Yarn guiding device for textile

A wire guide device and wire guide technology, applied in the textile field, can solve problems such as inflexible use and inconvenient scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

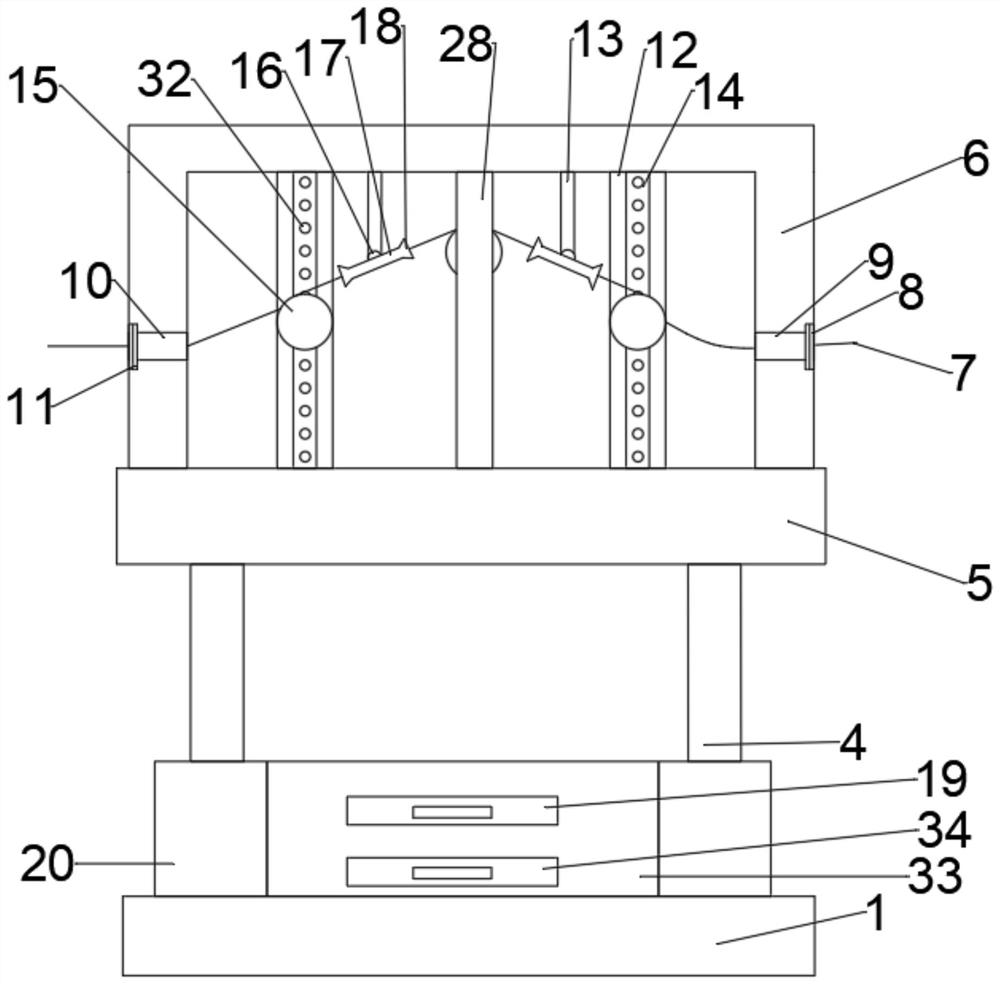

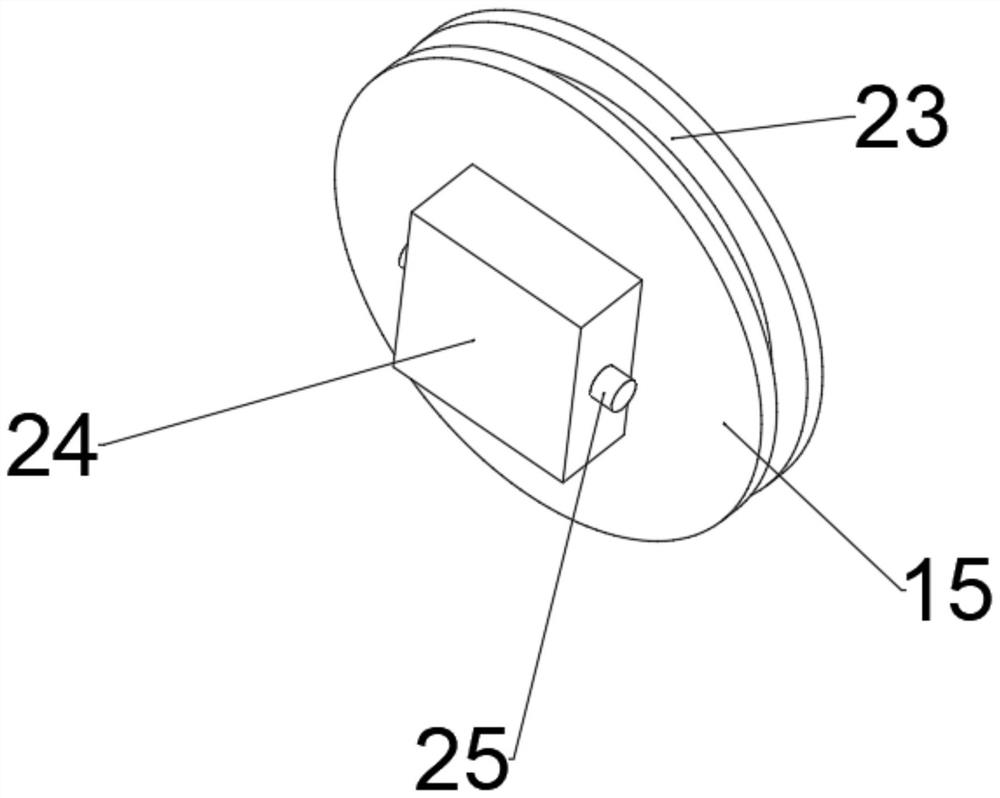

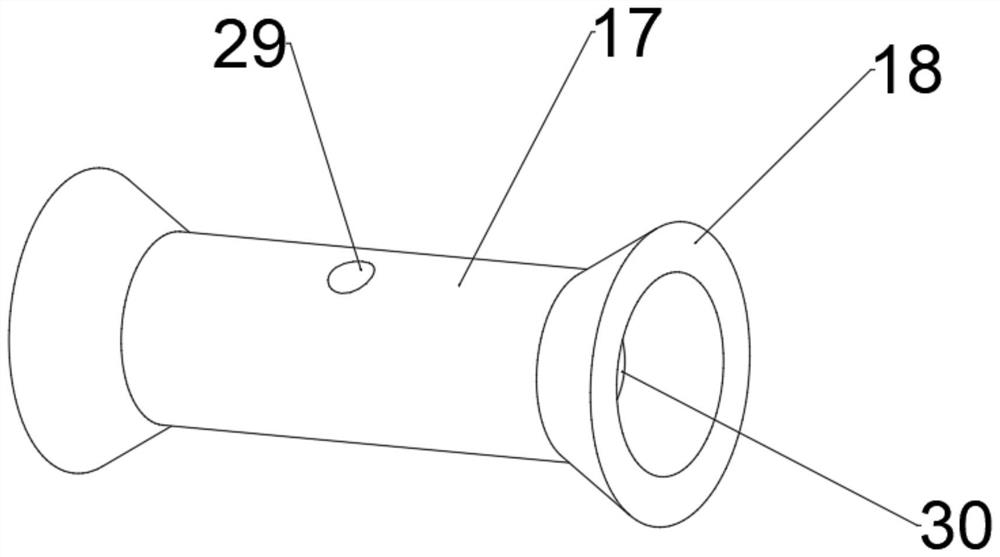

[0035] refer to Figure 1 to Figure 5, a kind of guide wire device for weaving, comprising a support plate 5 and a guide box 6, the top of the support plate 5 is connected with a guide box 6 by bolts, the upper surface of the support plate 5 and the inner top surface of the guide box 6 are provided with a second The third chute 22 and the second chute 21, the second chute 21 and the third chute 22 are slidably connected with the second slider 31 inside, and the end of the second slider 31 away from the bottom of the third chute 22 is bolted. There is a first slide plate 12, the second slide block 31 is bolted to the second slide plate 28 at one end away from the bottom of the second slide slot 21, and the front side of the first slide plate 12 and the rear side of the second slide plate 28 are provided with first slide slots 14. The first slider 24 is slidably connected in the first chute 14, and the end of the first slider 24 away from the first chute 14 is bolt-connected wit...

Embodiment 2

[0044] refer to Figure 4 , a guide wire device for textiles. Compared with Embodiment 1, this embodiment is provided with a running mechanism under the base 1, the running mechanism includes a rolling wheel 2 and a brake plate 3, and the bottom of the base 1 is connected with a rolling wheel 2 by bolts. , the bolts on the scroll wheel 2 are connected with a brake plate 3, and the device can move freely by using the scroll wheel 2. When the device moves to a designated position, the brake plate 3 is used to stop the scroll wheel 2 from rotating and limit the rotation of the scroll wheel 2. Make the device stable at the designated place, ensure that it will not move when the device is running, and increase its practicability.

[0045] Working principle: Use the scroll wheel 2 to make the device move freely. When the device moves to the specified position, use the brake plate 3 to stop the scroll wheel 2 from rotating, and limit the rotation of the scroll wheel 2, so that the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com