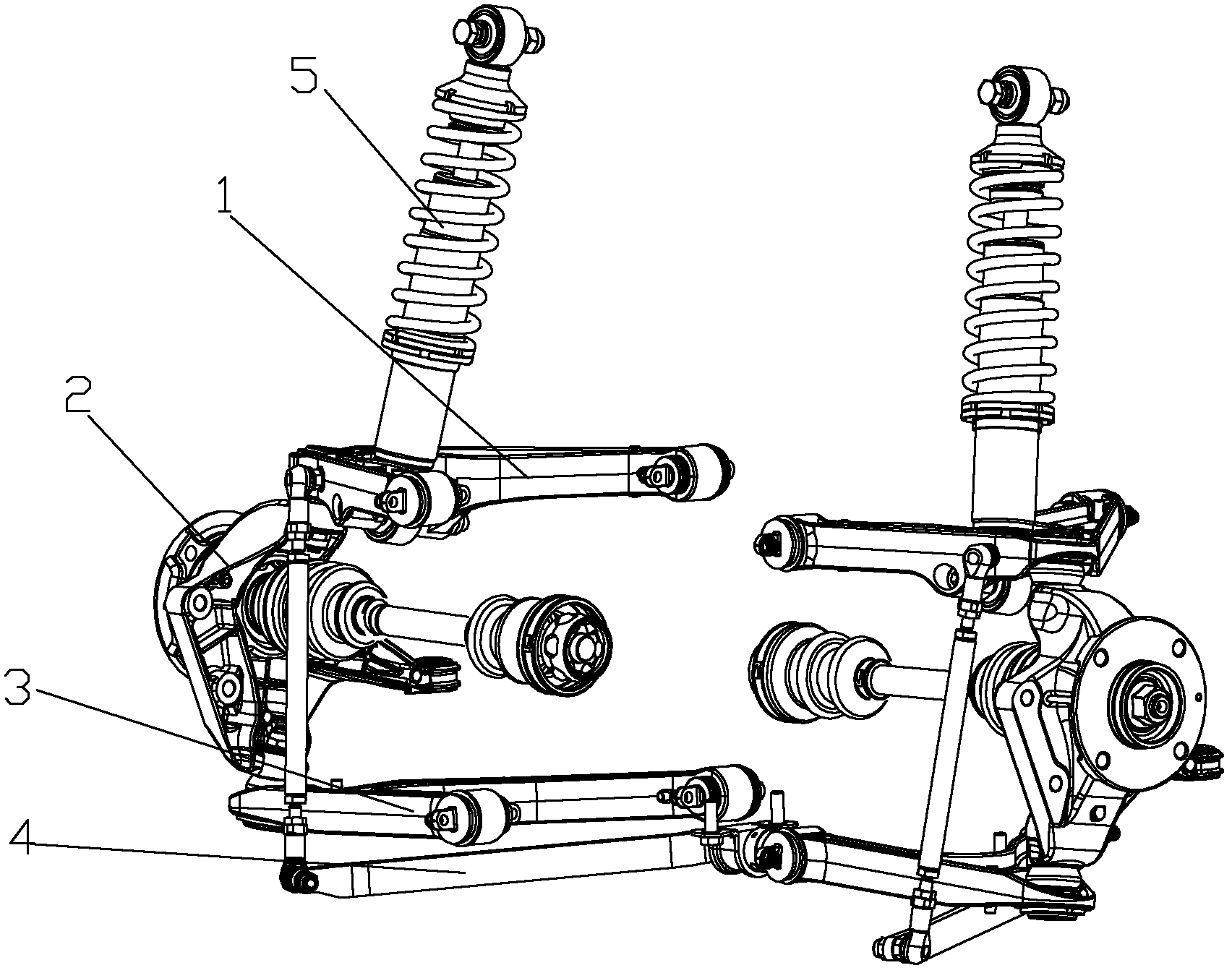

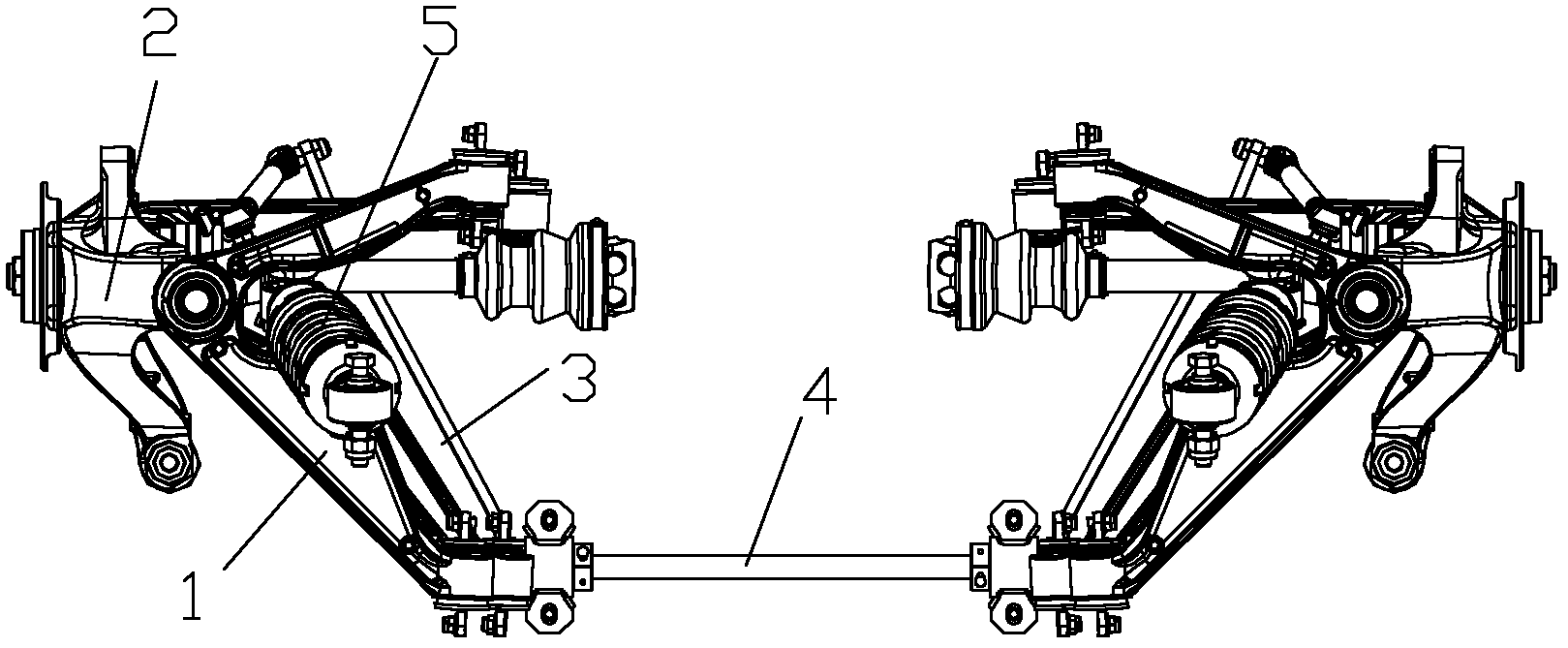

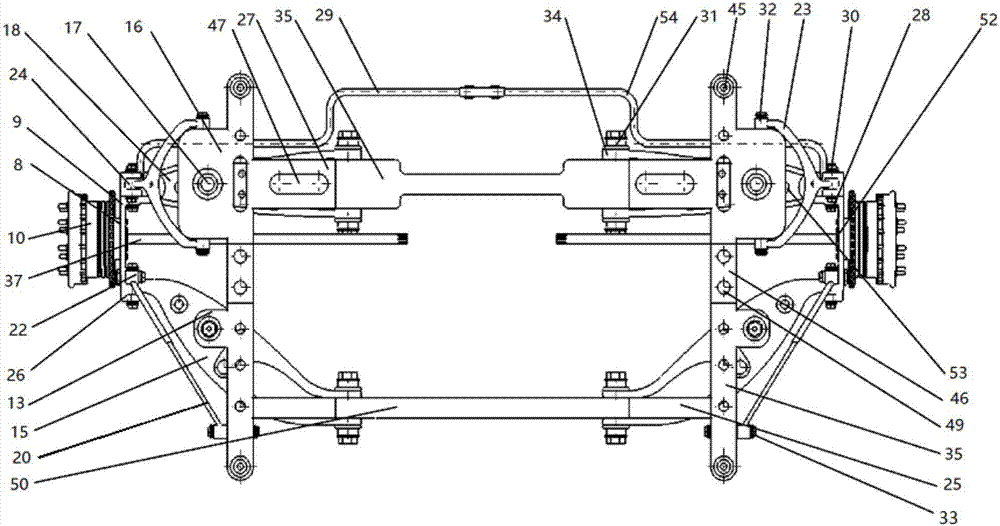

Multi-connecting-rod independent suspension for drive axle of commercial vehicle

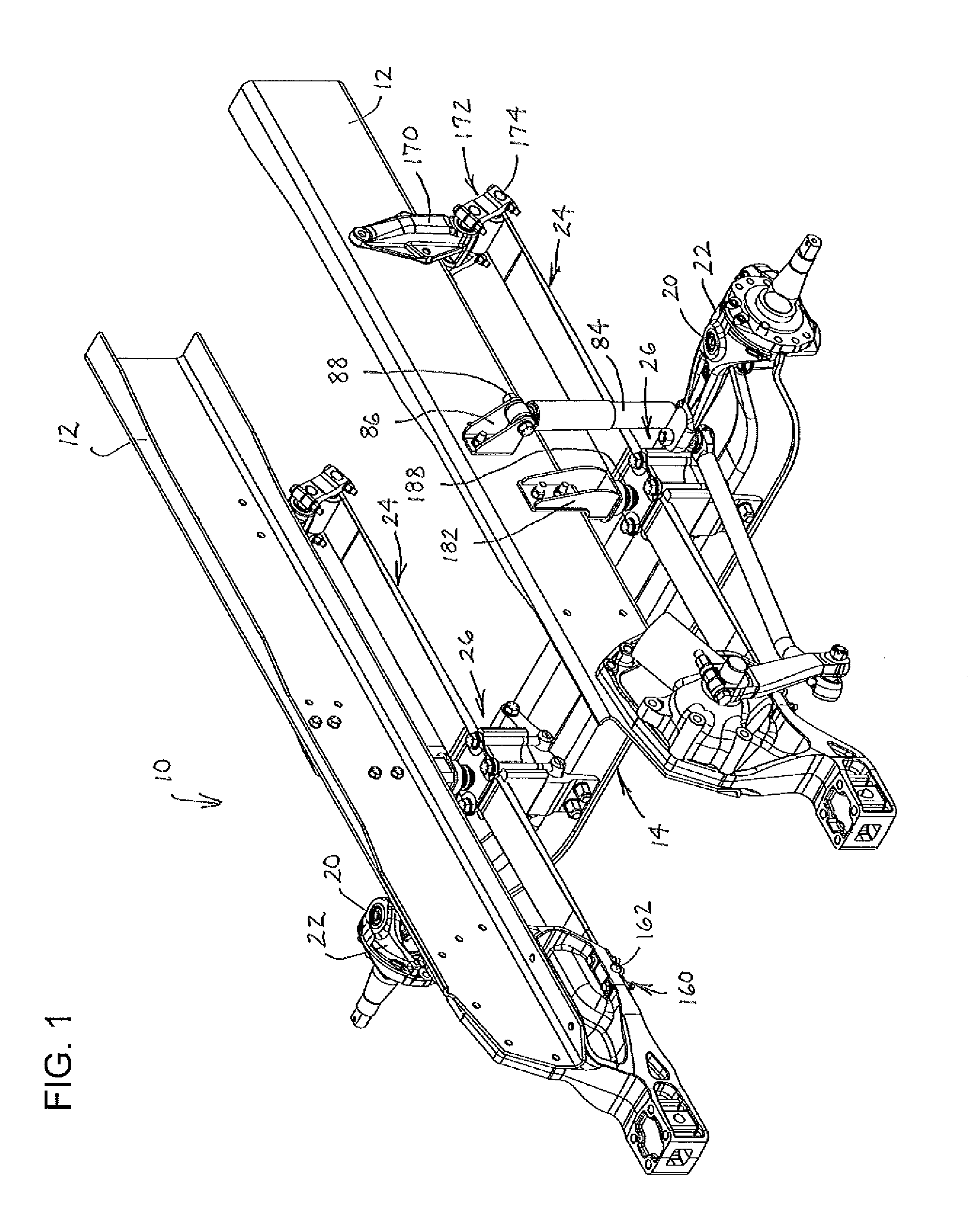

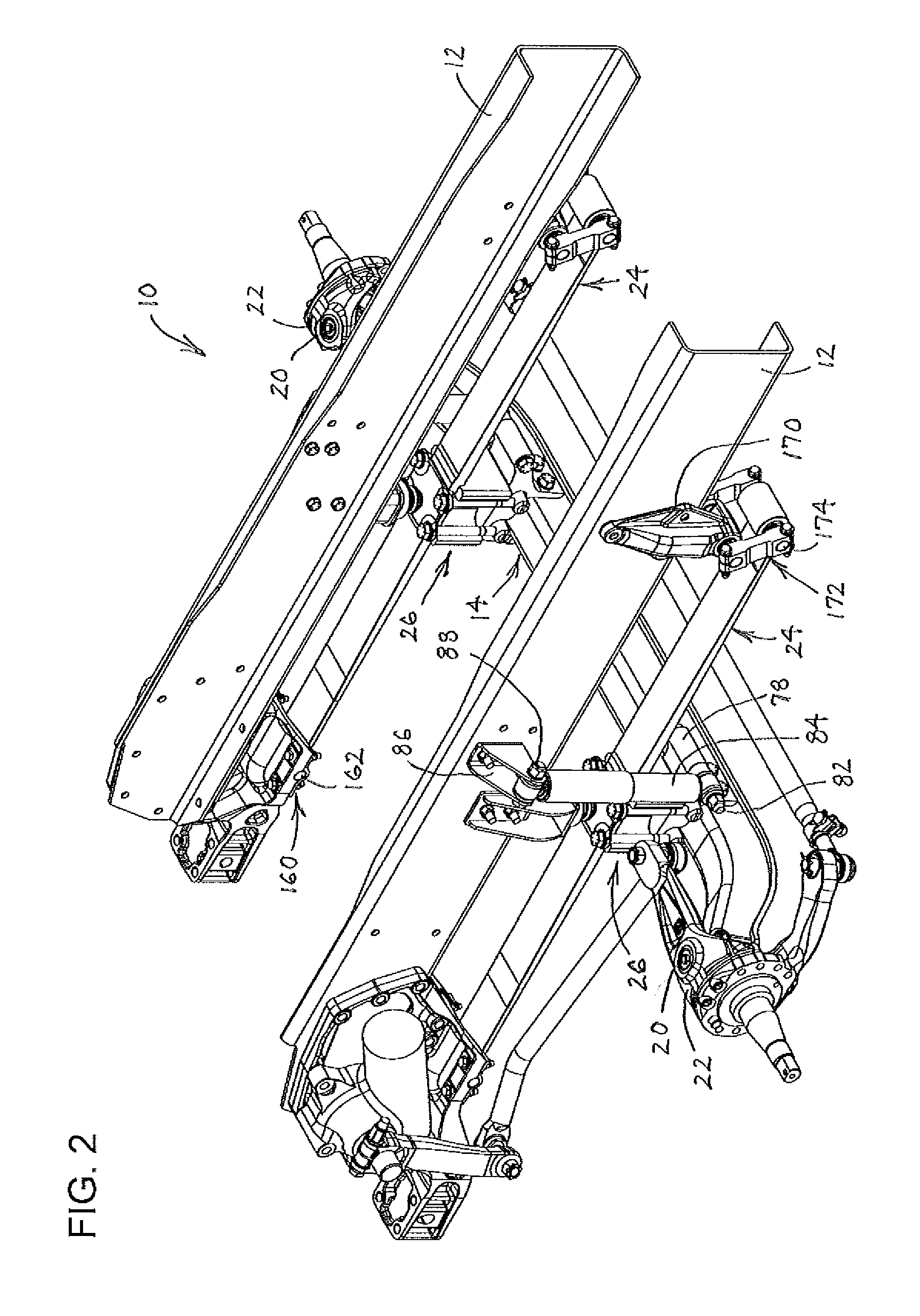

ActiveCN107234934ANo motion interferenceNo concentrated stressUnderstructuresInterconnection systemsVehicle frameCommercial vehicle

Disclosed is a multi-connecting-rod independent suspension for a drive axle of a commercial vehicle. The multi-connecting-rod independent suspension for the drive axle of the commercial vehicle comprises an auxiliary vehicle frame assembly used for being connected with vehicle frame longitudinal beams, an upper longitudinal pulling rod assembly, an upper horizontal pulling rod assembly, a lower horizontal pulling rod assembly, a stable pulling rod assembly, an absorber spring assembly and a bearing base assembly. The auxiliary vehicle frame assembly mainly comprises an auxiliary vehicle frame with a structure of double longitudinal beams and double horizontal beams. The auxiliary vehicle frame comprises an auxiliary vehicle frame front horizontal beam, an auxiliary vehicle frame back horizontal beam and an auxiliary vehicle frame longitudinal beam. The upper longitudinal pulling rod assembly mainly comprises upper longitudinal pulling rods. The upper horizontal pulling rod assembly mainly comprises upper horizontal pulling rods. The lower horizontal pulling rod assembly mainly comprises lower front horizontal pulling rods and lower back horizontal pulling rods. The stable pulling rod assembly mainly comprises stable pulling rods and stable pulling rod connecting bosses. The absorber spring assembly mainly comprises absorbers and springs. The multi-connecting-rod independent suspension for the drive axle of the commercial vehicle has the enough bearing capacity, the comfort performance and stability of the vehicles are improved, the weight of the drive axle is greatly reduced, the fuel oil economy is improved, the space layout can met the electrification demands of the commercial vehicle, and geometric deformation of the suspension does not happen under the extreme load.

