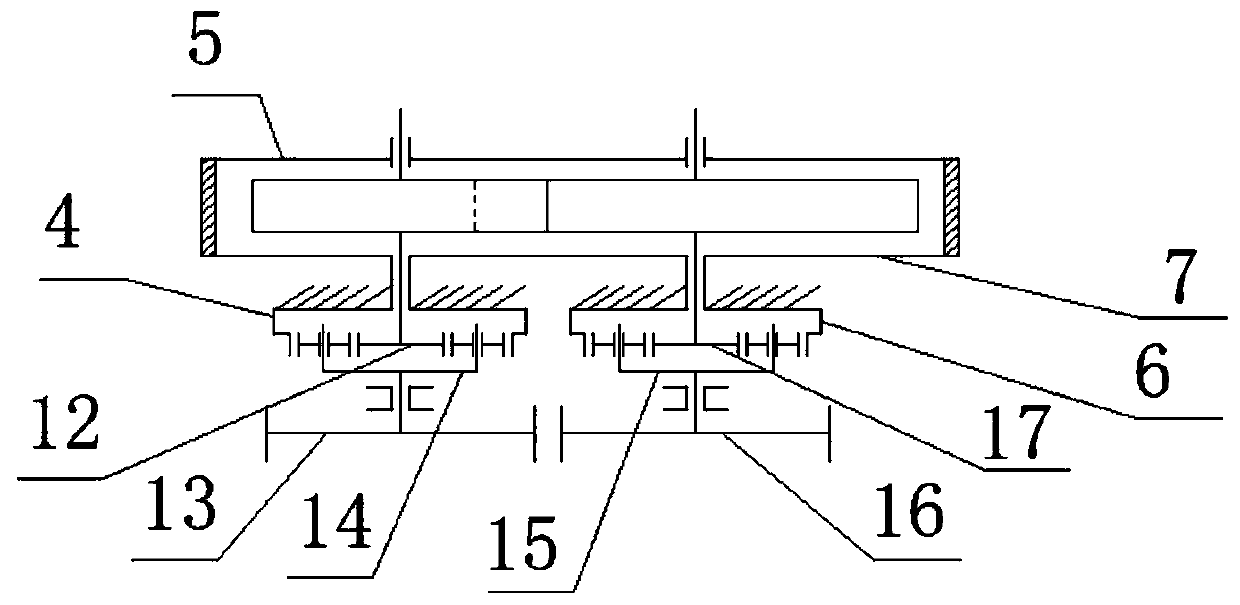

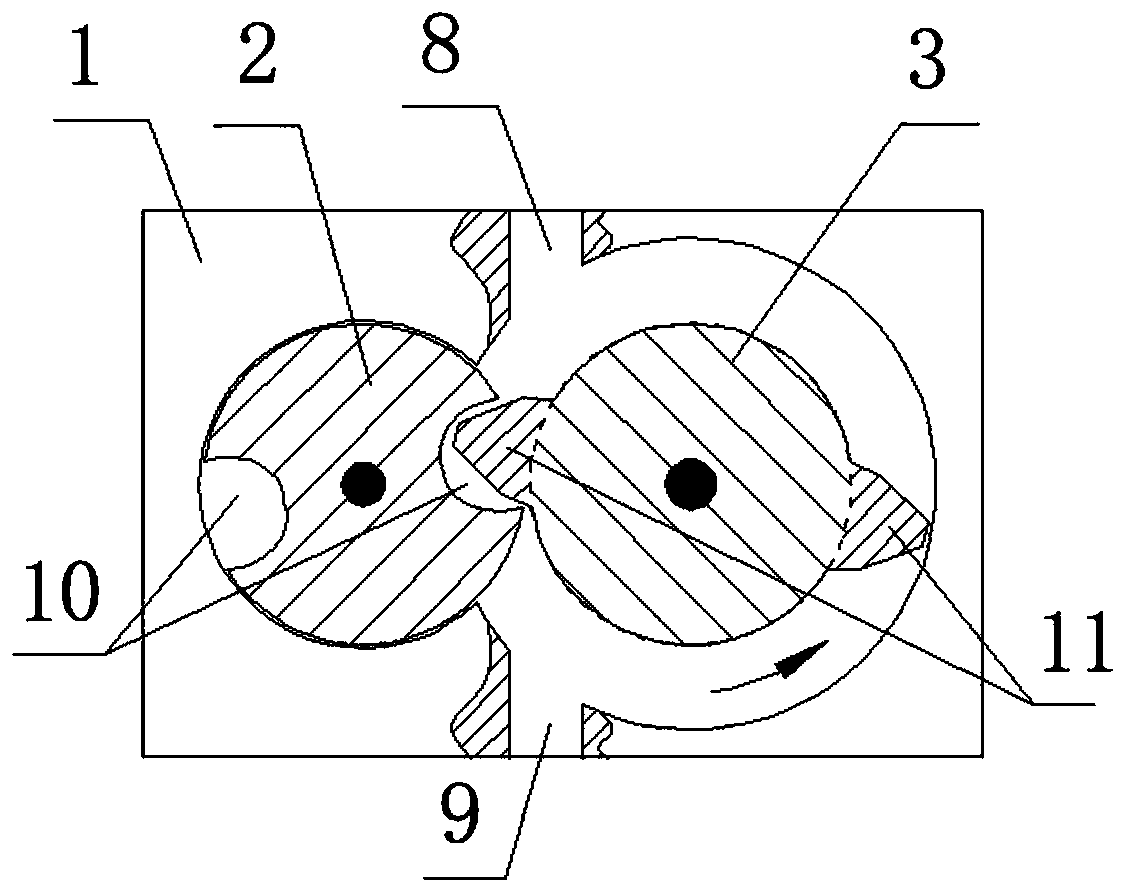

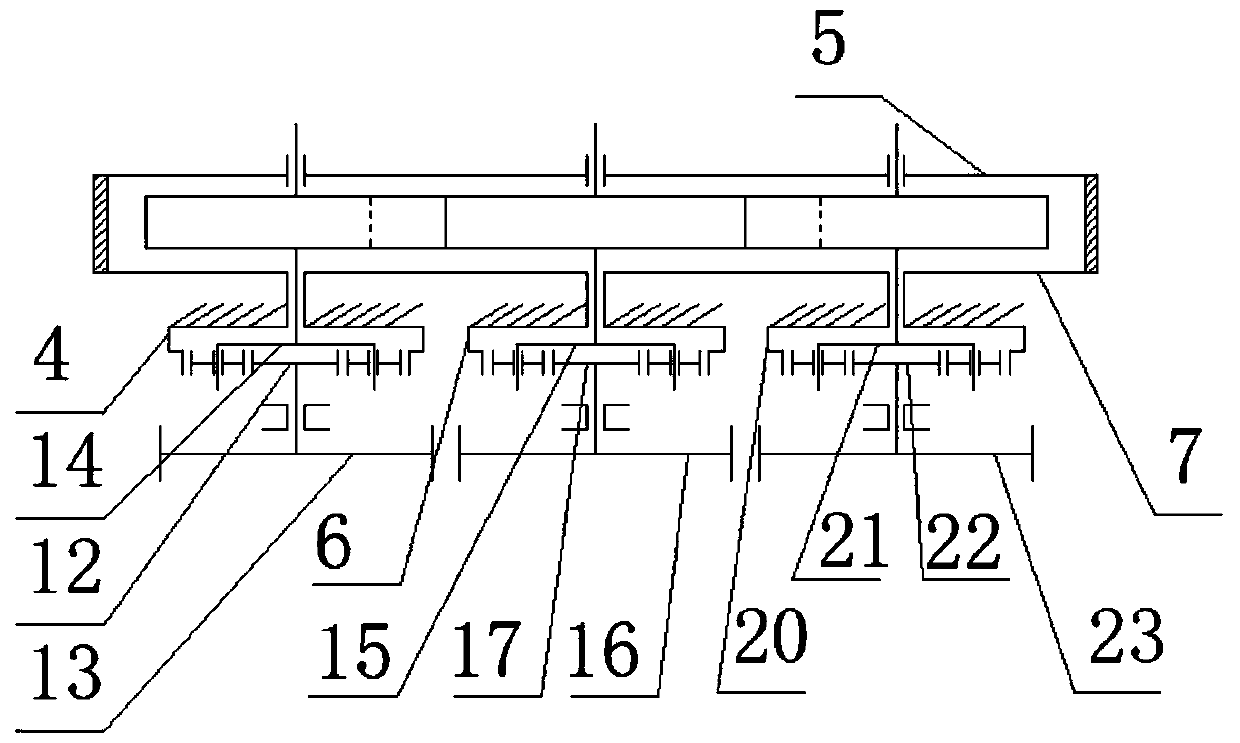

Circumference coupled planet synchronous rotating piston pump

A rotary piston pump, circular line technology, applied in rotary piston pumps, rotary piston machines, rotary piston engines, etc., can solve the problems of low cost, high production cost, gear wear, etc., and achieve the effect of improving life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Select the SU-04 piston pump, which is currently sold well in the market,

[0045] 2. Connect it to the control valve, drive it to rotate, and perform a load test on it, a seven-day full-power test. At this time, a small amount of wear occurs on the first day, and obvious wear occurs after seven days.

Embodiment 2

[0047] 1. Use the piston pump in Example 1,

[0048] 2. Connect it to the control valve, drive it to rotate clockwise, and perform a load test on it, a seven-day full-power test. At this time, there is no wear on the first day, and a small amount of wear occurs after seven days.

[0049] In summary, Embodiment 2 said that the device used has obviously improved its service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com