Vehicle double withbone arm type independent suspension system

An independent suspension, double wishbone technology, applied in the direction of interconnection systems, vehicle components, suspensions, etc., can solve problems such as inability to exert technical effects, affecting driving stability and riding comfort, body tilt and vibration, etc. Responsiveness, improved handling and ride comfort, reduced load effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

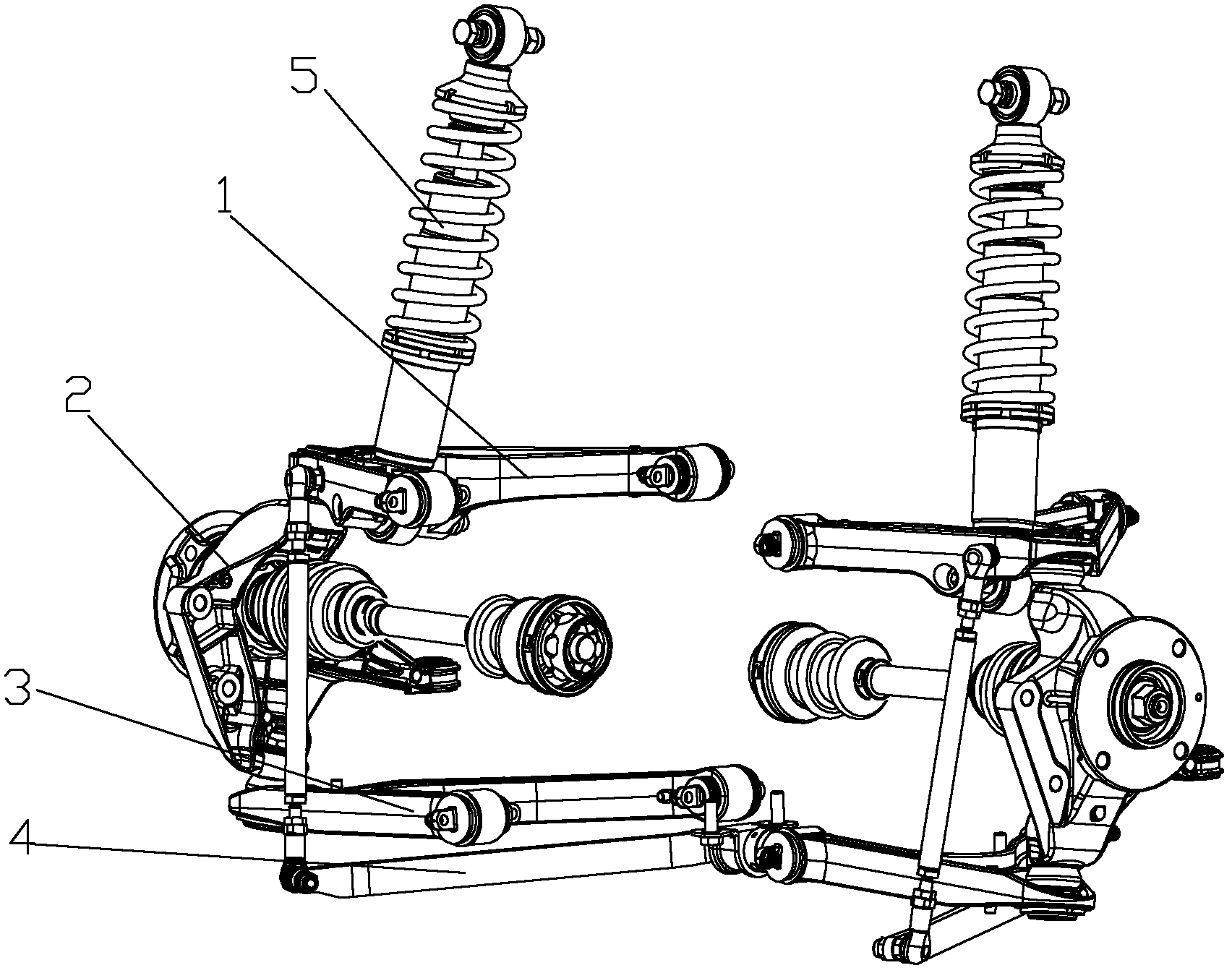

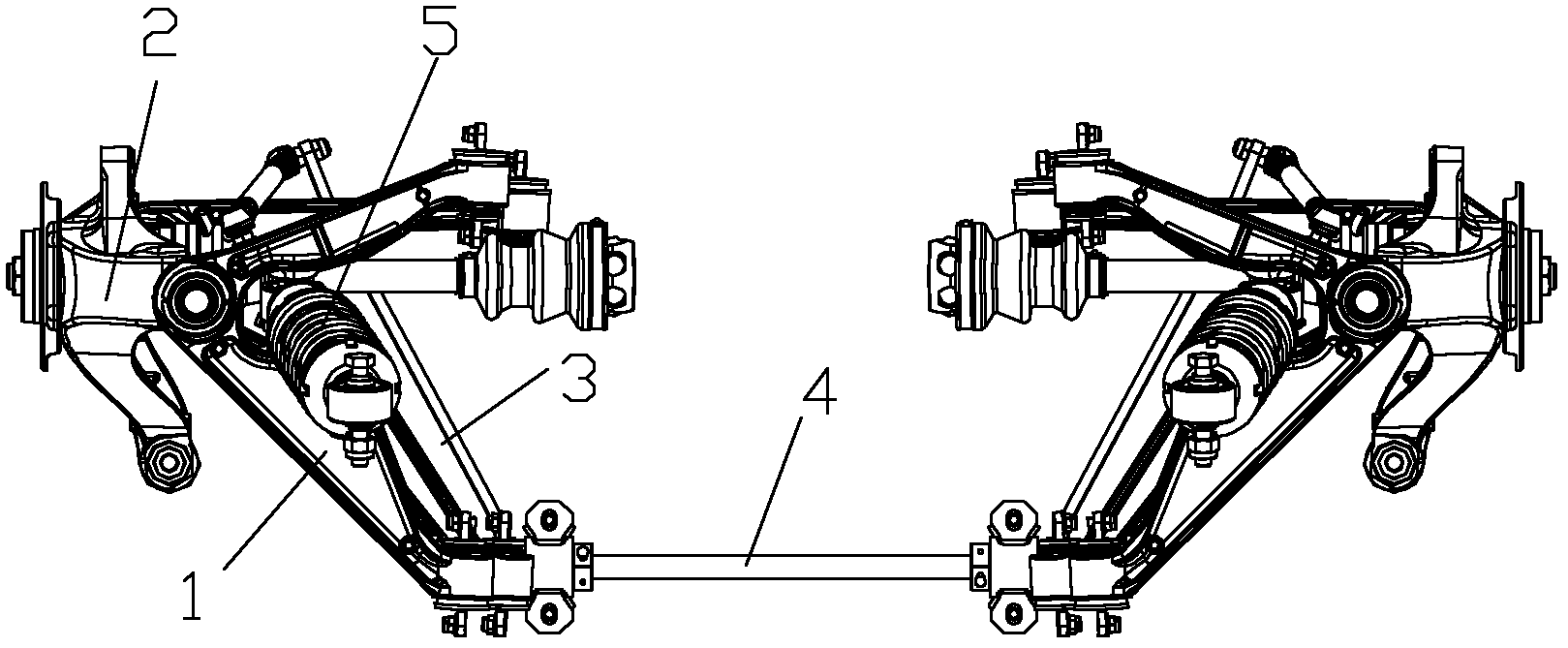

