High-adhesive-force and low-temperature refinishing paint composition and preparation method thereof

A technology of high adhesion and repair paint, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of poor adhesion, affecting the appearance, and consuming a lot of manpower and material resources, so as to shorten the repair process time and avoid insufficient grinding , The effect of saving repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

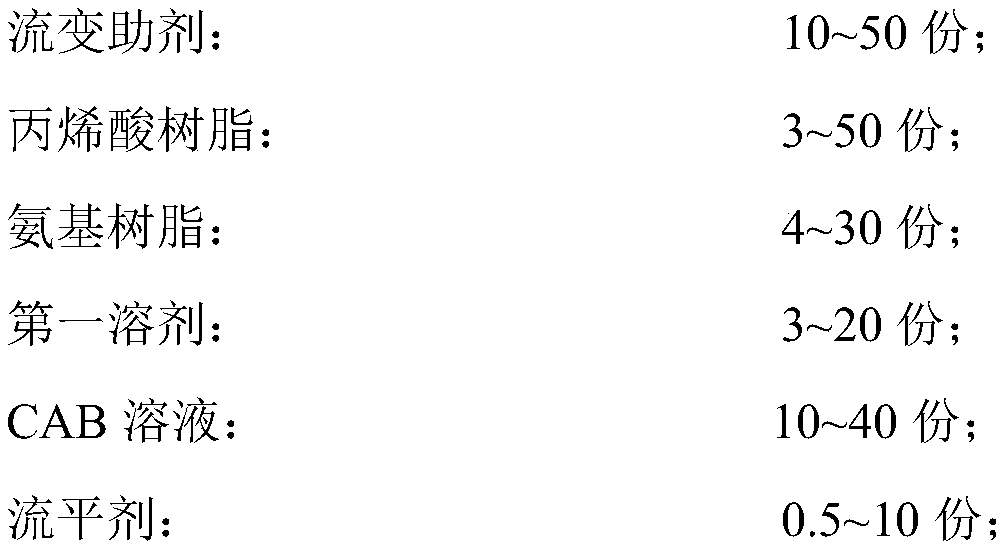

Method used

Image

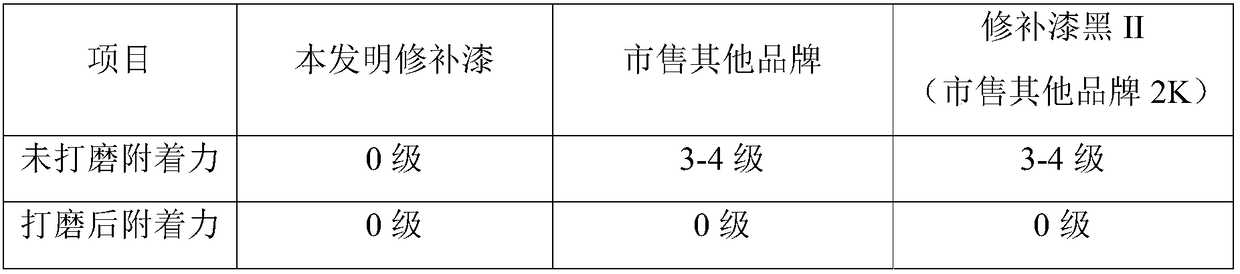

Examples

Embodiment 1-4

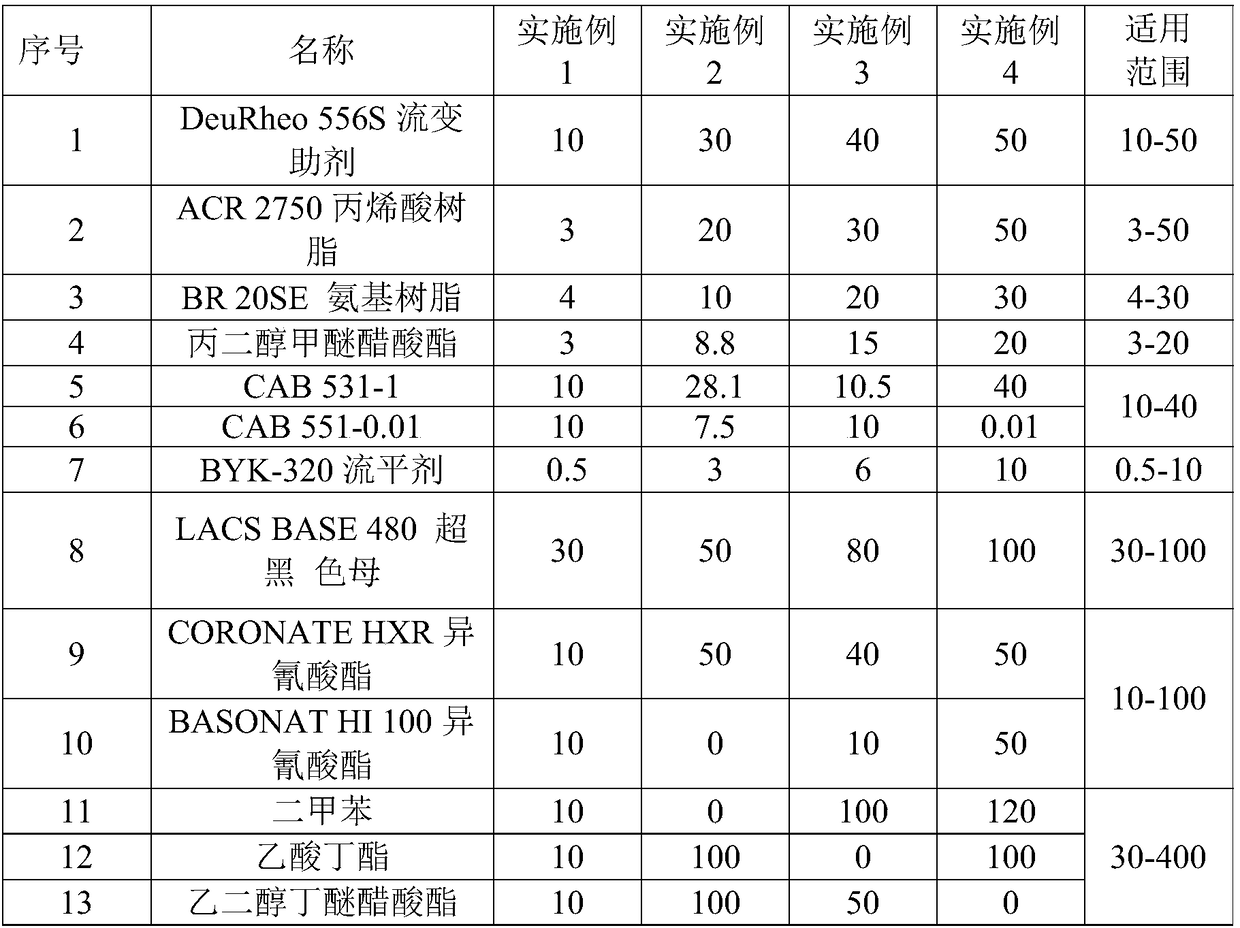

[0052] The components (parts by weight) of a kind of black single-color low-temperature repair paint composition provided by the present embodiment 1-4 are respectively shown in table 1, and different ratios have been tested according to the present invention in the scope of application in the formula:

[0053] Table 1

[0054]

[0055] The preparation method of the black single-color low-temperature repair paint composition of present embodiment 1~4, comprises the following steps:

[0056] Prepare curing components:

[0057] A. Take a suitable container A, put in 1, 2, 3, start stirring (600-800rpm), stir for 30 minutes; disperse evenly until the confirmed fineness is ≤20μm;

[0058] B. Under stirring (600-800rpm), add 4, 5, 6, 7 in turn and stir (600-1000rpm) for 30 minutes;

[0059] C. Add 8, adjust the color to be suitable, and release the package to obtain the curing component;

[0060] Prepare dilution components:

[0061] D. Take another suitable container B, put...

Embodiment 5~8

[0081] The components (parts by weight) of a kind of silver-gray metal low-temperature repair paint composition provided by the present embodiment 5 to 8 are shown in Table 4:

[0082] Table 4

[0083]

