Patents

Literature

110results about How to "Implement patching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

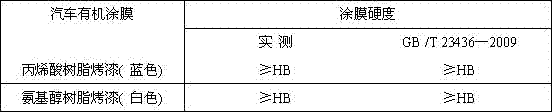

Anhydrous car washing liquid

ActiveCN104974859AImprove conductivityPotential window widthInorganic/elemental detergent compounding agentsCationic surface-active compoundsEmulsionActive agent

The invention belongs to the field of automobile surface washing, and relates to an anhydrous car washing liquid. The washing liquid is mainly composed of the following raw materials in parts by weight: 10 to 35 parts of paint film protective agent, 3 to 15 parts of luster-enhancing / lubricating conditioning agent, 2 to 18 parts of ionic liquid, 5 to 32 parts of surfactant, 4 to 16 parts of auxiliary surfactant, 0.1 to 5 parts of scratch filler, 0 to 10 parts of deionized water, and 0.01 to 0.3 part of essence. The selected ionic liquid and surfactant can generate a synergetic effect, under the help of a co-emulsifier, a thermally-stable micro-emulsion system can be formed, the system is stable, the dirt removing performance is greatly improved, and the organic attachment such as bird manure can be easily removed by the provided washing liquid.

Owner:陈士友

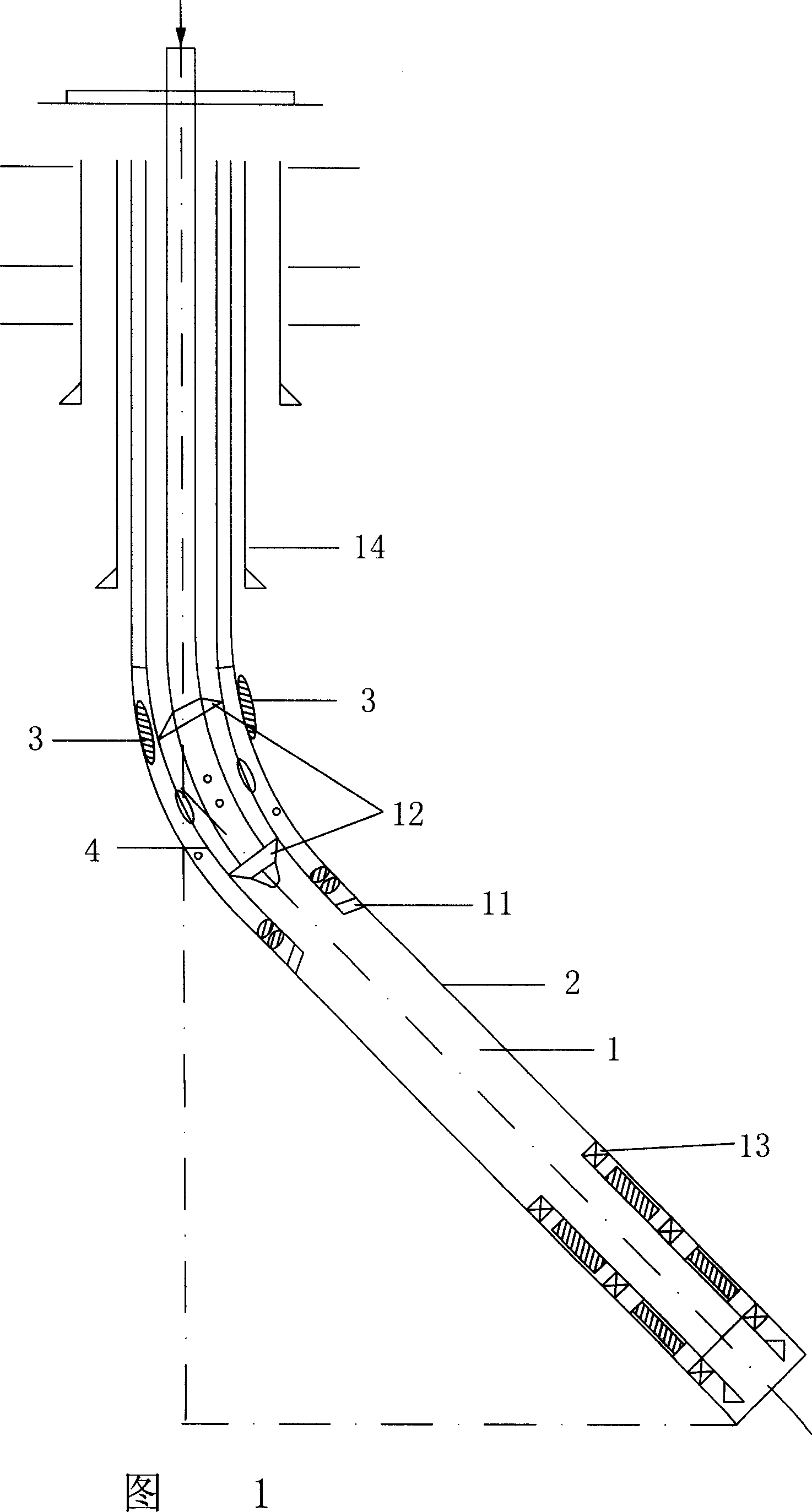

Method and device for repairing oil/gas drilling bushing

The invention relates to a method for repairing drill sleeve, and a relative device, wherein it first complete the well via normal 9-5 / 8 sleeve anti-sand method, then repairs the producing sleeve that damaged; in the repair, it first inserts the repair tubes formed by connected 7 sleeves into the 9-5 / 8 producing sleeve to aim the cement section to the damaged part of said producing sleeve; then pours cement via 5 pour bowl into the cement section 4; and uses the through hole at the section to pour cement into the annular space between the repair tubes and the producing sleeve; and uses the cement umbrella at the cement section to support upper cement when the well is closed, to repair the damaged part when the cement is solidified. The invention can reduce cost and time.

Owner:CHINA NAT OFFSHORE OIL CORP +1

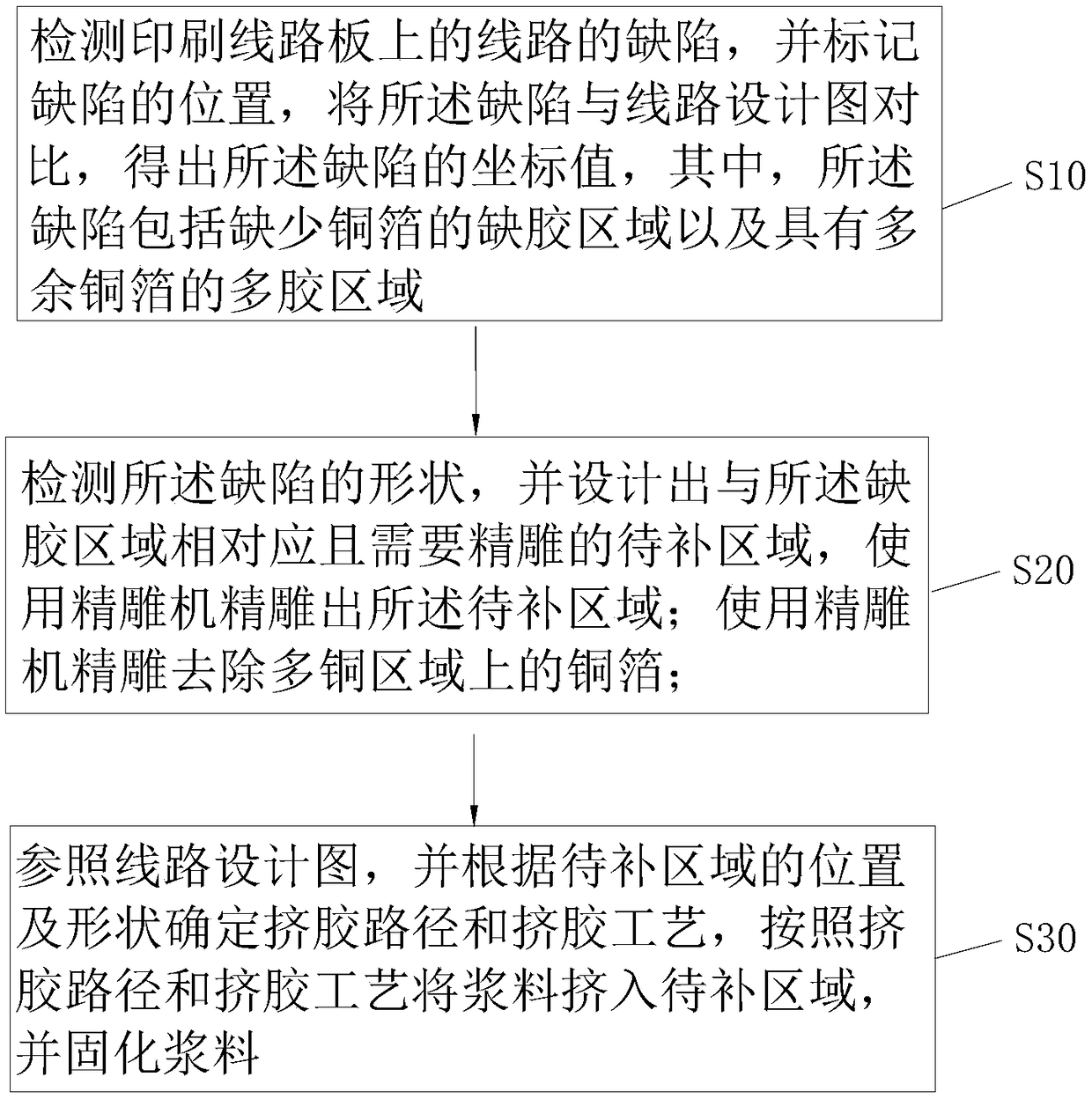

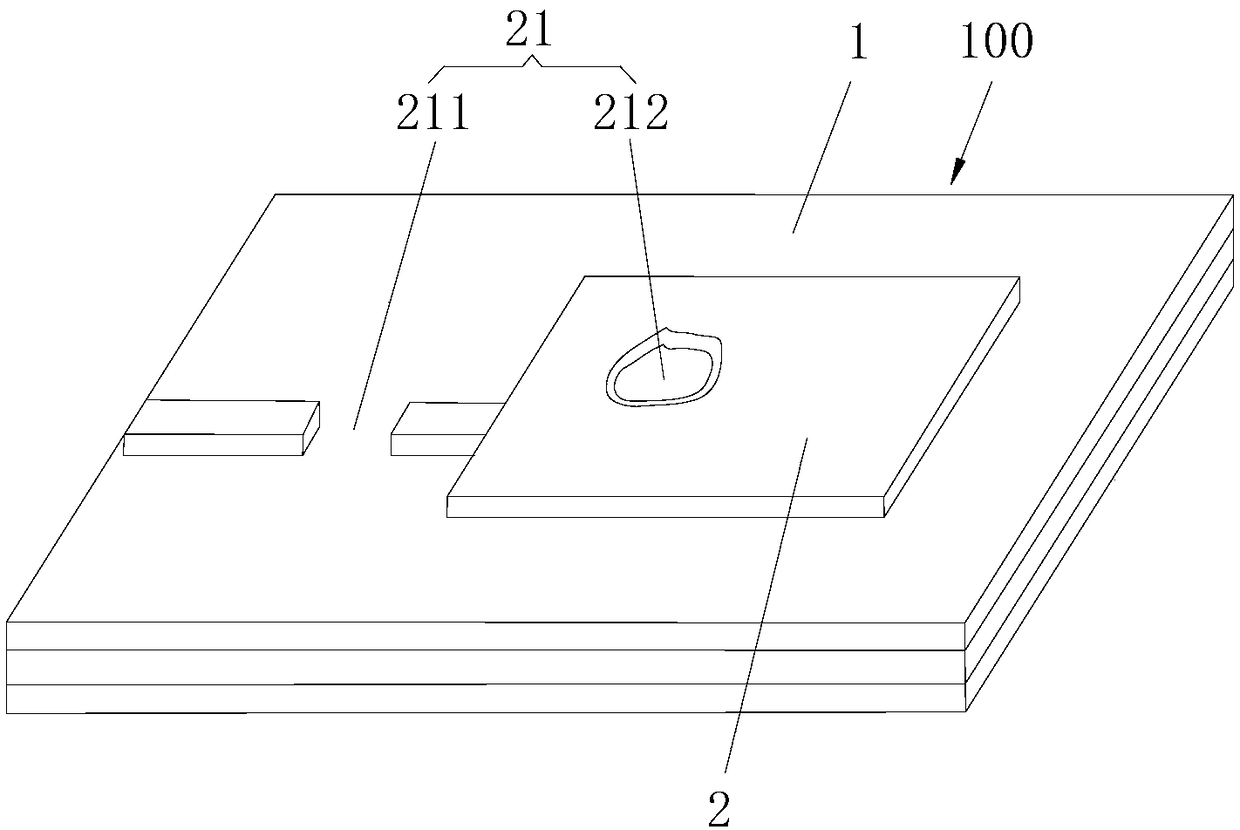

Circuit repairing method for printed circuit board

ActiveCN108848620AImprove production yieldReduce manufacturing costPrinted circuits repair/correctingCopper foilEngineering

The invention provides a circuit repairing method used for a printed circuit board, comprising the following steps: firstly detecting a circuit on the printed circuit board, marking a position of a defect on the circuit, comparing the defect with a circuit design drawing, and obtaining coordinate values of the defect; then detecting a shape of the defect, designing and carving a to-be-repaired region according to the shape of the defect, and carving and removing a copper foil in a copper-rich region by using a carving machine; and finally referring to the circuit design drawing, determining aglue extrusion path and a glue extrusion technology according to the position and shape of the to-be-repaired region, extruding slurry into the to-be-repaired region according to the glue extrusion path and the glue extrusion technology, and solidifying the slurry. The provided circuit repairing method used for the printed circuit board has the advantages that the position and shape of the defectare detected, the copper-rich region and a copper-deficient region are carved, a short circuit defect is eliminated, then the to-be-repaired region is filled by using the slurry, repairing on the defects such as circuit breakage and a pit is realized, and production yield of the printed circuit board is improved.

