Air spring and plate spring composite suspension system

An air spring, leaf spring technology, applied in elastic suspension, suspension, interconnection system, etc., can solve the problems of limiting the installation height and working stroke of the air spring, reducing the roll performance of the suspension, and achieving good absorption of high frequency Vibration ability, smoothness improvement, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

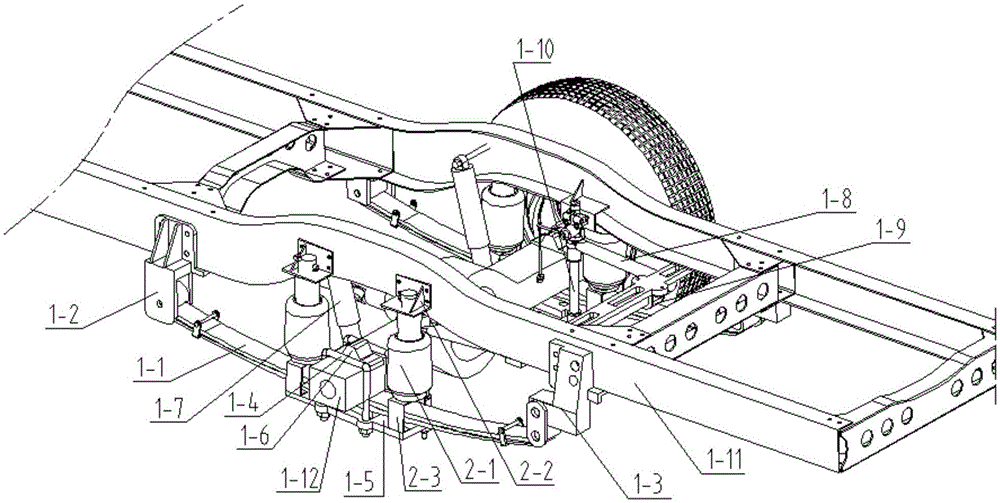

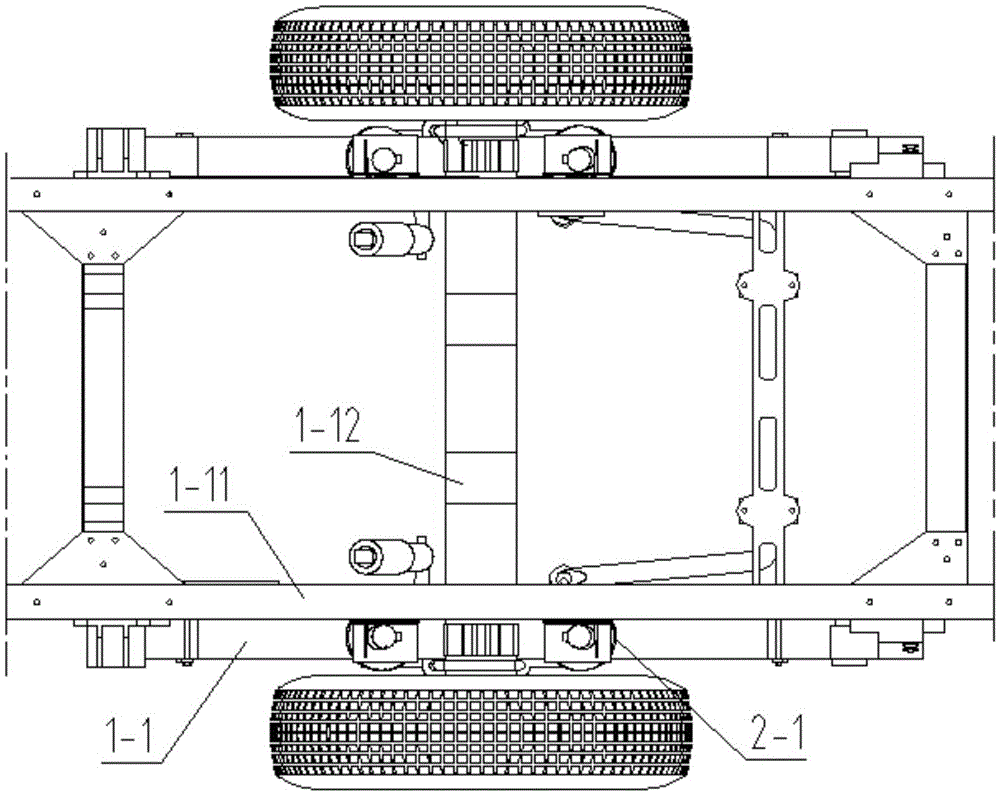

[0020] Further illustrate the specific content and working process of the present invention below in conjunction with accompanying drawing.

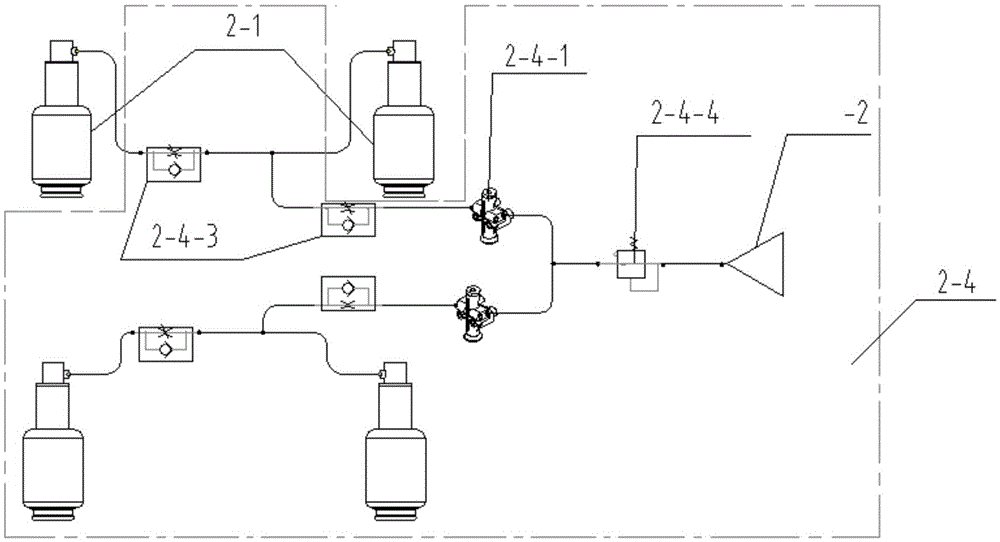

[0021] Such as figure 1 , 2 As shown: the present invention is a composite non-independent suspension system of an air spring and a leaf spring. The suspension system is symmetrically arranged on both sides of the frame 1-11. The suspension system includes a leaf spring 1-1, a front Lifting lug 1-2, leaf spring rear end coil ear 1-3, U-shaped bolt 1-4, leaf spring pressure plate 1-5, buffer block 1-6, shock absorber 1-7, lateral stabilizer bar 1-8, Stabilizer bar and frame mounting bracket 1-9, stabilizer bar pull rod 1-10, frame 1-11, axle 1-12, air spring 2-1, air spring upper mounting bracket 2-2, air spring lower mounting bracket 2-3 and an air spring height adjustment mechanism 2-4; the air spring 2-1 is installed on the outside of the vehicle frame 1-11, between the vehicle frame 1-11 and the leaf spring 1-1.

[0022] Wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com