Pump rotor with splayed top and involute combination profile

An involute and combined technology, applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve unfavorable rotor system dynamic unbalance vibration faults, rotor blade mass deviation at the peak, large maximum shape coefficient, etc. problems, to achieve the effect of improved shape factor, simplified processing, and low radial leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

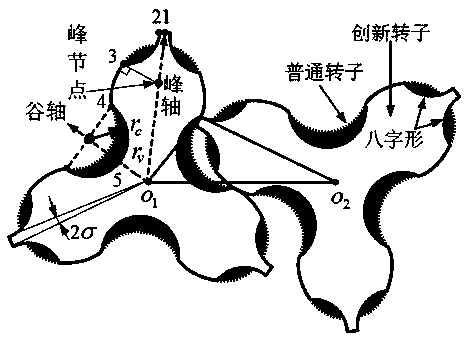

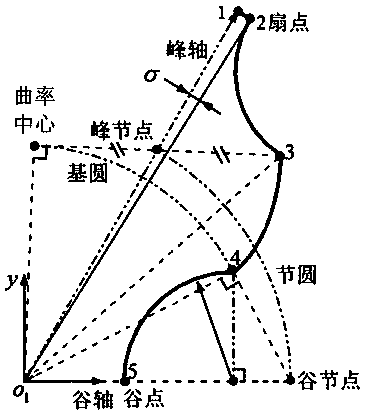

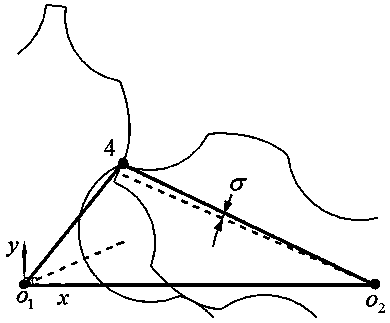

[0020] Such as Figure 1 to Figure 3 As shown, a pump rotor of the present invention with a combination of splayed crest and involute profile is referred to as an innovative rotor, and a common involute rotor is referred to as an ordinary rotor; where the intersection point of the peak axis and the pitch circle is referred to as the peak node ; The end point 2 of the fan arc is referred to as the fan point for short; the central angle of the concentric fan arc segment σ Referred to as the fan angle; point 1 is the peak point; point 5 is the valley point, the end point 3 of the involute arc is the starting point of the involute, the end point 4 of the involute arc is the end point of the involute, and the number of leaves of the rotor is N .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com