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

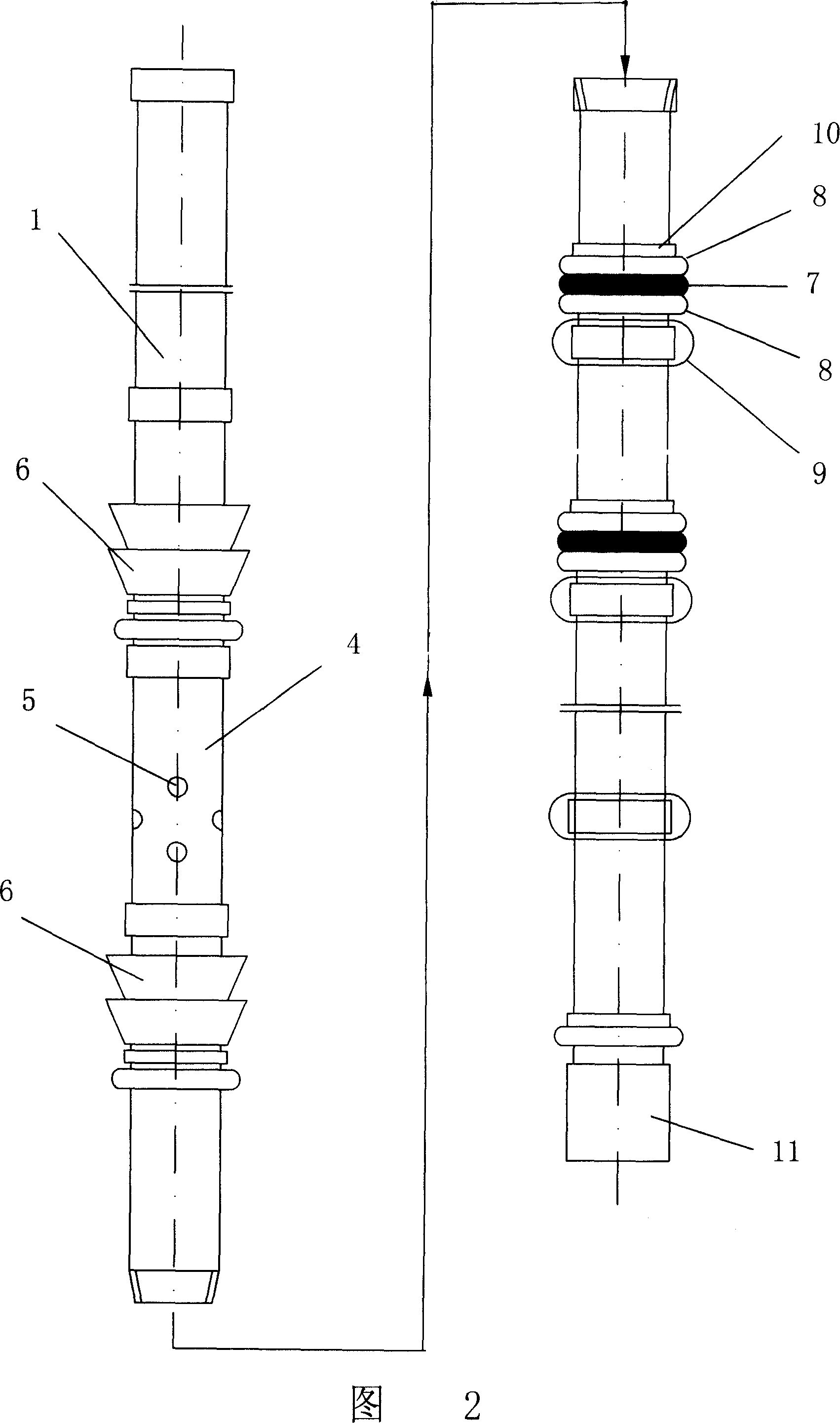

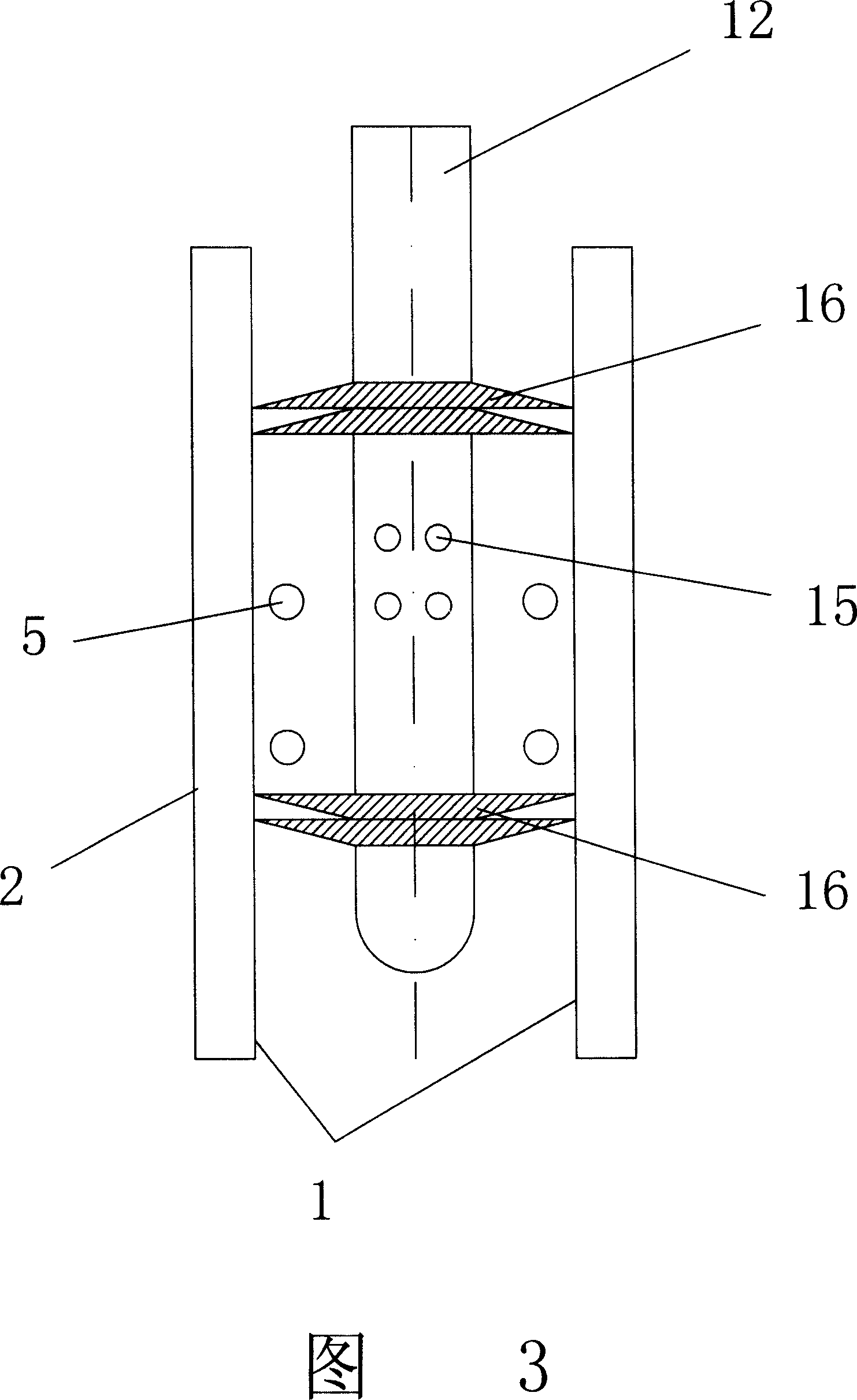

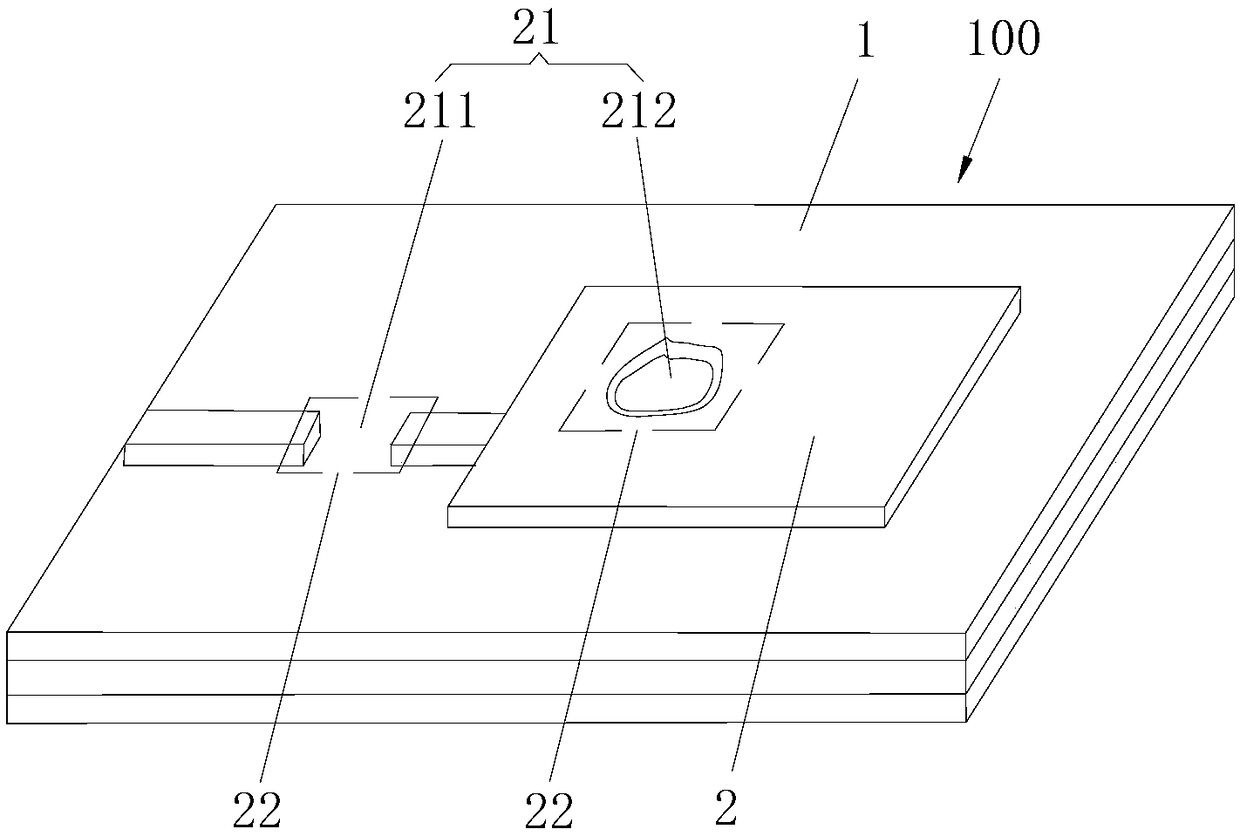

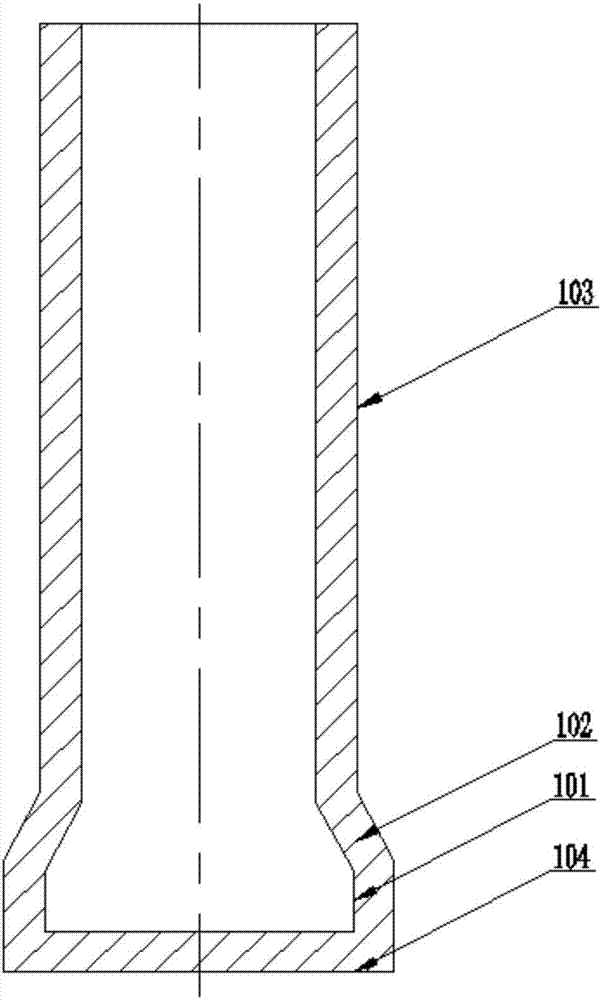

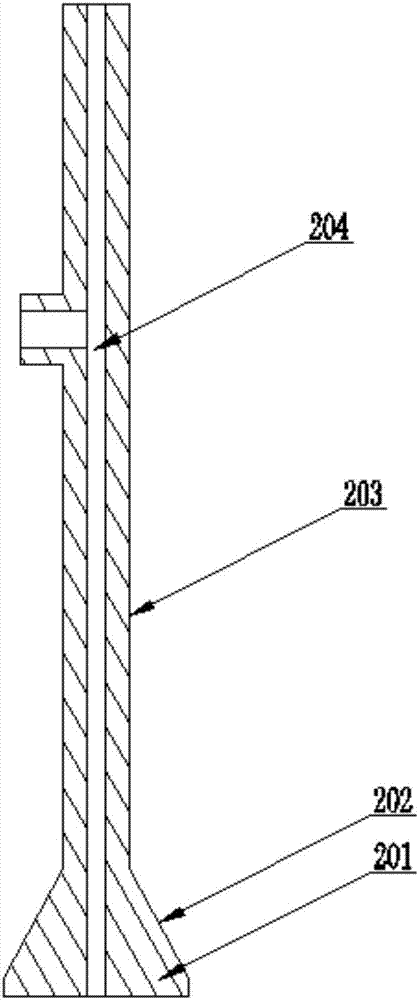

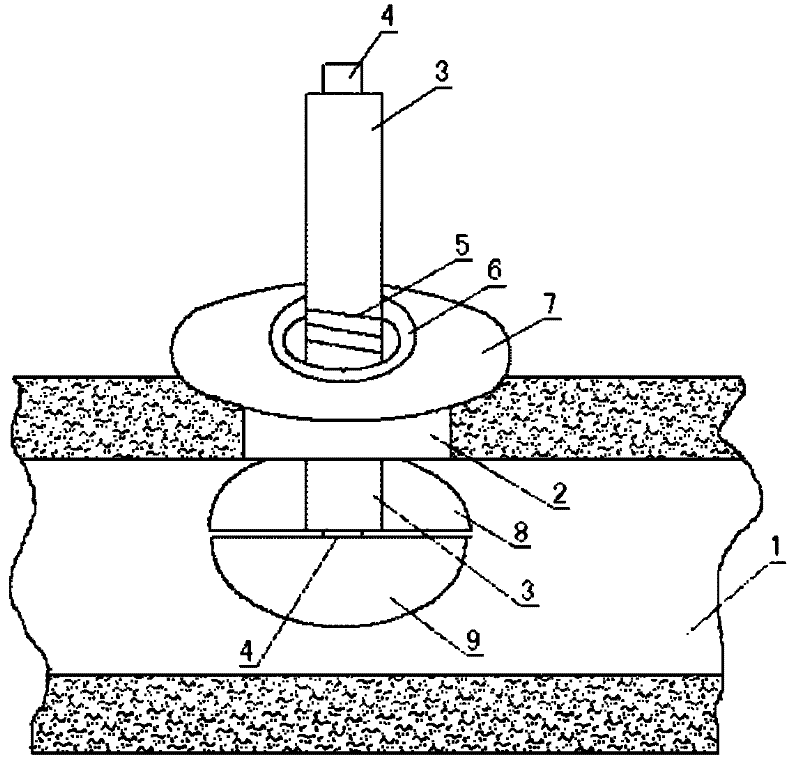

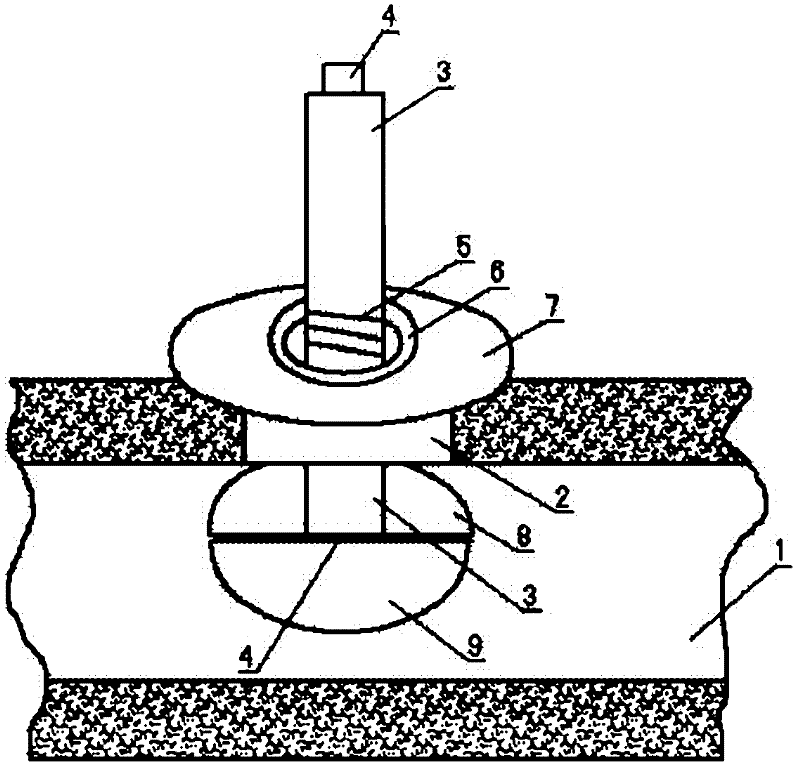

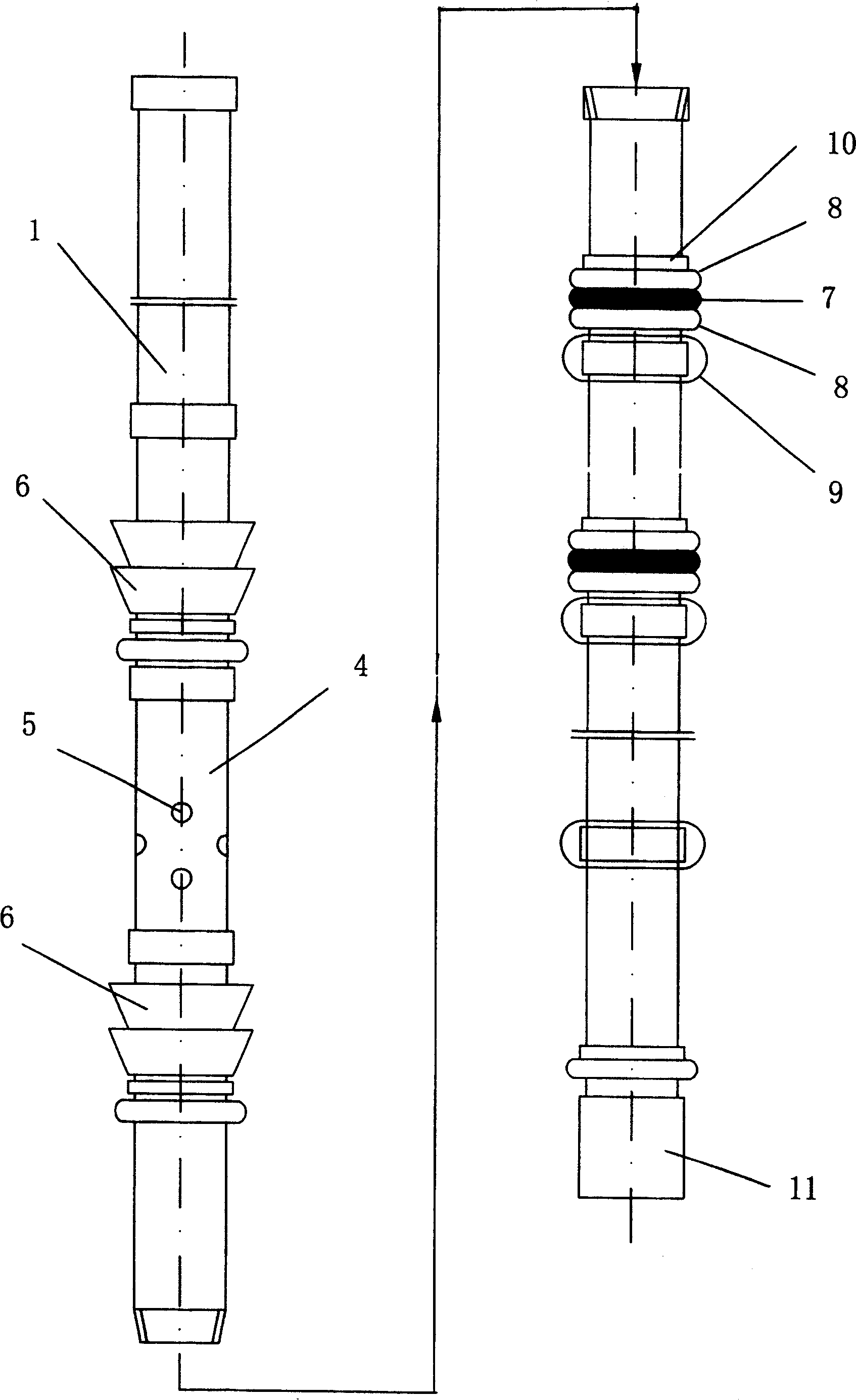

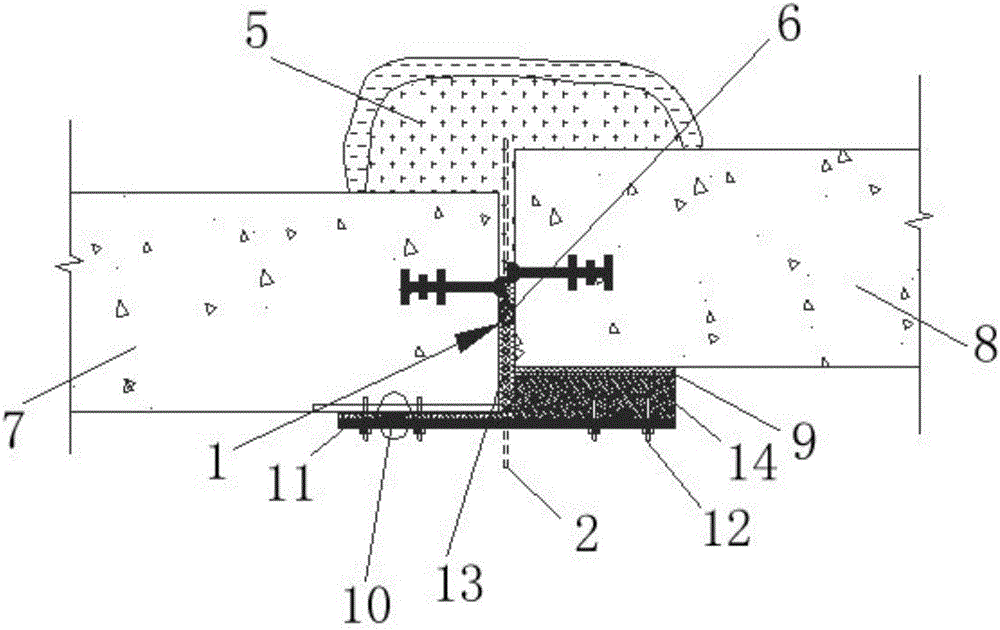

Grouting pipe and concrete defect repairing method

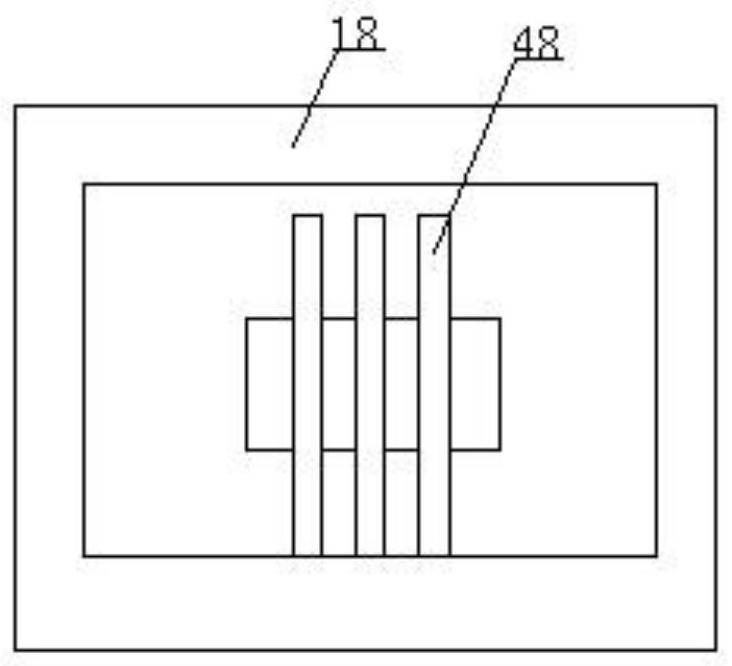

ActiveCN106498929AImplement patchingRealize anti-shedding effectUnderground chambersTunnel liningEngineeringScrew thread

The invention discloses a grouting pipe. The grouting pipe comprises an expansion grouting pipe body, a conical head, a fastening threaded rod and a wheel disc. The expansion grouting pipe body is a hollow barrel body. The side wall of one end of the expansion grouting pipe body is provided with at least two notches in the axial direction of the side wall of one end of the expansion grouting pipe body. The conical head is a conical body of which the radius is gradually decreased from left to right. An inner threaded hole is formed in the central axis direction of the conical head. The fastening threaded rod is a metal rod with an outer thread. One end of the fastening threaded rod is screwed into the conical head, and the other end of the fastening threaded rod penetrates through the expansion grouting pipe body and is connected with the wheel disc. The invention further discloses a concrete defect repairing method.

Owner:北京鸿锐嘉科技发展有限公司

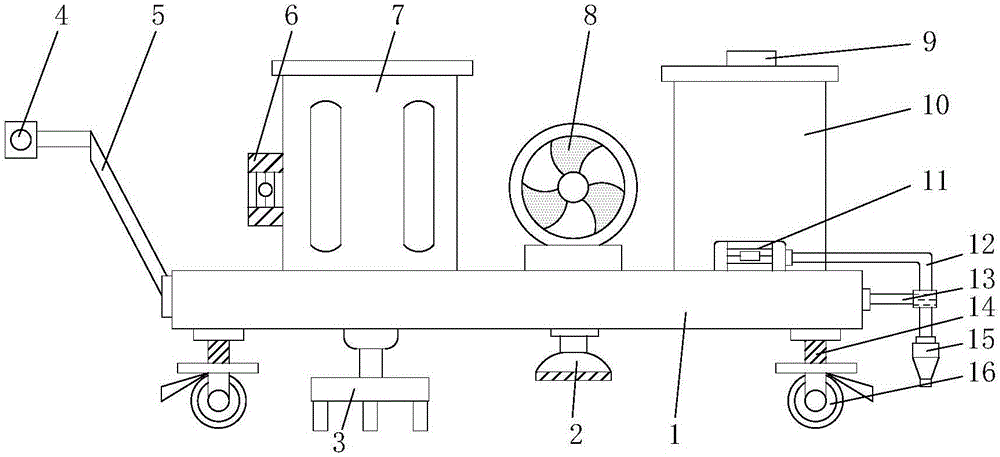

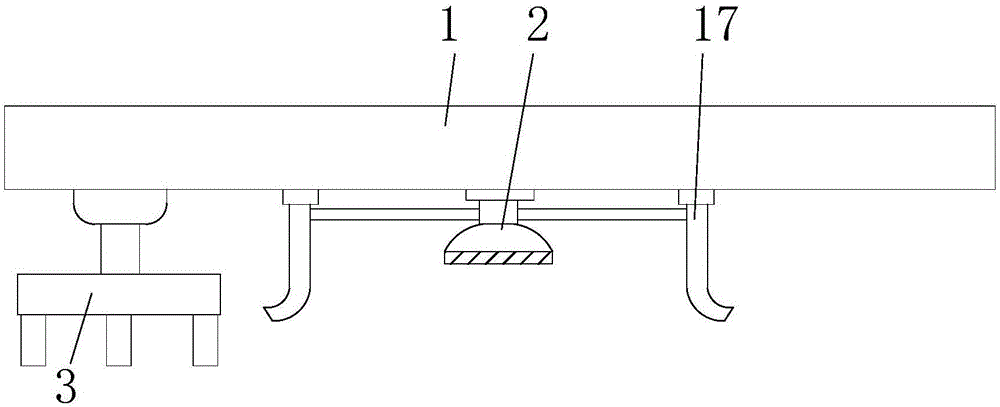

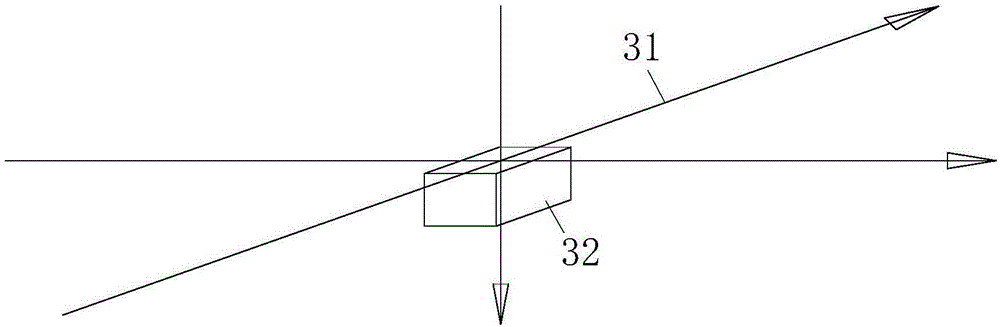

Road surface lining crack repair device

ActiveCN107524075AImprove adhesionIncrease elasticityRoads maintainenceWater storage tankRoad surface

The invention discloses a road surface lining crack repair device. The road surface lining crack repair device comprises a supporting bottom plate, a crack repair agent storage chamber, an air blower and a water storage tank. The crack repair agent storage chamber is positioned on one side of the air blower, a water pump connected with a water guide pipe is mounted in the water storage tank, and a water spraying nozzle is fixed to one end of the water guide pipe. An air nozzle is connected with an air outlet pipe of the air blower and positioned at the bottom end of the supporting bottom plate, a repair device is connected with an output pipe of the crack repair agent storage chamber, and a handle is fixed to a push rod which is connected to one side of the supporting bottom plate. The road surface lining crack repair device has advantages that road surface crack repair processes of cutting, leveling, adhesive squeezing and the like can be realized, a crack repair agent is compacted and leveled after repairing, and crack repair quality is guaranteed.

