Environment-friendly oil pipe flaw detection device for well drilling/repairing operation

A technology of flaw detection and oil pipe, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problems of high cost of use, harsh use conditions, and small leaks are not easy to see, etc. problem, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

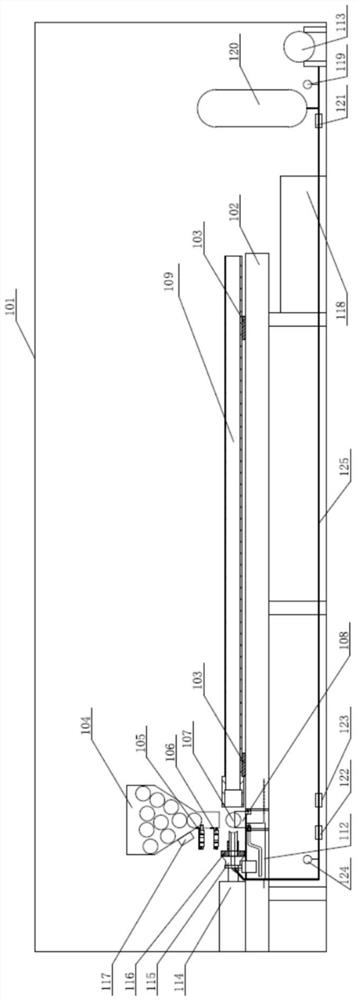

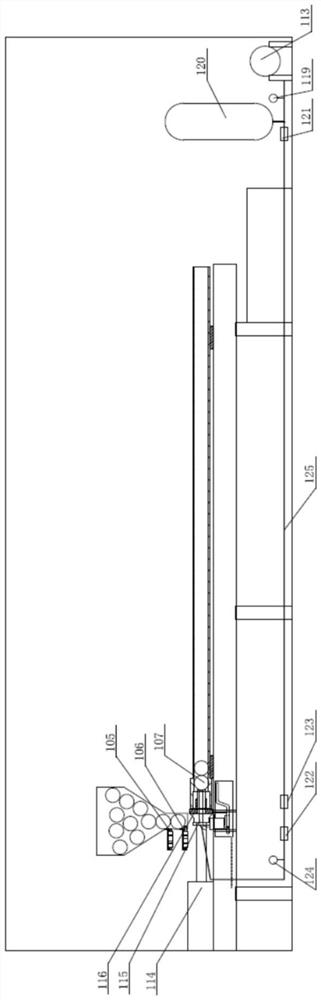

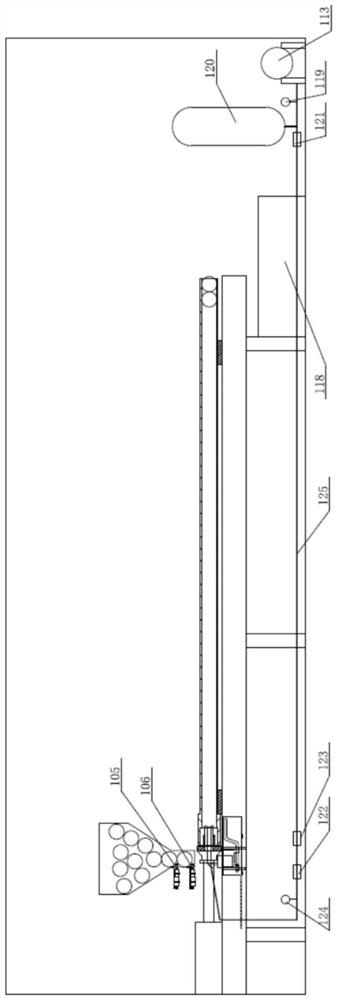

[0028] Below in conjunction with the accompanying drawings and specific embodiments, the overall scheme of the present invention is described in further detail:

[0029] see figure 1 , the structure of the specific embodiment of the present invention includes a tube box 101, a flaw detection platform 102, a flaw detection ball box 104, a lifting platform 108, a push device, a power transmission device and a pressure detection device. The flaw detection platform 102 is erected inside the tube box 101. The limit supports 103 are distributed on the flaw detection platform 102. A flaw detection ball box 104 is arranged on the front and upper part of the flaw detection platform 102. A plurality of flaw detection balls 107 are arranged in the flaw detection ball box 104. The bottom of the flaw detection ball box 104 is provided with an outlet, and the outlet is provided with a The switch for controlling the falling out of the flaw detection ball 107 includes a first switch 105 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com