Owner:WUHAN UNIV OF TECH

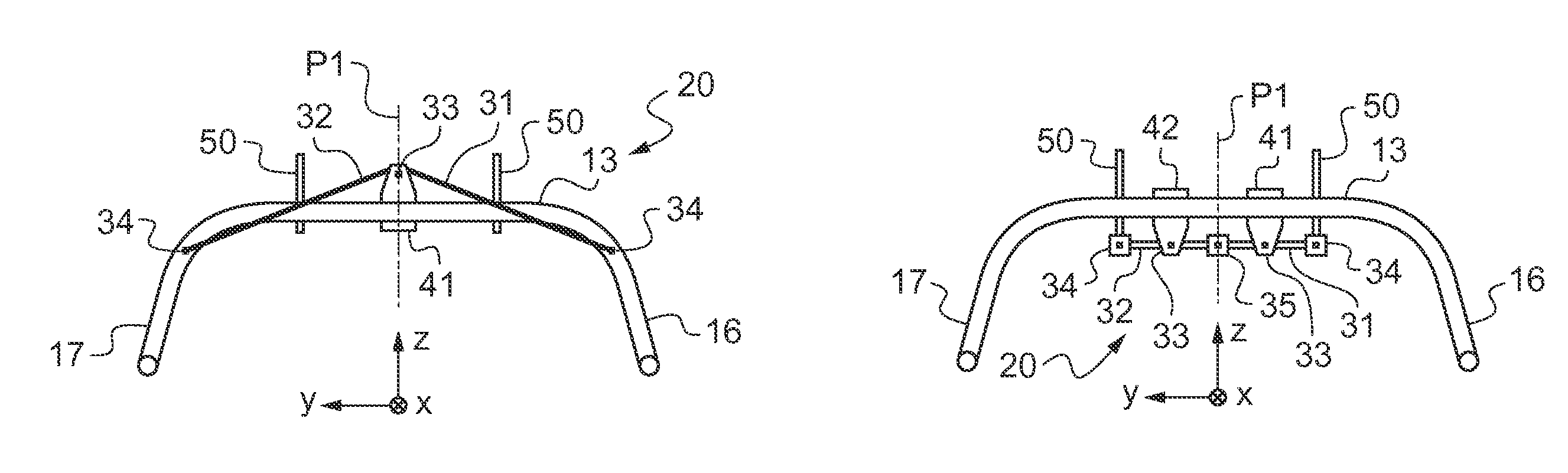

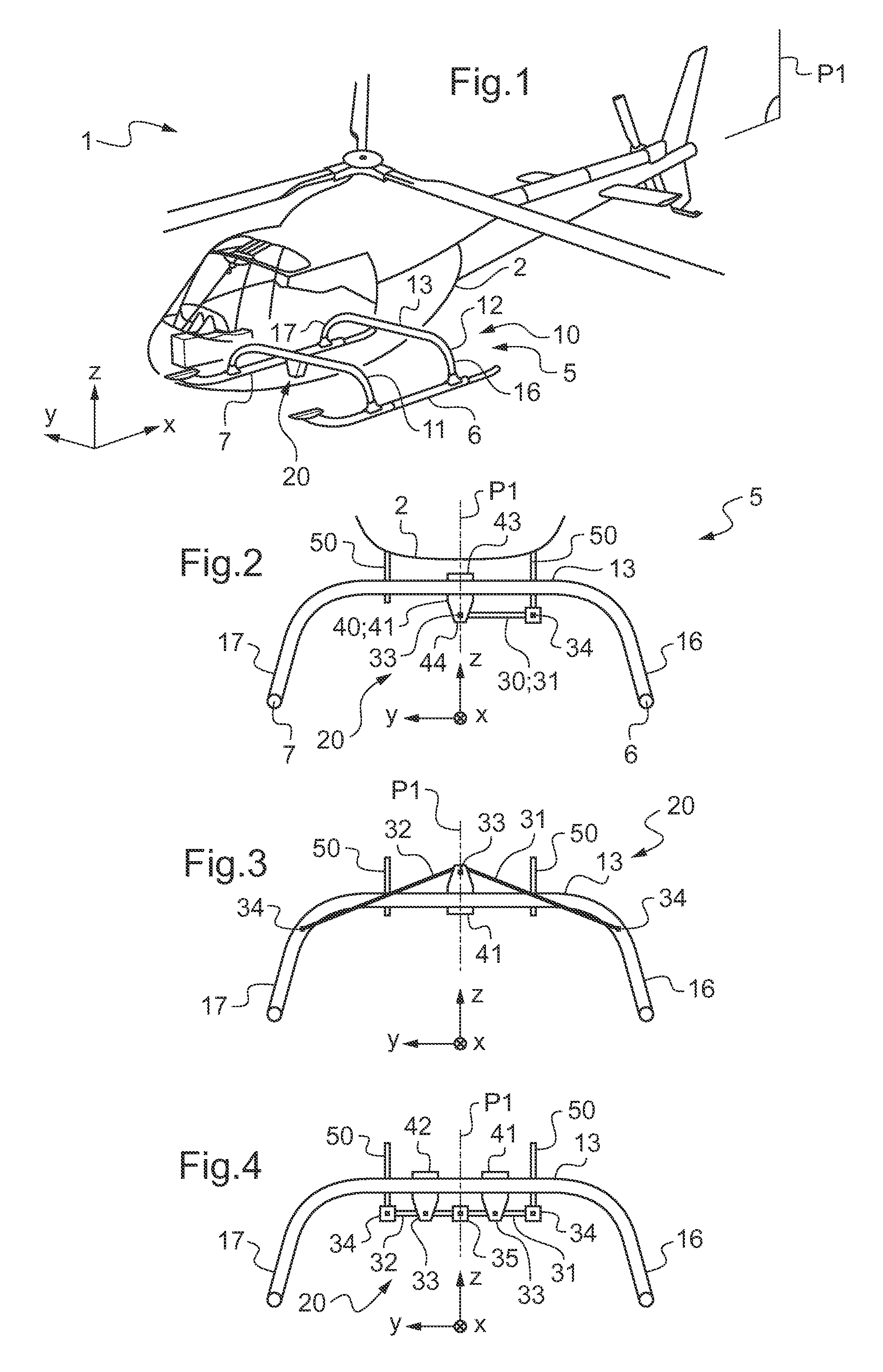

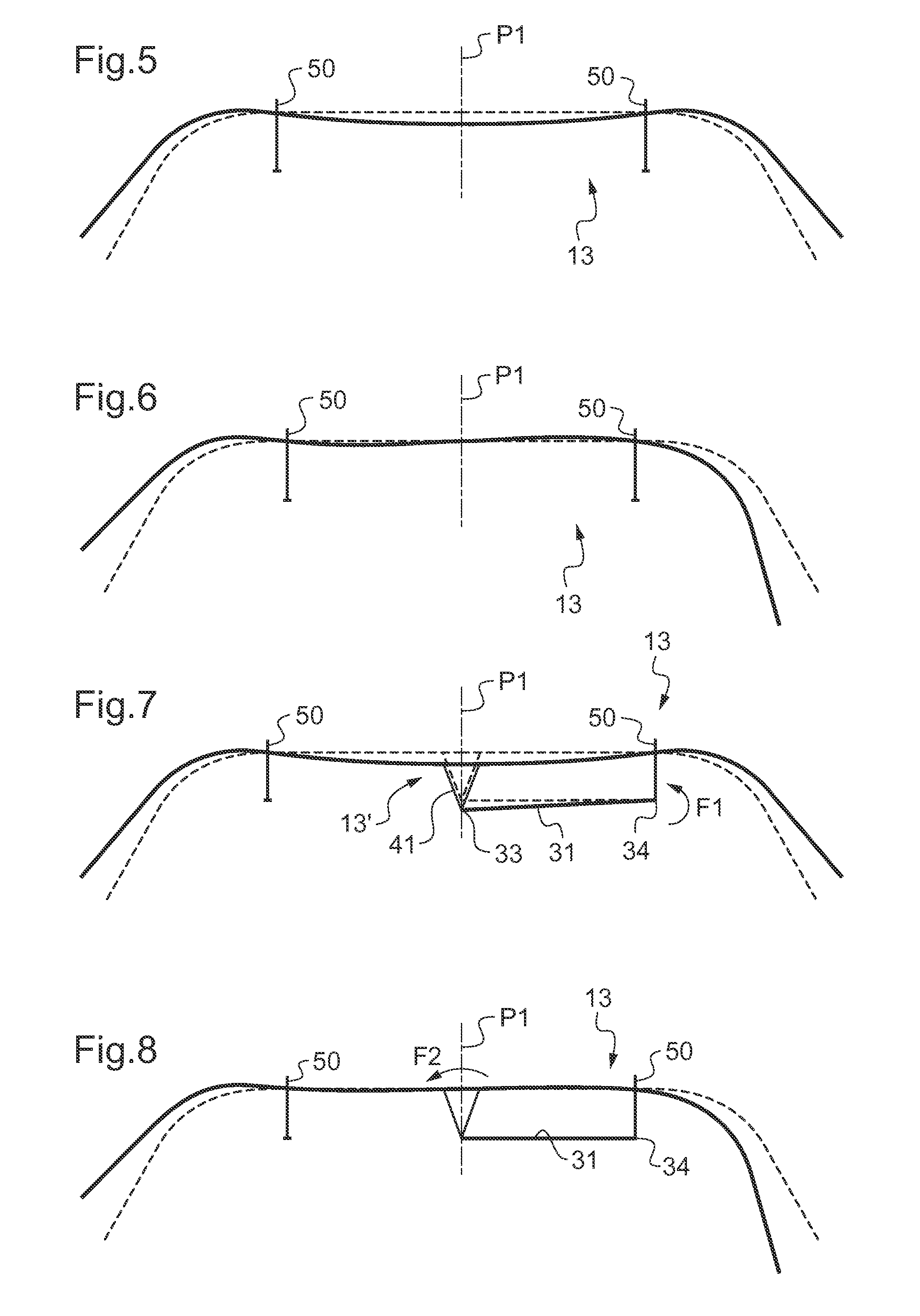

Landing gear provided with a stiffener for increasing its stiffness in roll, and an aircraft

Aircraft landing gear (5) having a first skid (6) and a second skid (7), together with two cross-members, each having a first branch (16) secured to the first skid (6) and a second branch (17) secured to the second skid (7), and a central portion (13) secured to the downward first branch (16) and to the second branch (17). The landing gear (5) has at least one stiffener (20) with at least one connecting rod (30) and at least one limiter means (40) for limiting roll deformation of the central portion (13) of a cross-member, each limiter means (40) being secured to said central portion (13) of the cross-member, at least one main hinge (33) hinging each connecting rod to said limiter means and a secondary hinge (34) connecting each connecting rod to an outside point that is outside the central portion (13) in order to limit the deformation of the central portion (13) as a result of a roll movement of an aircraft (1).

