Composition used in flat protective layer, preparation method thereof, and display device

A flat protective layer and composition technology, which is applied in transportation, packaging, coating, instruments, etc., can solve the problem that the OC layer has no effective repair means, and achieve the effect of improving product yield and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] An embodiment of the present invention provides a method for preparing a composition for a flat protective layer, comprising:

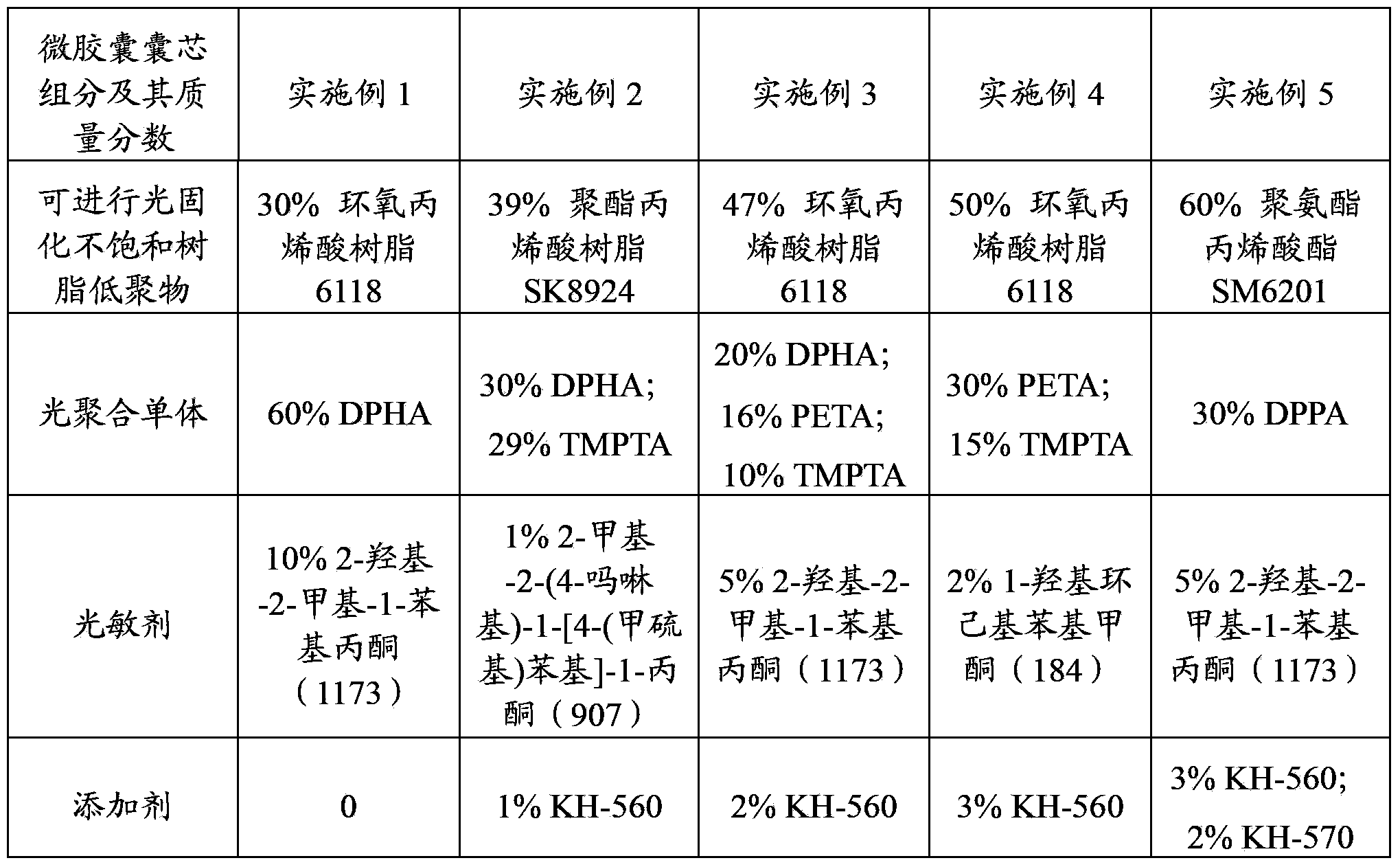

[0047] A photocurable unsaturated resin oligomer with a mass fraction of 30% to 60%, a photopolymerizable monomer with a mass fraction of 30% to 60%, a photosensitizer with a mass fraction of 1% to 10%, and a mass fraction of Additives with a fraction of 0% to 5% are mixed and dispersed to obtain a composition for microcapsule cores;

