Automotive double-front-axle structure adopting non-independent oblique leaf spring suspensions

A technology of leaf spring suspension and double front axle, which is applied in the field of automobile engineering, can solve problems such as insufficient strength, achieve the effects of improving anti-rolling ability, improving wheel positioning parameters, and increasing the distance between bearing centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure, principle and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

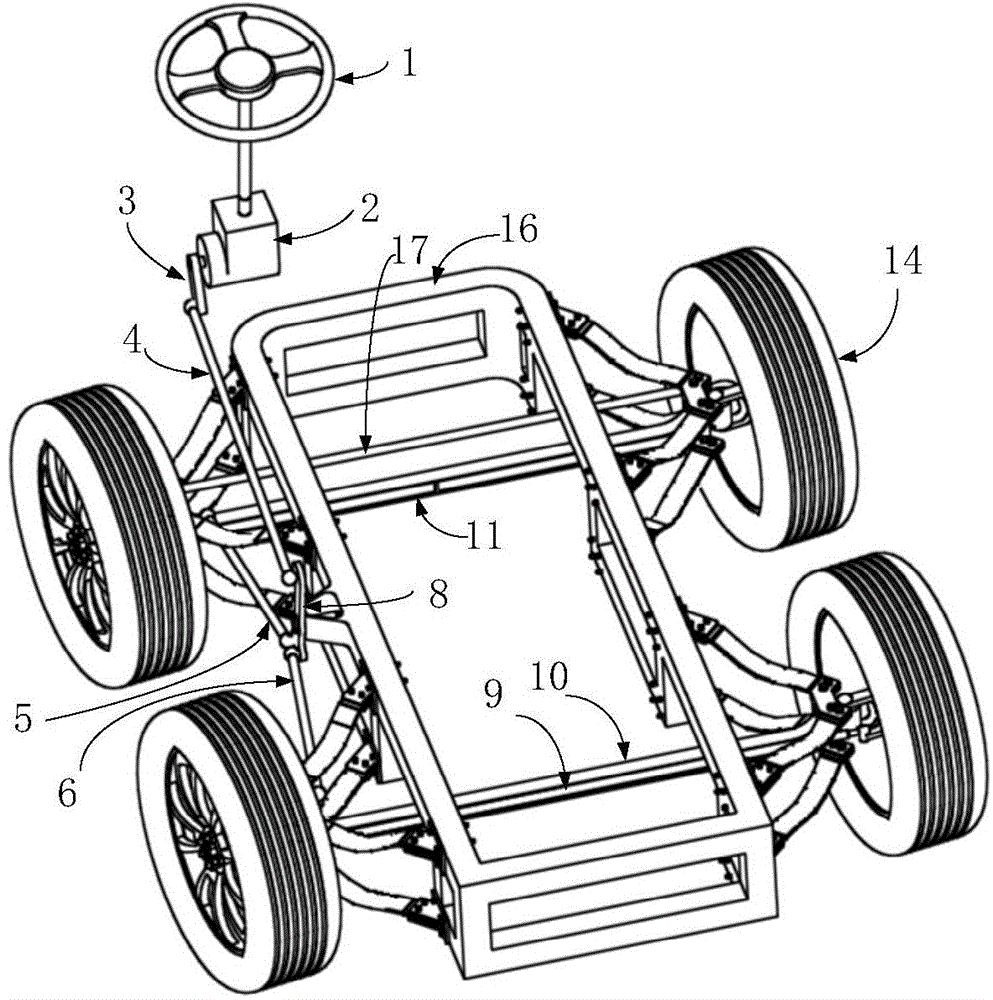

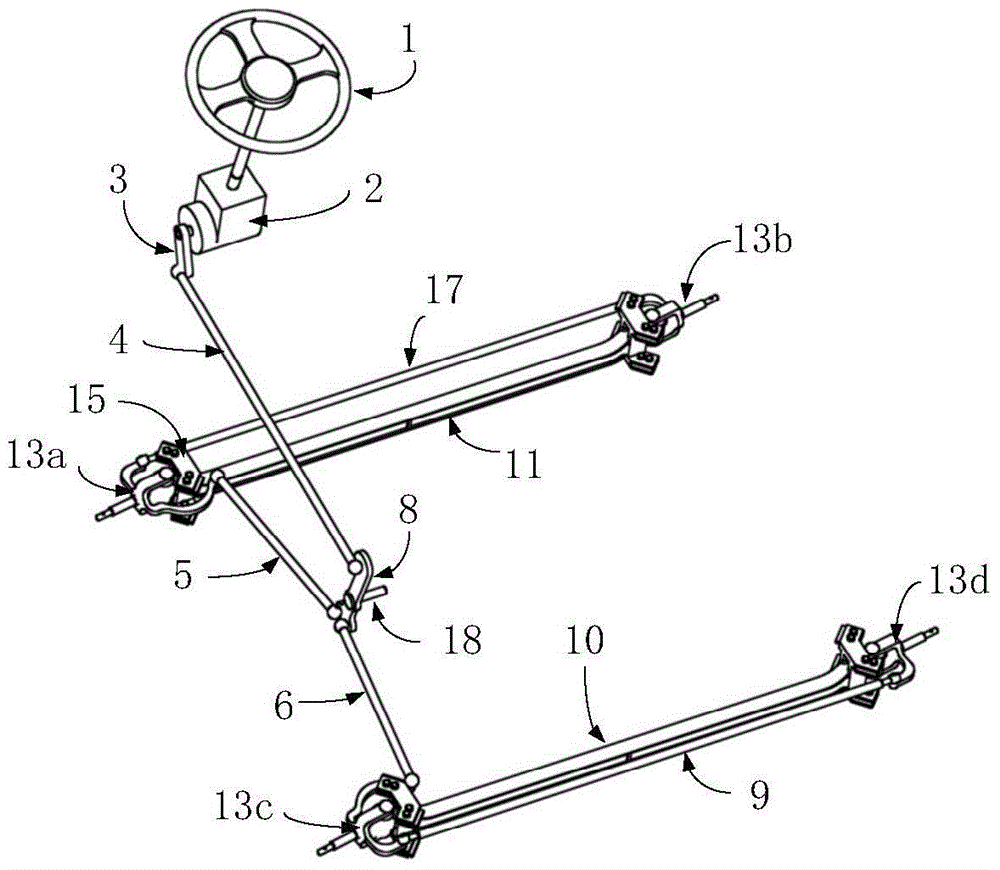

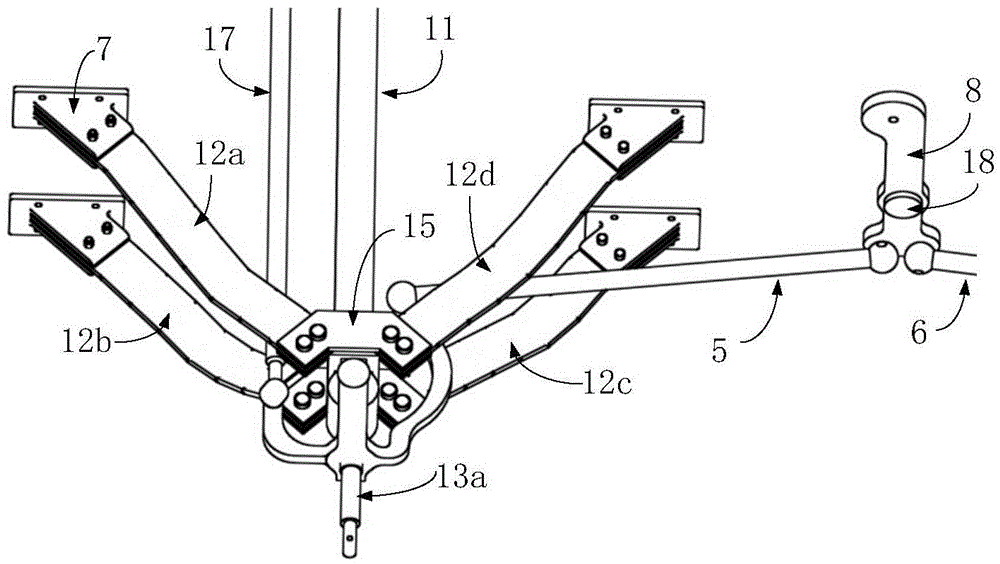

[0027] figure 1 It is a schematic diagram of the overall structure of the present invention, which includes a vehicle frame 16, a steering system, a first front axle and a second front axle; the steering system is made up of a steering wheel 1, a steering gear 2 and a steering linkage; the first The front axle includes leaf spring suspensions on both sides of the vehicle frame, the first integral axle 11, wheels 14 and the first trapezoidal steering mechanism; the second front axle includes oblique leaf spring suspensions on both sides of the vehicle frame, the second Two integral axles 10, wheels 14 and the second trapezoidal steering mechanism; the first trapezoidal steering mechanism includes the first front axle left steering knuckle 13a, the first front axle right steering knuckle 13b and the fifth connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com