Owner:EUROCOPTER

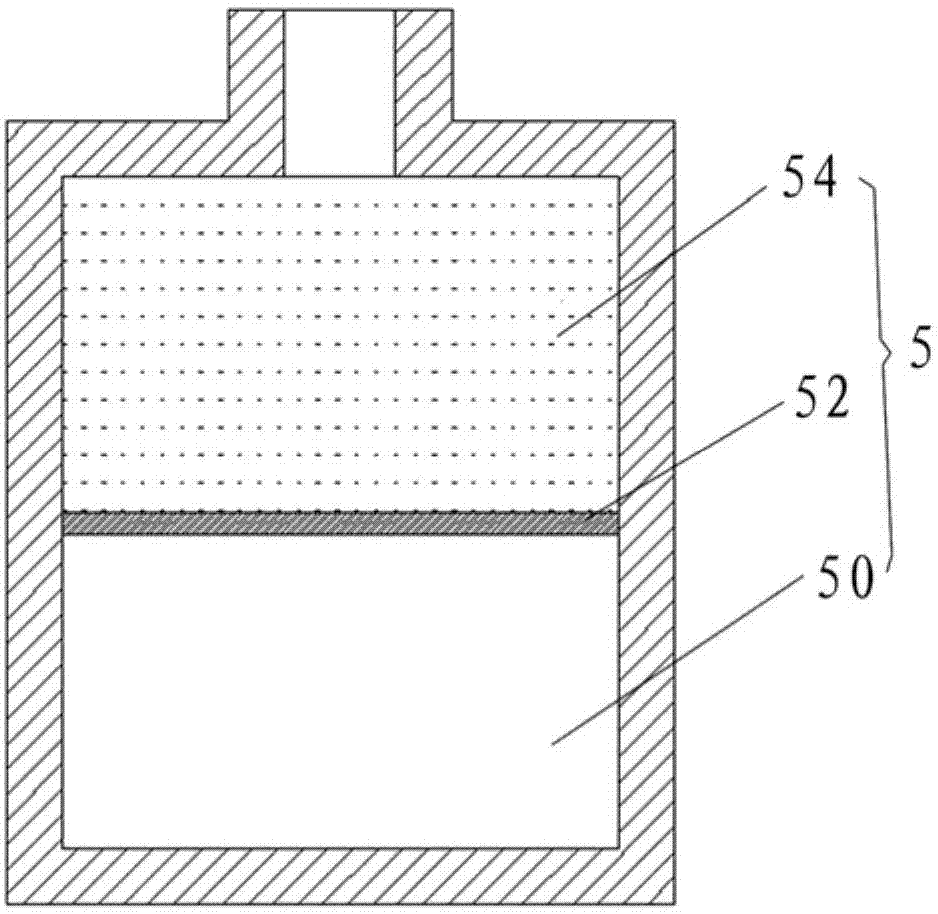

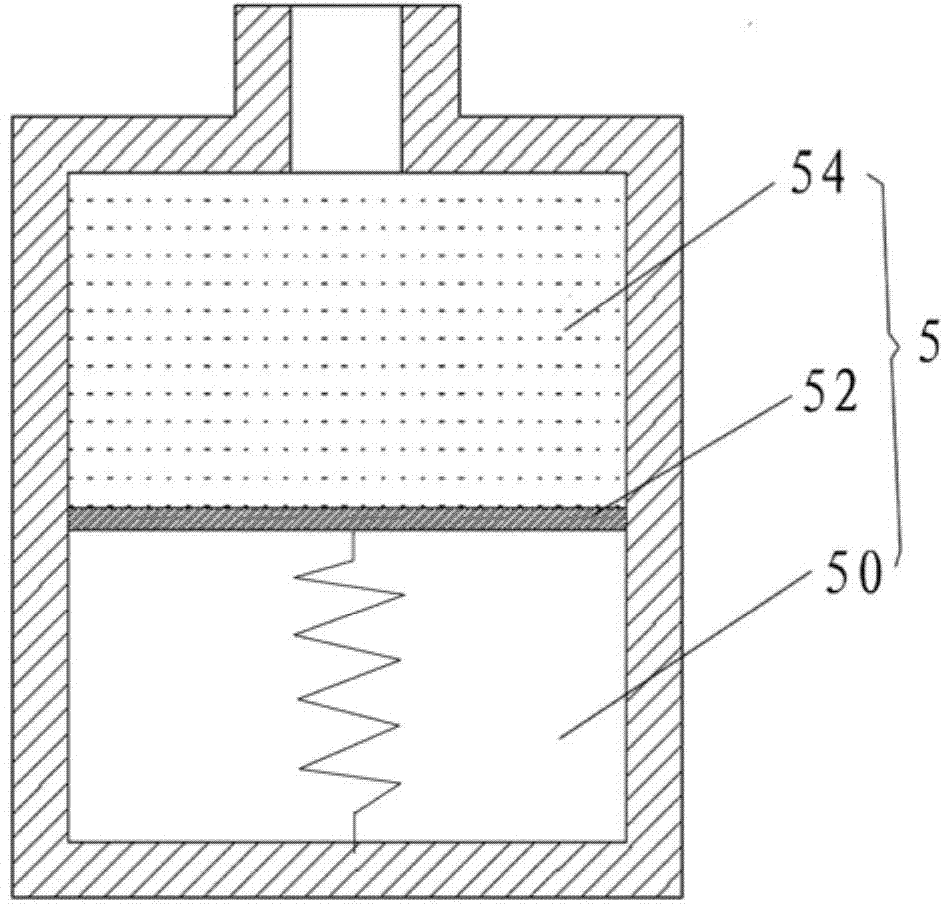

Suspension device and accumulator

InactiveUS20180162188A1Improve roll stiffnessIncrease internal pressureSpringsInterconnection systemsEngineeringGas chamber

There is provided a suspension device capable of improving roll stiffness without deteriorating the durability of a seal and the riding comfort of a vehicle, the suspension device including: a pair of liquid pressure dampers; a first passage which communicates the extension side chamber with the compression side chamber; a second passage which communicates the compression side chamber with the extension side chamber; and two accumulators, in which each of the accumulators includes a casing, a first free piston which defines a gas chamber inside the casing, and a second free piston which defines a first gas chamber and a second gas chamber inside the gas chamber, and a pressure receiving area near the first gas chamber in the second free piston is set to be smaller than a pressure receiving area near the second gas chamber.

Owner:KYB CORP

Automobile suspension system and motor vehicle

ActiveCN103879260AImprove roll stiffnessImprove vehicle stabilityInterconnection systemsAutomotive engineeringHydraulic cylinder

The invention provides an automobile suspension system. The automobile suspension system comprises a left front hydraulic cylinder provided with a left front piston rod, a left front cylinder, a right front hydraulic cylinder, a left rear hydraulic cylinder, a right rear hydraulic cylinder, a first hydraulic circuit, a second hydraulic circuit, a third hydraulic circuit, a fourth hydraulic circuit, at least one first energy accumulator, at least one second energy accumulator, at least one third energy accumulator, and at least one fourth energy accumulator. The left front piston rod is connected with a left front wheel assembly and the left front cylinder is connected with an automobile body. The structures of the right front hydraulic cylinder, the left rear hydraulic cylinder and the right rear hydraulic cylinder are similar to the structure of the left front hydraulic cylinder. The first hydraulic circuit is provided with two ports which are communicated with a rod cavity of the left front cylinder and a rodless cavity of the right rear cylinder respectively. The structures of the second hydraulic circuit, the third hydraulic circuit and the fourth hydraulic circuit are similar to the structure of the first hydraulic circuit. The first energy accumulator is arranged in the first hydraulic circuit. The structures of the second energy accumulator, the third energy accumulator and the fourth energy accumulator are similar to the structure of the first energy accumulator. The invention further provides a similar automobile suspension system and a motor vehicle provided with the suspension frame. The piston rod is connected with an automobile body and the hydraulic cylinder is connected with the wheel assembly.

