Vehicle suspension roll angle rigidity checking method

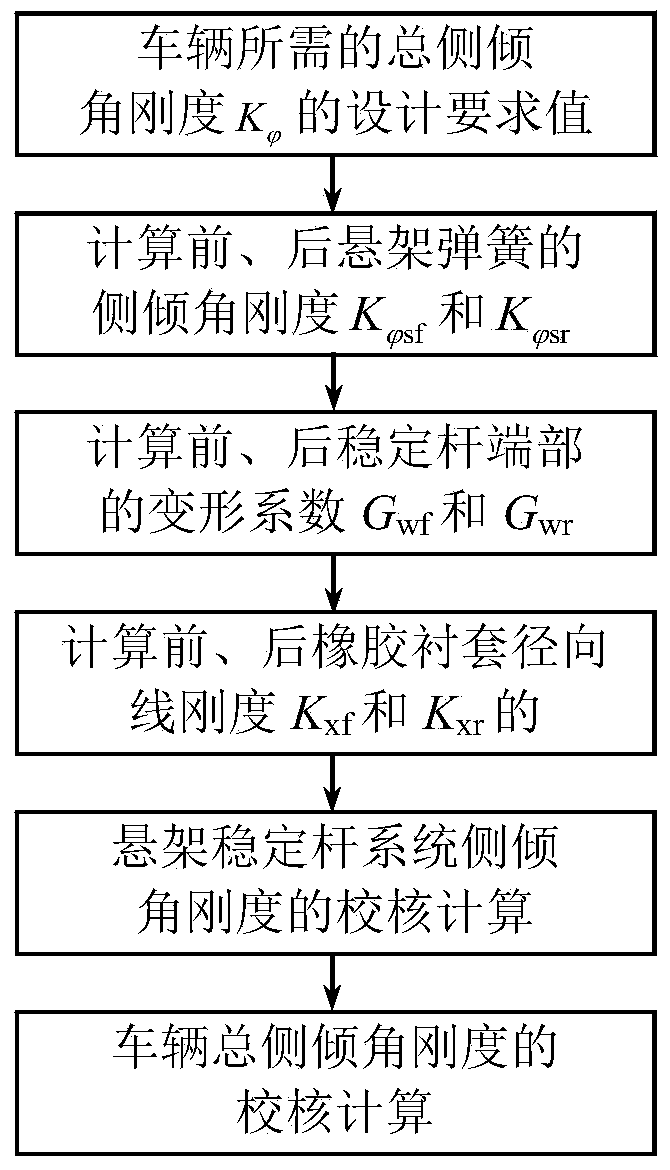

A roll angle stiffness and vehicle suspension technology, which is applied in the field of vehicle suspension roll angle stiffness check, can solve problems such as inability to provide analytical calculation formulas, failure to give analytical calculation methods, failure to meet suspension stabilizer bars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