[0084] The preparation method of the silver-gray metal low-temperature repair paint composition of the present embodiment may further comprise the steps:

[0085] Prepare curing components:

[0086] A. Take a suitable container A, put in 1, 2, 3, start stirring (600-800rpm), and stir for 30 minutes; evenly disperse until the confirmed fineness is ≤20μm,

[0087] B. Under stirring (600-800rpm), add 4, 5, and 6 in turn and stir (600-1000rpm) for 30 minutes;

[0088] C. Add 11 and 12, use 13 to adjust the color to a suitable value, and release the package to obtain the curing component;

[0089] Prepare dilution components:

[0090] D. Take another suitable container B, put 9 and 10 into it, start stirring (400-600rpm), stir for 30 minutes, add 7 and 8 in turn under stirri...

Embodiment 9~12

[0104] The components (parts by weight) of a kind of red pearlescent low temperature repair paint composition provided by the present embodiment 9~12 are respectively as shown in table 6:

[0105] Table 6

[0106]

[0107] The preparation method of the red pearlescent low temperature repair paint composition of the present embodiment may further comprise the steps:

[0108] Prepare curing components:

[0109] A. Take a suitable container A, put in 1, 2, 3, start stirring (600-800rpm), and stir for 30 minutes; evenly disperse until the confirmed fineness is ≤20μm,

[0110] B. Under stirring (600-800rpm), add 4, 5, and 6 in turn and stir (600-1000rpm) for 30 minutes;

[0111] C. Add 13, use 14, 15, 16, and 12 to adjust the color to a suitable value, and release the package to obtain the curing component;

[0112] Prepare the dilution components:

[0113] D. Take another suitable container B, put in 9, 10, and 11, start stirring (400-600rpm), stir for 30 minutes, add 7, 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com