Owner:安徽宜家管业有限公司

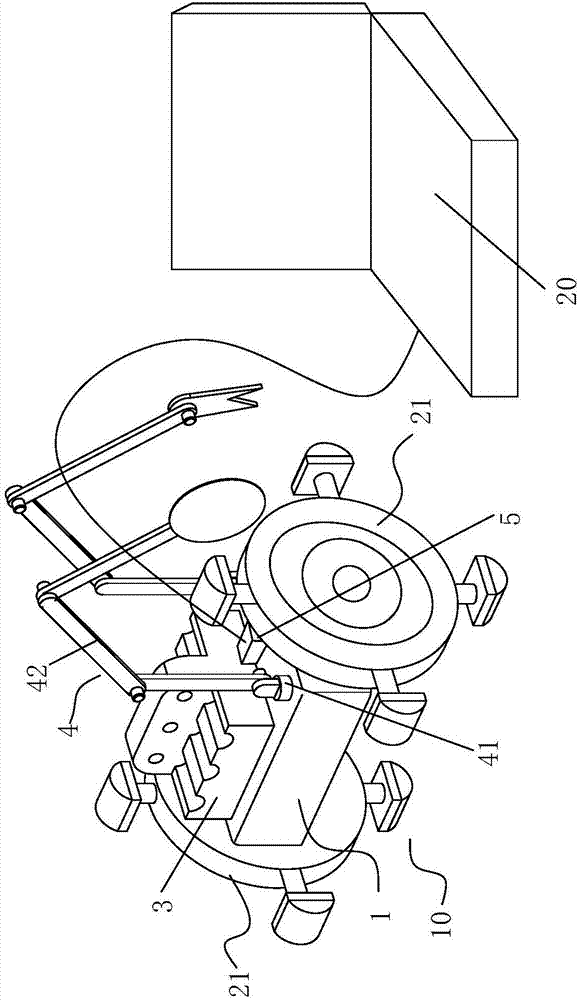

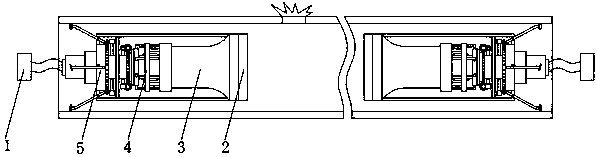

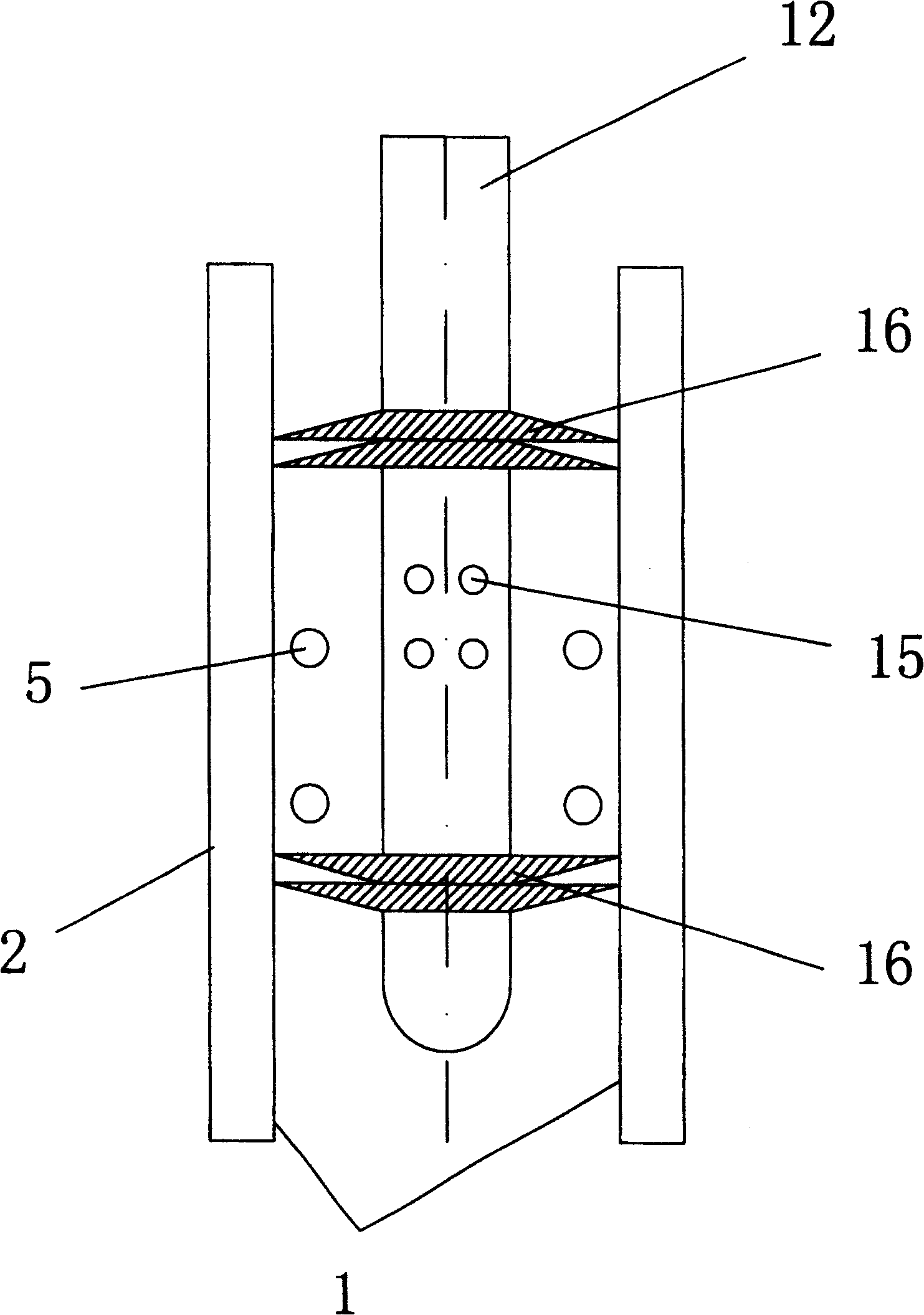

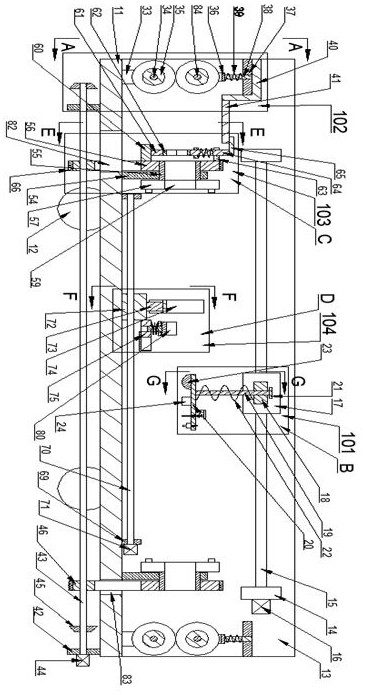

Self-walking type pipeline inwall overhauling system and overhauling method

ActiveCN107339546ARealize flaw detectionAchieve reductionGripping headsPigs/molesEngineeringMechanical engineering

The invention discloses a self-walking type pipeline inwall overhauling system. The self-walking type pipeline inwall overhauling system comprises a control host and a self-walking pipeline inwall overhauling integrated machine. The self-walking pipeline inwall overhauling integrated machine comprises a machine body. The machine body is provided with a walking mechanism, a function tool frame and mechanical arms. The walking mechanism comprises a main beam and radial fixing devices which are arranged at the two ends of the main beam. Each radial fixing device comprises a main beam sliding block, a sliding disk and piston shoes. The walking mechanism is fixed to the inner side of the pipe wall through the piston shoes. The sliding disk in at least one radial fixing device can move back and forth relative to the main beam and is driven by a sliding disk air cylinder which is arranged on the main beam. The main beam is composed of a front half section and a rear half section which are independent from each other, and the front half section and the rear half section of the main beam are connected through a rotating assembly and can mutually rotate. The invention further discloses an overhauling method of the self-walking type pipeline inwall overhauling system, and the self-walking type pipeline inwall overhauling system can freely walk on the pipeline inwall and can achieve pipeline flaw detection, cutting and repairing.

Owner:ZHEJIANG KING MAZON MACHINERY

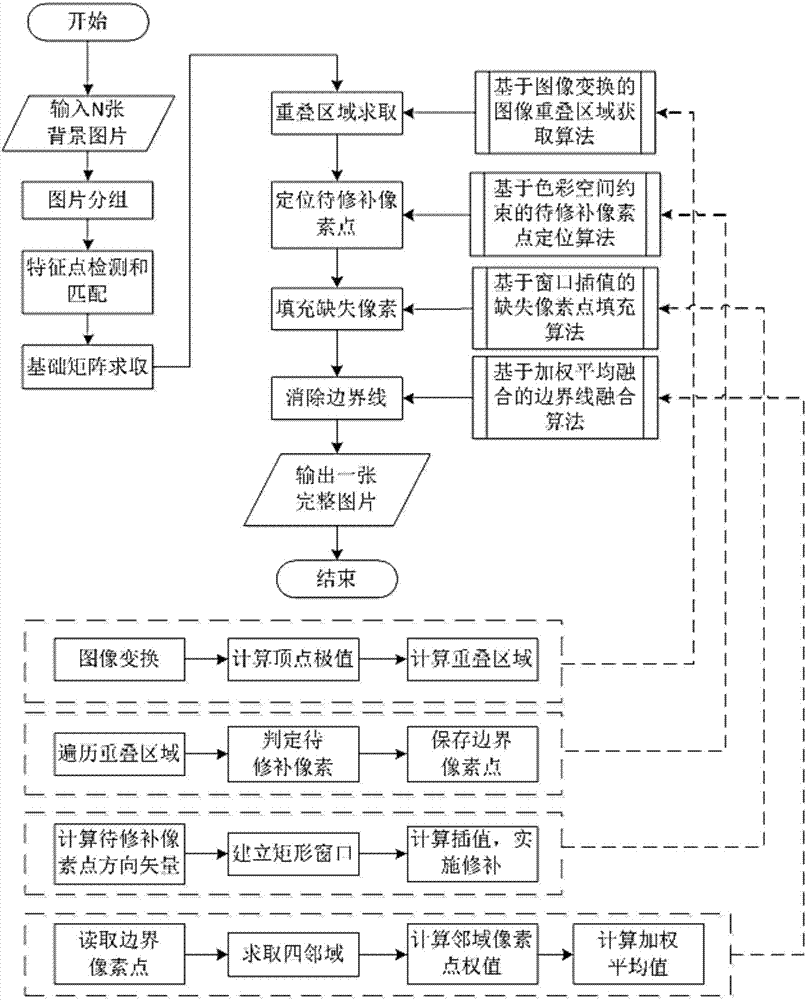

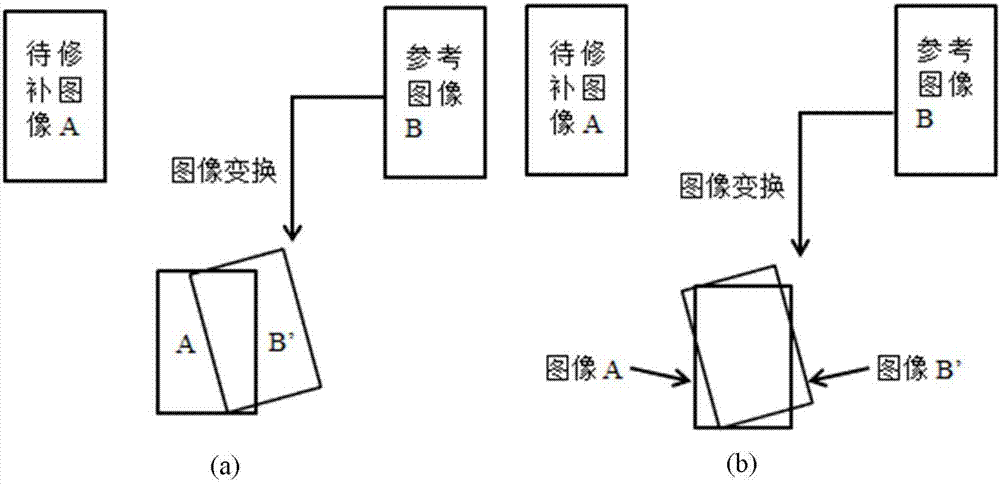

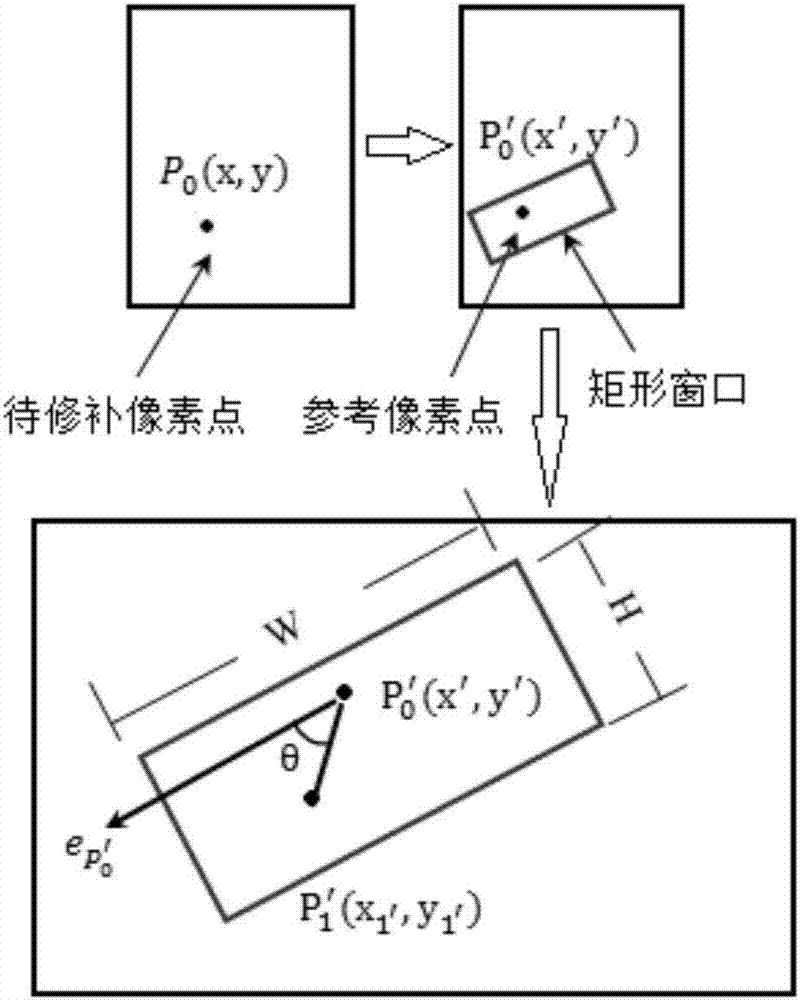

Window interpolation-based three-dimensional reconstruction texture recovery method

ActiveCN107301674APromote recoveryEasy to operate3D-image rendering3D modellingDefect repairImage transformation

The invention discloses a window interpolation-based three-dimensional reconstruction texture recovery method. For the problems that a complete point cloud of a background cannot be reconstructed and a complete map texture cannot be obtained due to shielding of a foreground by a barrier in a sequence image-based background three-dimensional reconstruction process, through sequence image comparison, any defective background picture is effectively recovered, so that the purpose of reconstructing the complete point cloud is achieved. The method mainly comprises the steps of firstly performing picture grouping on defective background pictures under different view angles, and for each picture pair, unifying the picture pair under the same view angle by use of image transformation; and then performing operations of image overlapping region calculation, to-be-repaired defective pixel point locating, defective pixel point filling, boundary line removal and the like to finish picture repair. According to the method, image defect repair can be quickly and efficiently performed for sequence images under the different view angles.