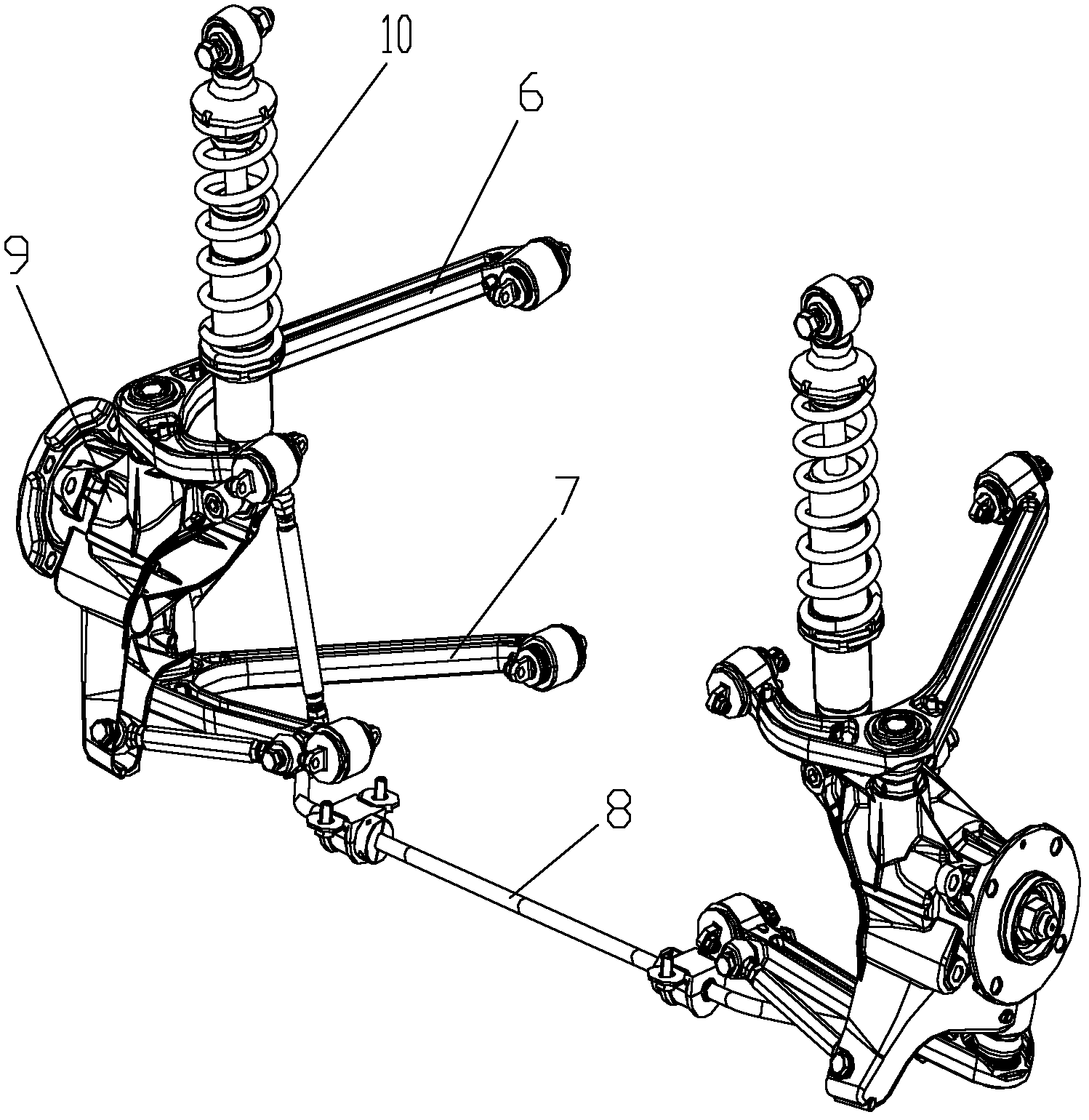

[0017] figure 1 It is a schematic diagram of the three-dimensional structure of the front suspension system of the present invention, figure 2 It is a top view of the front suspension system of the present invention, image 3 It is a schematic diagram of the three-dimensional structure of the rear suspension system of the present invention, Figure 4 It is a top view of the rear suspension system of the present invention, as shown in the figure: the vehicle double-wishbone independent suspension system of the present embodiment includes a front suspension assembly and a rear suspension assembly, and the front suspension assembly and the rear suspension assembly are respectively The two left and right are oppositely arranged, and the front suspension assembly includes a front shock absorber 5 and a front swing arm assembly, and the front swing arm assembly includes a front upper swing arm 1 and a front lower swing arm arranged side by side Arm 3, the projection size of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com