Repairing method of photoresist pattern

A photoresist pattern and photoresist technology, applied to the photoplate making process of the pattern surface, the original for photomechanical processing, optics, etc., can solve the problems of increasing production cost, low production efficiency, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention discloses a method for repairing a photoresist pattern. In order to make the description of the present invention more detailed and complete, reference may be made to the following description in conjunction with the accompanying drawings Figure 1A to Figure 6B .

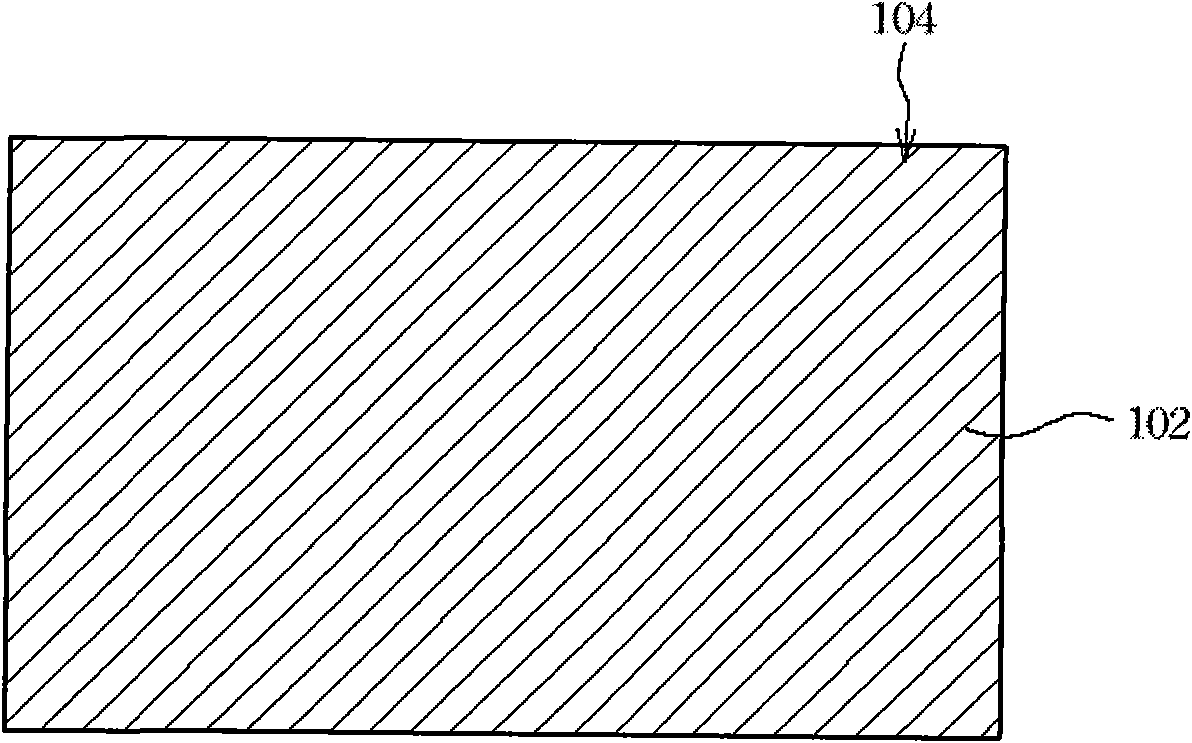

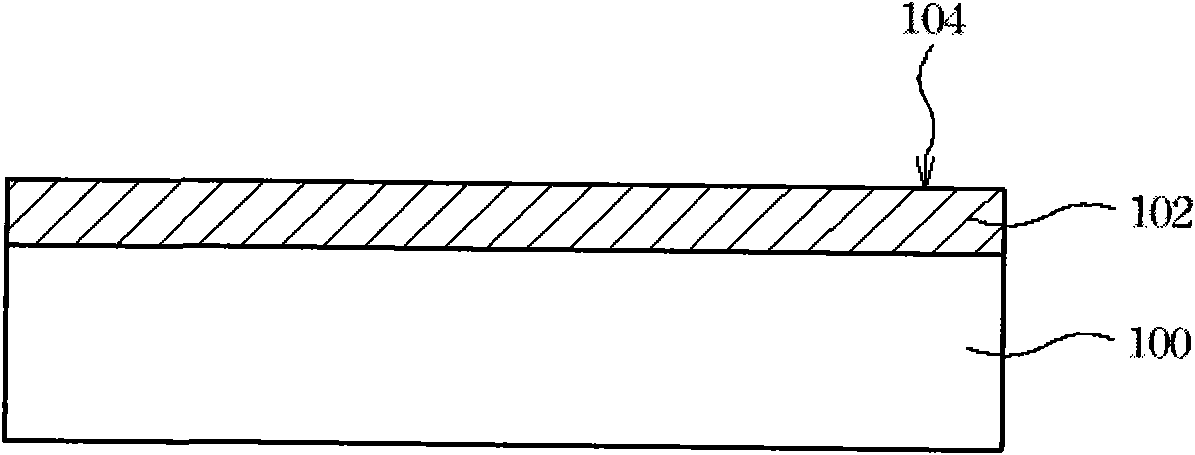

[0021] Please refer to Figure 1A to Figure 5B , which shows a process diagram of a method for repairing a photoresist pattern according to a preferred embodiment of the present invention, wherein Figure 1A , Figure 2A , Figure 3A , Figure 4A and Figure 5A for the top view, and Figure 1B , Figure 2B , Figure 3B , Figure 4B and Figure 5B respectively Figure 1A , Figure 2A , Figure 3A , Figure 4A and Figure 5A sectional view. In an exemplary embodiment, when performing the photoresist pattern repairing process, a substrate 100 is provided first, wherein the substrate 100 preferably has a flat surface for device structures to be disposed thereon. The substrate 100 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com