Owner:SOUTHEAST UNIV

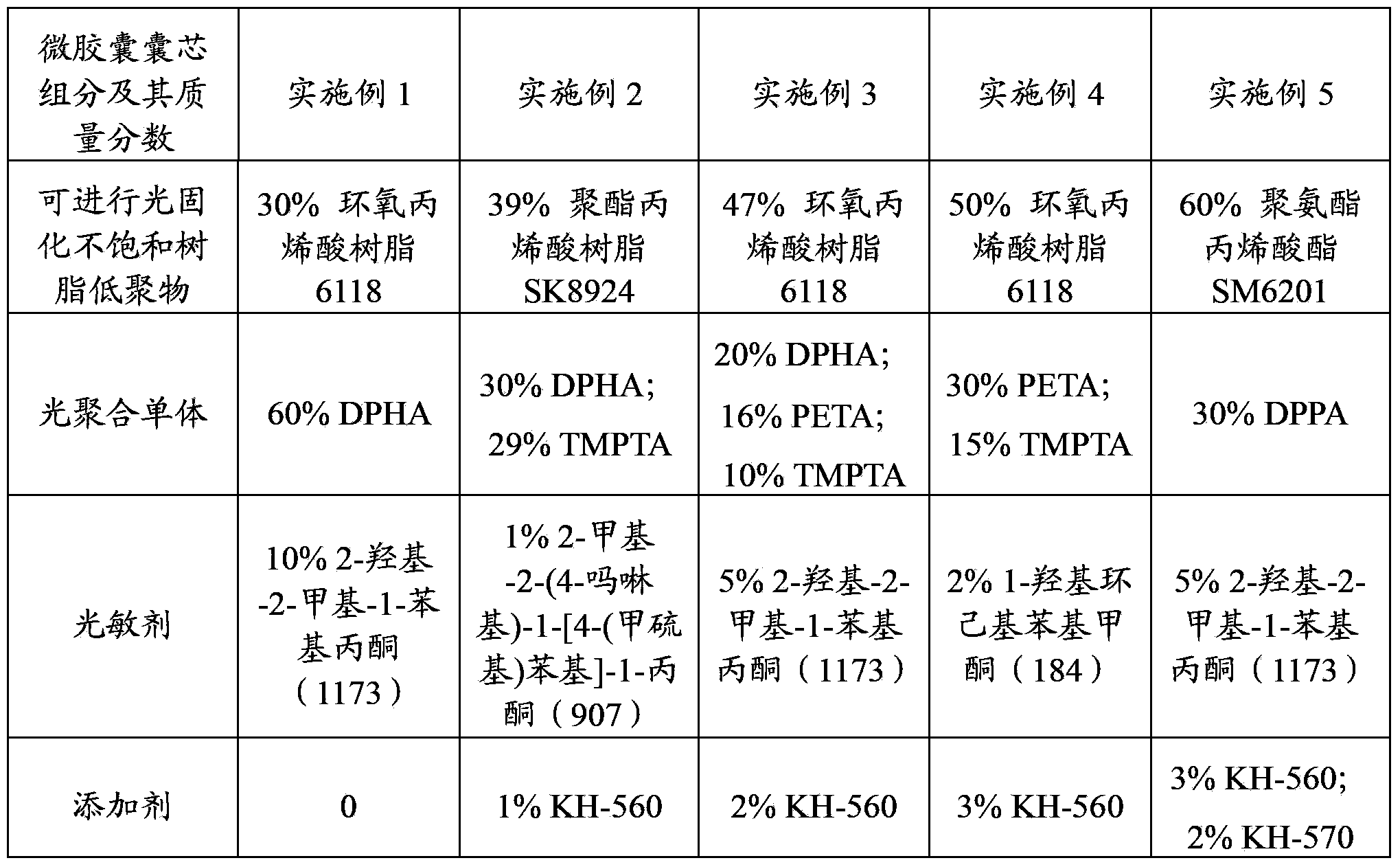

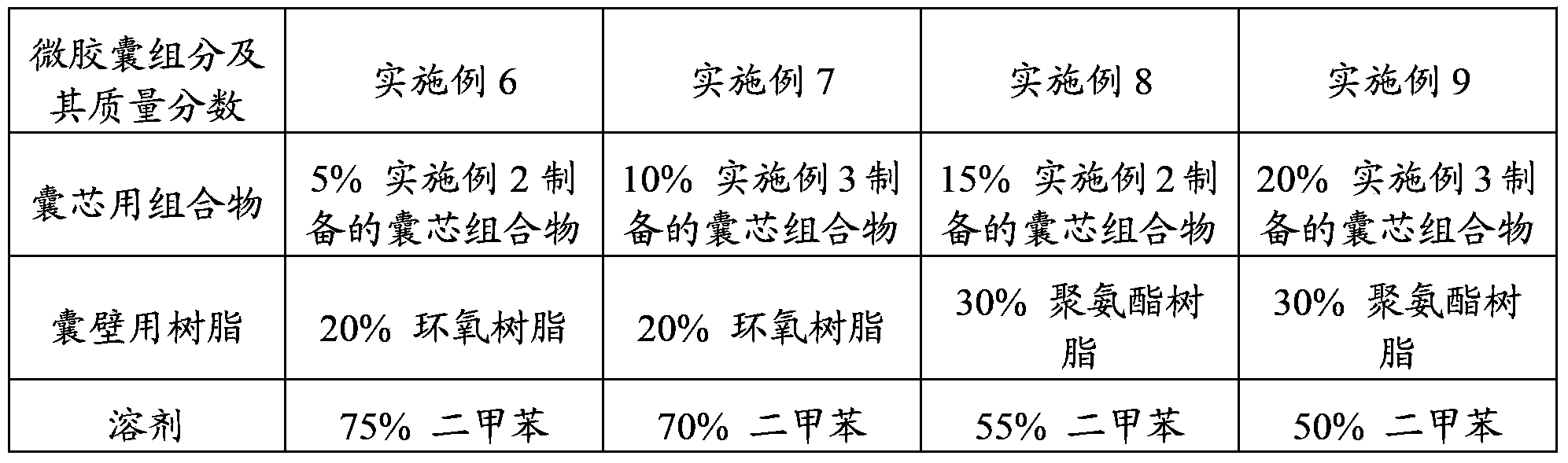

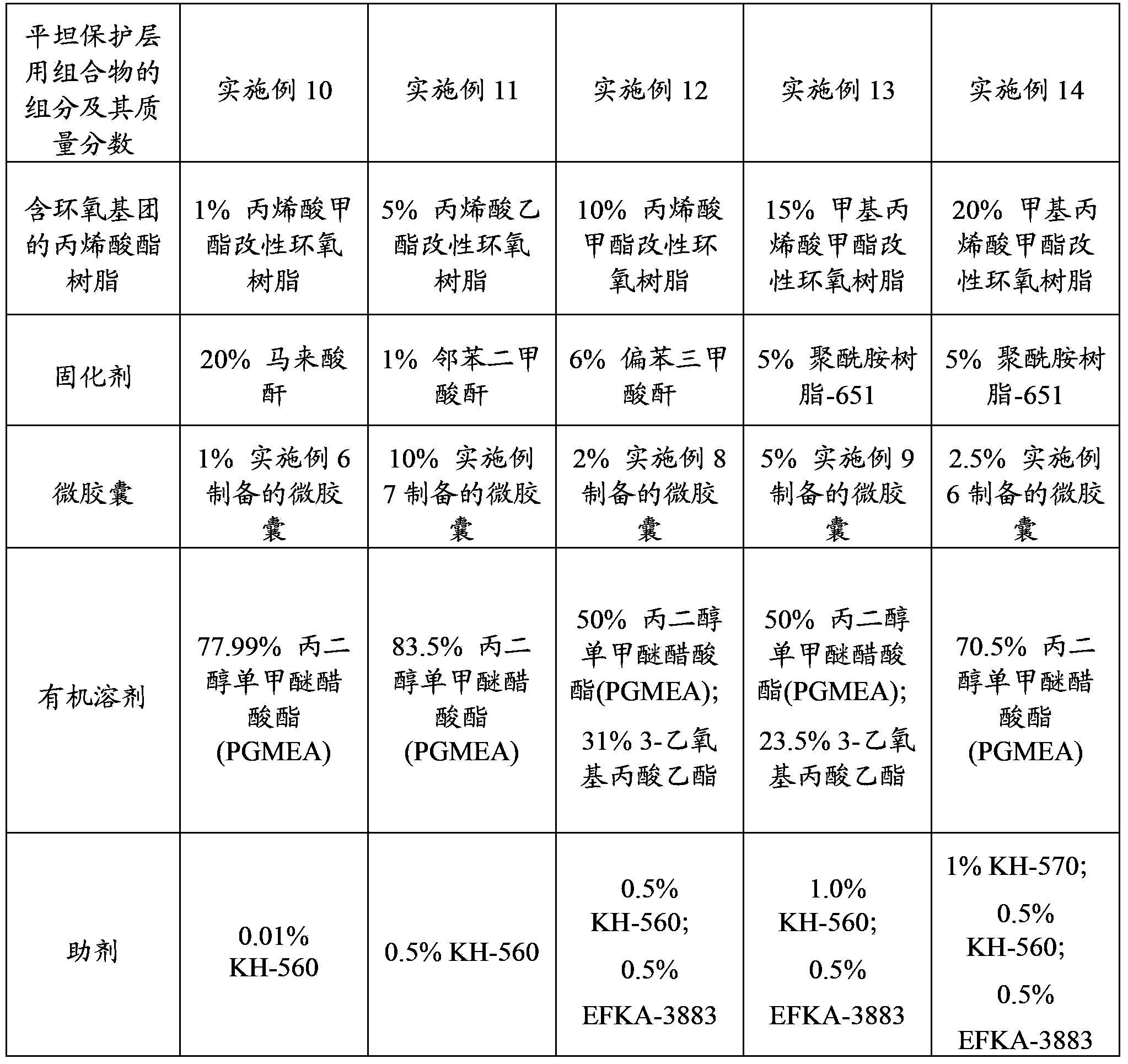

Composition used in flat protective layer, preparation method thereof, and display device

ActiveCN103360857AImprove yieldImprove qualityPolyurea/polyurethane coatingsThin material handlingOligomerPhotosensitizer

The invention relates to the technical field of display, and especially relates to a composition used in a flat protective layer, a preparation method thereof, and a display device. The composition used in the flat protective layer comprises microcapsules with a mass percentage of 1-10%. The microcapsule wall comprises alkali-insoluble resin. The microcapsule core comprises, by mass, 30-60% of a light-curable unsaturated resin oligomer, 30-60% of photopolymerizable monomer, 1-10% of a photosensitizer, and 0-5% of an additive. With the technical scheme provided by the invention, reparation of a damaged part of a flat protective layer can be realized, and product yield can be greatly improved.

Owner:BOE TECH GRP CO LTD +1

Puncture type ground clamp and use method thereof

ActiveCN103531926AImplement patchingAchieve fixLine/current collector detailsElectric connection structural associationsMedicine

Owner:国网江苏省电力有限公司宝应县供电分公司 +3

Laser hot cladding process of blade

InactiveCN104831275AEasy to operateHigh control precisionMetallic material coating processesLaser scanningOptoelectronics

The invention relates to a laser hot cladding process of a blade. The laser hot cladding process comprises the following steps: (1) cleaning the surface; (2) detecting an abrasion area and a crack area of the blade by utilizing a detector, recording a to-be-repaired position, and imputing the to-be-repaired position to a human-machine interaction interface of a controller; (3) performing laser cladding, namely powering on a powder feeder and a laser, and controlling the movement of the laser and the powder feeding amount by utilizing a control instruction of the controller; and (4) subsequently processing. The powder feeder and the laser are simultaneously controlled by the controller so as to guarantee the synchronism of movement; meanwhile, the powder feeding amount, the laser input energy, the repetition frequency and the laser scanning speed can be precisely controlled, the sensitivity is high, a traditional way for manually adjusting a knob is substituted, the control efficiency is greatly improved, the laser cladding quality is guaranteed, the abraded blade can be repaired, the application performance of the blade is further improved, and the abrasion resistance of the blade can be improved.

Owner:WUHU DINGHAN REMFR TECH

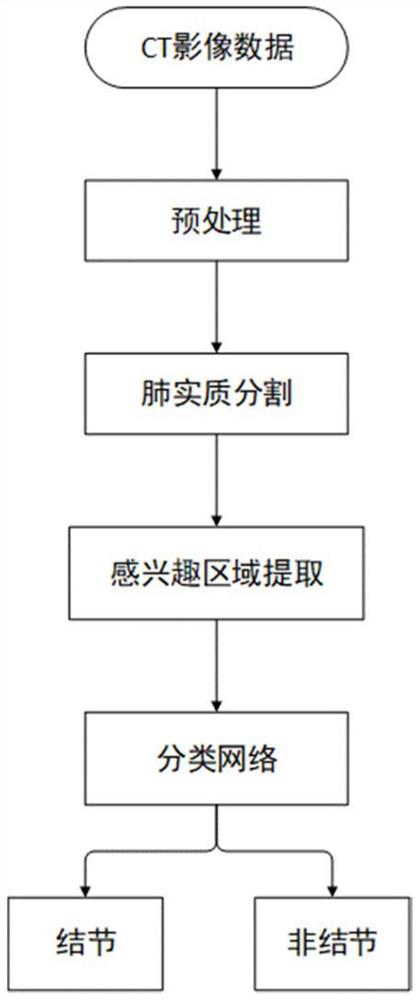

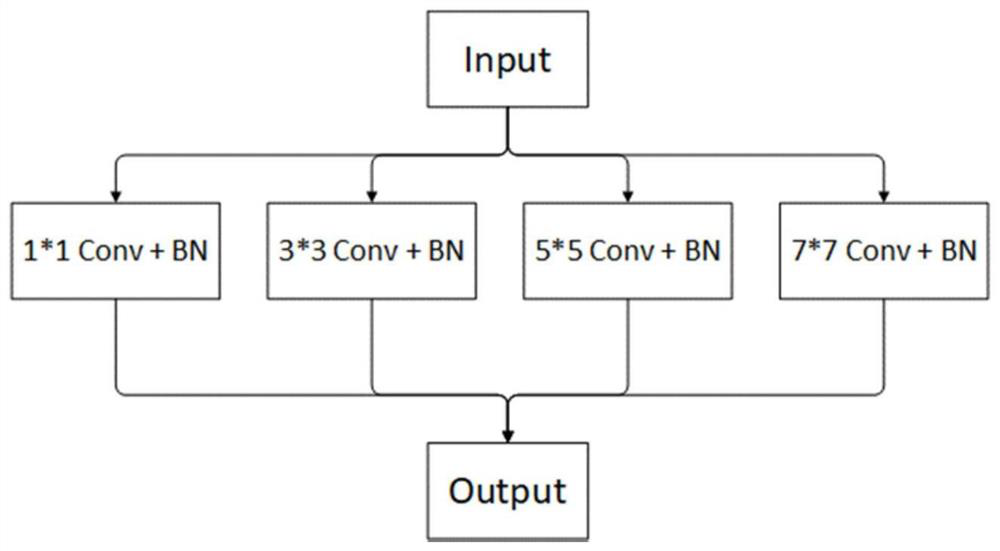

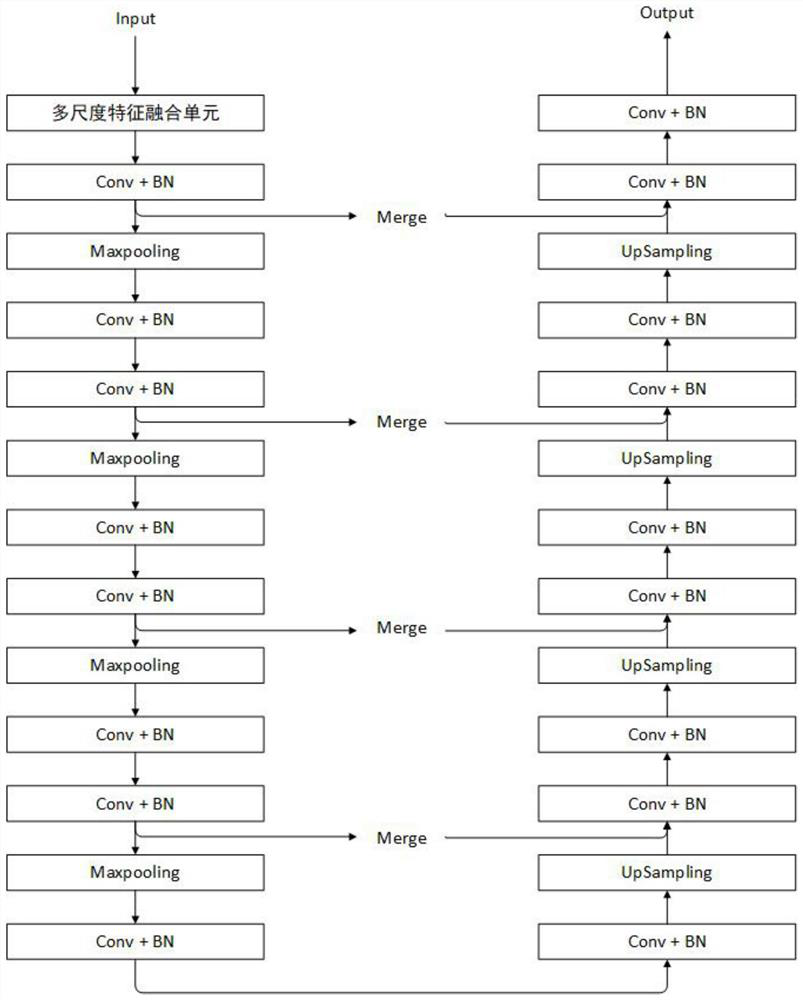

Pulmonary nodule automatic detection method and device and computer system

PendingCN112184657ADetection reachedOptimize detection resultsImage enhancementImage analysisPulmonary nodulePulmonary parenchyma

The invention relates to a pulmonary nodule automatic detection method, a pulmonary nodule automatic detection device and a computer system. The method comprises the following steps: acquiring a CT image to be detected; performing filtering enhancement processing on the CT image to be detected to obtain a lung enhanced CT image sequence; segmenting the CT image sequence by adopting a threshold method to obtain an image only containing a pulmonary parenchyma region; cutting the image obtained by the pulmonary parenchyma segmentation module into a plurality of image blocks, and obtaining a region of interest through a multi-scale feature fusion UNet network model; and carrying out automatic detection and identification on the region of interest by adopting a 3D CNN model to obtain a pulmonary nodule detection result. Compared with the prior art, the method has the advantages of high detection sensitivity and precision and the like.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI +1

Polyurethane putty for concrete surface treatment

InactiveCN102391706AEasy constructionEasy to embedCovering/liningsFilling pastesPolymer sciencePolymer chemistry

The invention provides bi-component polyurethane putty special for concrete surface treatment, and belongs to the field of chemical materials. A polyurethane primer special for the concrete surface treatment is characterized in that: a bi-component polyurethane system, namely an isocyanate component A and a resin component B, is used. The invention has the advantages that: the bi-component low surface tension polyurethane putty is suitable for filling and repairing planar defects (such as pin holes, air holes, pits and the like) of the concrete surface.

Owner:JIANGSU STEADY NEW ENERGY TECH DEV

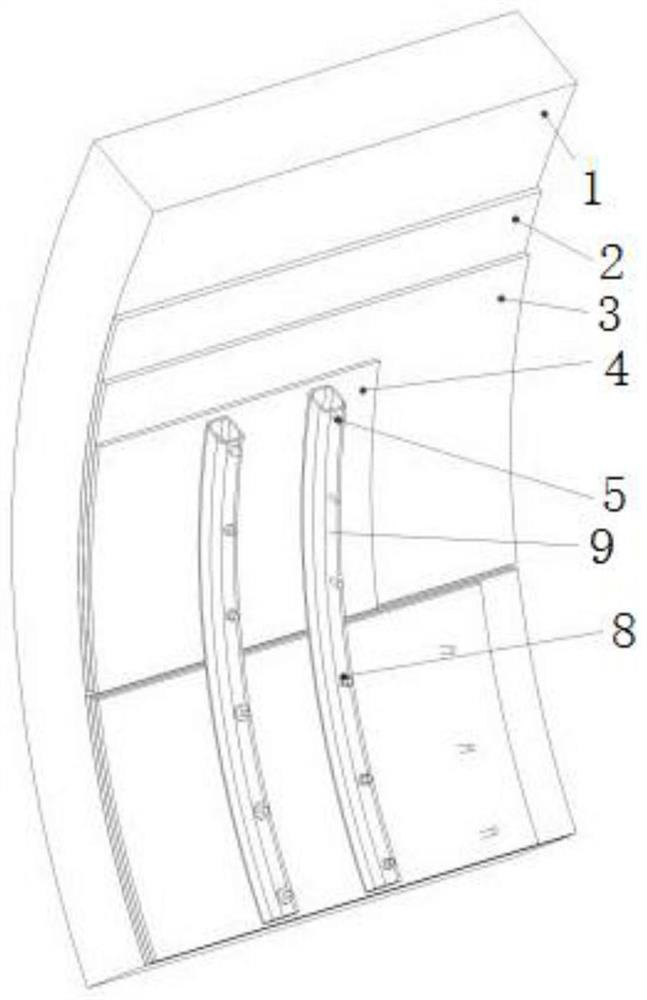

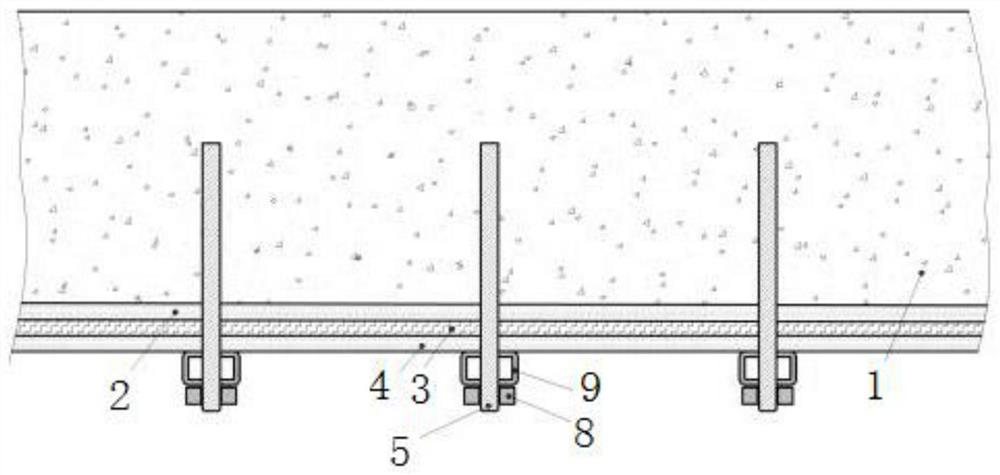

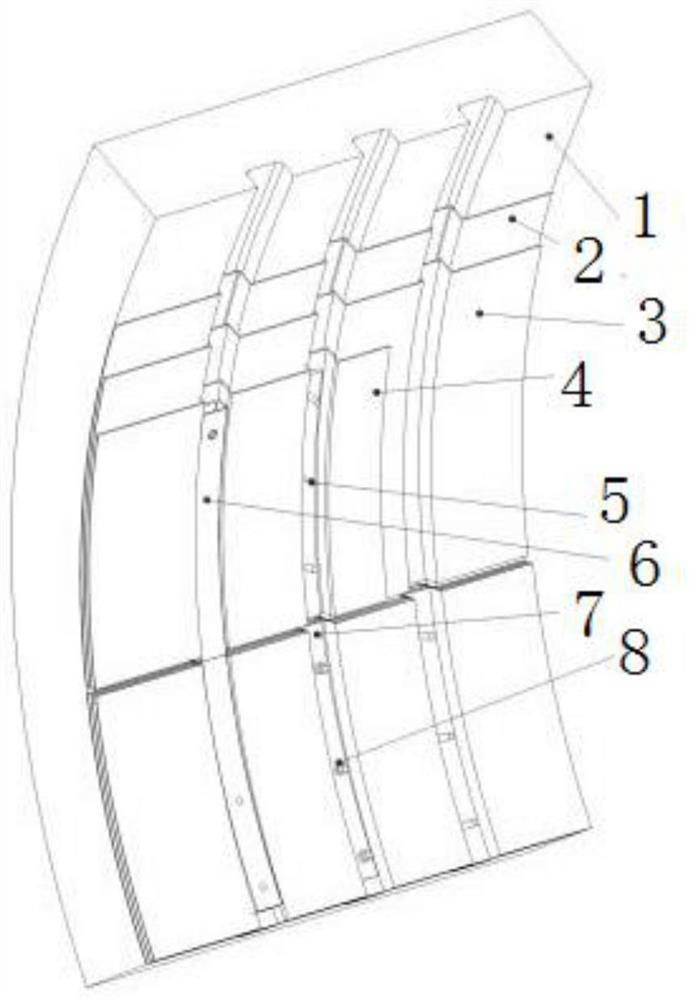

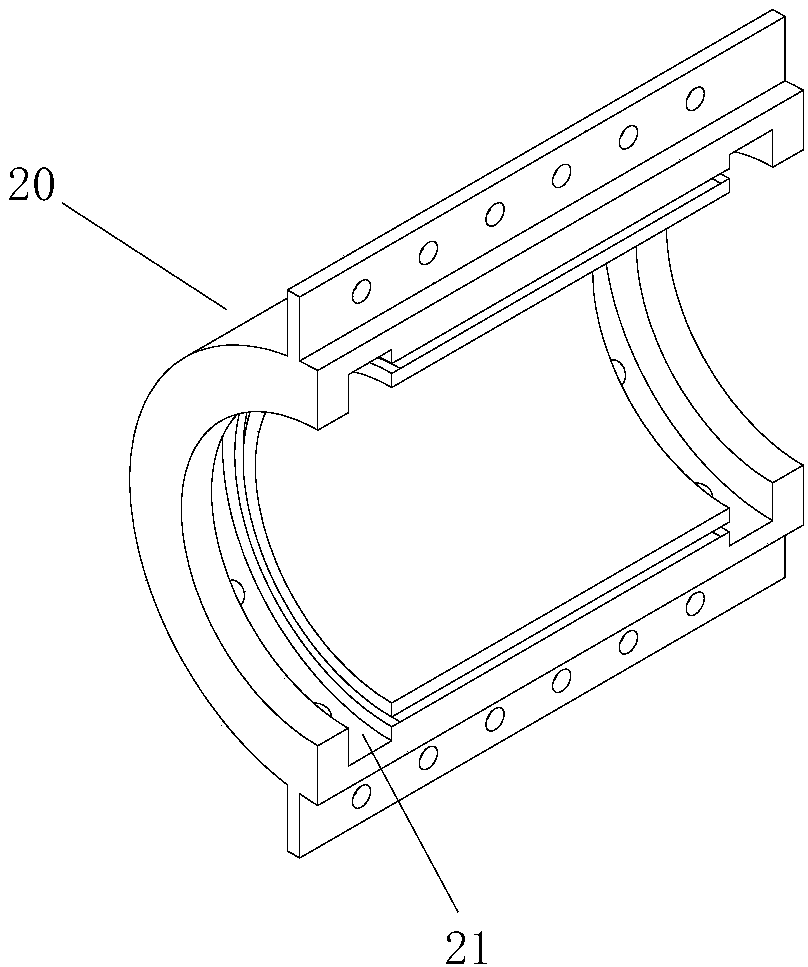

Reinforcing protection treatment method for tunnel lining defects

ActiveCN112031821AImplement patchingInhibit sheddingMining devicesUnderground chambersRailway tunnelArchitectural engineering

The invention discloses a reinforcing protection treatment method for tunnel lining defects. The reinforcing protection treatment method comprises the steps that the surface of lining concrete is brushed, sprayed or smeared with a bonding material; at least one layer of reinforcing net is pasted on the surface of the lining concrete in the longitudinal or circumferential direction of the tunnel; and the reinforcing net is fixed to the tunnel lining through a reinforcing structure. According to the reinforcing protection treatment method for the tunnel lining defects, through combination of thereinforcing net and the reinforcing structure, that is, through a protection matching reinforcing rigid-flexible combination method, the problems of cracking and chipping of tunnel lining concrete, especially sudden falling of concrete with cold joints, are solved, the problem of safety risk of air blast falling caused by train wind of protective reinforcement measures is solved, and a key role is played in railway tunnel operation safety.

