Device and design method for realizing rapid connection of frame body with different suspensions

A quick connection and suspension technology, which is applied in the automotive field, can solve the problems of long development cycle, heavy workload, and non-fixed installation position, and achieve the best rigidity performance, saving working time and workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

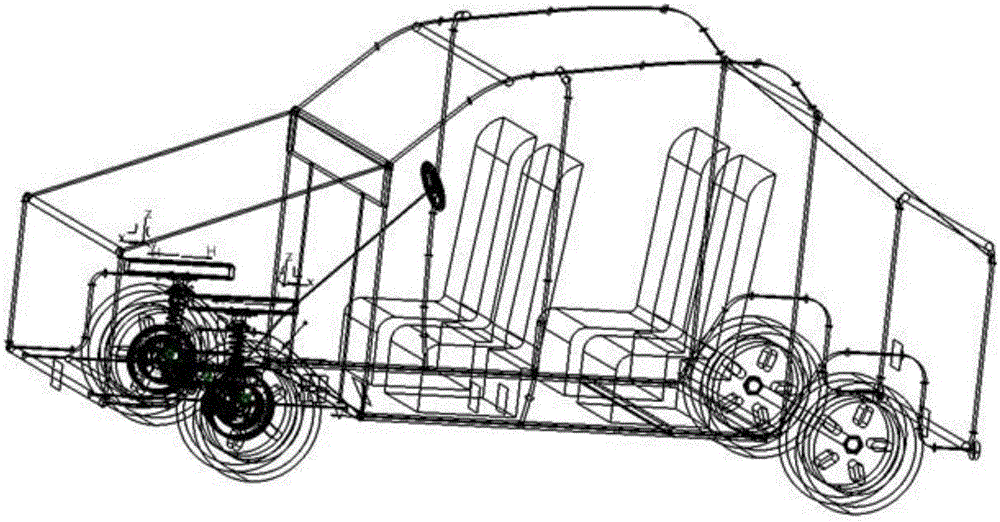

[0037] This instruction manual introduces the design method of the quick-change mechanism by taking an ordinary hatchback as an example, and the method involved can be applied to various vehicle types.

