Bending tester for of tools and utensils

A bending testing machine and tool technology, which is applied in the direction of applying a stable bending force to test the strength of materials, can solve the problems of high labor intensity, poor applicability of the support mechanism, low efficiency, etc., and achieves high test accuracy and convenient adjustment of spacing. , the effect of high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

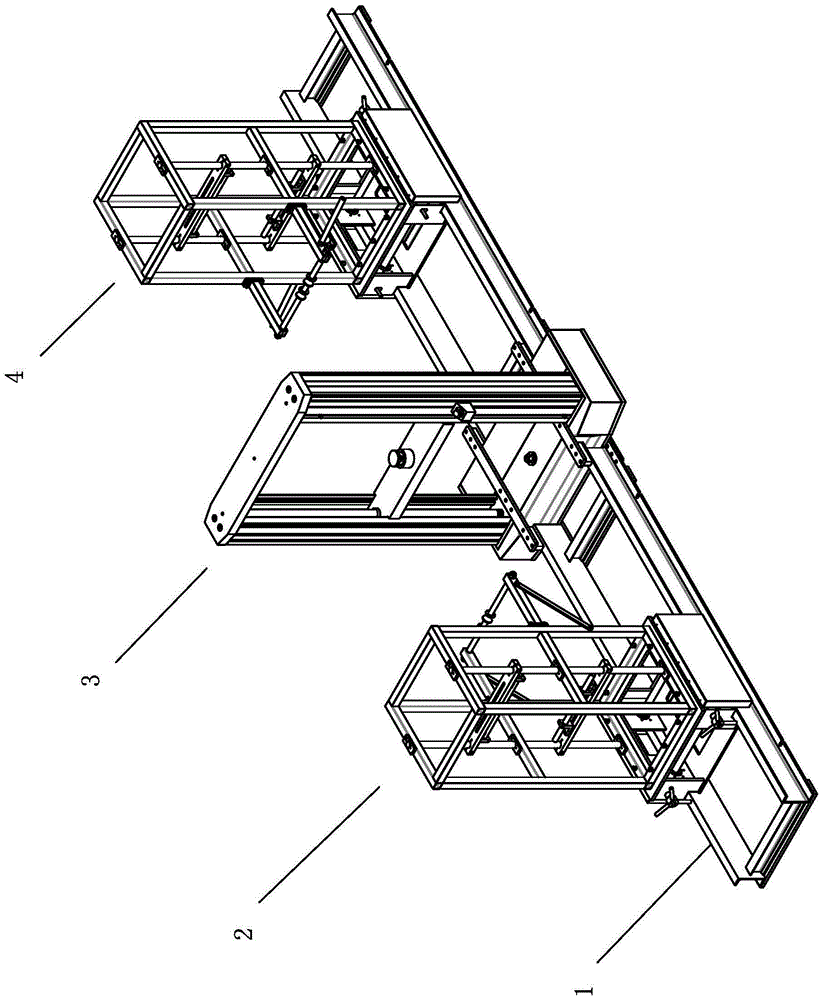

[0026] refer to figure 1 , the tool bending tester of the present invention comprises a guide rail 1, a universal testing machine loading part 3 and two moving ends 2, 4, and the loading part 3 is fixed on the guide rail 1; the guide rail 1 can be It is slidably arranged on the guide rail 1 and placed at both ends of the loading part 3 of the testing machine respectively.

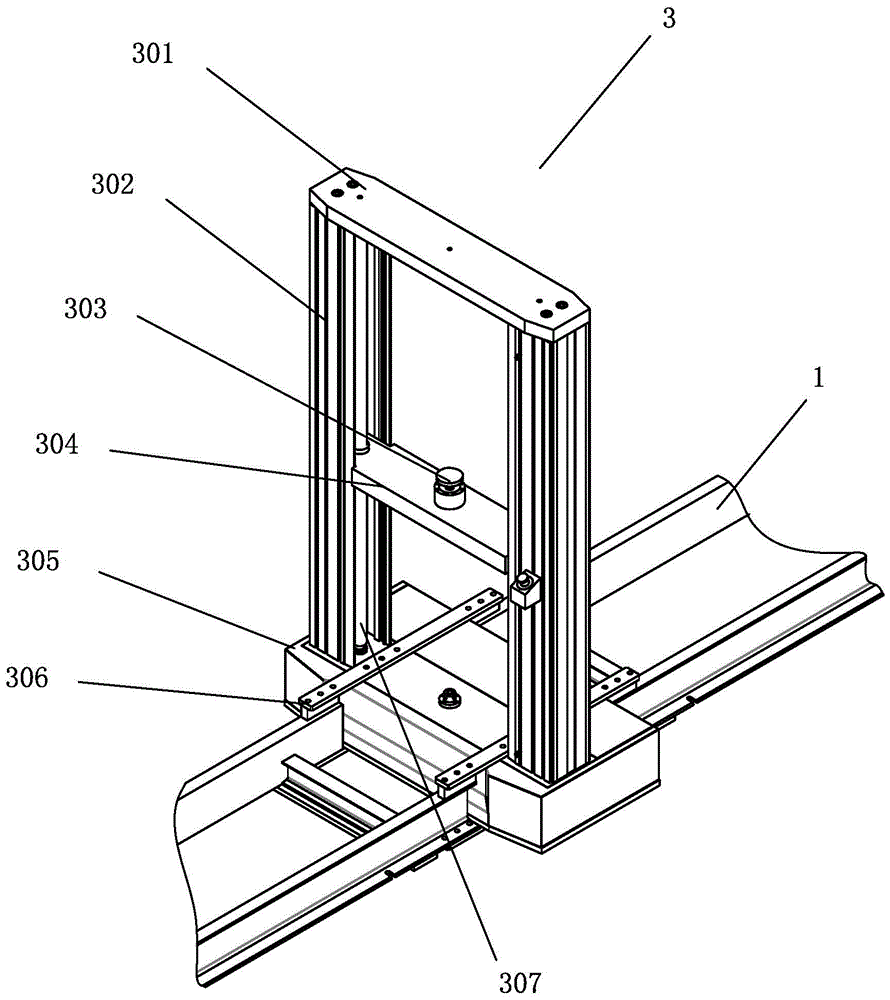

[0027] refer to figure 2 , The loading part 3 of the universal testing machine includes a top plate 301 , a column 302 , a pressure plate 303 , an indenter 304 and a base 305 . The upright column 302 is two left and right, and its top and bottom are respectively fixed with the top plate 301 and the base 306 . A pair of guide pillars 307 is also arranged between the top plate 301 and the base 306. The pressing plate 303 is arranged on the pair of guide pillars 307, and can move up and down along the guide pillars 307, and adjust to a suitable height according to different samples. The pressing head 304 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com