Owner:北京鸿锐嘉科技发展有限公司

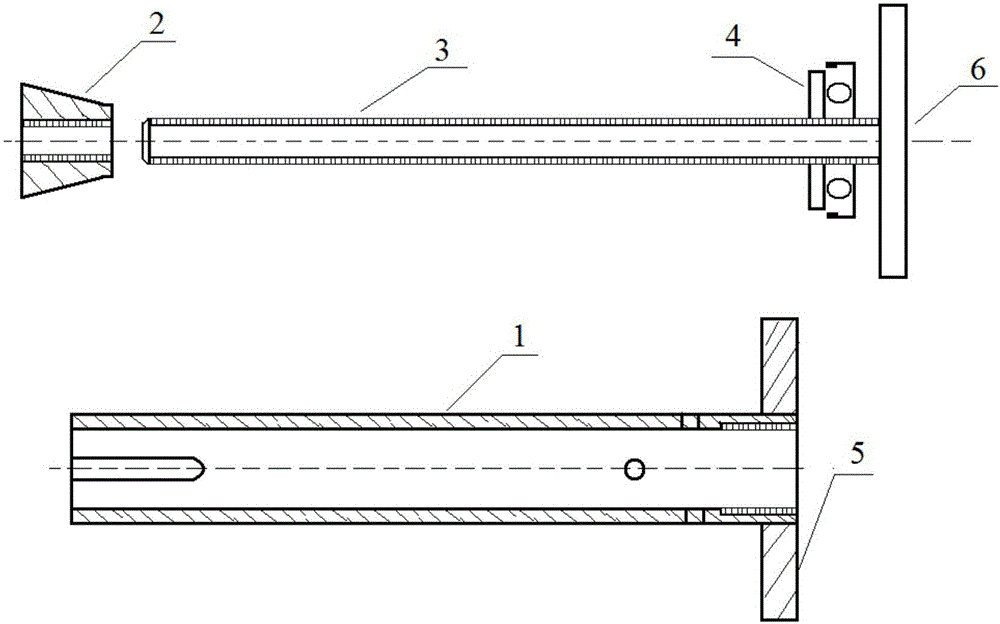

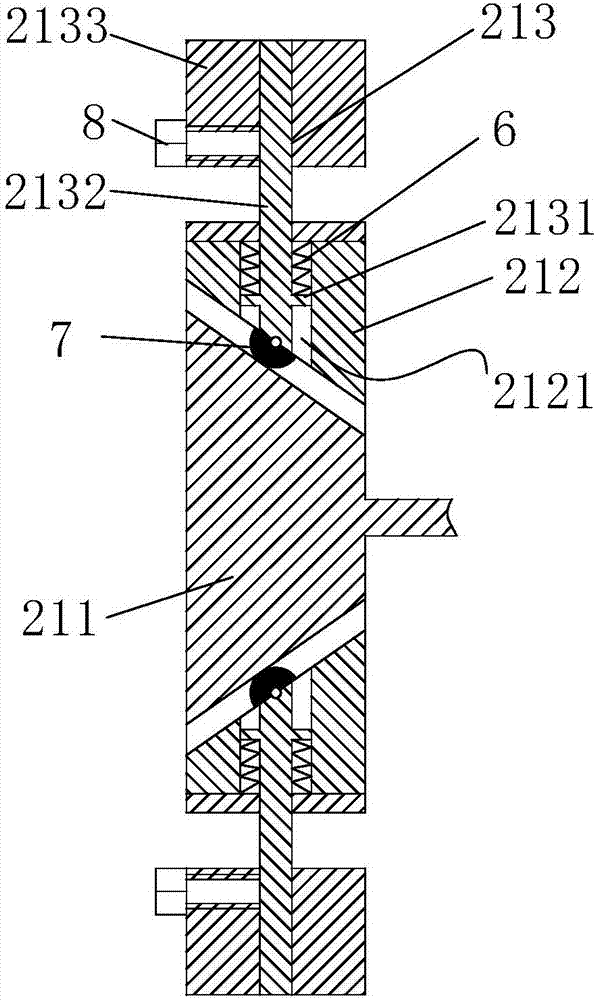

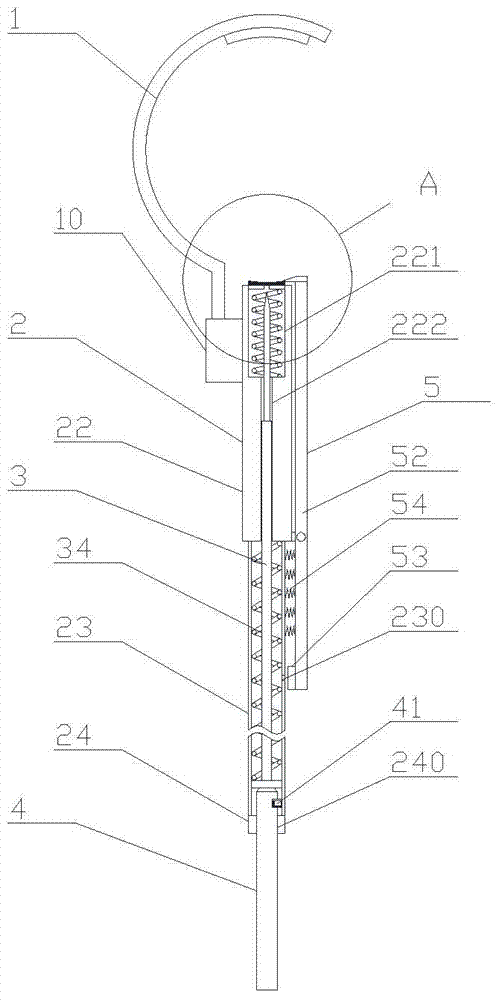

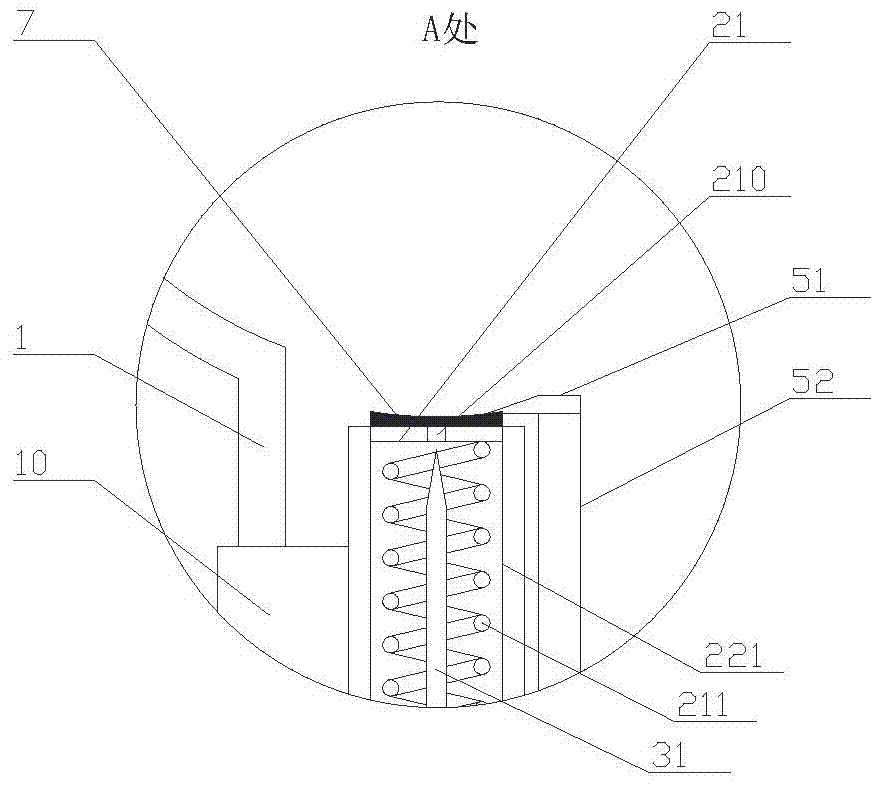

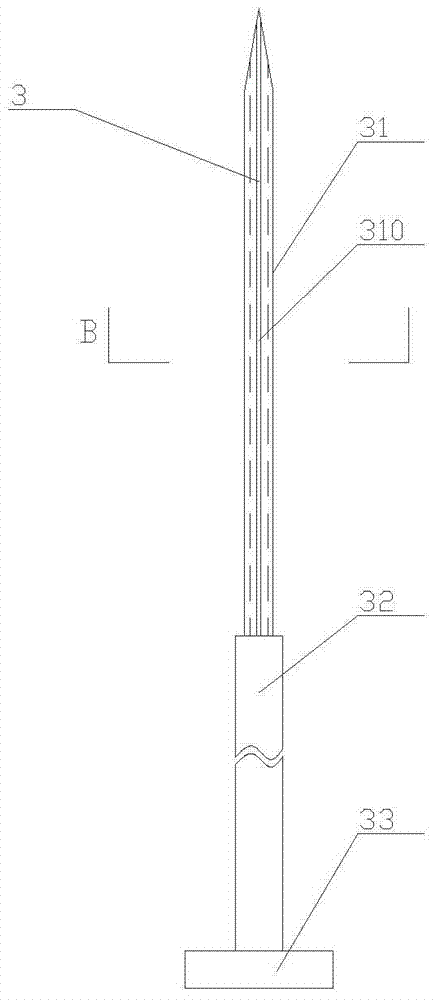

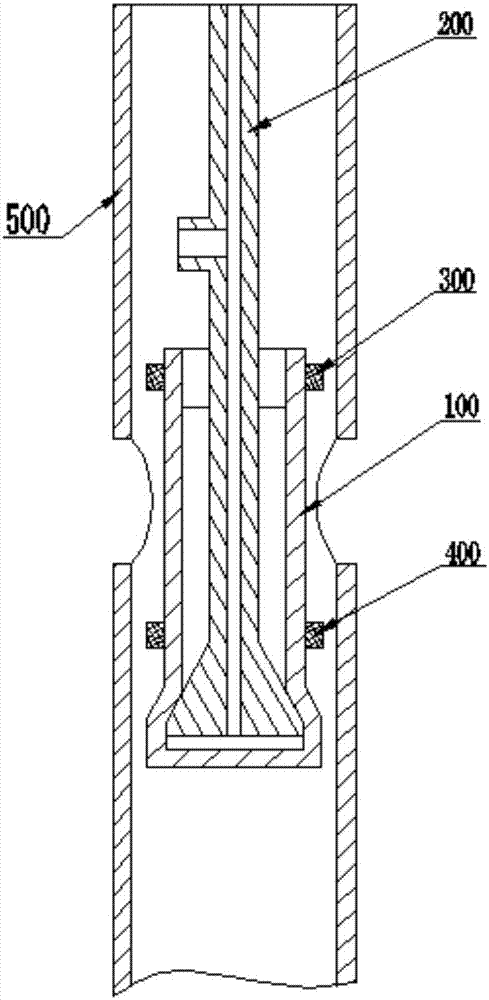

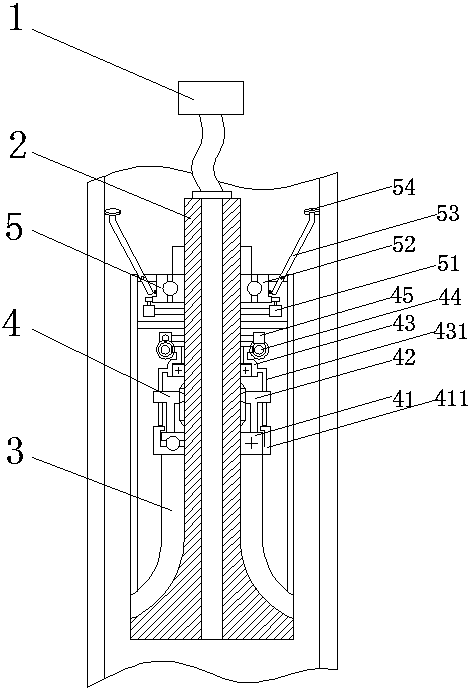

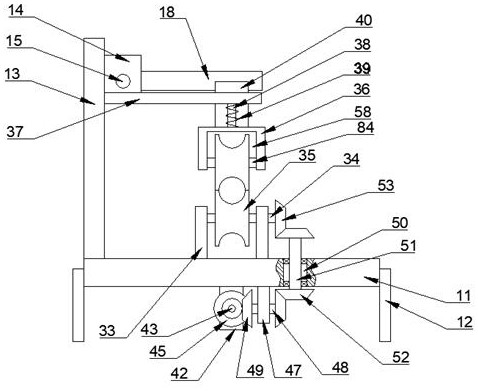

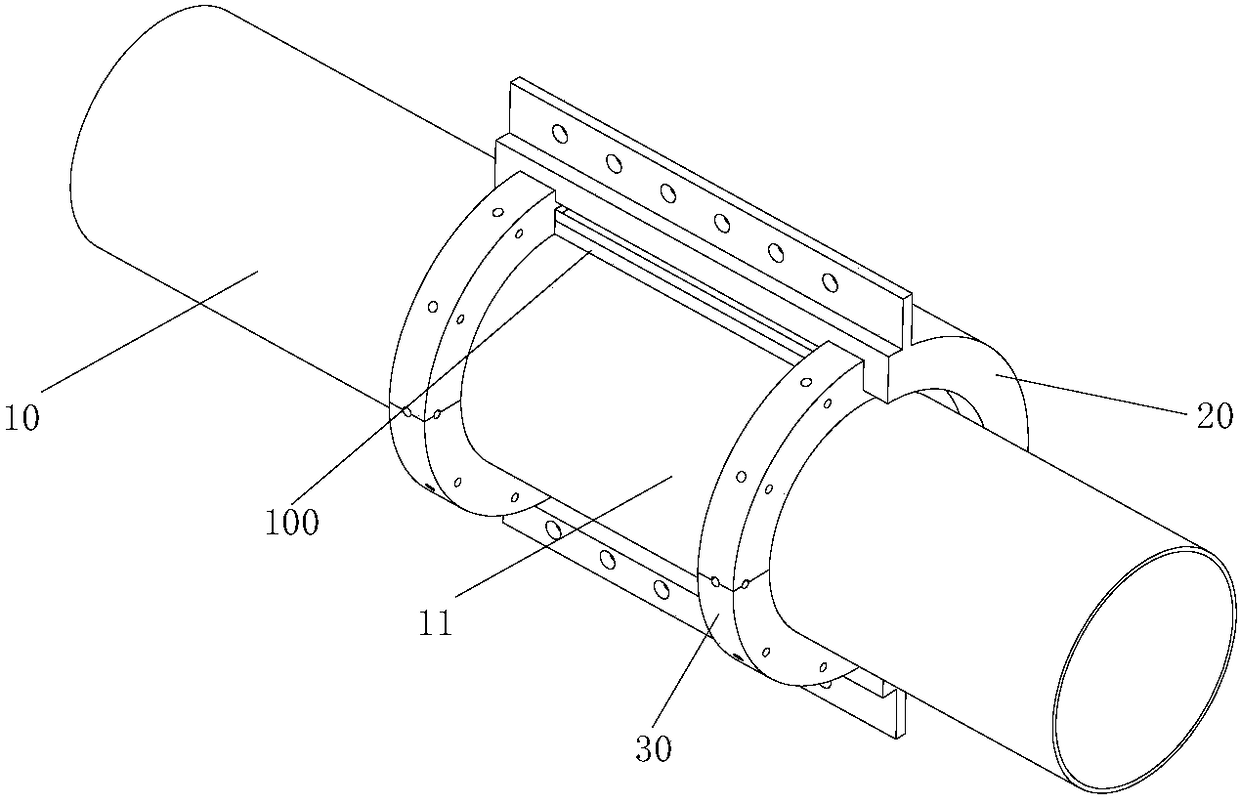

Casing damage well thin walled pipe patching device

InactiveCN107503701AReduce repair costsReduce the difficulty of repairBorehole/well accessoriesWell drillingEngineering

The invention discloses a casing damage well thin walled pipe patching device, and belongs to the technical field of casing pipe repair. The casing damage well thin walled pipe patching device comprises a patching pipe, an expansion cone of which the lower end is arranged inside the patching pipe, an upper sealing ring arranged at the upper end of the outer wall of the patching pipe and a lower sealing ring arranged at the lower end of the outer wall of the patching pipe, wherein a middle conical section of the expansion cone and a first conical section are matched with each other, high-pressure power liquid is injected into an inner cavity between the expansion cone and the patching pipe through a through hole formed in the center of the expansion cone, under driving of pressure difference force, the expansion cone moves to the upper portion of the patching pipe from the lower portion, the patching pipe continuously expands in the process that the expansion cone moves inside the patching pipe till the patching pipe is attached to the casing pipe, the patching pipe is permanently deformed under the effect of the expansion cone, and reinforcement of the thin walled pipe of a casing damage well and repair of loopholes are achieved. By the adoption of the upper sealing ring and the lower sealing ring, the sealing effect after the casing damage well is repaired is guaranteed, the repair cost and the repair difficulty of the casing damage well are lowered, and the well drilling cost is very obviously lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