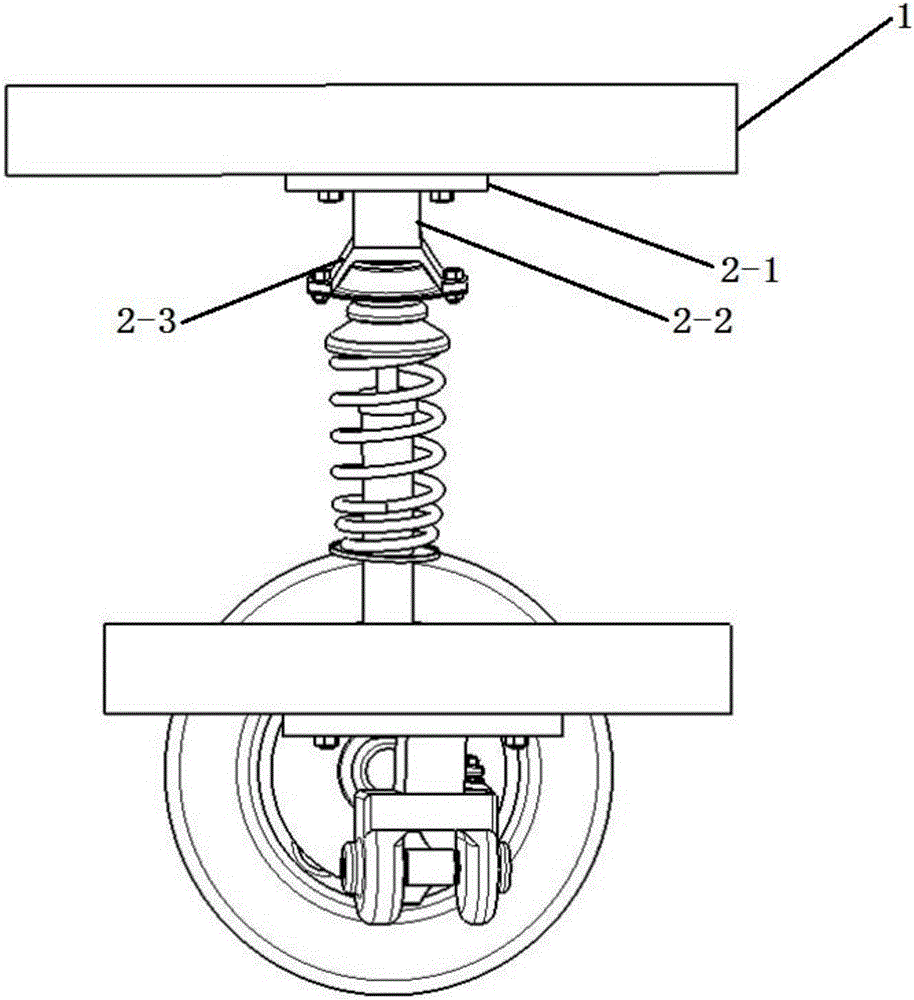

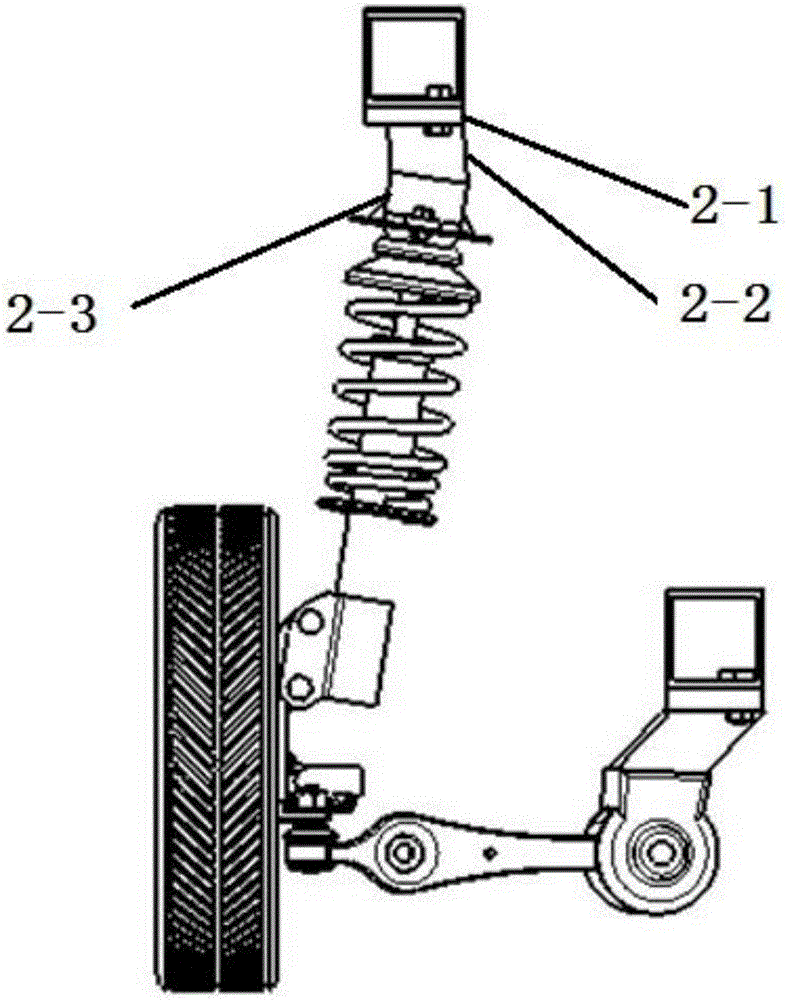

[0038] refer to figure 1 , figure 2 , a device for quickly connecting the vehicle body with the suspension, the device includes a mounting rod 1 and a base; wherein the mounting rod 1 is connected to the vehicle body; the base is connected by a mounting plate 2-1, a bracket 2-2 and The frame 2-3 is fixed as one; the bracket 2-2 is welded under the mounting plate 2-1; the connecting frame 2-3 is welded under the bracket 2-2; the mounting plate 2-1 It is fixed under the mounting rod 1 by bolts; the connecting frame 2-3 is connected with the automobile suspension.

[0039] The mounting plate 2-1 is a cuboid with a length of 200 mm, a width of 50 mm, and a height of 15 mm. The mounting plate 2-1 has two bolt holes with a diameter of 8 mm.

[0040] The installation rod 1 is a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com