Owner:常州万安汽车部件科技有限公司

Vehicle suspension system and vehicle with same

InactiveCN103213468AIncrease widthLarge steering angleInterconnection systemsPivoted suspension armsTurn angleDrop structure

The invention provides a vehicle suspension system and a vehicle with the same. The vehicle suspension system comprises an axle and an elastic element which is arranged on the axle, wherein a bearing surface on the axle for mounting the elastic element is arranged at a position above the tops of wheels, so that the elastic element is arranged above the tops of the wheels. The vehicle suspension system is preferably a front suspension system, and the axle is preferably a front axle. C-shaped beam structures can be formed on the two sides of the axle respectively, the bearing surface of the elastic element is arranged at the upper ends of the C-shaped beam structures, and the lower ends of the C-shaped beam structures are provided with main pin mounting holes. A large-drop structure can be adopted at the middle section of the axle. According to the vehicle suspension system and the vehicle, the width of a passenger passage and the turning angle of the wheels can be greatly increased, large roll stiffness can be obtained under the condition that no lateral stabilizer bar is arranged, and meanwhile, one-step low floor can be realized.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

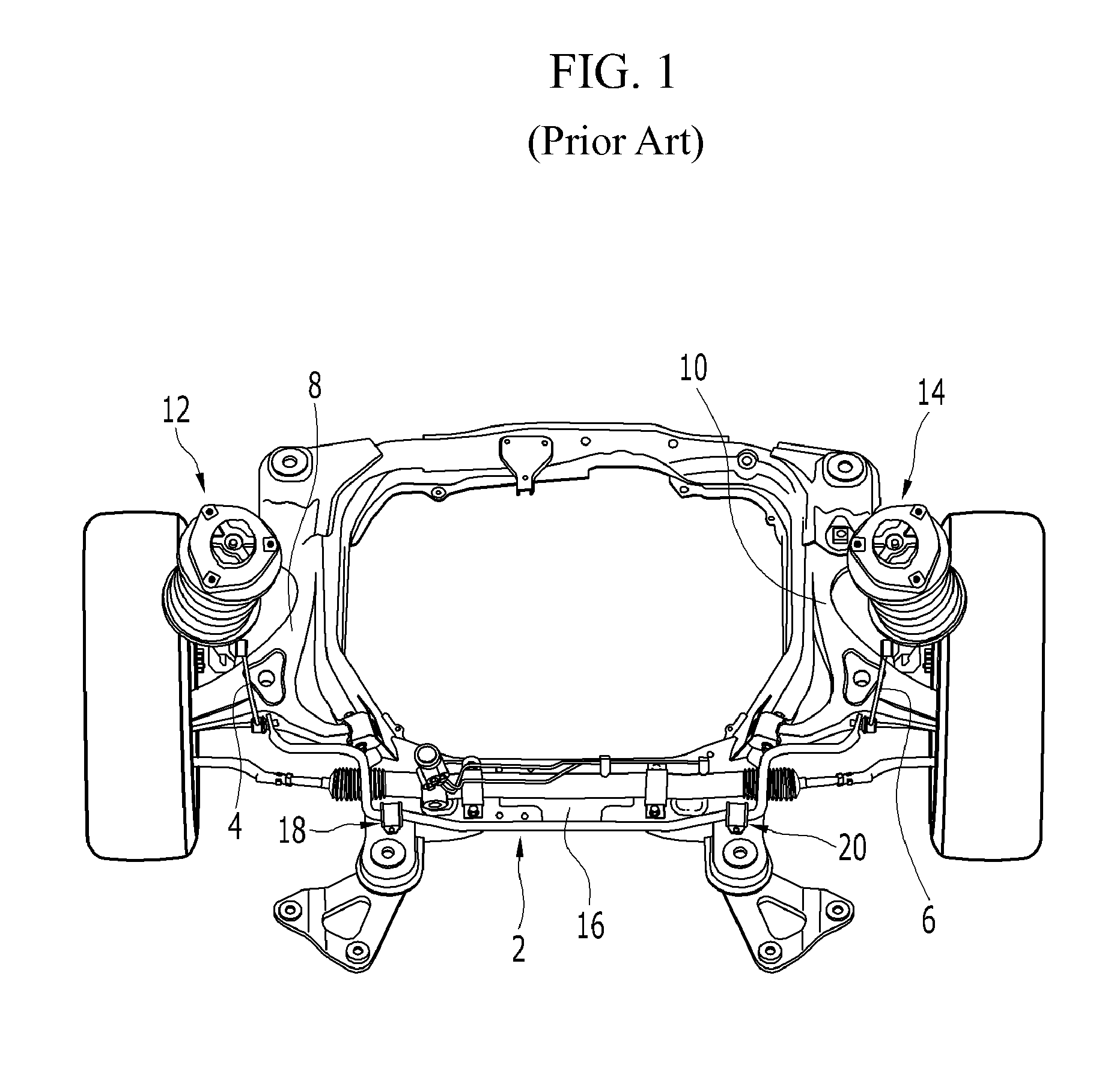

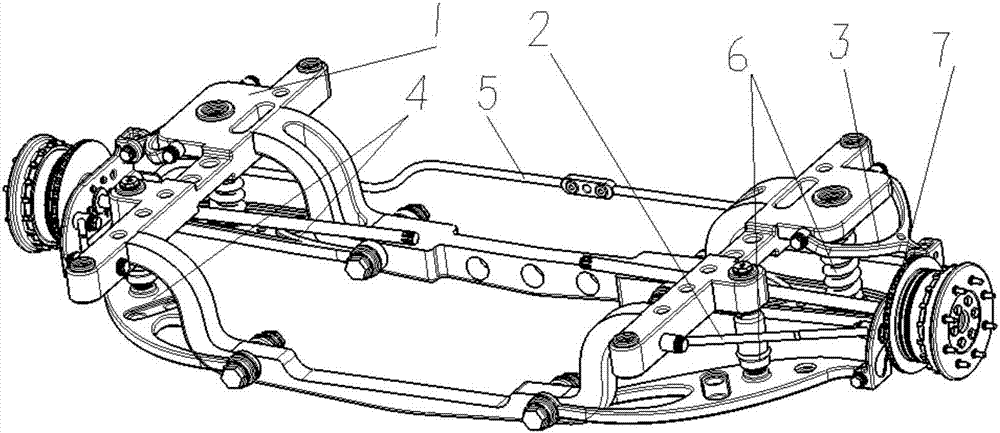

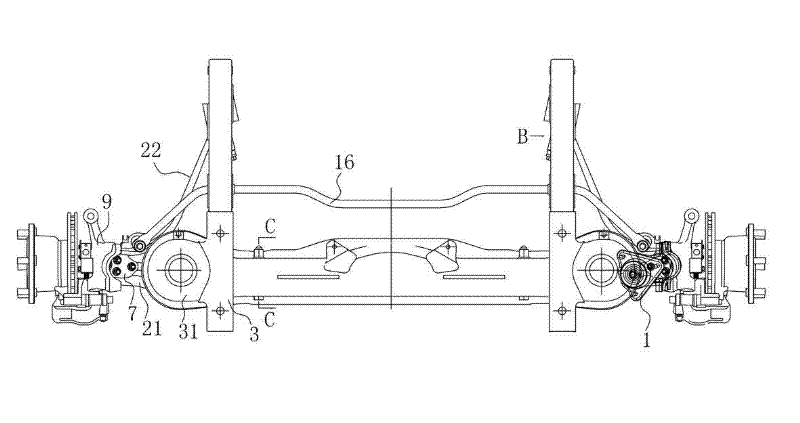

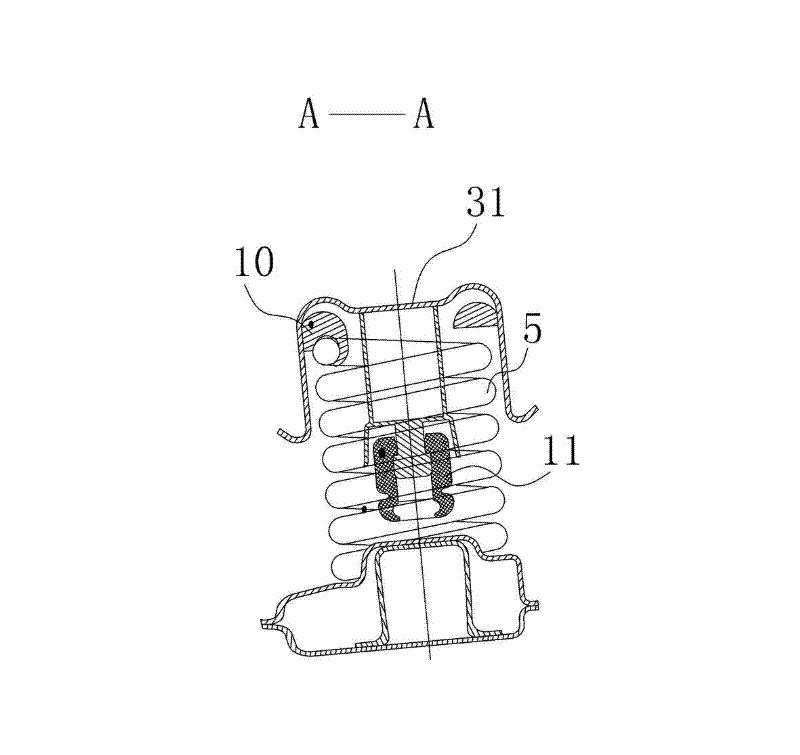

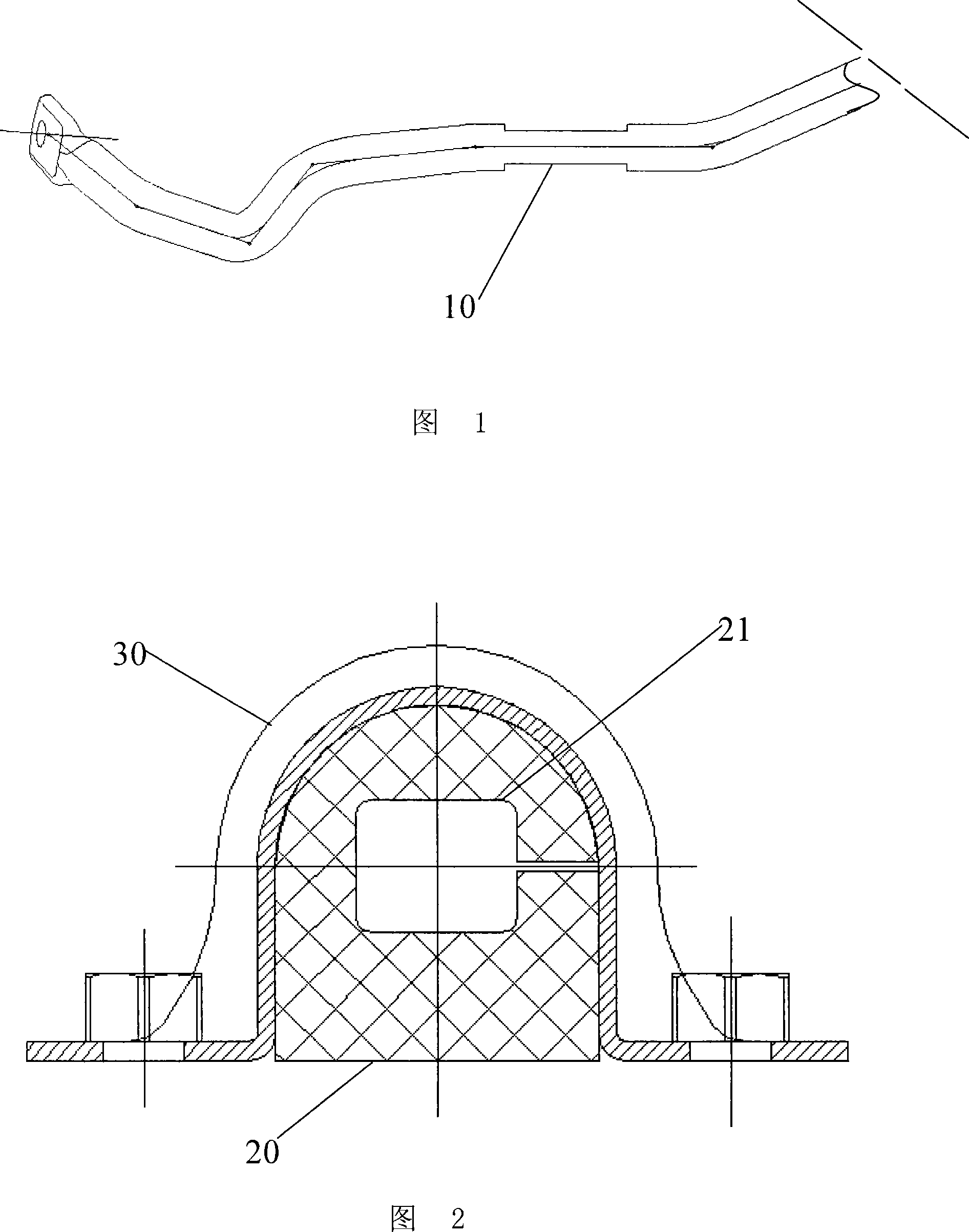

Front suspension assembly

InactiveCN102358128AImprove versatilityReduce occupancyInterconnection systemsResilient suspensionsVehicle frameCoil spring

