A damage detection device for external cylindrical pipes of valves

A damage detection, cylindrical technology, applied in the direction of measuring devices, program control manipulators, instruments, etc., can solve the problems of cylindrical pipeline damage, valve pipeline inspection inconvenience, etc., to achieve convenient operation, wide range of flaw detection, high degree of intelligence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

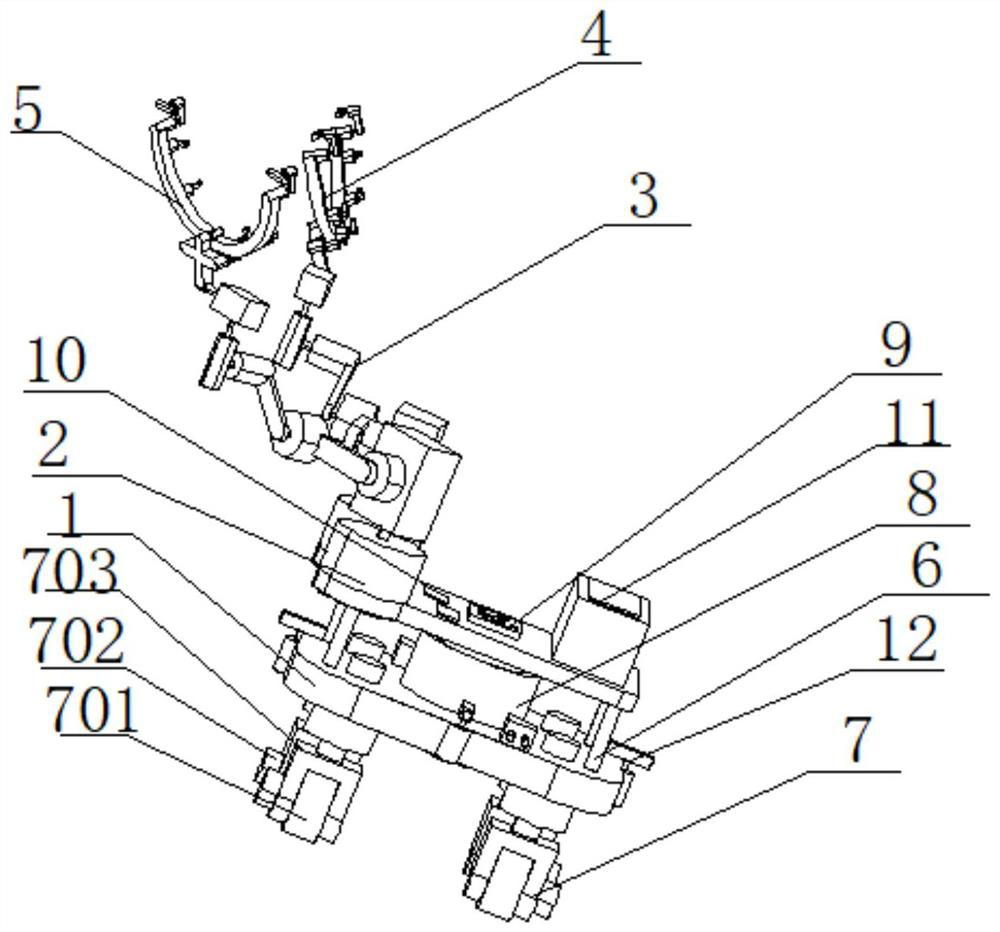

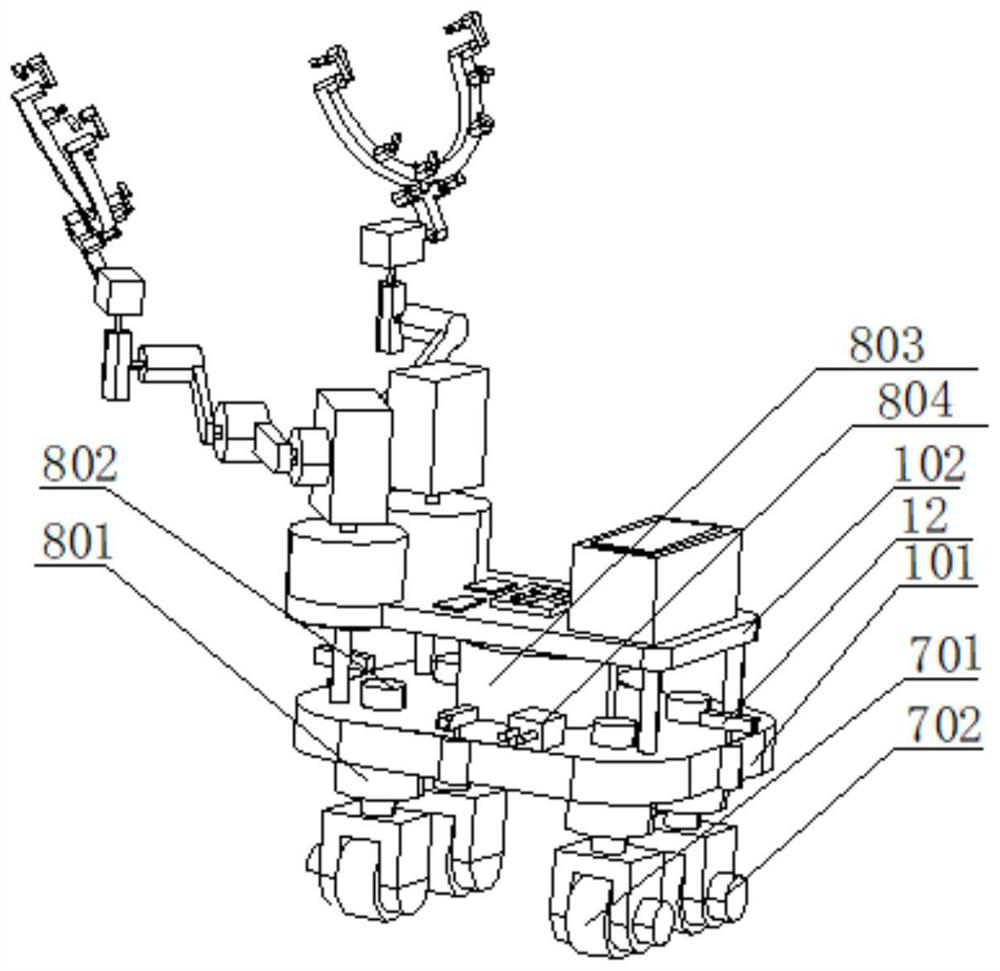

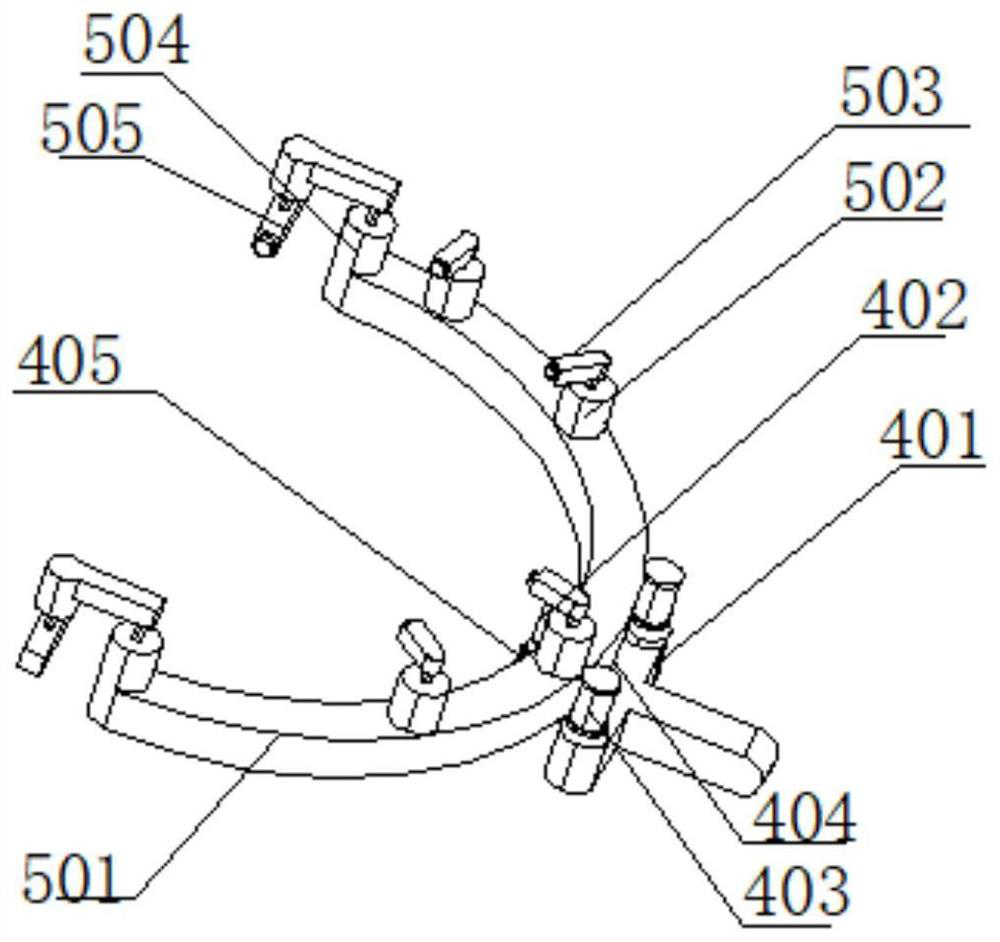

[0035] like Figure 1-3 As shown, a valve external cylindrical pipeline damage detection device provided in this embodiment includes a support frame 1, two rotating motors 2, a rotating mechanical arm 3, a clamping mechanism 4 and a detection mechanism 5, and the rotating motor 2 are installed on the support frame 1 at intervals, and a rotating mechanical arm 3 is installed on the output end of the rotating motor 2, a clamping mechanism 4 is installed above the rotating mechanical arm 3, and a detection mechanism 5 is installed above the clamping mechanism 4; In this embodiment, rotating motors 2 are installed at intervals on the support frame 1 , and the rotating motor 2 drives the mechanical arm 3 to rotate to realize the detection of various parts of the pipeline.

[0036] like figure 1 As shown, the support frame 1 in this embodiment includes a main support plate 101 and an upper support plate 102, the upper support plate 102 is located above the main support plate 101, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com