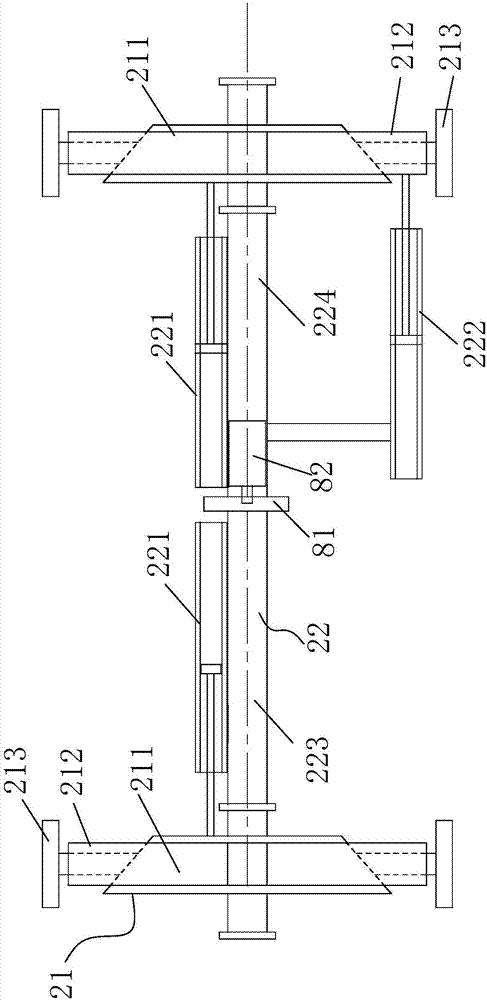

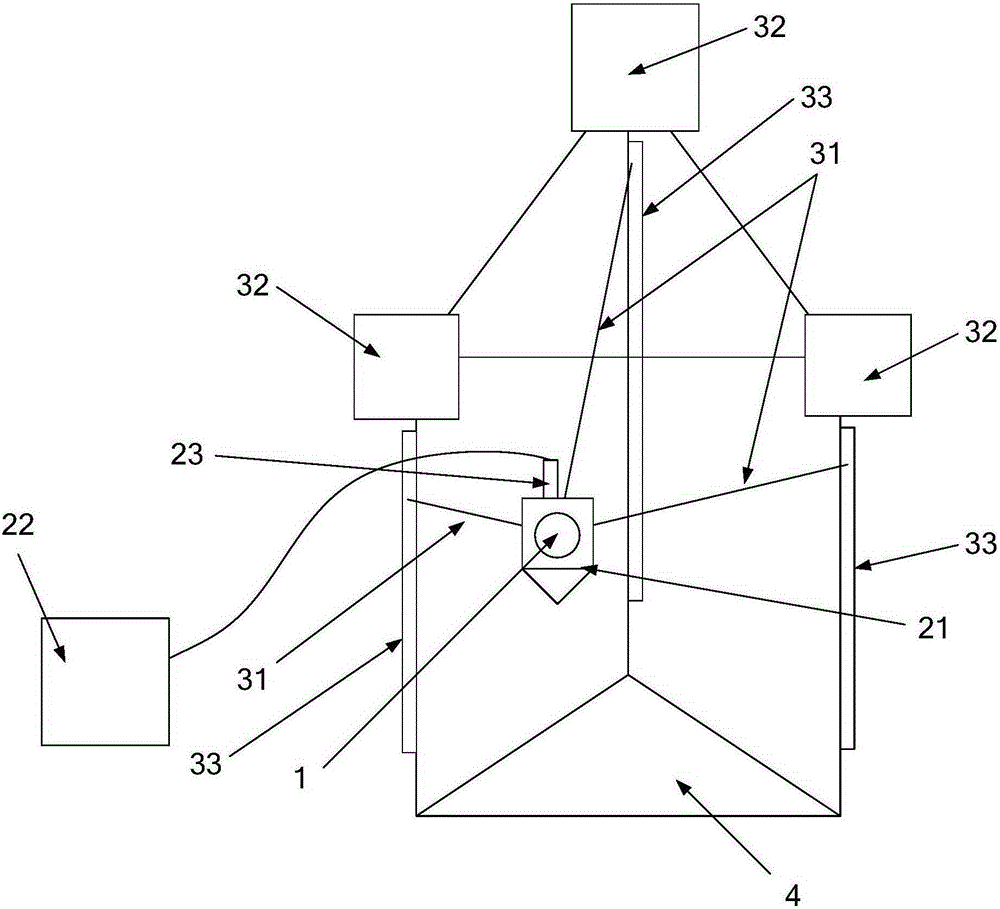

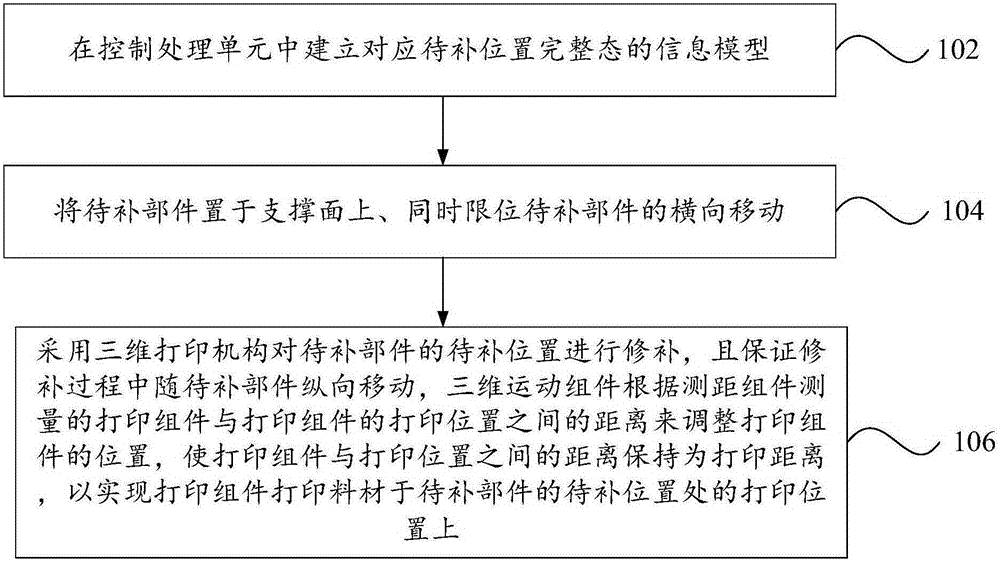

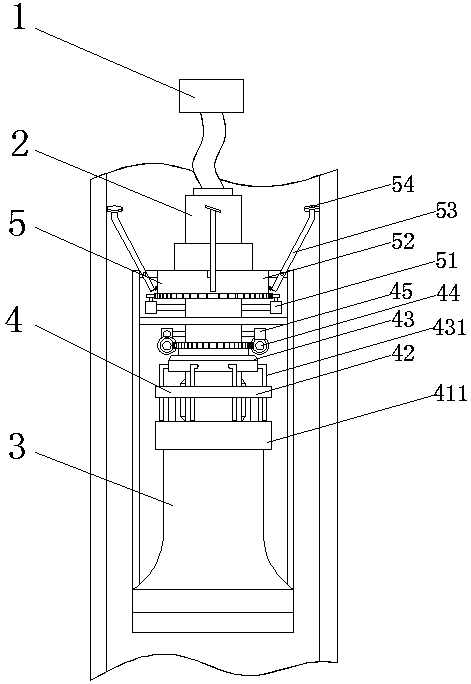

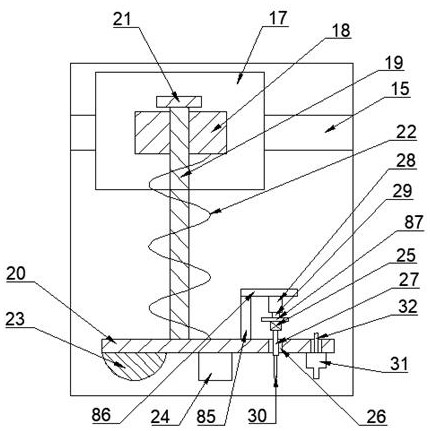

Three-dimensional printing mechanism and repairing method for component to be repaired

InactiveCN105216317ARealize dynamic printingImplement patchingAdditive manufacturing apparatusRepair methodMedical treatment

The invention relates to a three-dimensional printing mechanism and a repairing method for a component to be repaired. The three-dimensional printing mechanism comprises a three-dimensional moving assembly, a printing assembly used for printing a target object, a distance measuring assembly and a control processing unit. The printing assembly is installed on the three-dimensional moving assembly. The three-dimensional moving assembly is used for driving the printing assembly to do three-dimensional movement. The distance measuring assembly is fixedly installed on the printing assembly, does three-dimensional movement together with the printing assembly and is used for measuring the distance between the printing assembly and a printing position of the printing assembly. The control processing unit is connected with the distance measuring assembly, the three-dimensional moving assembly and the printing assembly. According to the three-dimensional printing mechanism in the embodiment, due to the fact that the distance measuring assembly is fixedly installed on the printing assembly, dynamic printing in the vertical direction is achieved, and the three-dimensional printing mechanism can be applied to the industries like medical treatment and is remarkable in practicability.

Owner:滕华建 +2

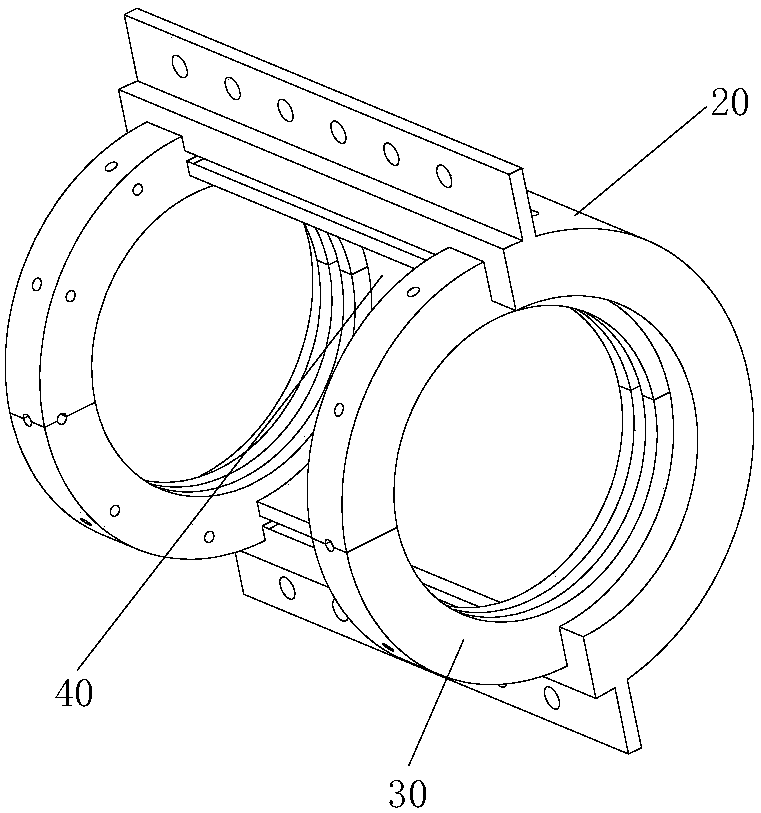

Emergency-repair tool for pipe line of prestress steel cylinder concrete pipe

The invention discloses an emergency-repair tool for a pipe line of a prestress steel cylinder concrete pipe. The tool comprises a connecting piece, a bearing part and a seal part which are respectively arranged at two ends of the connecting piece, wherein the bearing part comprises two semi-circular bearing plates which can be split and combined; the circle area formed by splitting the two semi-circular bearing plates is greater than the area of a damaged opening on a pipeline; the seal part comprises a seal plate and a fastening piece, wherein the area of the seal plate is greater than the area of the damaged opening on the pipeline; and the semi-circular bearing plate and the seal plate can be movably and respectively arranged at two sides of the damaged opening on the pipeline. In the emergency-repair tool for the pipe line of the prestress steel cylinder concrete pipe, through arranging the bearing part and the seal part, the damaged opening at the inner part and the outer part of the pipe line is respectively sealed, then further concrete is filled in the seal space, and the repair of the pipe line of the prestress steel cylinder concrete pipe can be realized, thus the emergency repair work of the pipe line can be finished without draining water in the pipe line completely.

Owner:SILVERY DRAGON PRESTRESSED MATERIALS CO LTD

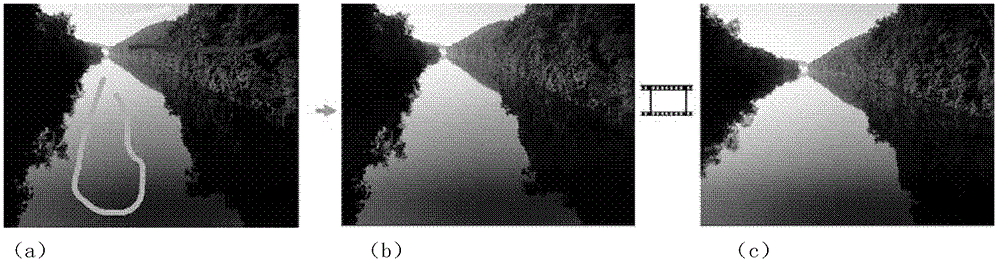

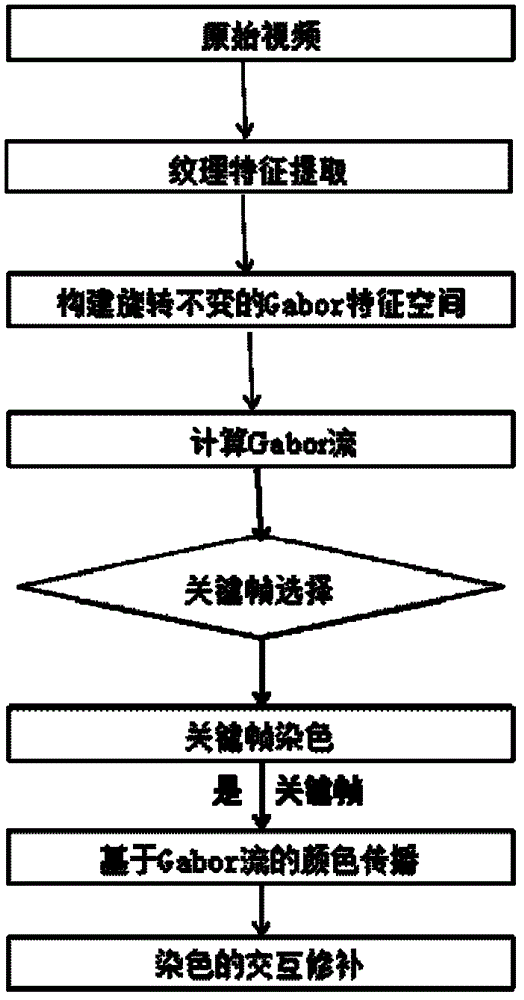

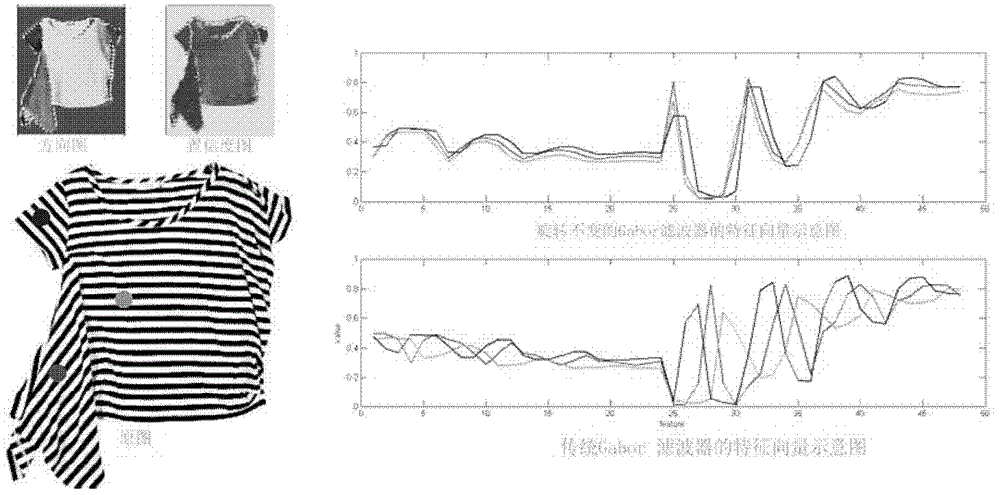

Video dyeing method based on Gabor feature space

The invention discloses a video dyeing method based on a Gabor feature space. The video dyeing method based on the Gabor feature space comprises creating a rotation invariant Gabor filter and a Gabor feature space by using the texture feature of a video and generating Gabor current of the video and choosing keys. The keys are firstly to be dyed and then the color of the keys is spread between video frames according to a computed result of the Gabor current. Users can modify the color of a part where a high error of dyeing effect exists through an interactive operation. The video dyeing method based on the Gabor feature space is simple, easy to use, applicable to all kinds of video data with regional textures, capable of being completed on a graphics hardware graphics processing unit (GPU) platform, and fast in operation speed.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI +1

