Whole steel wire radial tyre cold-patch rubber sheet and special glue for repairing tyre using said rubber sheet

A radial tire and steel cord technology, applied in tires, applications, adhesives, etc., can solve the problems of not applicable to all-steel radial tires, unable to carry large trucks, unable to block air and moisture, etc., to save repair time , Reduce the repair cost, the effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] At room temperature, mix 1Kg of natural rubber with carbon black and 3Kg of gasoline, add 0.3Kg of lexinone and 0.15Kg of epoxy resin after 24 hours to form a special rubber for cold patching of steel radial tires.

Embodiment 2

[0025] At room temperature, mix 1Kg of natural rubber with carbon black and 4Kg of gasoline, add 0.55Kg of sodium lexiconate and 0.3Kg of epoxy resin after 24 hours to form a special rubber for cold patching of steel radial tires.

Embodiment 3

[0027] Mix 1Kg of natural rubber with carbon black and 3.7Kg of gasoline at room temperature, add 0.47Kg of sodium lexiconate and 0.25Kg of epoxy resin after 24 hours to form a special rubber for cold patching of all-steel radial tires.

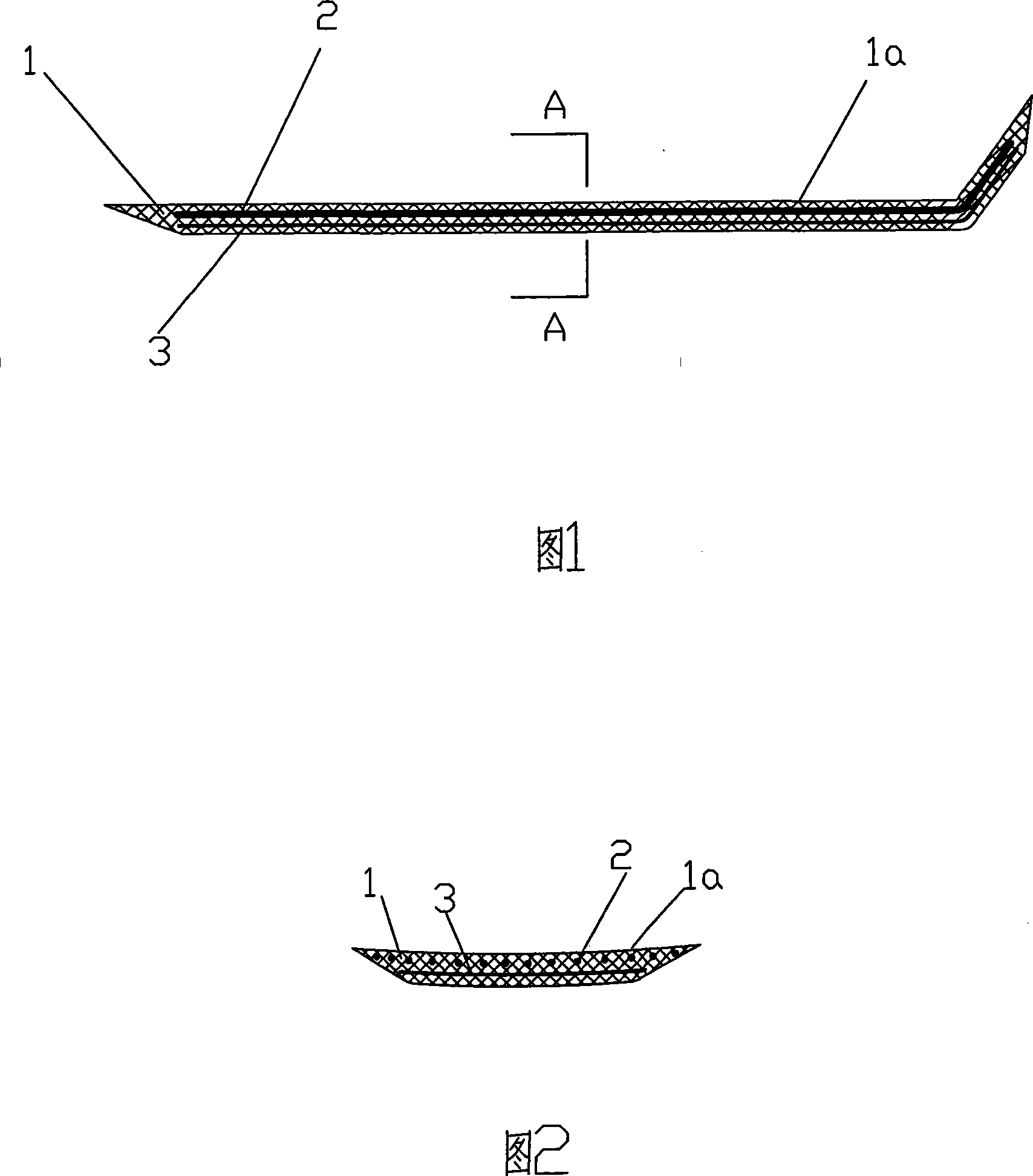

[0028] Utilize the cold repair film and special glue of the present invention to repair the tire, apply the special glue on the adhesive surface 1a, the glue reacts with the adhesive surface 1a, paste the film coated with the special glue on the adhesive surface 1a on the tire wound surface, and the process is completed Tire repair work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com