Three-dimensional multi-directional displacement comb tooth telescopic device

A three-dimensional multi-directional, telescopic device technology, used in bridge parts, bridge materials, bridges, etc., can solve the problems of untimely maintenance, complicated repair and replacement construction, loss of expansion and contraction function of comb tooth gaps, etc. Synchronization, ensuring bridge expansion and traffic safety, and alleviating the effect of bridge damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

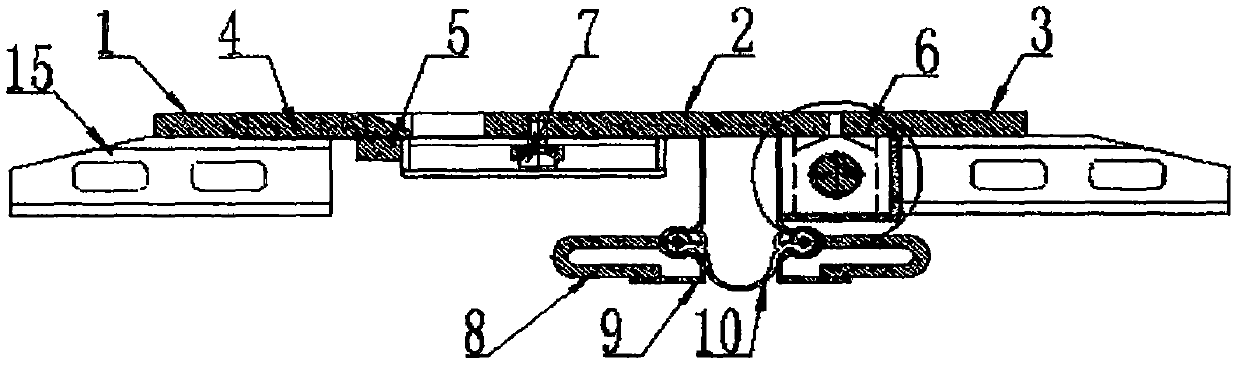

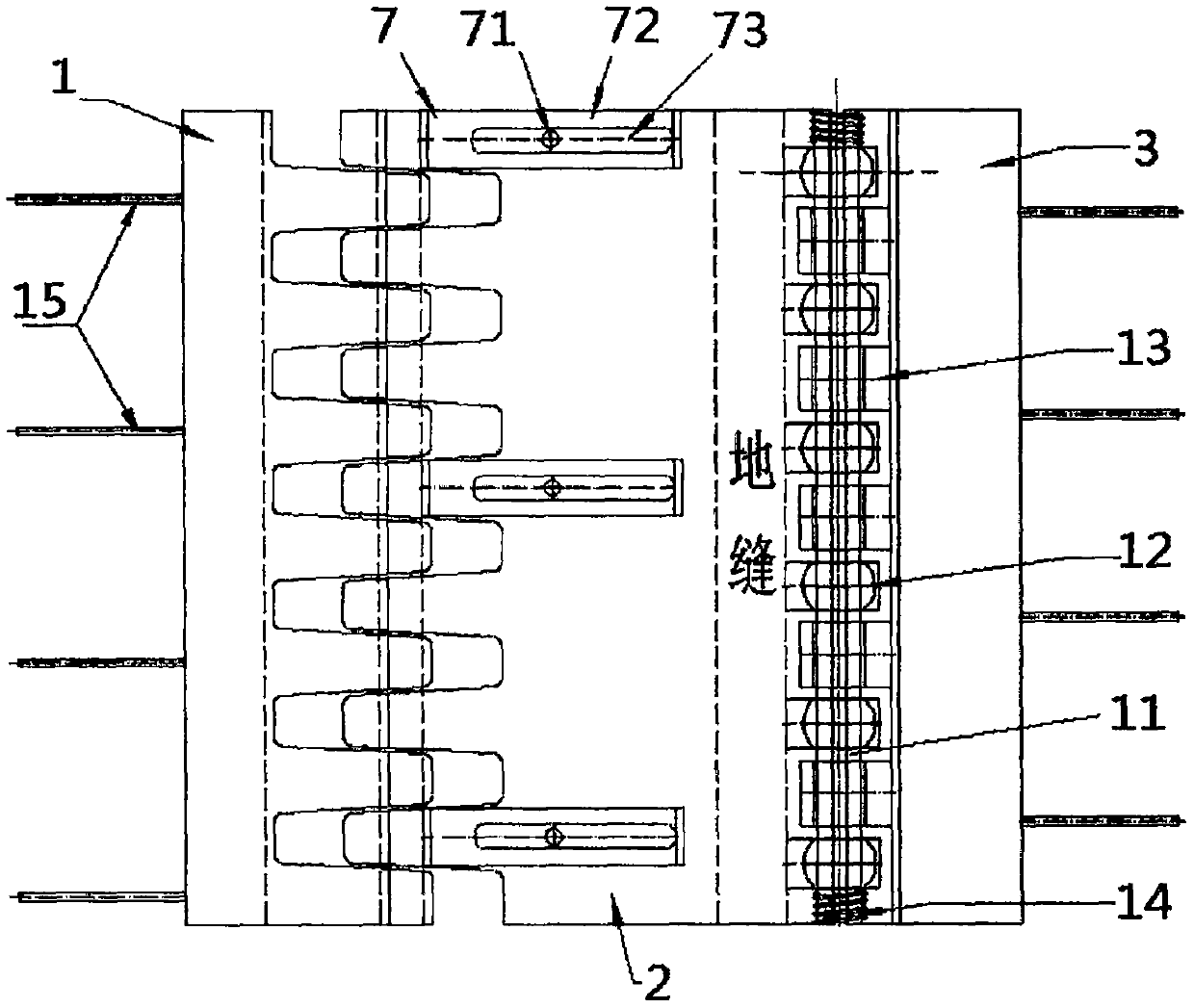

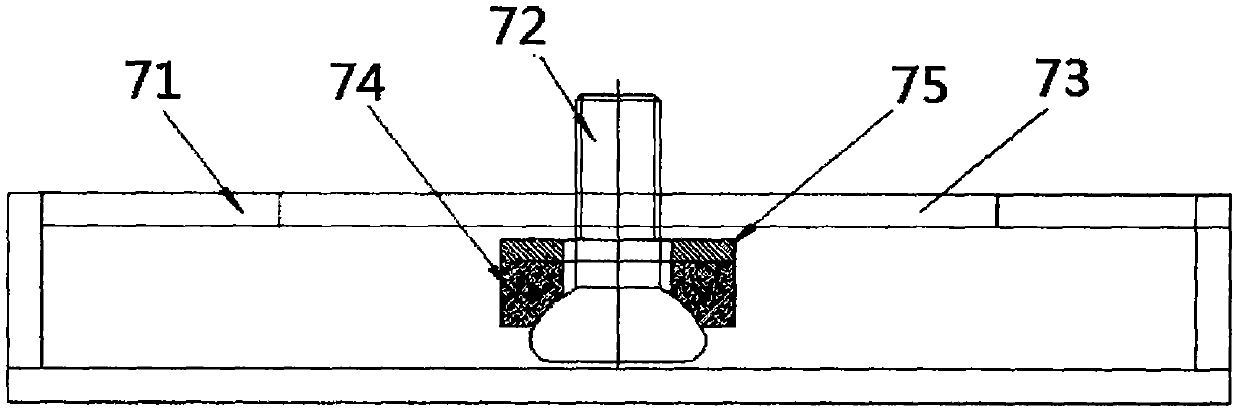

[0022] refer to figure 1 , figure 2 , image 3 , Figure 4 , a three-dimensional multi-directional shifting comb telescopic device, including a corresponding comb main tooth plate 2, a comb tooth auxiliary tooth plate 1, a main tooth fixing plate 3, and the main tooth fixing plate 3 and the comb main tooth plate 2 are movable Connection, the stainless steel plate 4 is welded under the comb-tooth sub-tooth plate 1, the support beam 5 presses the stainless steel plate 4 and is welded on the comb teeth of the comb-tooth sub-tooth plate, and the comb main tooth plate 2 and the comb-tooth sub-tooth plate 1 stretching process will be kept on the same level, and will not be out of joint. There is a guide groove 73 on the limit box 71 on the limit device 7, and the round head bolt 72 is fastened under the comb tooth main tooth plate 2. The round head bolt 72 can move along the guide groove 73, and is used to limit the comb tooth main tooth plate. The telescoping and vertical lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com