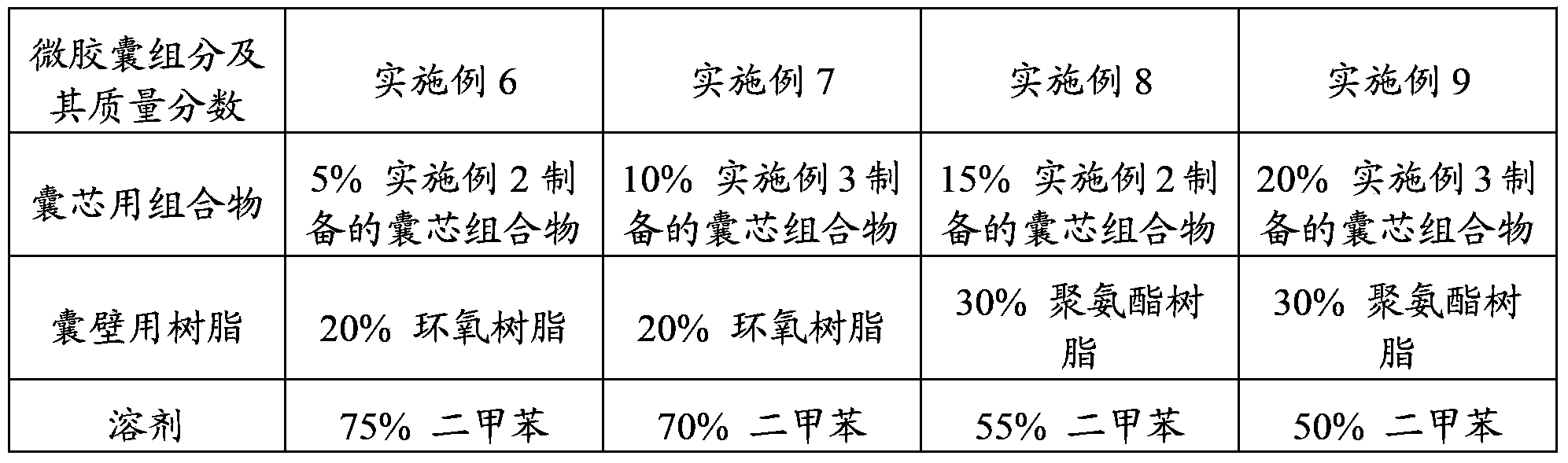

[0048] adding the composition for the microcapsule core dropwise into the solution of the microcapsule wall to form microcapsules;

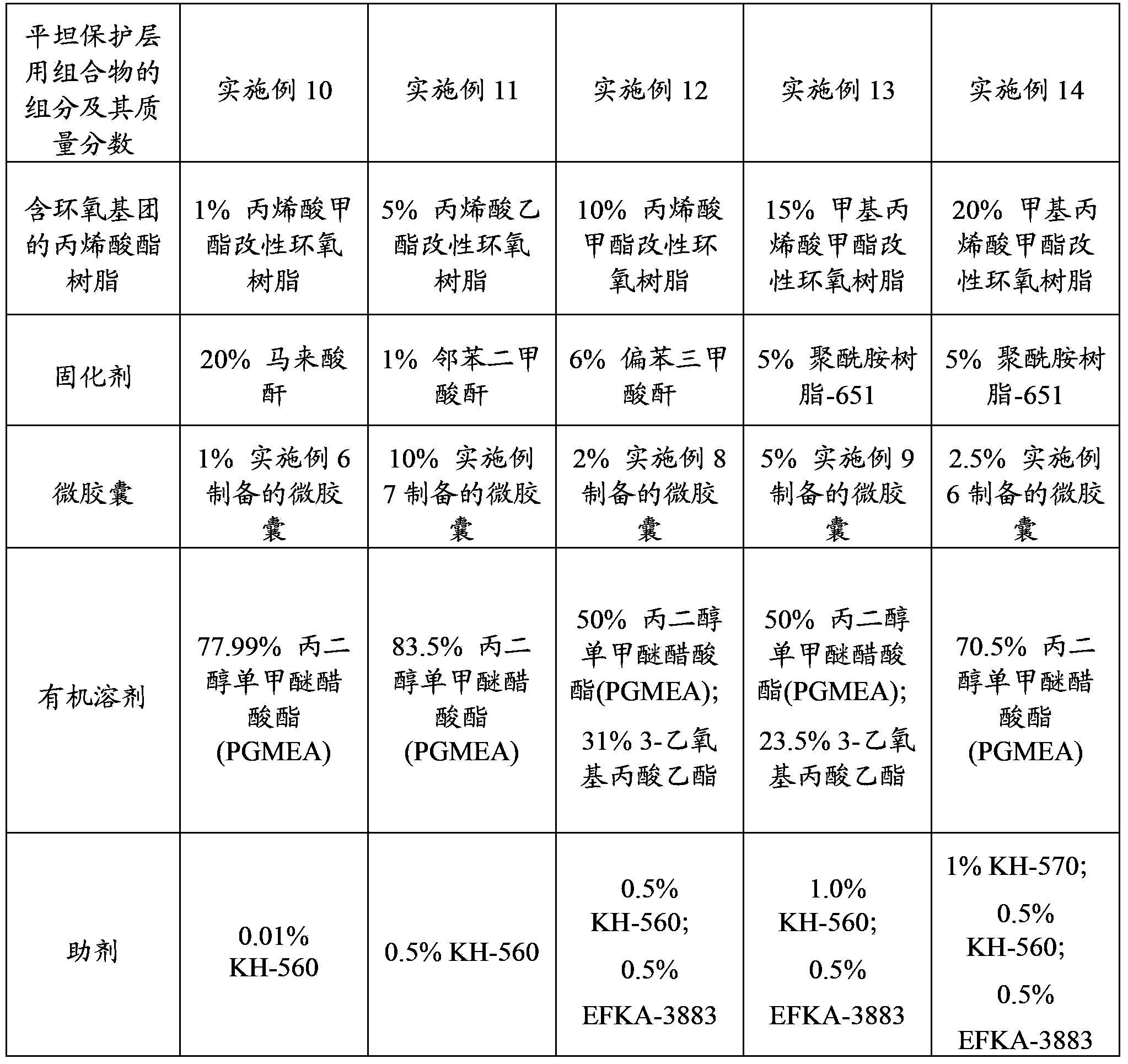

[0049] The microcapsules with a mass fraction of 1% to 10% are mixed with the components of the composition for flat protective layer to form the composition for flat protective layer. The components of the composition for a flat protective layer may be other components of the composition for a flat protective layer of the present invention excluding microcapsules, or may be compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com