Front suspension assembly

A front suspension and assembly technology, applied in the direction of suspension, elastic suspension, interconnection system, etc., can solve the problems affecting the layout of the engine and steering system, inconvenient maintenance and transportation, and large space occupation, and achieves high versatility. , to avoid mutual interference and reduce the effect of occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

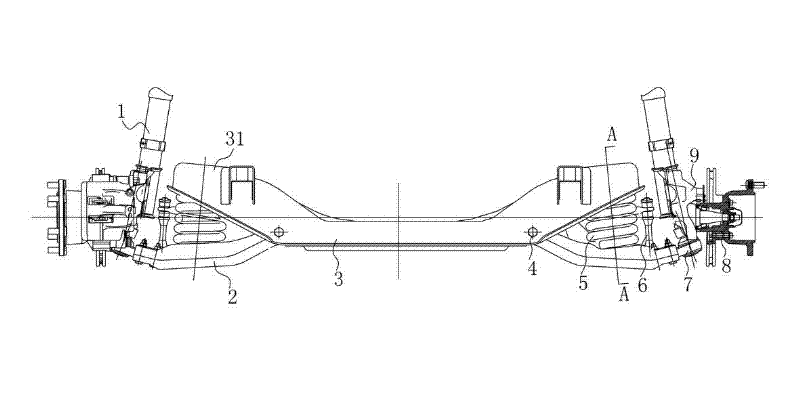

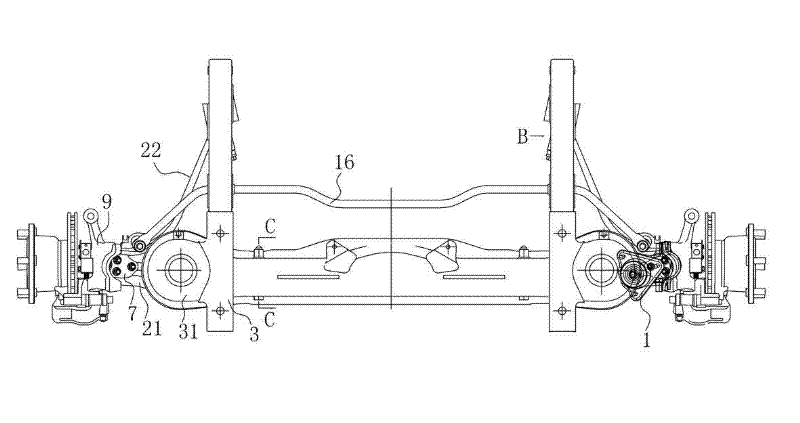

[0017] Such as figure 1 As shown, a front suspension assembly of the present invention includes a subframe 3, the subframe 3 can improve the connection stiffness of the whole bridge, the subframe 3 is connected to the vehicle through bolts, and the remaining parts can be connected to the subframe respectively. on frame 3.

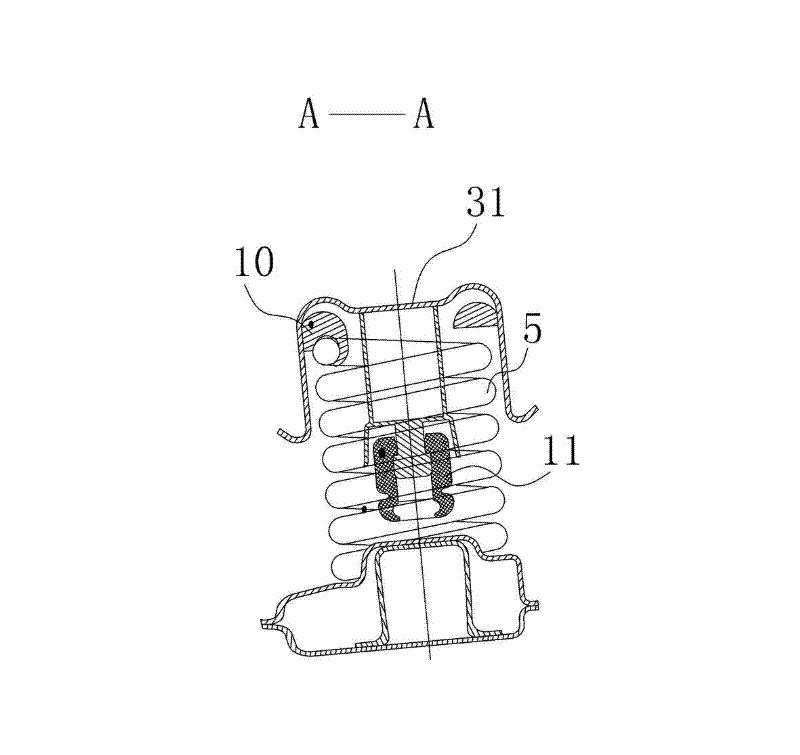

[0018] The two sides of the subframe 3 are connected with the left and right lower swing arm assemblies 2 respectively, and each lower swing arm assembly 2 has two connection points with the subframe 3, such as Figure 5 As shown, at the first place, the lower swing arm assembly 2 has a first connecting arm 21 protruding laterally, and a connecting hole is formed on the first connecting arm 21, a rubber bush 15 is embedded in the connecting hole, and a A u-shaped connecting bracket has a pair of coaxial through holes on the connecting bracket, and the first connecting arm 21 can extend into the u-shaped connecting bracket, and is connected with the subfram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com