Active control type variable-rigidity anti-side-rolling torsion bar device and variable-rigidity method thereof

An anti-rolling torsion bar and active control technology, applied in the direction of the device for lateral relative movement between the undercarriage and the bogie, can solve problems such as overturning coefficient and derailment coefficient adverse effects, and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

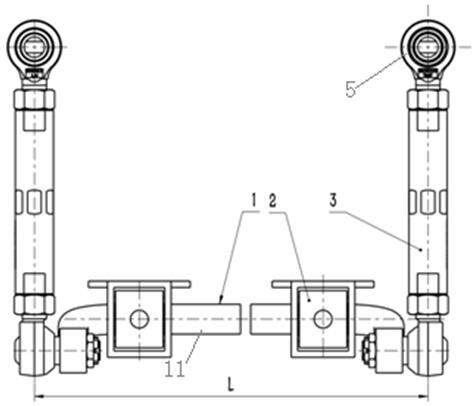

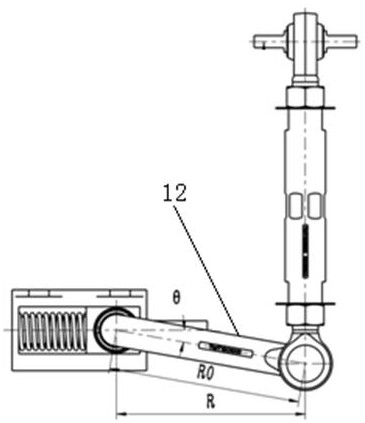

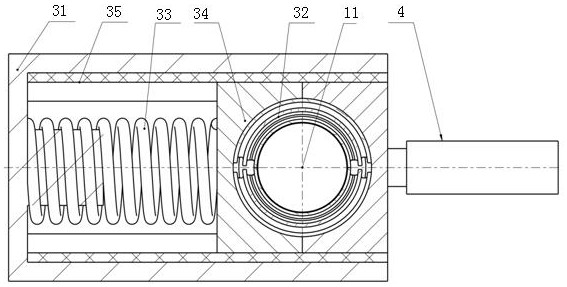

[0027] Combine below Figure 1~5 Embodiments of the present invention are described in detail.

[0028] The active control type variable stiffness anti-roll torsion bar device includes a torsion bar 1, a support base assembly 2 connected to the bogie and a connecting rod assembly 3 hinged to the vehicle body. The torsion bar 1 includes a torsion bar shaft 11 and is arranged on The rotating arm 12 at the end of the torsion bar shaft 11, the support seat assembly 2 is sleeved on the torsion bar shaft 11, the connecting rod assembly 3 is hinged with the free end of the rotating arm 12, and the feature is that the effective arm of the anti-rolling torsion bar device The length is R, and the support seat assembly 3 is connected to the hydraulic system, which can drive the torsion bar 1 and the connecting rod assembly 3 to move synchronously with the drive of the hydraulic system, so that the effective arm length R of the anti-roll torsion bar device can be changed.

[0029] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com