Transverse wave focusing and flushing ultrasonic probe

An ultrasonic and flushing technology, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as unstable echo signals, loss of probes, and poor coupling, so as to improve social benefits and Economic benefits, ensuring normal working conditions, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

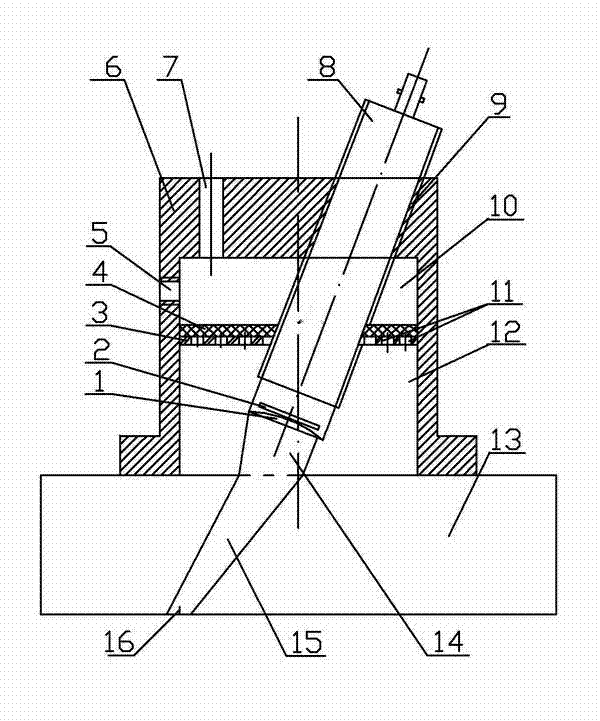

[0008] A shear wave focused flushing ultrasonic probe, comprising a probe shell 6 and a probe core 8, characterized in that the probe core 8 is inserted into the inner cavity of the probe shell 6 from the inclined hole 9 at the top of the probe shell 6, and the probe core 8 and the probe shell The inclined hole 9 at the top is threaded, the axial direction of the inclined hole 9 forms an angle of 10-30 degrees with the vertical direction, and the inner cavity of the probe housing 6 is provided with a water cavity isolation bracket 3, which is set on the outside of the probe core 8. On the circle, the water cavity isolation bracket 3 divides the inner cavity of the probe housing 6 into an upper water cavity 10 and a lower water cavity 12. The upper water cavity 10 and the lower water cavity 12 are connected by the leak hole 11 on the water cavity isolation bracket 3, and the filter interlayer 4 Adhesive together with the water cavity isolation bracket 3, the spherical concave mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com