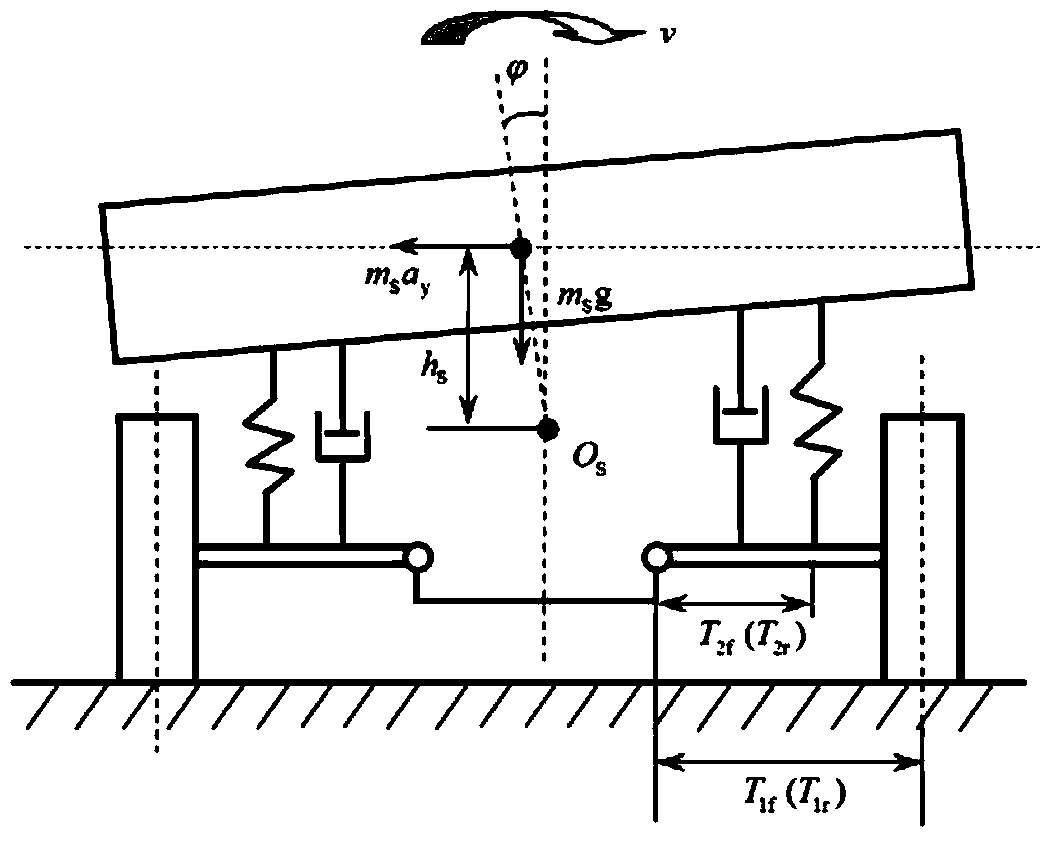

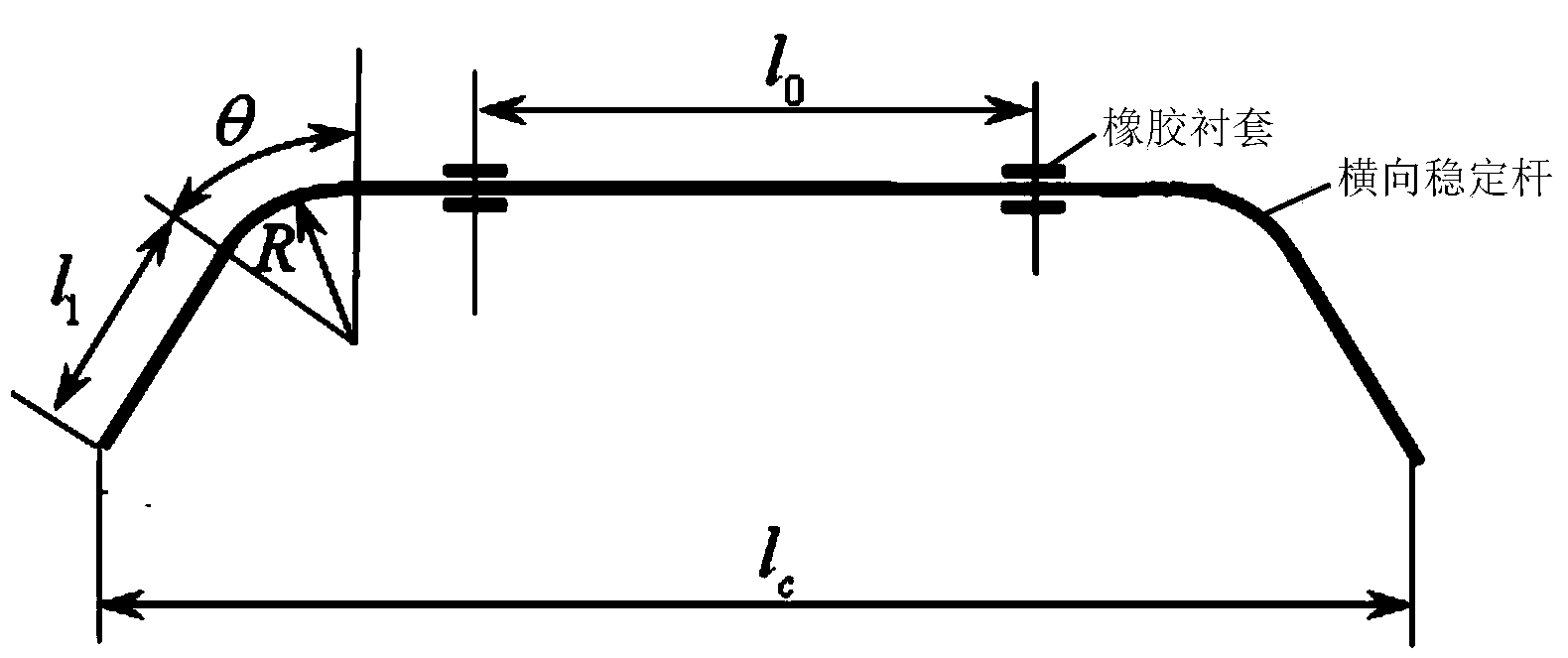

[0070] Embodiment one: the body mass m of a certain vehicle s =4690kg, lateral acceleration a y =0.4g, the distance h between the body center of mass and the roll axis s =1069mm, the design requirement value of body roll angle Front suspension swing arm length T 1f =675mm, spring wire stiffness k sf =102.45N / mm, the distance T between the center of the spring and the hinge point of the swing arm 2f =430mm; rear suspension swing arm length T 1r =650mm, spring wire stiffness K rs =261N / mm, the distance T between the center of the spring and the hinge point of the swing arm 2r =400mm; the wheelbase of the front axle of the vehicle B f =1650mm, rear axle track B r =1485mm; the vehicle is only equipped with a stabilizer bar system in the front suspension, and its structural diagram is as follows image 3 shown, where the straight d of the stabilizer bar f =20mm, total length l cf =800mm, arm length, l 1f =150mm, transition arc radius R f =50mm, transition arc central ...

Embodiment 2

[0112] Embodiment 2: Known certain vehicle body mass m s =5000kg, lateral acceleration a y =0.4g, the distance h between the body center of mass and the roll axis s = 1150mm, body roll angle Spring wire stiffness k of the vehicle's front suspension sf =90.761N / mm, spring line stiffness k of rear suspension sr =176.23N / mm; front track B f =1650mm, rear track B r =1600mm; front suspension arm length T 1f =660mm, the distance T between the center of the front suspension