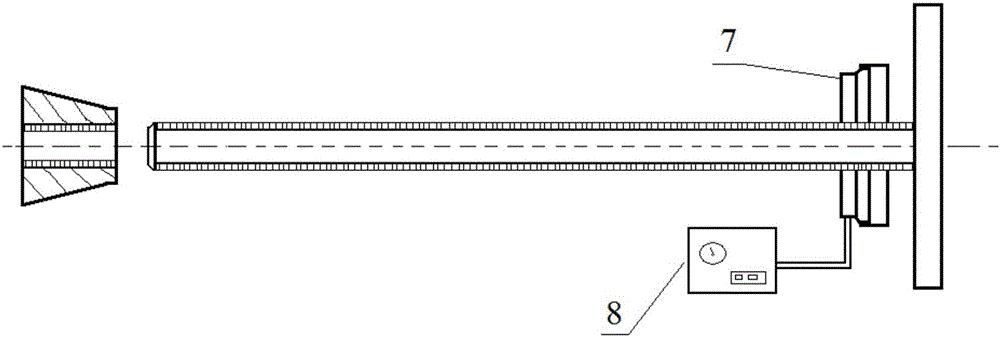

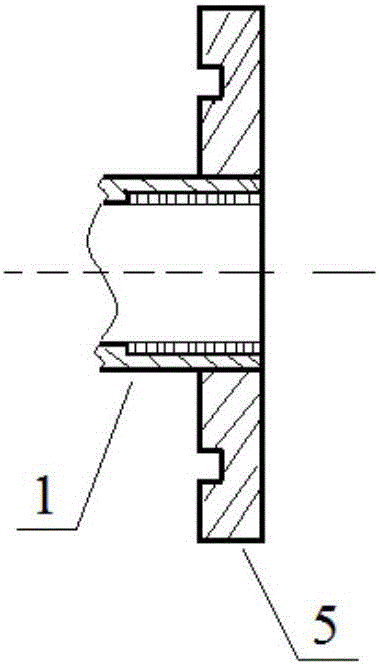

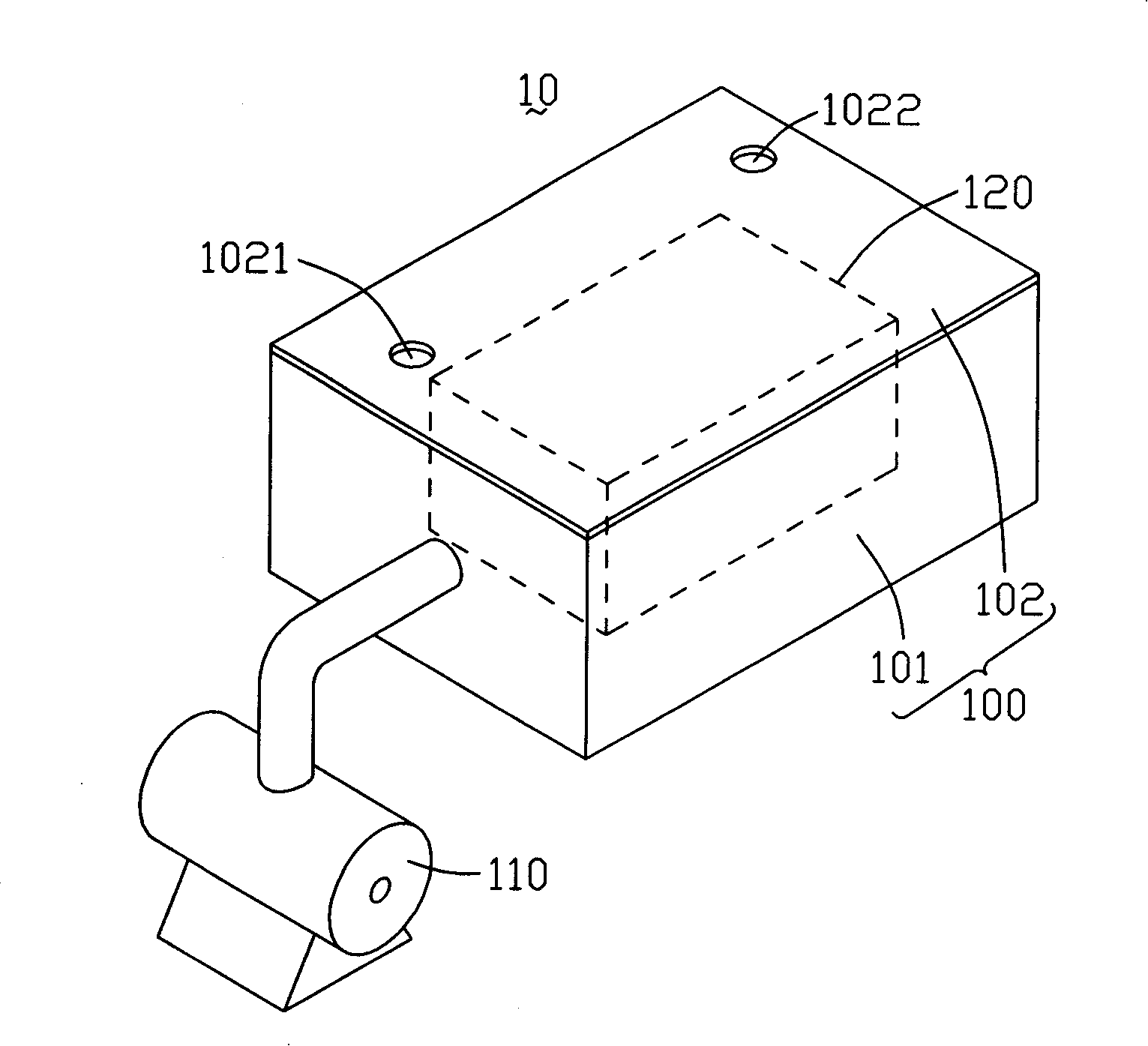

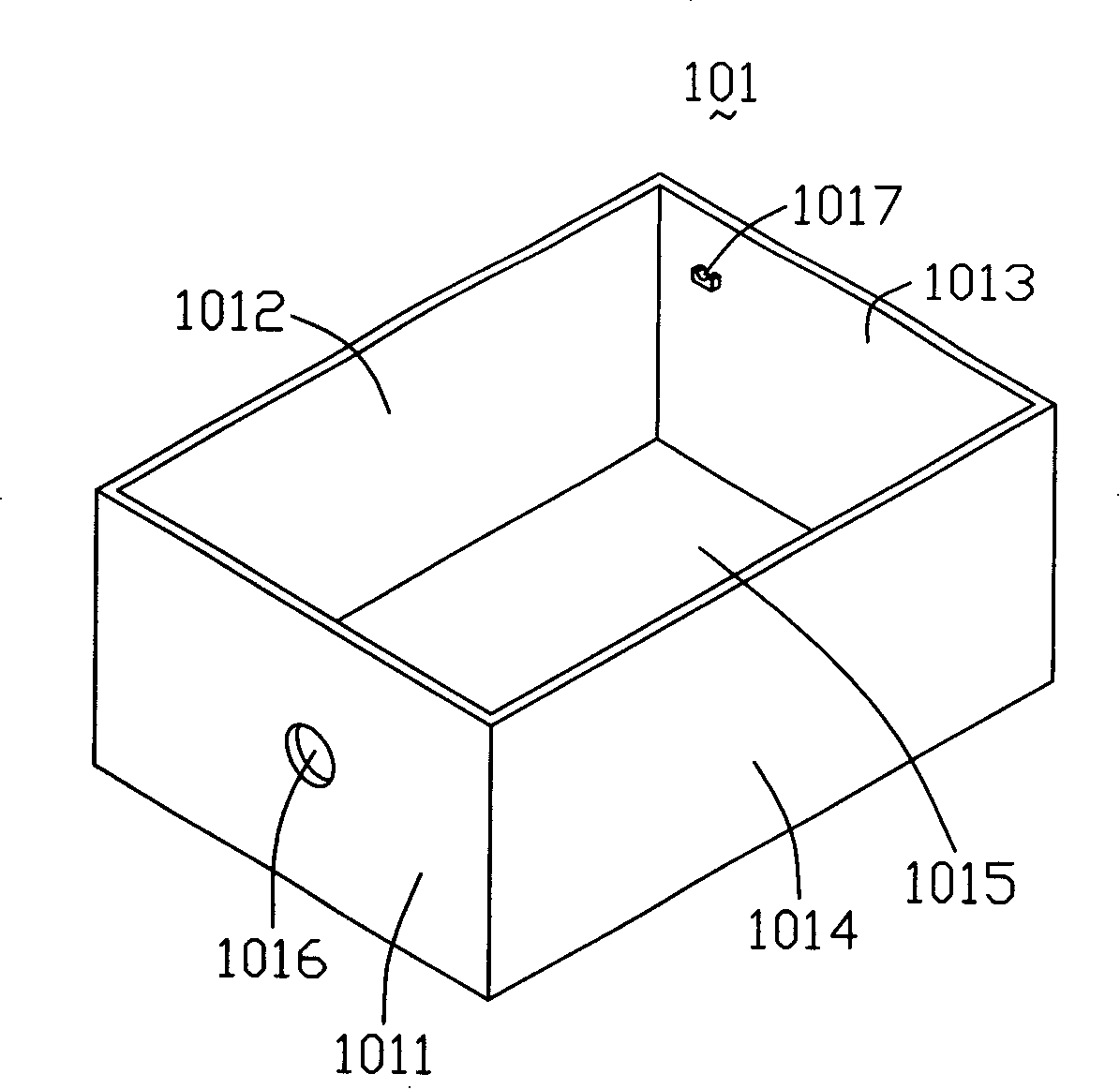

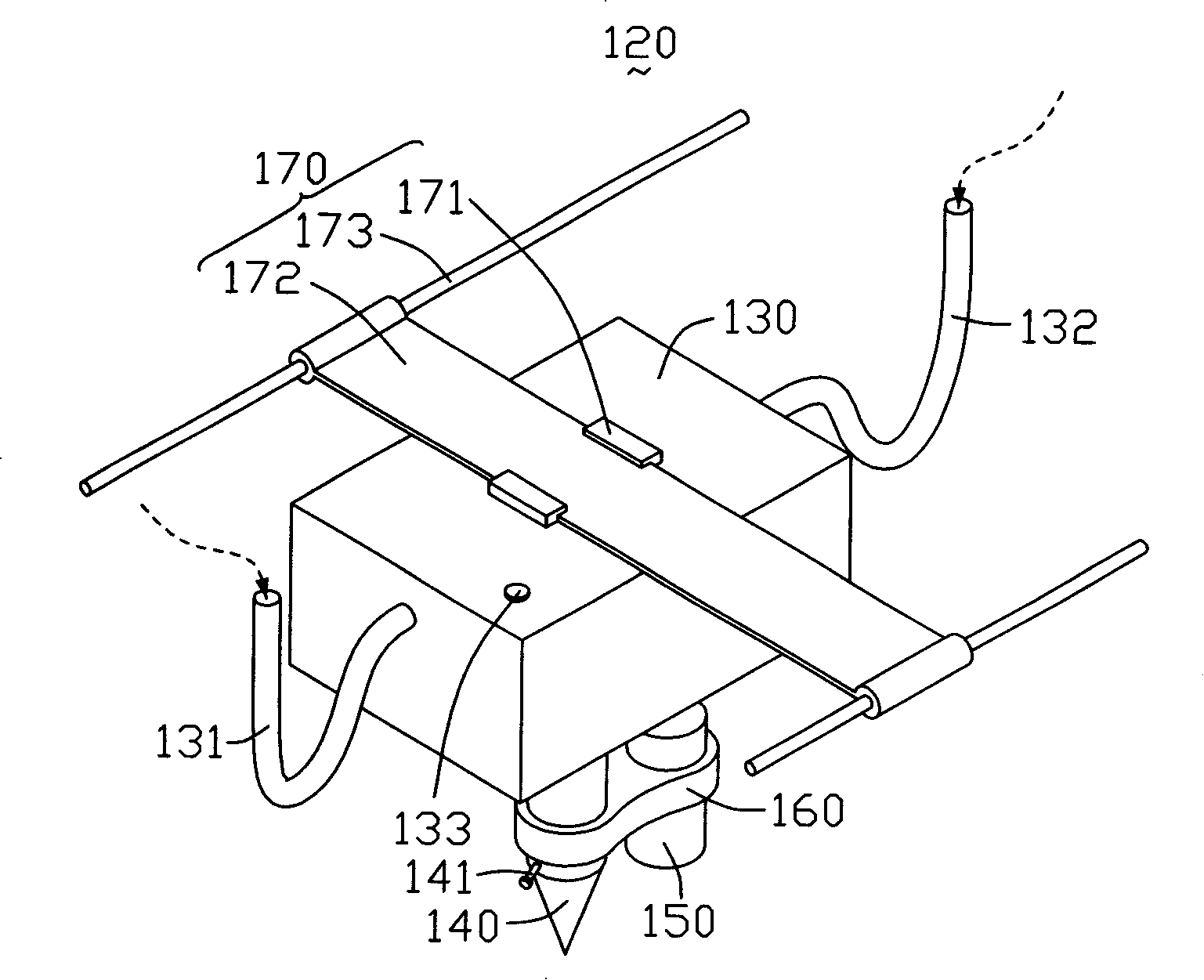

Central air conditioning heat exchange tube leak point detecting device

ActiveCN108318192ASave human effortAccurate detectionMeasurement of fluid loss/gain rateCentral air conditioningEngineering

The invention relates to the technical field of central air-conditioning, in particular to a central air-conditioning heat exchange tube leakage point detecting device. The central air-conditioning heat exchange tube leakage point detecting device comprises: an industrial personal computer, a detecting head, a plugging casing pipe, a casing pipe extruding device and a probe moving device; the detecting head is connected to the industrial personal computer through a vacuum tube; the lower end of the detecting head has a plugging casing pipe sleeve; the center of the detecting head is sleeved with the casing pipe extruding device; the probe moving device sleeves the upper end of the detecting head; a repairing device comprises an elastic sleeve, expansion rings and a locking mechanism, wherein each of both ends of the elastic sleeve is provided with an expansion ring, the two expansion rings are sleeved inside the elastic sleeve, and the locking mechanism is clamped on the two expansionrings; segmentation pressure maintaining test of the interior of the heat exchange tube can be achieved, the position of a leak point inside the heat exchange tube can be found; the locking mechanismdrives the two expansion rings to fix the elastic sleeve inside the heat exchange tube, and then the leak point of the heat exchange point is repaired.

Owner:河北纳森空调有限公司

waterless car wash

ActiveCN104974859BImprove conductivityPotential window widthInorganic/elemental detergent compounding agentsCationic surface-active compoundsEmulsionActive agent

Owner:陈士友

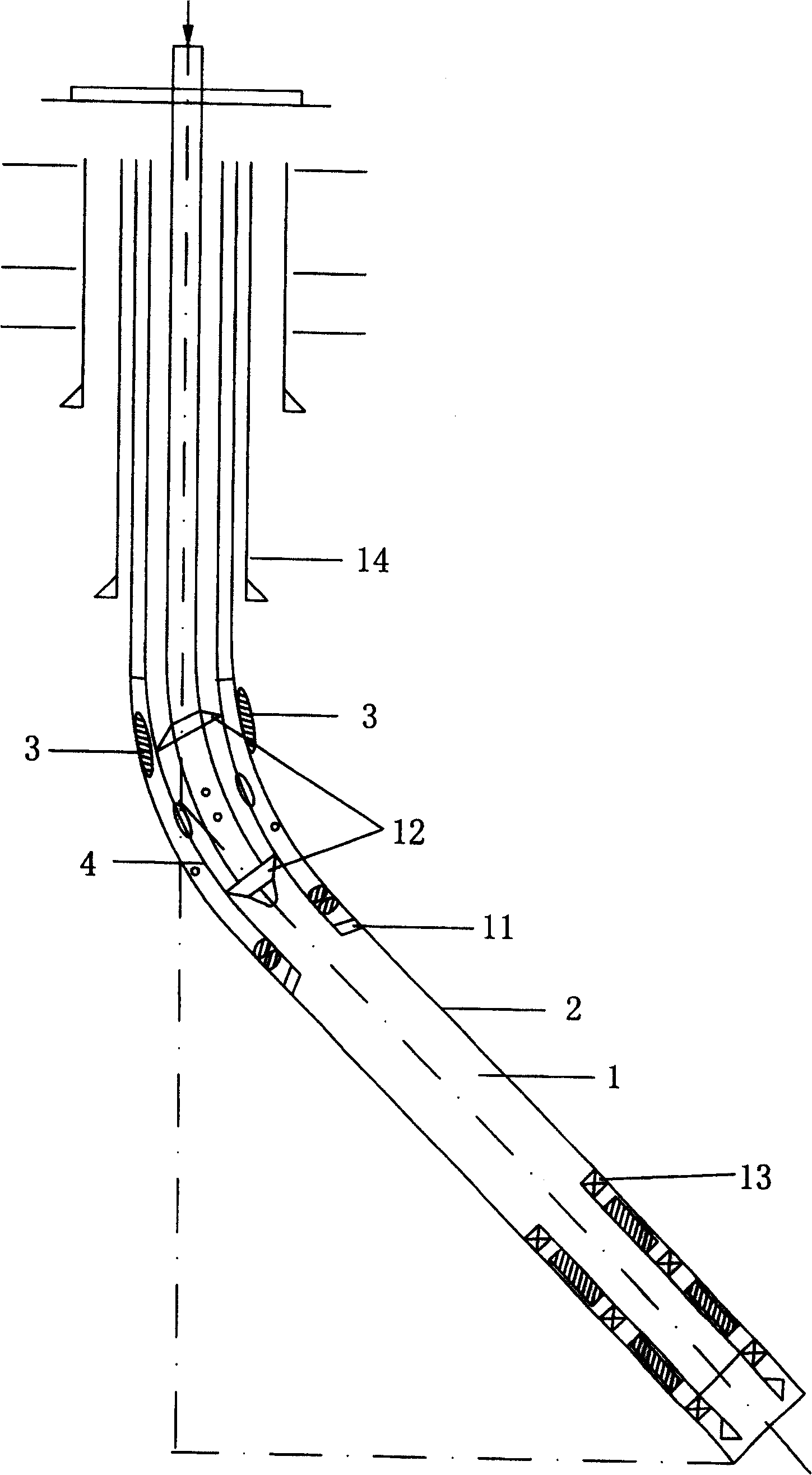

Method and device for repairing oil/gas drilling bushing

ActiveCN100412312CEasy to operateShort construction periodBorehole/well accessoriesWell drillingDrill

The invention relates to a method for repairing drill sleeve, and a relative device, wherein it first complete the well via normal 9-5 / 8 sleeve anti-sand method, then repairs the producing sleeve that damaged; in the repair, it first inserts the repair tubes formed by connected 7 sleeves into the 9-5 / 8 producing sleeve to aim the cement section to the damaged part of said producing sleeve; then pours cement via 5 pour bowl into the cement section 4; and uses the through hole at the section to pour cement into the annular space between the repair tubes and the producing sleeve; and uses the cement umbrella at the cement section to support upper cement when the well is closed, to repair the damaged part when the cement is solidified. The invention can reduce cost and time.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Device for automatically detecting and repairing building steel pipe crack

InactiveCN111761294ATake advantage ofImprove repair efficiencyOther manufacturing equipments/toolsArchitectural engineeringPipe

The invention discloses a device for automatically detecting and repairing a building steel pipe crack. The device for automatically detecting and repairing the building steel pipe crack comprises a base, wherein a first fixed plate is fixedly connected to the upper side end face of the base; a detecting and welding mechanism is arranged on the front side end face of the first fixed plate and is used for detecting and welding a building steel pipe; the detecting and welding mechanism comprises two left-and-right symmetrical first screw rod installation plates fixedly connected onto the front side end face of the first fixed plate; a first screw rod is rotatably connected between the two first screw rod installation plates; a feeding mechanism is arranged on the upper side end face of the base; a derusting mechanism is arranged on the right side of the feeding mechanism; and a grinding mechanism is arranged on the right side of the derusting mechanism. Therefore, the device provided bythe invention can be used for automatically detecting and repairing the building steel pipe crack, so that the building steel pipe repairing efficiency is improved, and a lot of manpower and time aresaved.

Owner:杭州圣埃蒂机械科技有限公司

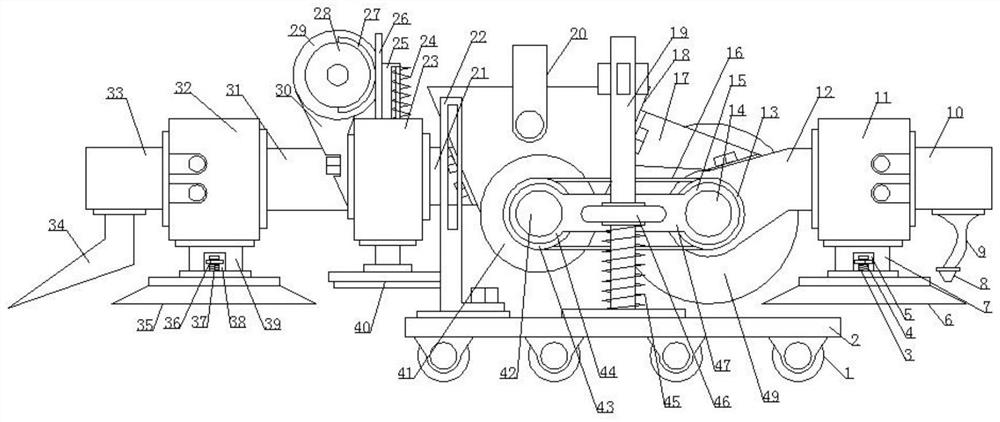

Road repair all-in-one machine

The invention aims to solve the problem that pavement defects are difficult to repair in the prior art. The invention discloses a road repair all-in-one machine. The road repair all-in-one machine comprises a brake wheel, a support frame, a first spiral spring, a first slider, a first guide frame, a first cleaning brush, a first rotating shaft, a nozzle, a water guide pipe, a water pump, a first motor, an inclined frame, a first gear, a second rotating shaft, a first connecting ring, a chain, a connecting frame, a containing box, a guide rod, a handle, a connecting rod, a guide frame, a guidecylinder, a second spiral spring, a sliding frame, a first rack, a second rack, a rotating disc, a second motor, a rack, fixing rods, a third motor, a pumping pump, a material guide cover, a second cleaning brush and a second slider. The road repair all-in-one machine is of an integrated structure, can clean the road surface, can fill stones into the defect parts of the road surface for repair, and is convenient to operate.

Owner:马孟杰

Variable-diameter pipeline sealing clamp and pipeline maintenance method

ActiveCN108240524ASolve the problem that the scope of use is relatively singleImplement patchingPipe elementsWrap aroundMechanical engineering

The invention provides a variable-diameter pipeline sealing clamp and a pipeline maintenance method. The variable-diameter pipeline sealing clamp comprises a plurality of clamping plates which are sequentially spliced along the circumferential direction of a to-be-repaired pipeline, wherein the pipeline comprises a damaged pipe section and non-damaged pipe sections arranged on the two sides of thedamaged pipe section; the variable-diameter pipeline sealing clamp further comprises of transition assemblies, the transition assemblies sleeve the non-damaged pipe sections at least one side of thedamaged tube section, the plurality of clamping plates wrap around the outer side of the damaged pipe section and are connected with the non-damaged pipe sections through the transition assemblies, wherein the inner diameter of each transition assembly is matched with the outer diameter of the corresponding non-damaged pipe sections; and a pipe body wrapping space used for wrapping around the damaged pipe section is formed between the plurality of clamping plates and the transition assemblies on the two sides of the damaged pipe section, the damaged pipe section is sealed in the pipe body wrapping space. According to the variable-diameter pipeline sealing clamp, the problem that a using range of a pipeline repairing device in the prior art is relatively single is solved.

Owner:PETROCHINA CO LTD

Metal conducting wire repairing method and repairing apparatus

InactiveCN101225509ARealize OKImplement patchingChemical vapor deposition coatingMetallurgyChemical vapor deposition

The invention relates to a metal conducting wire mending method, comprising a base plate, determining a broken-circuit part of a metal conducting wire and forming a metal film at the broken-circuit part of the metal conducting wire by chemical vapor deposition method.

Owner:INNOCOM TECH SHENZHEN +1

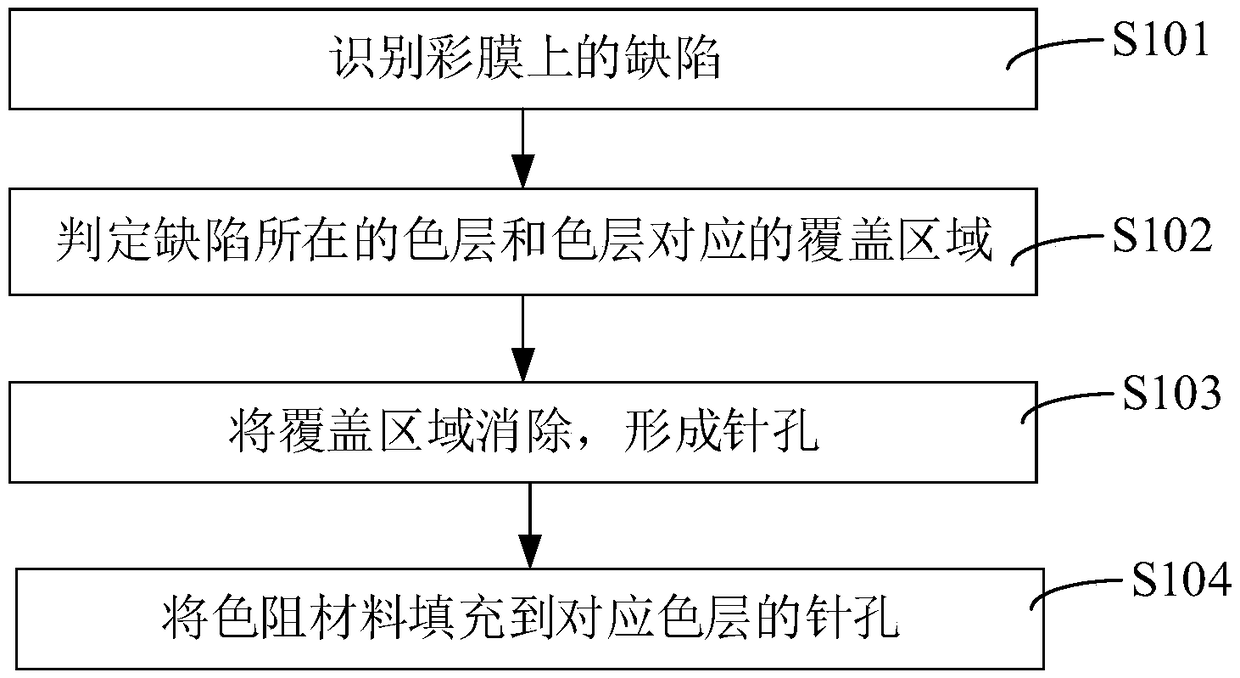

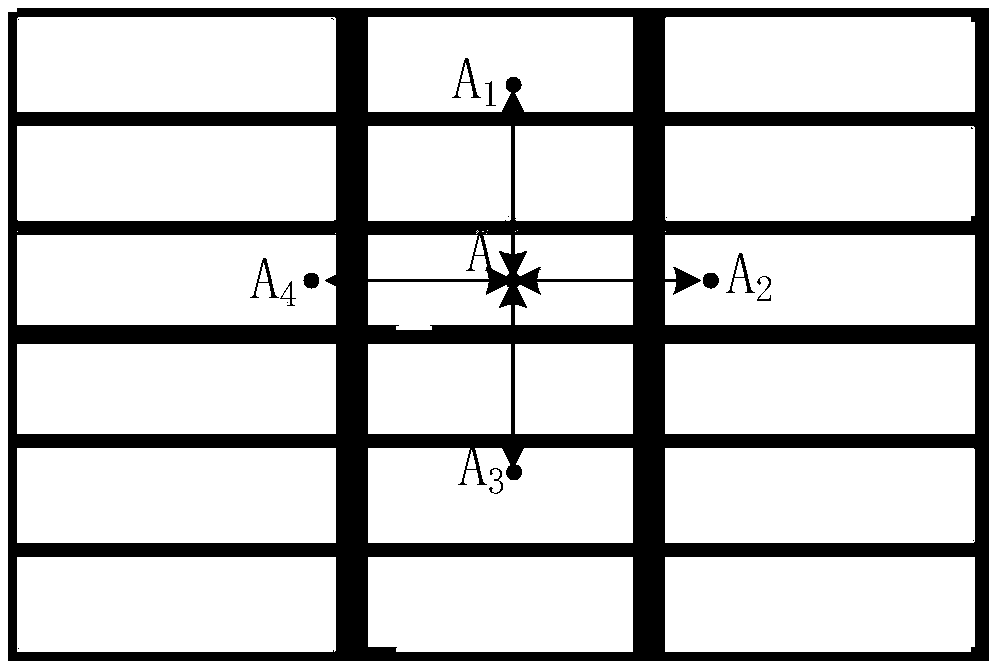

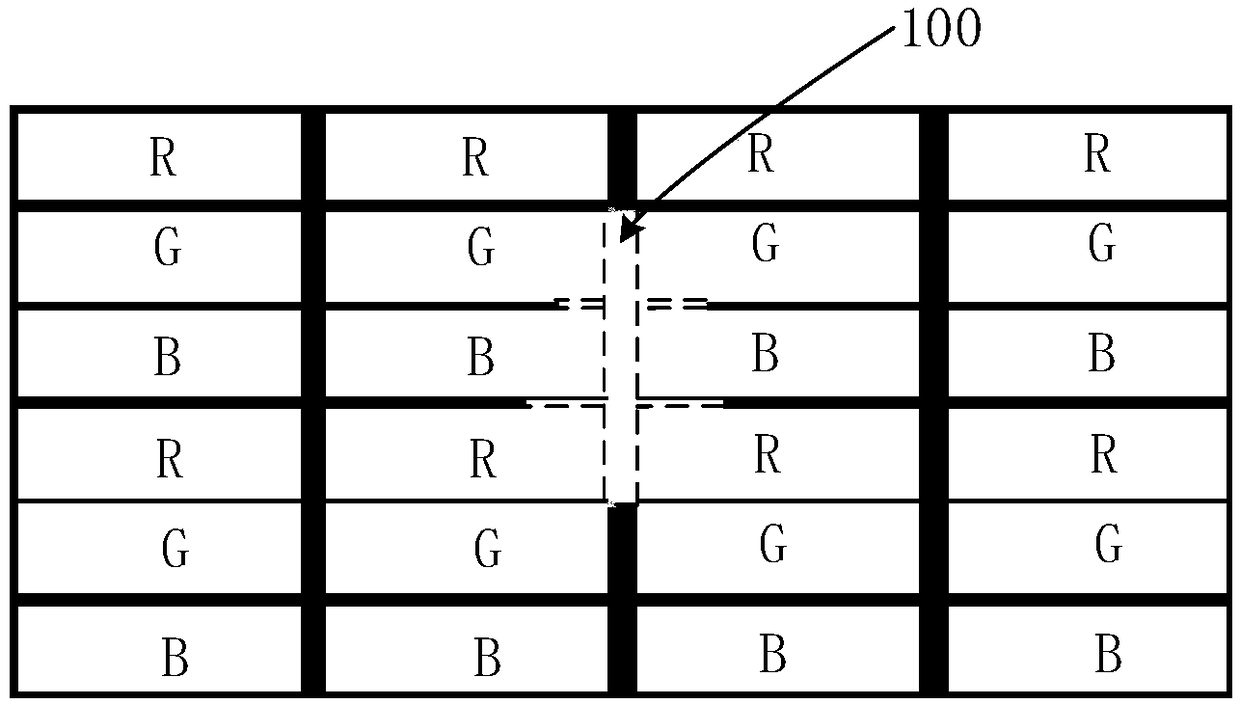

Repairing method and repairing device

The invention relates to a repairing method and a repairing device. In the repairing method, gray scale information of a color film is obtained automatically, the gray scale information is compared with preset gray scale information, defects on the color film is identified; moreover, by judgement of a color layer where the defects are and a rectangular coverage area corresponding to the color layer, elimination of the rectangular coverage area and filling of a color resistance material, automatic identification, elimination an repairing for the defects can be realized. The method and the device have the advantages of having high degree of automation, reducing manual operations, improving color film defect repairing speed and repairing quality and reducing cost.

