A full-section flaw detection method and device for rail bottoms in service

A flaw detection device and full-section technology, which is applied in the field of flaw detection of in-service rails, can solve the problems of affecting the safety of rail transportation, failure to detect flaws, and long time consumption, etc., to achieve good flaw detection effects, stable and reliable flaw detection process, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

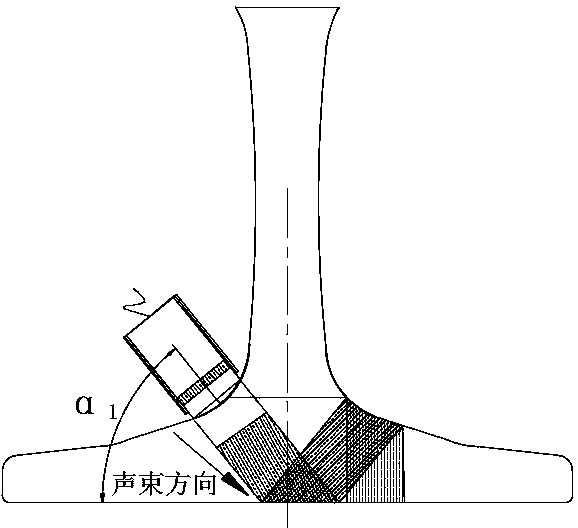

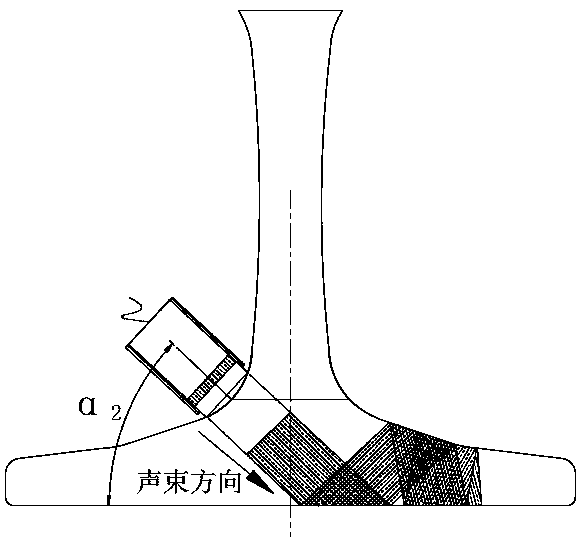

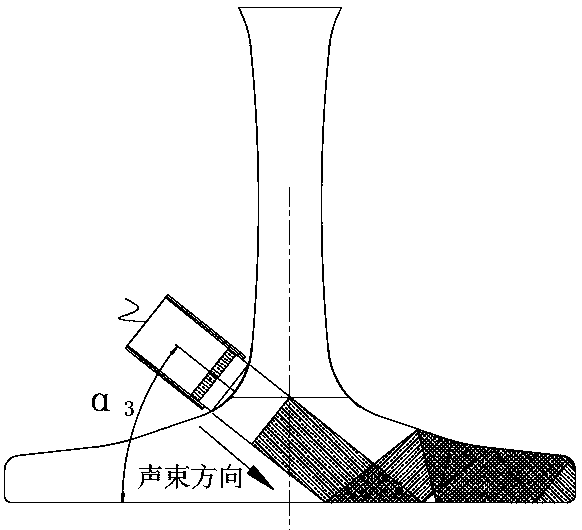

[0069] As shown in Figures 1 to 13 and 17, an in-service rail bottom full-section flaw detection device includes a trolley 1 and a flaw detection structure. The front and rear ends of the bottom of the trolley 1 are provided with track wheels 2, and the track wheels 2 are trolley 1 on the rail 3. The supporting rolling wheels on the tread surface play a supporting and guiding role for the trolley 1 to move forward on the rail 3. The flaw detection structure is set on the beam 4 at the bottom of the trolley 1 through the clamping mechanism. The flaw detection structure includes two sets of probes set on both sides of the rail 3 frame 5 and the probes 6 installed in the probe frame 5, when the flaw detection device is installed on the rail 3, the corresponding probes 6 in the two groups of probe frames 5 are symmetrical with respect to the central axis of the rail 3, and each set of probes includes at least three Each probe 6, the angle α between each probe 6 in a single group of...

Embodiment 2

[0074] Such as Figures 1 to 17 As shown, on the basis of Embodiment 1, the upper end of the probe frame 5 is fixedly connected with front and rear connecting rods 28,29, and the other ends of the front and rear connecting rods 28,29 are respectively equipped with front and rear landing gears 30,31. , The other ends of the rear landing gear 30, 31 are rotatably connected to the two ends of the same landing gear mounting seat 32, thereby realizing the closing and opening of the landing gear, making the loading and unloading of the flaw detection device faster and more convenient, and the front and rear connecting rods 28 , 29 are respectively adjustable in installation height on the front and rear landing gears 30, 31, and the landing gear mounting seat 32 is connected to the M-shaped connecting seat 14 bottom by the above-mentioned compensating rod 20, and the top of the above-mentioned arc waist-shaped hole 15 is all provided with Arcuate hole 33 is arranged, and the top of t...

Embodiment 3

[0079] Such as Figures 9 to 11, 17, on the basis of embodiment 2, the front end of the probe frame 5 (i.e. the forward end of the trolley 1) is provided with a rail 3 cleaning structure, and the rail 3 cleaning structure includes a motor 57, a steel brush head 58 and a motor holder 59, and the motor 57 is set on the front end of the probe frame 5 through the motor fixing seat 59, and the steel brush head 58 is connected to the end of the motor 57 through the coupling 60. 7, the arc zone 62 between 7, the motor 57 can automatically compensate and adjust downwards relative to the motor holder 59; it also includes a brush 63 arranged on the front end face of the probe frame 5, the brush 63 is positioned at the steel brush head 58 rear, the brush 63 Closely attached to the area to be tested; specifically, the motor 57 is connected to the motor fixing seat 59 through the motor mounting plate 64, the motor 57 is fixedly mounted on the front end of the motor mounting plate 64, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com