Transverse arresting apparatus

A technology of lateral stabilizer and stabilizer bar, which is applied in transportation and packaging, interconnection systems, suspensions, etc., and can solve problems such as low bushing life and inability to limit the axial movement of the stabilizer bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

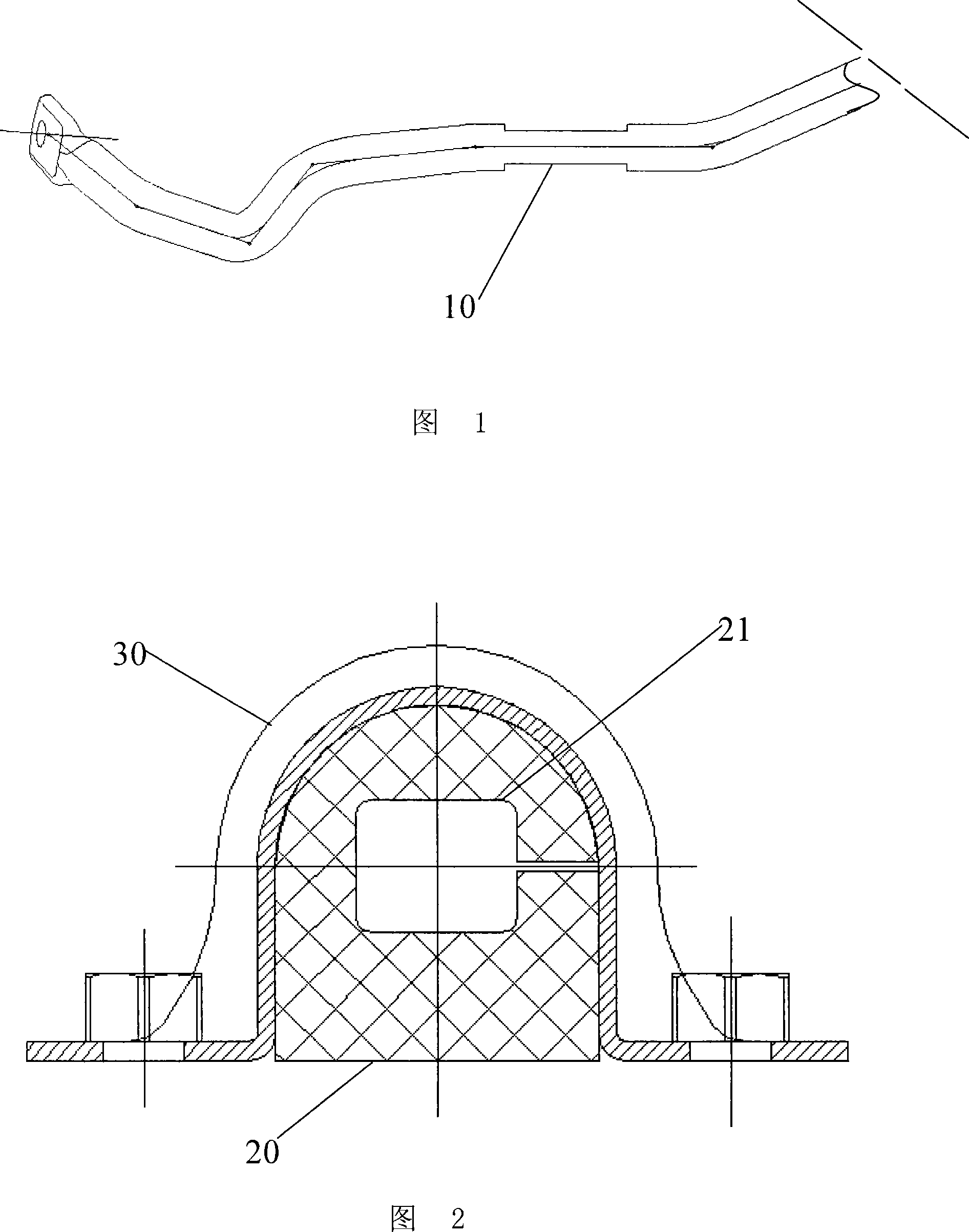

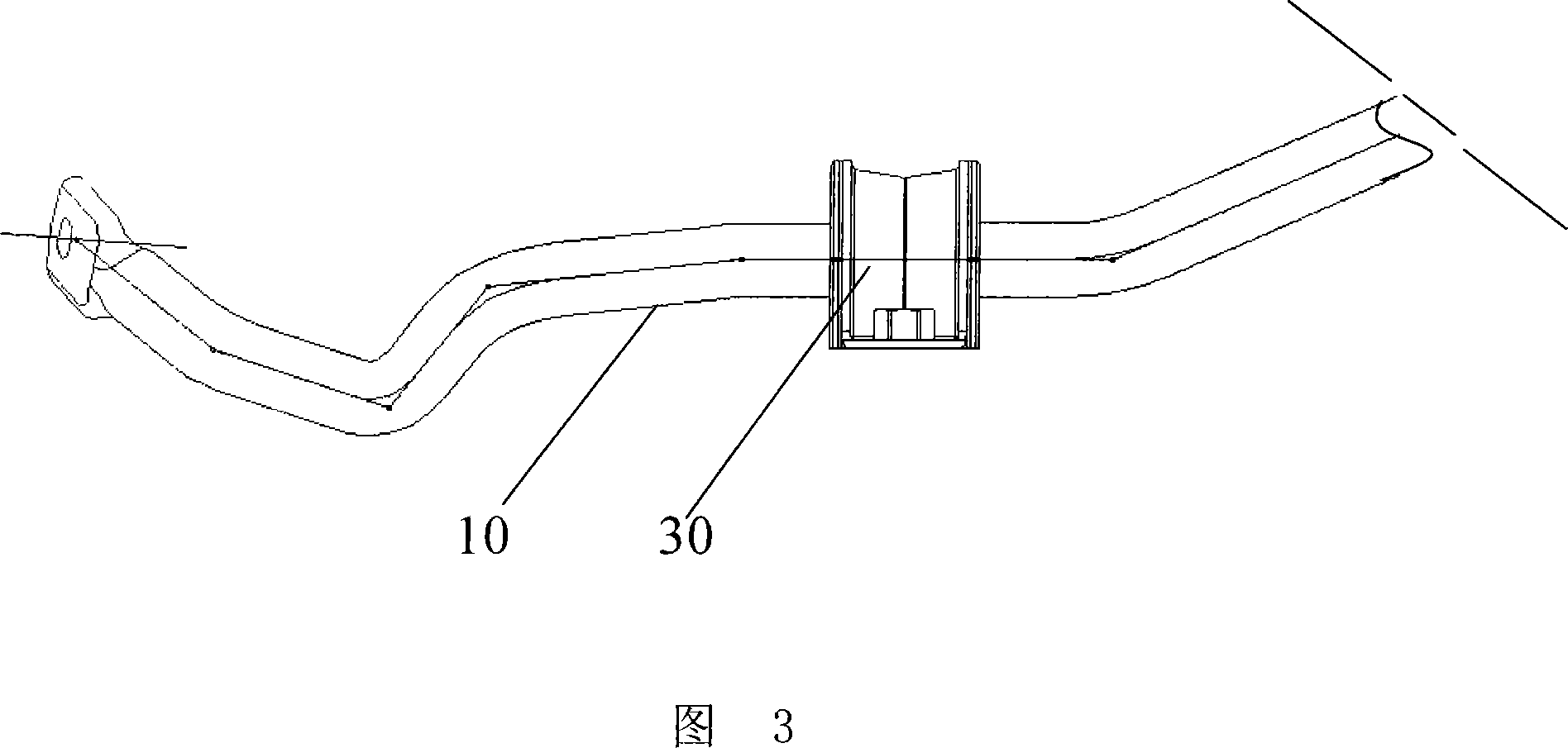

[0009] A lateral stabilizing device, comprising a stabilizing bar 10 and a bushing 20 covered on the stabilizing bar 10, the cross section of the joint between the stabilizing bar and the bushing and the cross sections at both ends of the joint are shaped cross sections, and the joint The shape coincides with the shape of the hole provided on the bushing 20, and the clip seat 30 covers the bushing 20, and fixes the stabilizer bar 10 and the bushing 20 on the vehicle body or the sub-frame. For the convenience of description, the “combination” referred to below refers to the joint between the stabilizer bar 10 and the bushing 20 .

[0010] There are two options for the bushing 20 to be realized. One: the bushing 20 is open and has a square through hole 21 on it. The shape of the through hole 21 matches the shape of the junction. The opening runs through the inner wall and the outer wall of the bushing 20, and is used to cover the stabilizer bar 10 in the bushing 20, as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com