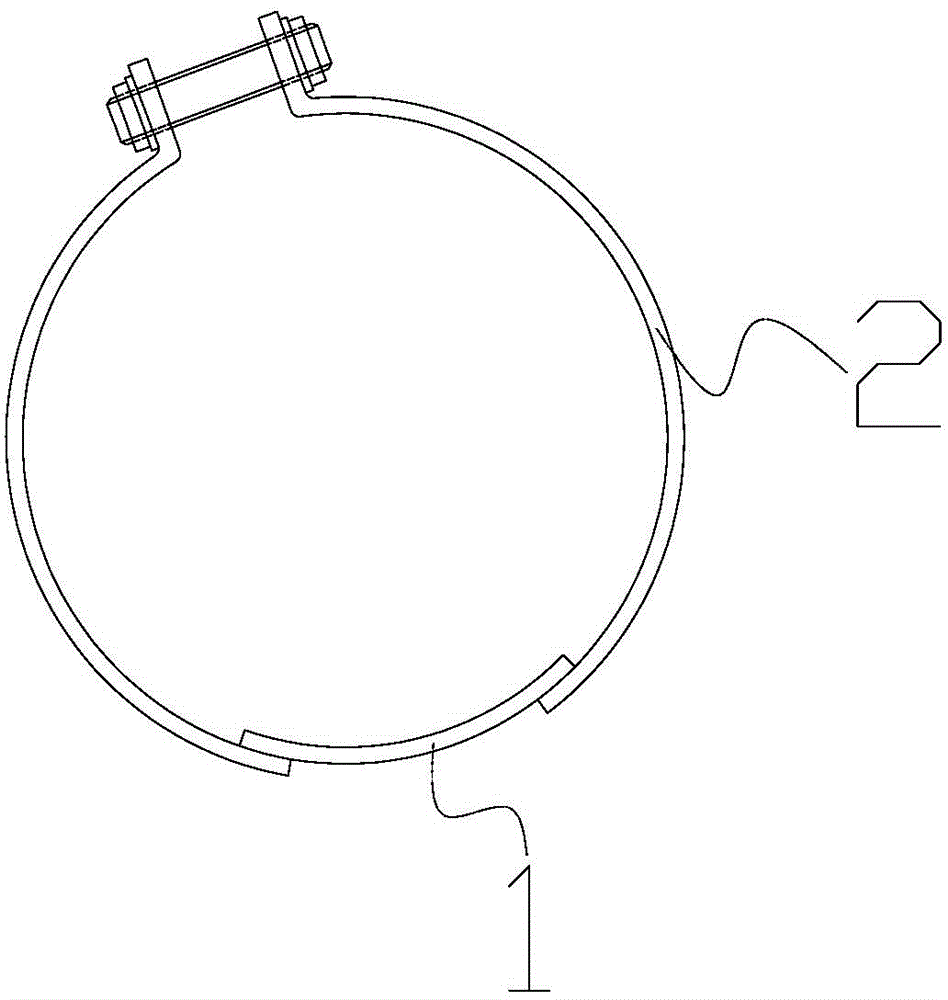

Ring wrapping leakage treatment method of coke oven bridge pipe

A bridge tube and coke oven technology, which is applied in coke ovens, coke oven heating, coke oven parts, etc., can solve the problems of high implementation cost, heavy workload, and shortened service life of bridge tubes, so as to reduce construction difficulty, The effect of increasing the service life and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