The invention relates to a front suspension assembly. The front suspension assembly comprises a secondary vehicle frame (3), coil spring assemblies (5), shock absorbers (1) and lower swinging arm assemblies (2), wherein the two sides of the secondary vehicle frame (3) are respectively connected with left and right lower swinging arm (2) assemblies in a matching way; the front suspension assembly is characterized in that: a spring seat (31) positioned above the lower swinging arm (2) is respectively arranged on the two sides of the secondary vehicle frame; a coil spring assembly (5) is embedded into each spring seat (31); each coil spring assembly (5) is connected with the corresponding lower swinging arm (2) assembly; a steering knuckle (9) is arranged outside each lower swinging arm assembly (2); and a shock absorber (1) is arranged on each steering knuckle (9). The front suspension assembly has the advantages that: by using the structure that the coil springs and the shock absorbers are arranged separately, namely the springs are arranged below the secondary vehicle frame and the shock absorbers are arranged on the side surfaces of the secondary vehicle frame, the space occupation of a front suspension is reduced, and enough space is reserved for the arrangement of an engine; and the springs and the shock absorbers work separately so as to avoid mutual interference, reasonably play respective roles, and improve the stability and the smoothness of an overall vehicle.

Owner:HEFEI AUTOMOBILE AXLE

Transverse arresting apparatus

InactiveCN101157330ALimit lateral movementImprove roll stiffnessInterconnection systemsVehicle frameEngineering

The invention relates to a horizontal stabilizing device, which comprises a stabilizing rod and a bushing covering on the stabilizing rod; the cross section of the joint of the stabilizing rod and the bushing and the cross sections of the two ends of the joint are not arranged in the same plane; and the shape of the joint is matched with the shape of the hole arranged on the bushing; a clamping base covers on the bushing and fixes the stabilizing rod and the bushing on a vehicle body or an auxiliary vehicle frame. The invention successfully limits the horizontal movement of the stabilizing rod, thereby not only achieving natural limit, but also improving the roll stiffness of the vehicle suspension.