Owner:HKC CORP LTD +1

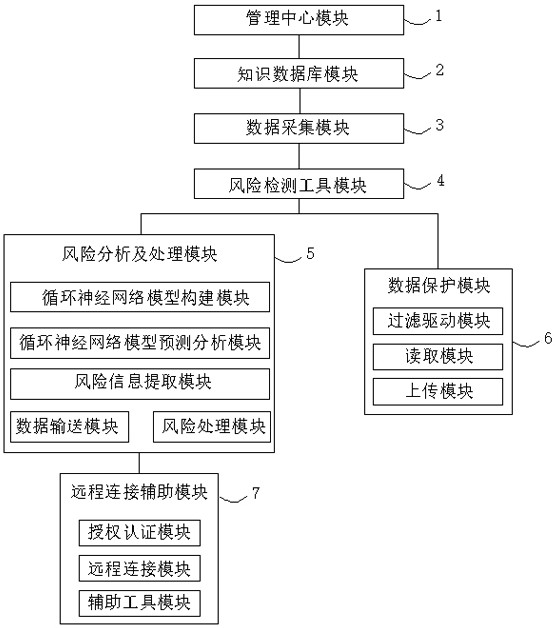

Network security emergency disposal system based on recurrent neural network model

InactiveCN113824745AImprove securityEnsure safetyNeural architecturesTransmissionSystems managementData acquisition

The invention discloses a network security emergency disposal system based on a recurrent neural network model, and the system comprises the following modules: a management center module which is used for carrying out system management and completing the connection and calling of each module; a knowledge database module which is used for storing risk data and expert knowledge data and regularly updating the data; a data acquisition module which is used for monitoring and acquiring network data in real time; a risk detection tool module which is used for carrying out security detection on the network data and carrying out detection and classification on abnormal data; a risk analysis and processing module which is used for analyzing, matching and processing the abnormal data; a data protection module which is used for protecting local data after abnormal data is detected; and a remote connection auxiliary module which is used for realizing remote assisted processing of the security event. The invention has the beneficial effects that the risk database is utilized to construct the recurrent neural network model, so that the risk can be conveniently rectified and corrected in time, and the process of emergency processing vulnerability detection and rectification is greatly reduced.

Owner:WUHAN UNIV

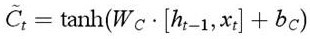

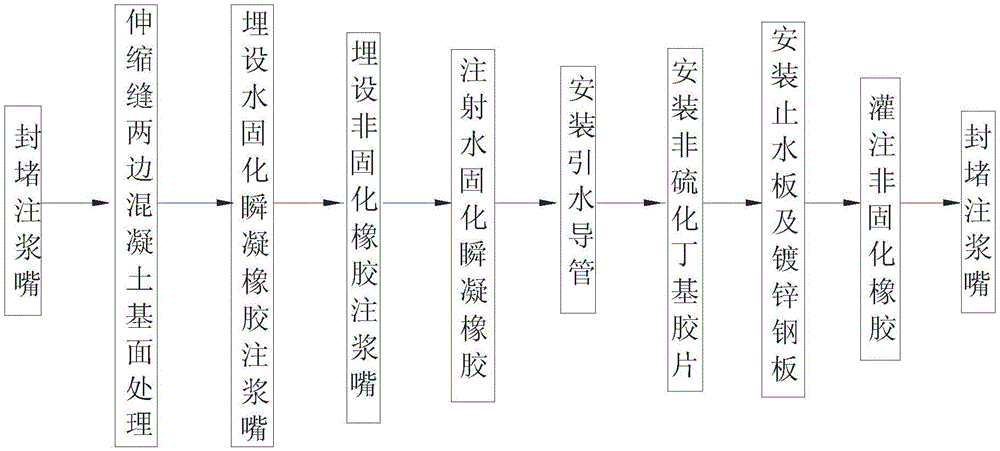

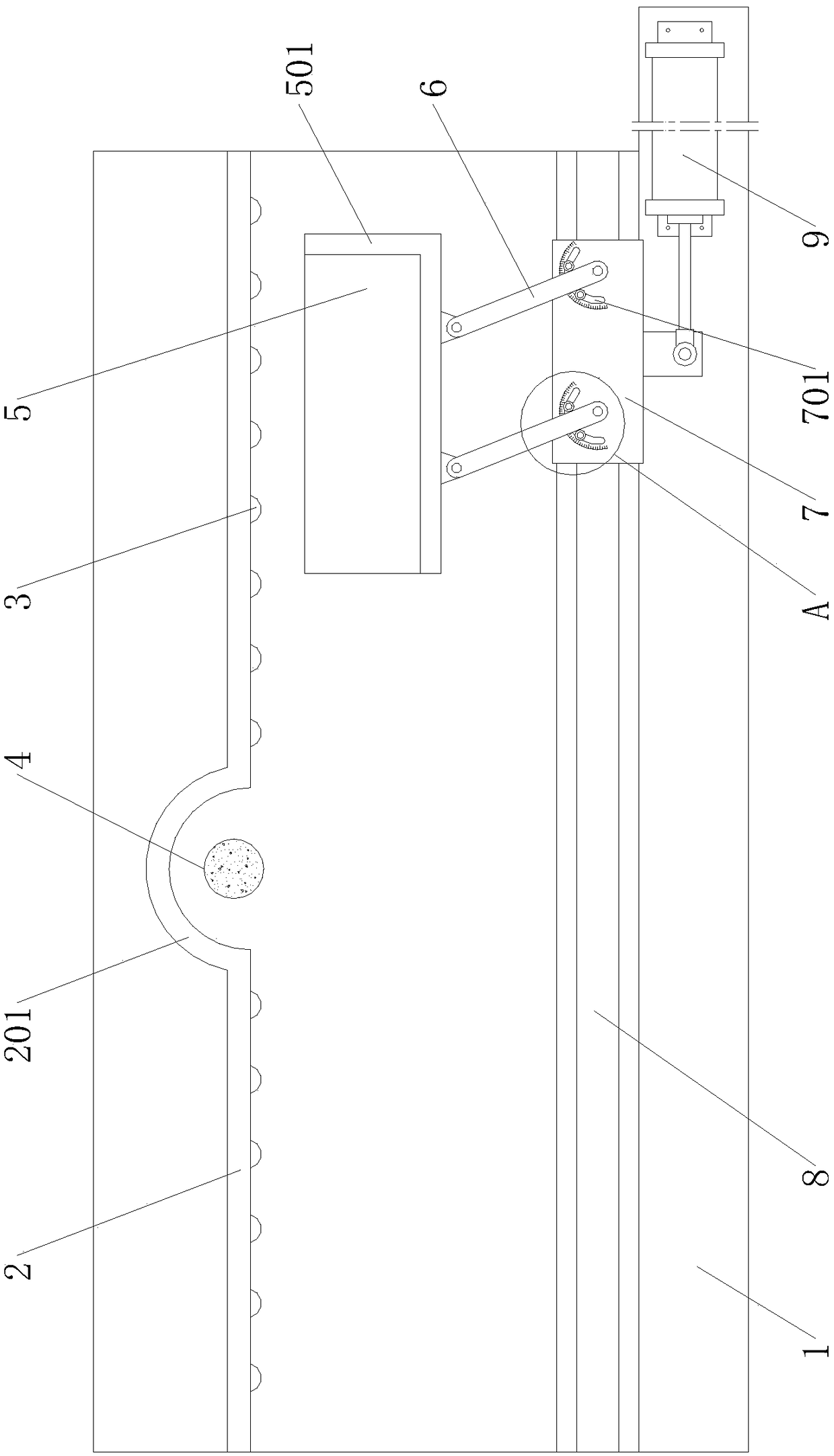

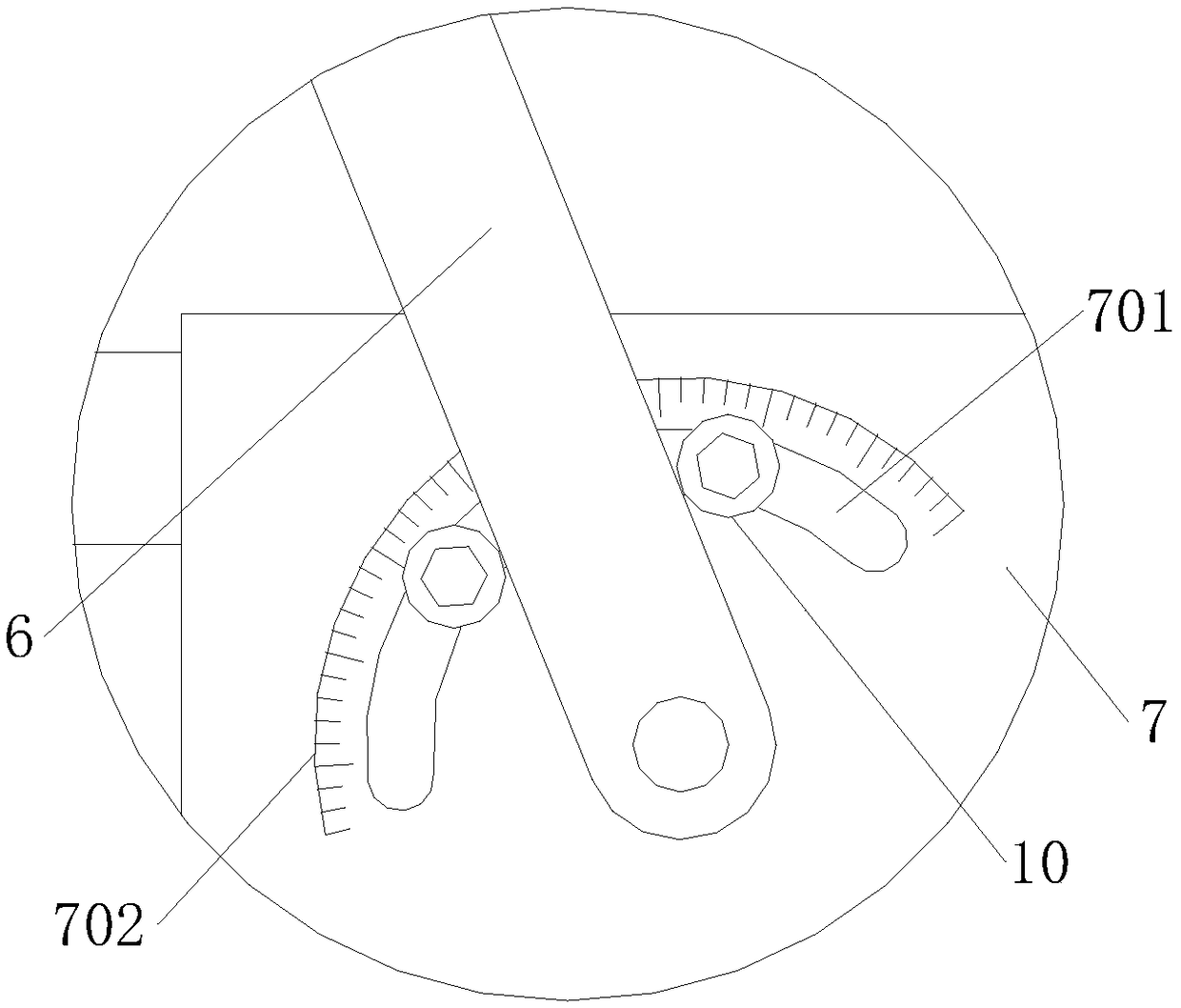

Tunnel and city pipe gallery leakage expansion joint repairing method and expansion joint device

ActiveCN106436771AExtended service lifeImplement patchingArtificial islandsUnderground chambersDevice formEngineering

The invention relates to a tunnel and city pipe gallery leakage expansion joint repairing method and an expansion joint device. The method includes the following steps that expansion joint checking is carried out; treatment of base faces of concrete on the two sides of an expansion joint is carried out; a water-cured instant coagulating grouting nozzle is embedded; a non-cured rubber grouting nozzle is embedded; water-cured instant coagulating rubber is injected; a water guide pipe is installed; a non-vulcanized butyl rubber sheet is installed; a water stopping plate and a steel plate are installed; pouring of non-cured rubber is carried out; the grouting nozzles are plugged; and the expansion joint device is formed after repairing is carried out. Through a repairing method combining rigidity protection and the structural design that water guiding serves as a main and plugging serves as an auxiliary, flexible instant grouting leakage plugging is achieved; by means of the expansion joint device formed after repairing, repairing of the tunnel and pipe gallery expansion joint is achieved to a large extent, the overall device is high in firmness and not likely to be damaged, the expansion joint is filled with non-cured rubber strips, it is guaranteed that all components in the device structure do not move, the repairing quality is effectively guaranteed, guide and plugging are combined, and the service life of the expansion joint device is prolonged.

Owner:南京正隆环保工程有限公司

Vibration resisting small carpentry edge polishing machine

InactiveCN109129099AAvoid force bounceGuaranteed to be parallel to each otherEdge grinding machinesGrinding feed controlWoodworkingShip's carpenter

The invention discloses a vibration resisting small carpentry edge polishing machine. The vibration resisting small carpentry edge polishing machine comprises a working platform. A limiting plate is arranged on one side of the working platform. A plurality of rotary balls are arranged on the limiting plate side by side. An arc opening is formed in the middle of the limiting plate. A rotary polishing head is arranged in the arc opening. A sidesway plate is arranged on the outer side of the limiting plate. The lower end of the sidesway plate is positioned at the working platform through a plurality of pulleys. An L-shaped baffle is arranged on one side of the sidesway plate. Push rods are rotatably connected with the outer side of the baffle. A push block is rotatably connected with the endsof the push rods. The lower end of the push block is connected with the working platform by a linear slide rail. A push air cylinder is connected with one side of the push block. Arc mounting holes are formed in the push block. The arc mounting holes are internally provided with locking assemblies matched with the push rods. The vibration resisting small carpentry edge polishing machine has the characteristics that working stability is high, and the edge polishing effect is excellent.

Owner:湖州欧宝木业有限公司

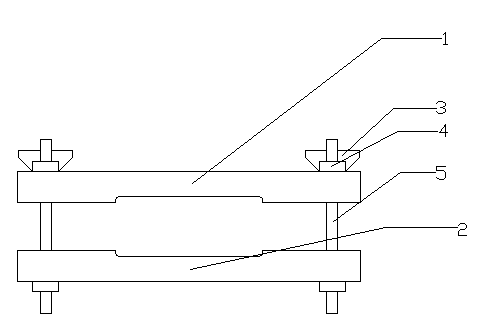

Tire repair fixer

The invention discloses a tire repair fixer which is provided with an upper clamp plate and a lower clamp plate; the upper clamp plate and the lower clamp plate are respectively and internally provided with a concave surface; a tire patch and a tire surface are fixed in a way of clamping at the upper part and the lower part; compared with the original beating fixing way, the tire repair fixer realizes the sticky fixing way between the tire patch and the tire surface, thus enabling adhesion to be more uniform, and being convenient and simple; and the concave surfaces are arranged in the clamp plates, so that spaces are reserved for the tire patch, the problems of uneven adhesion pressure, damage to a tire caused by the excessive pressure at the stuck part of the tire patch and the like can be solved, and the tire repair fixer bas good social benefit and practicability.

Owner:WUJIANG DONGXIN PLASTIC PACKAGING PLANT

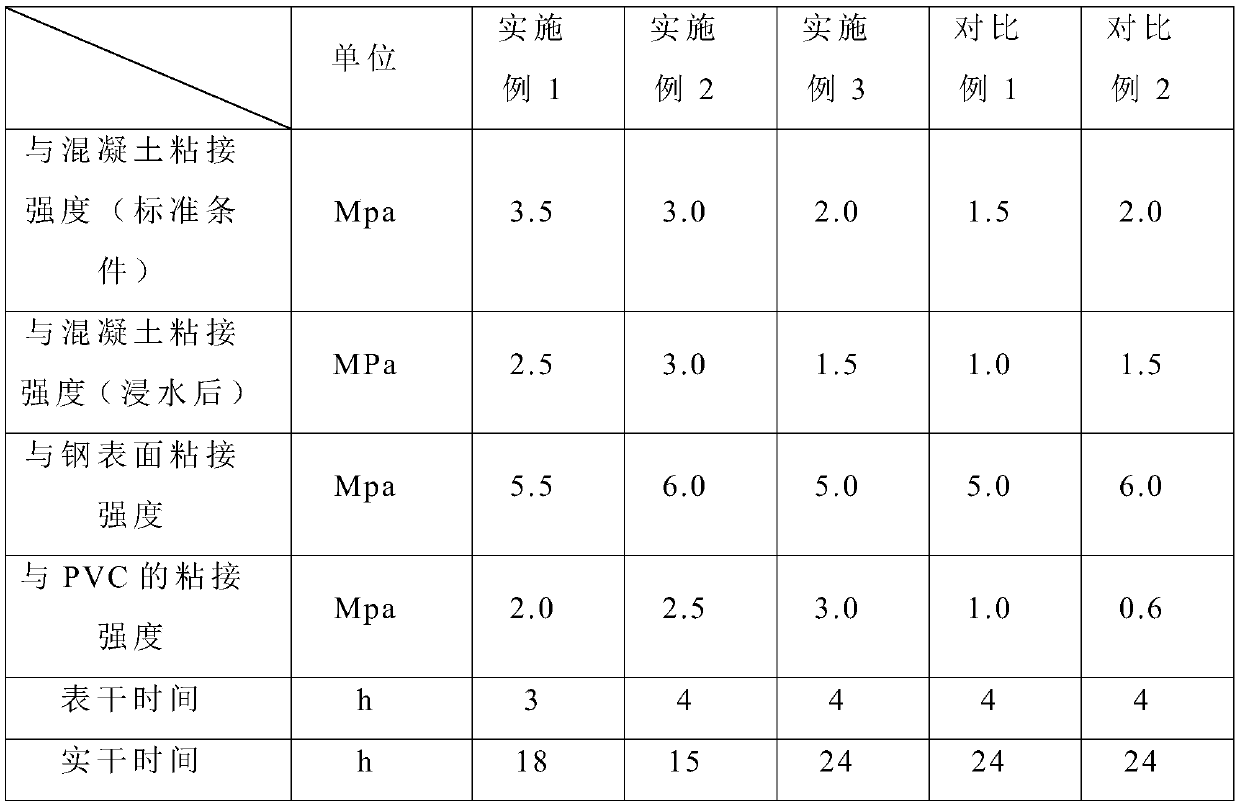

Curing agent composition for epoxy mortar and preparation method of curing agent composition

ActiveCN109762140AGood adhesionGuaranteed Adhesive AttachmentOrganic compound preparationAmino-hyroxy compound preparationAliphatic amineAlkylphenol

The invention discloses curing agent composition for epoxy mortar and a preparation method of the curing agent composition. The curing agent composition is prepared from modified polyether amine and modified aliphatic amine in the feeding mass ratio being 0.8-2.0:1, wherein modified polyether amine is prepared from a polyether amine curing agent, alkylphenol and tris(dimethylaminomethyl)phenol bya reaction and a reaction with benzyl alcohol; modified aliphatic amine is prepared from 2-ethylhexyl glycidyl ether and triethylenetetramine by a reaction. The preparation method comprises the following steps: modified polyether amine and modified aliphatic amine are prepared respectively firstly and then mixed in the formula ratio, and the curing agent composition is prepared. Compared with theconventional curing agent in the prior art, the curing agent composition can endow the epoxy mortar and PVC with quite good adhesive strength and further has excellent mechanical properties, durability and application property, and can adapt to dynamic deformation of concrete.

Owner:四川凯伦新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com