An ultrasonic phased array testing wedge for testing v-shaped corner workpieces

An ultrasonic phased array and wedge block technology, which is used in material analysis, measurement devices, and instruments using sonic/ultrasonic/infrasonic waves, can solve problems such as missed inspections at the top corners of V-shaped corner workpieces, and avoid waveform conversion and Multiple reflection attenuation, the best flaw detection effect, the effect of improving the detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

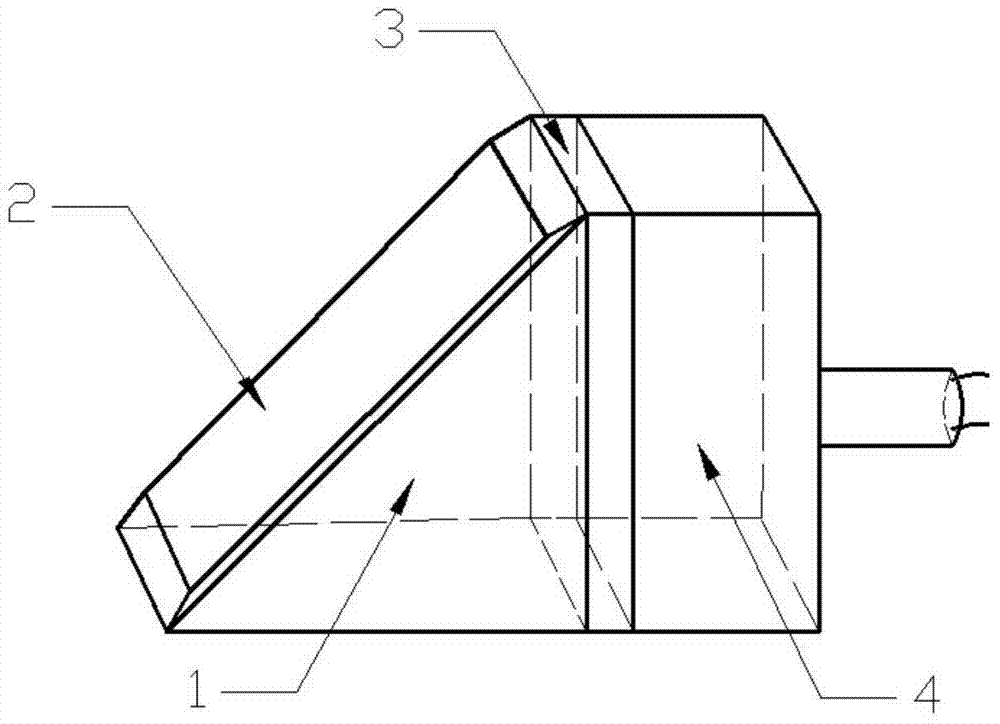

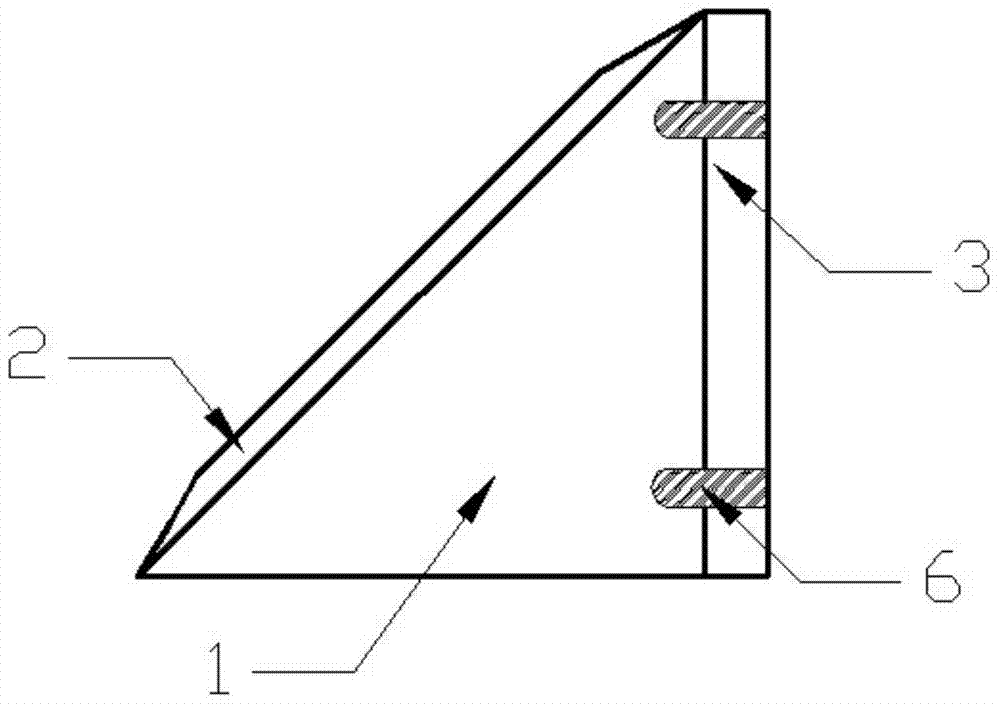

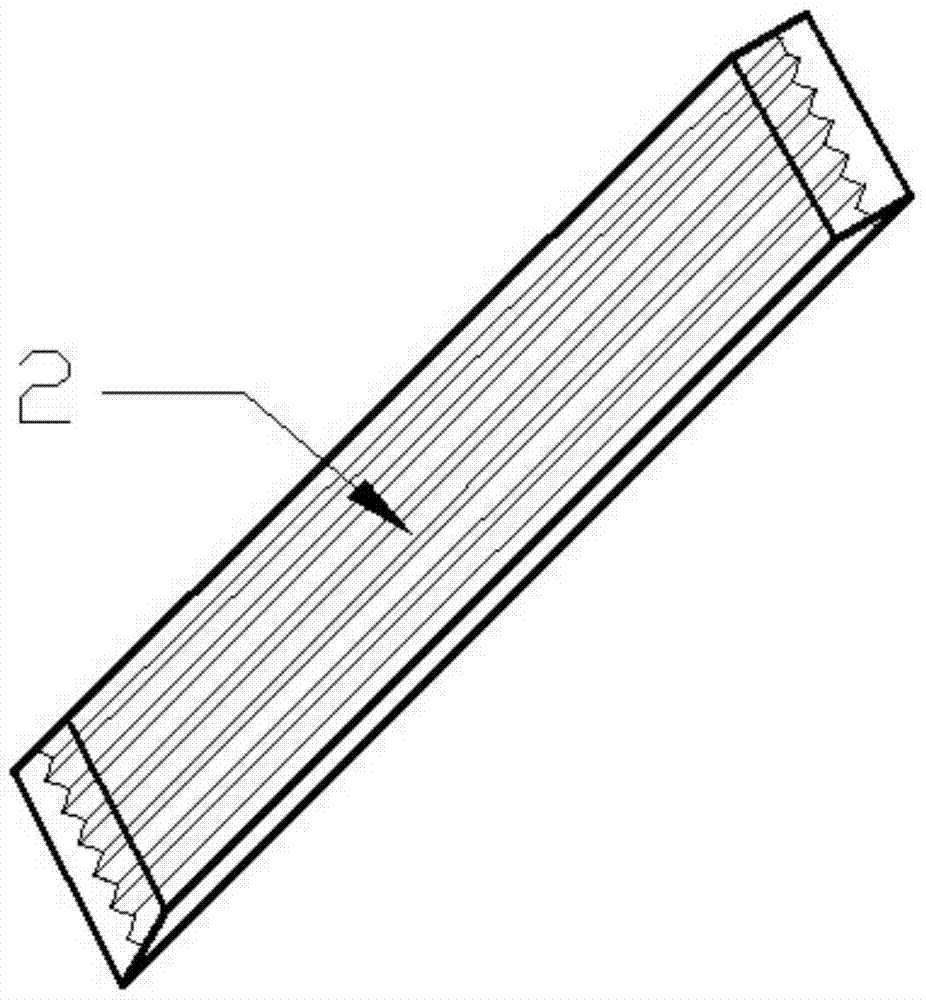

[0020] Such as Figure 1-5 As shown, the present invention is an ultrasonic phased array detection wedge, which can be used to realize the flaw detection of V-shaped corner workpieces, and the omnidirectional flaw detection of workpieces can be realized by using the wedges of the present invention. The wedge includes a wedge body 1 , a sound-absorbing layer 2 , a probe base 3 , and a threaded hole 6 . The wedge body 1 is a triangular prism, and the upper and lower bottom surfaces of the triangular prism are right triangles. The sound-absorbing layer 2 is a trapezoid, and there is a sawtooth-shaped area inside the trapezoid, which contains sound-absorbing materials, and its function is to absorb and refract the ultrasonic waves from the wedge main body 1 . The wedge main body 1 and the sound-absorbing layer 2 are connected by being embedded in each other. The probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com