Multi-connecting-rod independent suspension for drive axle of commercial vehicle

An independent suspension and drive axle technology, applied in the automotive field, can solve the problems of poor bearing capacity, inability to ensure suspension bearing capacity, easy deformation, etc., and achieve the effects of improving bearing capacity, ensuring vehicle comfort, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

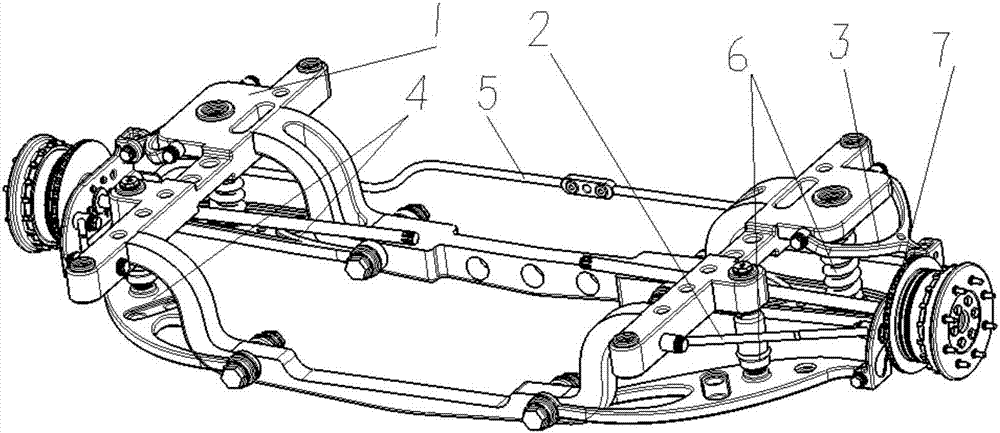

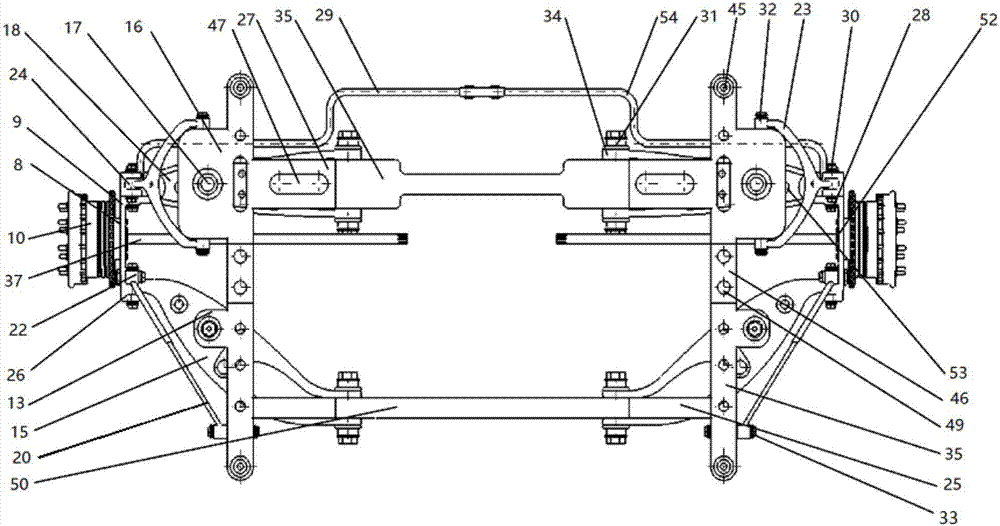

[0042] The specific implementation of the multi-link independent suspension for the commercial vehicle drive axle of the present invention will be described in further detail below with reference to the accompanying drawings, which will help those skilled in the art to understand the concept of the present invention and understand the technical principles, and help them implement.

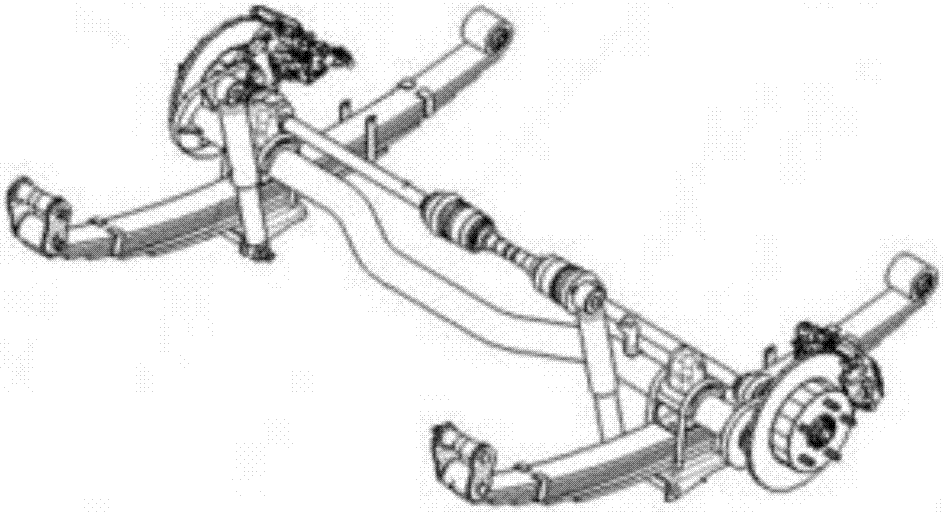

[0043] Such as Figure 2 to Figure 5 As shown, the multi-link independent suspension for a commercial vehicle drive axle described in the embodiment of the present invention includes a subframe assembly 1 for connecting with a frame longitudinal beam, an upper longitudinal tie rod assembly 2, an upper transverse Tie rod assembly 3 , lower cross tie rod assembly 4 , stabilizing tie rod assembly 5 , shock absorber spring assembly 6 and bearing block assembly 7 connected with wheel hub 10 .

[0044] The sub-frame assembly 1 mainly includes a sub-frame 35 with double longitudinal beams and double beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com