Rotor for pump and with offset main arc and split top

A splayed and rotor technology, which is applied to components of pumping devices for elastic fluids, rotary piston type/oscillating piston type pump components, pumps, etc., can solve the problem of large shape coefficient, center of gravity of rotor blades shifting to the peak, Unfavorable problems such as dynamic unbalance and vibration faults of the rotor system, achieving the effect of simple processing and improved shape coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

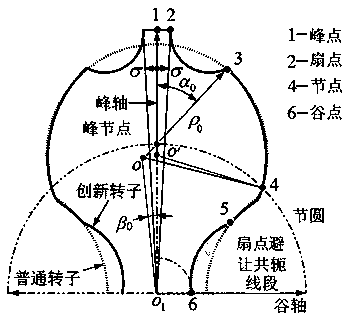

[0016] Example: Combination profile of offset main arc and splayed crown of 2-lobe rotor for pumps

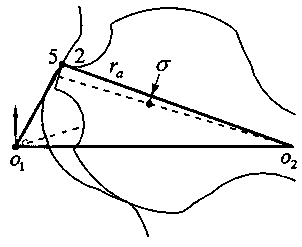

[0017] Such as figure 1 As shown, a Roots pump rotor with an offset main arc and a splayed top of the present invention is referred to as an innovative rotor; a common arc rotor is referred to as a traditional rotor, and its peak is the center of the circle. o' A single arc segment lying on the peak axis. The intersection point of the peak axis of the innovative rotor and the pitch circle is referred to as the peak node; the end point 2 of the fan arc is referred to as the fan point; the center angle of the concentric fan arc section of the peak Referred to as fan angle; point 1 is the peak point; point 6 is the valley point.

[0018] The semi-lobe theoretical profile of the innovative rotor of the present invention consists of a peak concentric fan arc section 12, a peak weight-reducing arc section 23, an offset main arc section 34, and a valley conjugate arc section 45 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com