spring and the hinge point of the swing arm on the same side 2f =450mm; rear swing arm length T 1r =650mm, the distance T between the installation center of the rear suspension spring and the hinge point of the cross arm on the same side 2r = 400mm. The front and rear suspension stabilizer bars and rubber bushings, except for the different diameters, other parameters are the same as those in Example 1, where the diameter of the front stabilizer bar is d f =22mm, rear stabilizer bar diameter d r =19mm; ...

Embodiment 3

[0141] Embodiment three: A certain vehicle except the diameter d of the front suspension stabilizer bar f and the inner circle radius r of the rubber bushing af and outer circle radius r bf In addition to being different, all other parameters are exactly the same as those of Embodiment 2, wherein, the diameter d of the front stabilizer bar f =21mm, the inner circle radius r of the rubber bushing af =12.5mm, and outer circle radius r bf = 22.5 mm. Check and calculate the roll angle stiffness of the vehicle suspension system.

[0142] Adopt the step of implementation example one, check and calculate the roll angle stiffness of this vehicle suspension system:

[0143] (1) The total roll angle stiffness required by the vehicle suspension The calculation of:

[0144] Because the vehicle parameters are exactly the same as those of the second embodiment, the total roll angle stiffness required by the vehicle suspension is also the same as that of the second embodiment, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com