Self-walking type pipeline inwall overhauling system and overhauling method

A self-propelled, pipeline technology, applied in the direction of special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of human and material resources, environment and society, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of this patent will be described in further detail below in conjunction with the accompanying drawings. Arrow direction among the figure points to the front side of running gear advancing direction.

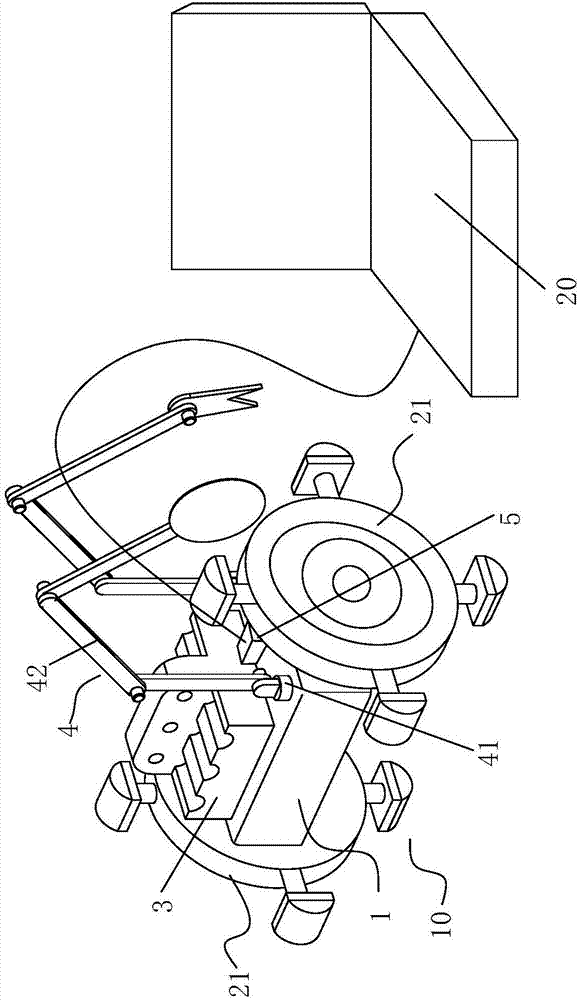

[0031] Such as figure 1 The self-propelled pipeline inner wall maintenance system shown in the figure includes a control host 20 and a self-propelled pipeline inner wall maintenance integrated machine 10, and information exchange is performed between the control host 20 and the self-propelled pipeline inner wall maintenance integrated machine 10 through a signal generator / receiver 5 . The self-propelled all-in-one machine for inspection and maintenance of the inner wall of the pipeline includes a body 1 on which a traveling mechanism, a functional appliance rack 3 , a mechanical arm 4 and a signal generator / receiver 5 are arranged.

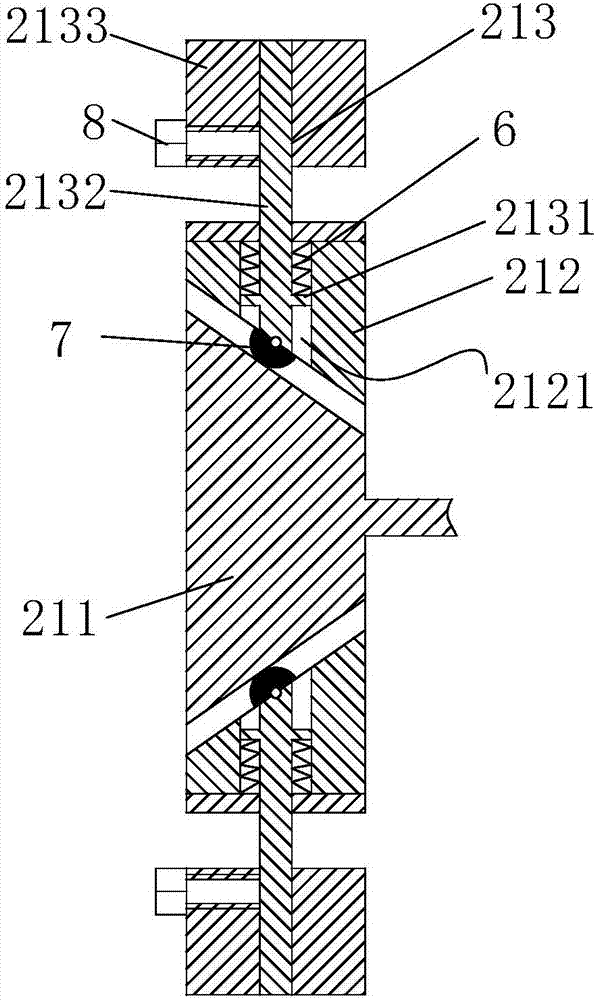

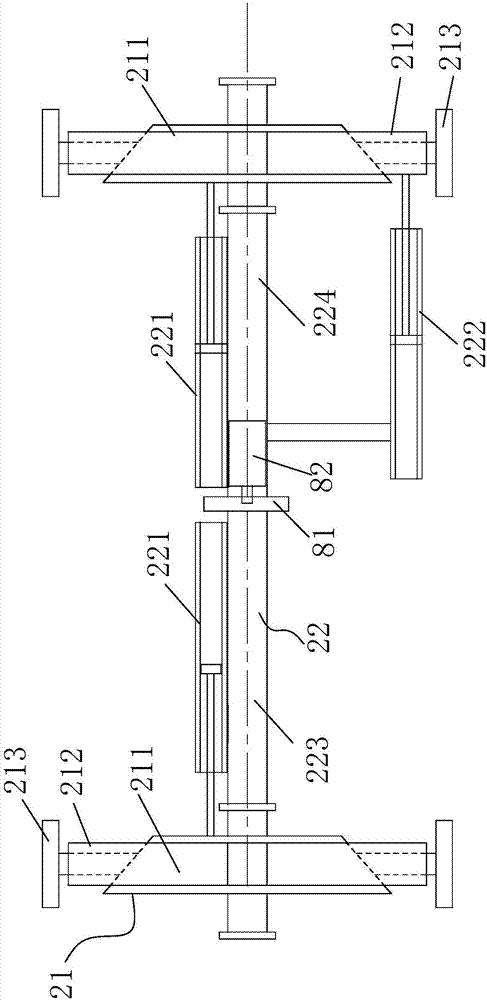

[0032] Such as figure 2 and image 3 The running mechanism shown includes a main beam 22 and radial fixing dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com