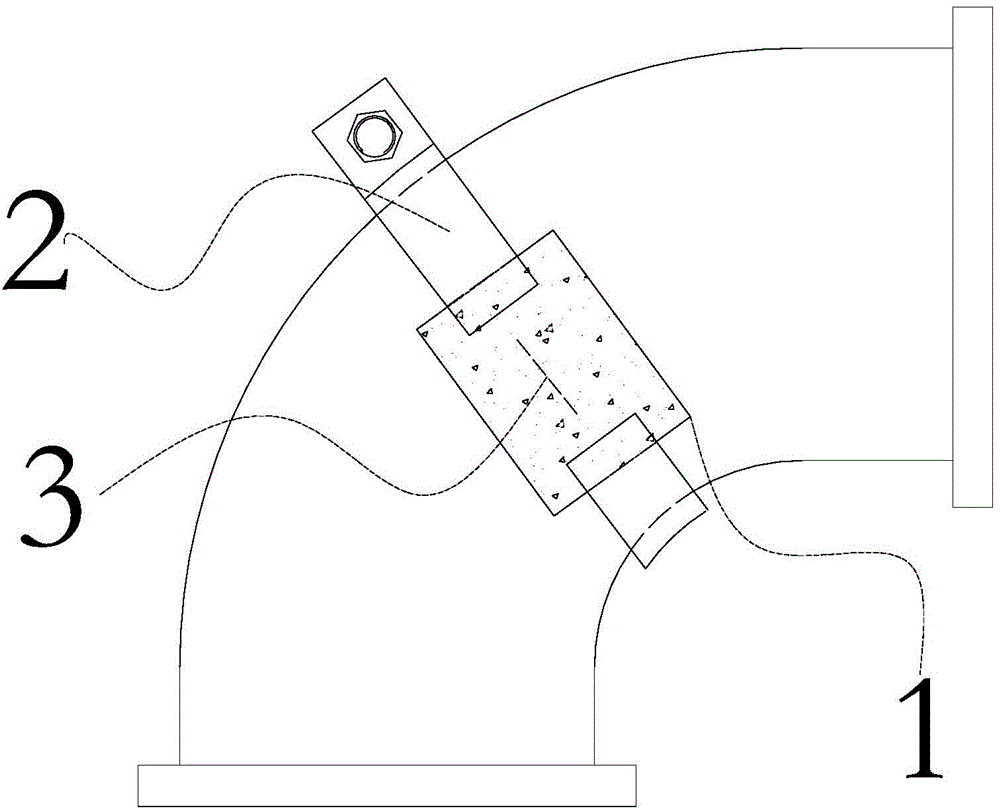

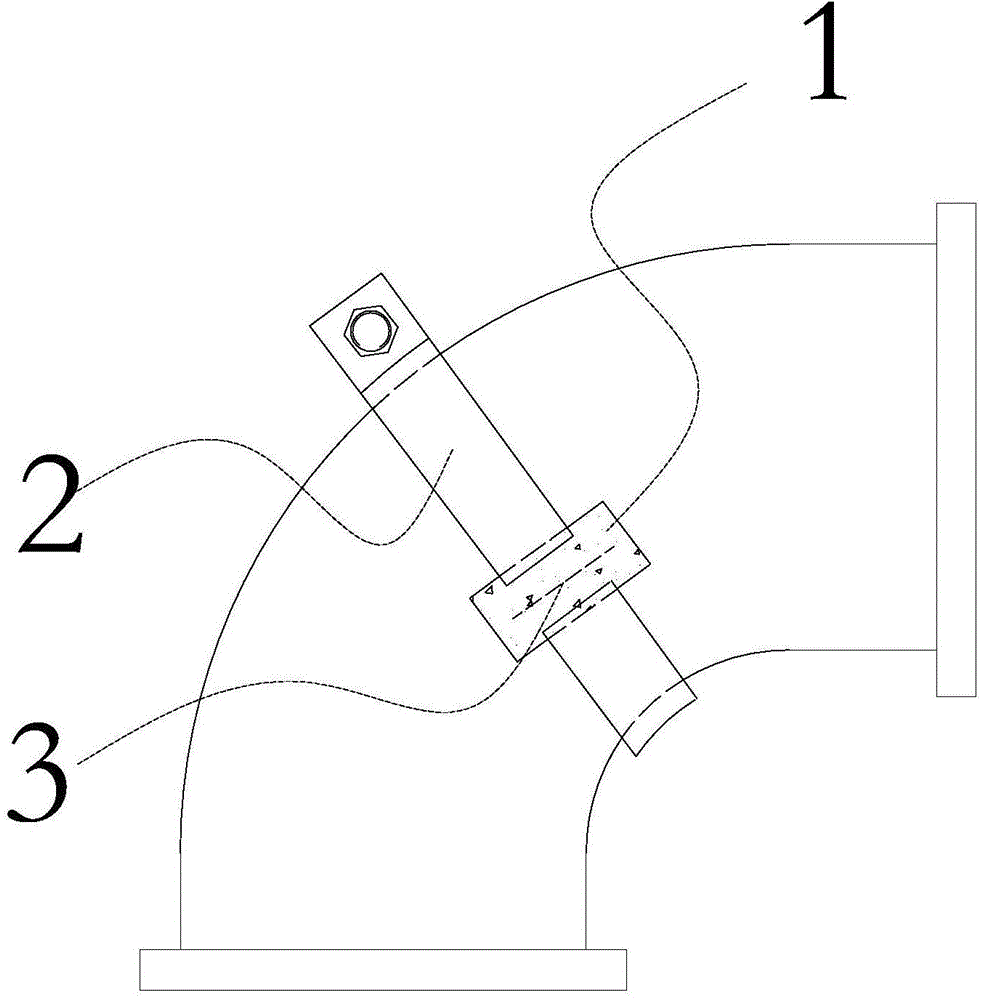

Examples

Embodiment 1 、 and 10%、35%、55%,1 and 2.8。 Embodiment 2 、 and 12.5%、37.5%、50%,1 and 3.5。 Embodiment 3

[0038] In step D, the mass proportions of the clay fire mud, high temperature cement and water are respectively: 10%-15%, 35%-40% and 45%-55%. The proper ratio of clay fire mud, high temperature cement and water can ensure the bonding strength of the adhesive. Too much moisture content, the adhesive fluidity is large, it is not easy to spread evenly, and the thickness of the application can not be guaranteed; the moisture content is too low , The adhesive solidifies quickly, and workers are required to press the sheath on the bridge pipe in a short period of time, which requires less debugging time and affects the bonding effect. Example 1: The mass proportions of clay fire mud, high-temperature cement and water are 10%, 35%, and 55%, respectively, and the effective bonding time between the metal pressure plate 1 and the bridge pipe is about 2.8 years. Embodiment 2: The mass proportions of clay fire mud, high-temperature cement and water are 12.5%, 37.5%, and 50% respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com