Owner:CHERY AUTOMOBILE CO LTD

Hanger bracket assembly, hanger bracket with the hanger bracket assembly and vehicle with the hanger bracket

InactiveCN103660831AReduce impactReduce roll angleInterconnection systemsResilient suspensionsVehicle frameJoist

The invention discloses a hanger bracket assembly, a hanger bracket with the hanger bracket assembly and a vehicle with the hanger bracket. The hanger bracket assembly comprises a balance beam, a supporting beam and a bag type air bag. The supporting beam is arranged on the balance beam and can rotate in a pivoted mode relative to the balance beam. The bag type air bag is arranged on the supporting beam. The hanger bracket assembly can greatly reduce impact force received by a vehicle frame, so that the comfort of the vehicle can be greatly improved, and the service life of the vehicle can be prolonged.

Owner:王芹

Vehicle suspension and vehicle

InactiveCN106379131AIncrease the total air chamber volumeThe total air chamber volume is stableInterconnection systemsResilient suspensionsPower unitAir chamber

The invention relates to a vehicle suspension and a vehicle. The suspension comprises an oil cylinder, a power unit and at least three accumulators, wherein a rod chamber of the oil cylinder is communicated with the first accumulator and the power unit respectively, and a rodless chamber of the oil cylinder is communicated with the second accumulator and the power unit respectively. The vehicle comprises the suspension which is arranged at the bottom of a vehicle body. The suspension and the vehicle have the beneficial effects that real-time and step adjustment of rigidity is achieved and the side-tipping and rollover resistance of the vehicle is improved, thus greatly improving the comfort, safety and handling stability of the vehicle; and the volume of the total air chamber of the accumulator connected with the rodless chamber of the oil cylinder is increased, thus reducing the rigidity of the suspension, so that the suspension is more flexible and then the vehicle runs more stably and comfortably.

Owner:张家口舒狮汽车科技有限公司

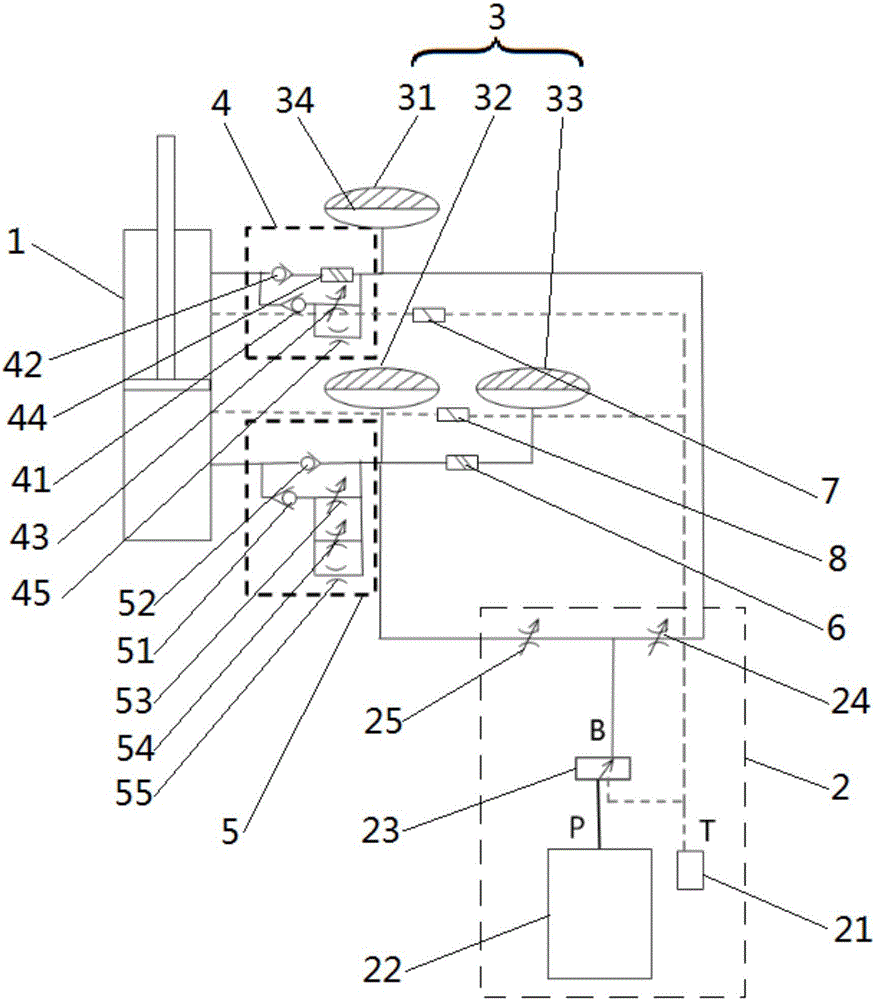

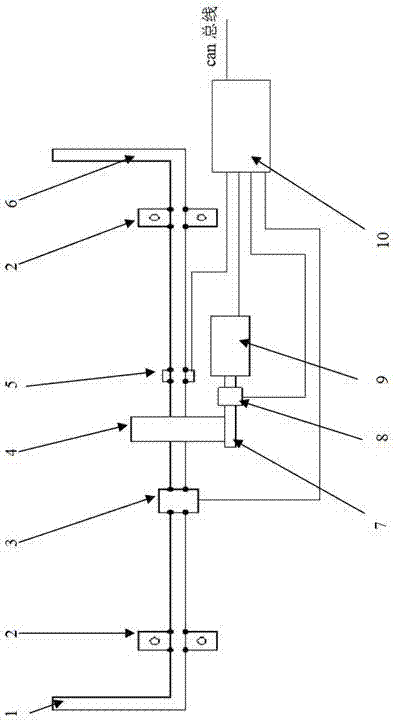

Electronically-controlled lateral stabilizer bar

InactiveCN107444059AImprove off-road performanceImprove roll stiffnessInterconnection systemsElectromagnetic clutchEngineering

The invention relates to an electronically-controlled lateral stabilizer bar for an automobile, in particular to an electronically-controlled lateral stabilizer bar capable of being disconnected and with the rigidity capable of being adjusted actively. The electronically-controlled lateral stabilizer bar comprises a stabilizer bar body, a motor, a worm wheel and worm reduction device, an electromagnetic clutch, a torque sensor and an electronic control unit. The motor and the electromagnetic clutch are controlled to work through the electronic control unit, and the functions of disconnecting and lock-up of the lateral stabilizer bar, active adjusting of the rigidity of the lateral stabilizer bar and the like are achieved. According to the electronically-controlled lateral stabilizer bar, the design problems of the safety, the comfort and the passing ability of the lateral stabilizer bar can be effectively solved, meanwhile the structure is compact, the cost is moderate, and the electronically-controlled lateral stabilizer bar has a certain application and popularization value.

Owner:合肥创智汽车技术开发有限公司

Rear suspension device of sport utility vehicle

InactiveCN101269617ALower centroid heightReduce roll angleResilient suspensionsVehicle frameEngineering

A rear suspension fork device for a motile multifunctional vehicle (SUV) is achieved by the following proposal: the upper side of the lower swing-arm of the present vehicle five-link suspension fork and the lower side of the vehicle frame longitudinal beam are respectively provided with a spring seat; the upper and the lower ends of the spring are respectively connected to the spring seat. The rear suspension fork device has simple and reasonable structure as well as easy processing, and can effectively lower the centroid height, increase the spring distance, and improve the operation stability and the drive security; the rear suspension fork device can be used by matching with various SUV vehicles so that the industrialized production can be achieved, and the rear suspension fork device can be used as the renewal product of rear suspension fork of existing SUV vehicles.

Owner:湖南长丰汽车研发股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com