Patents

Literature

42results about How to "Accurate flaw detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Middle-low-speed magnetic suspension rescue robot

ActiveCN106239474AEffective Public Works MaintenanceEffective Operational SecurityProgramme-controlled manipulatorLow speedRescue robot

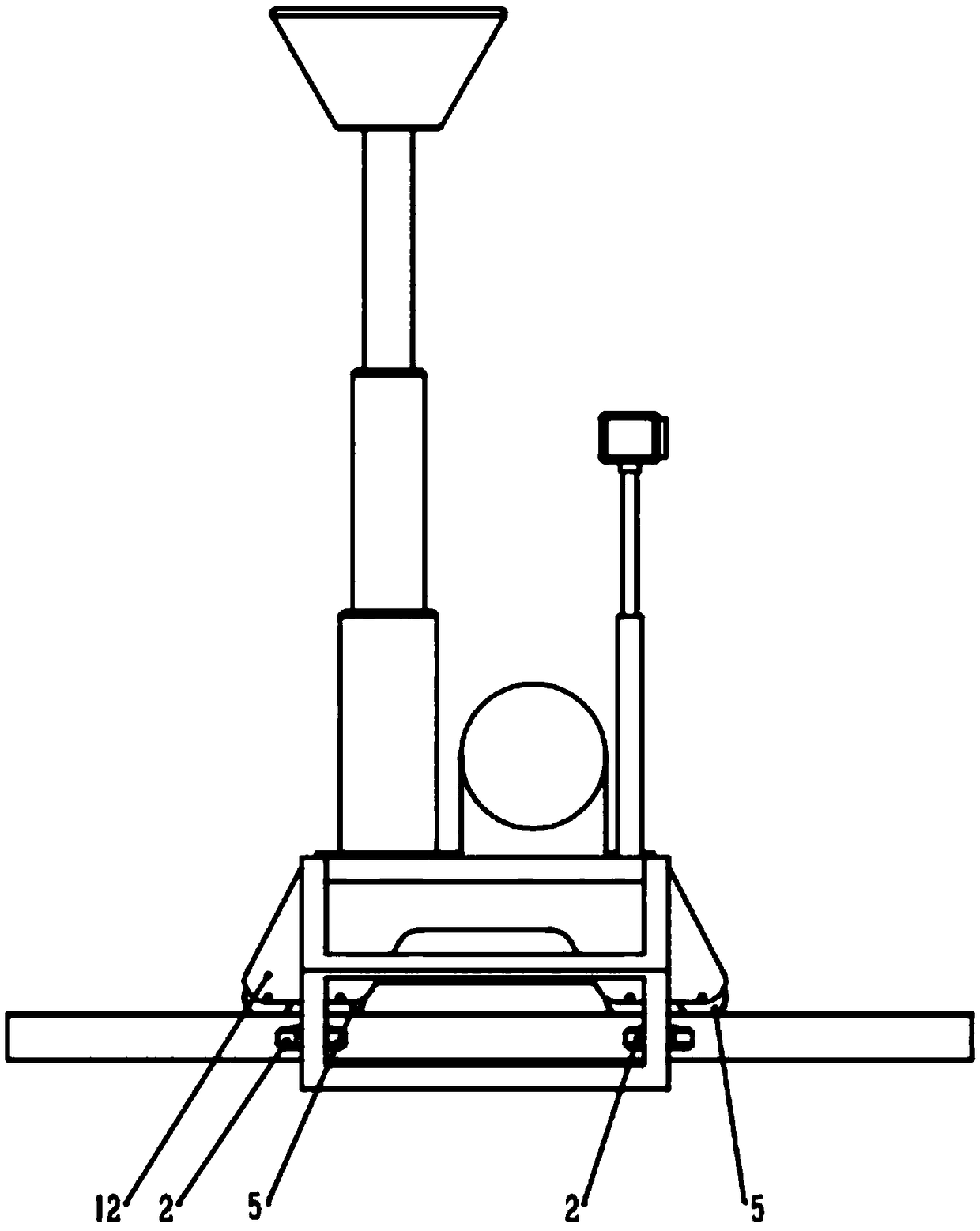

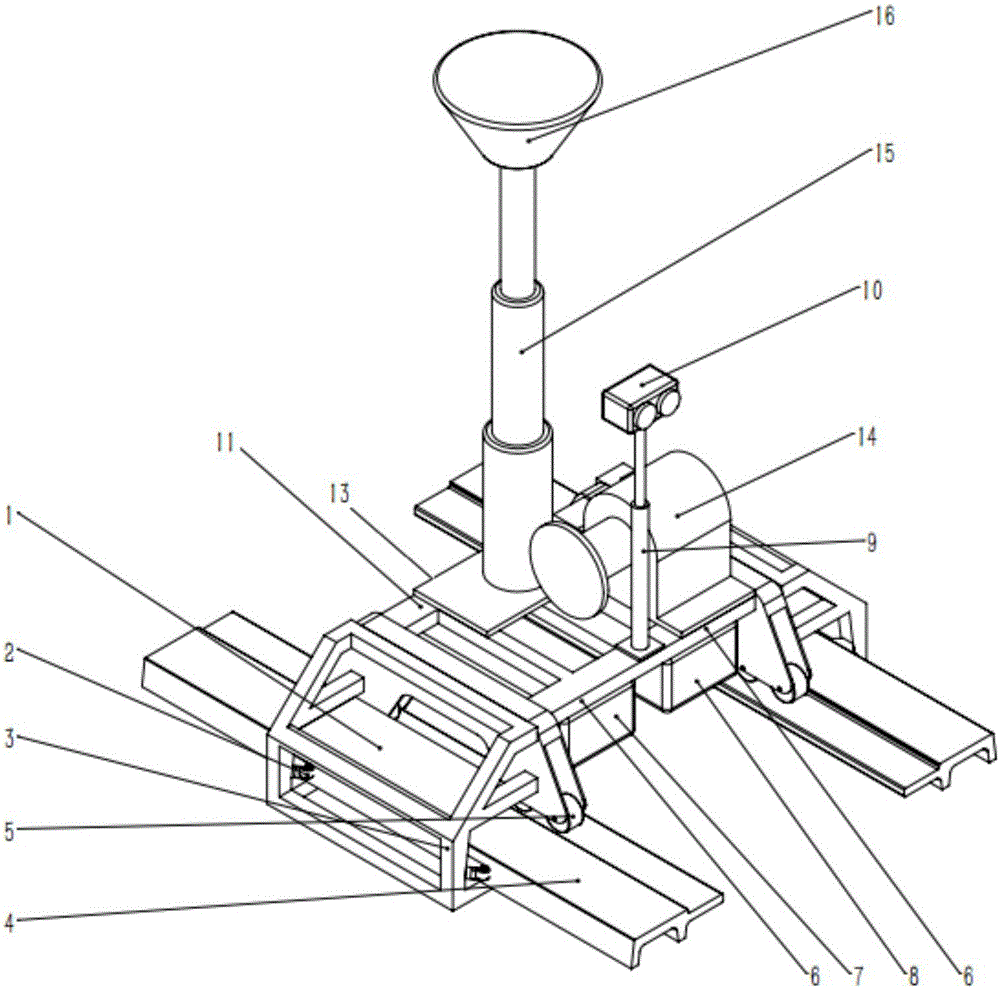

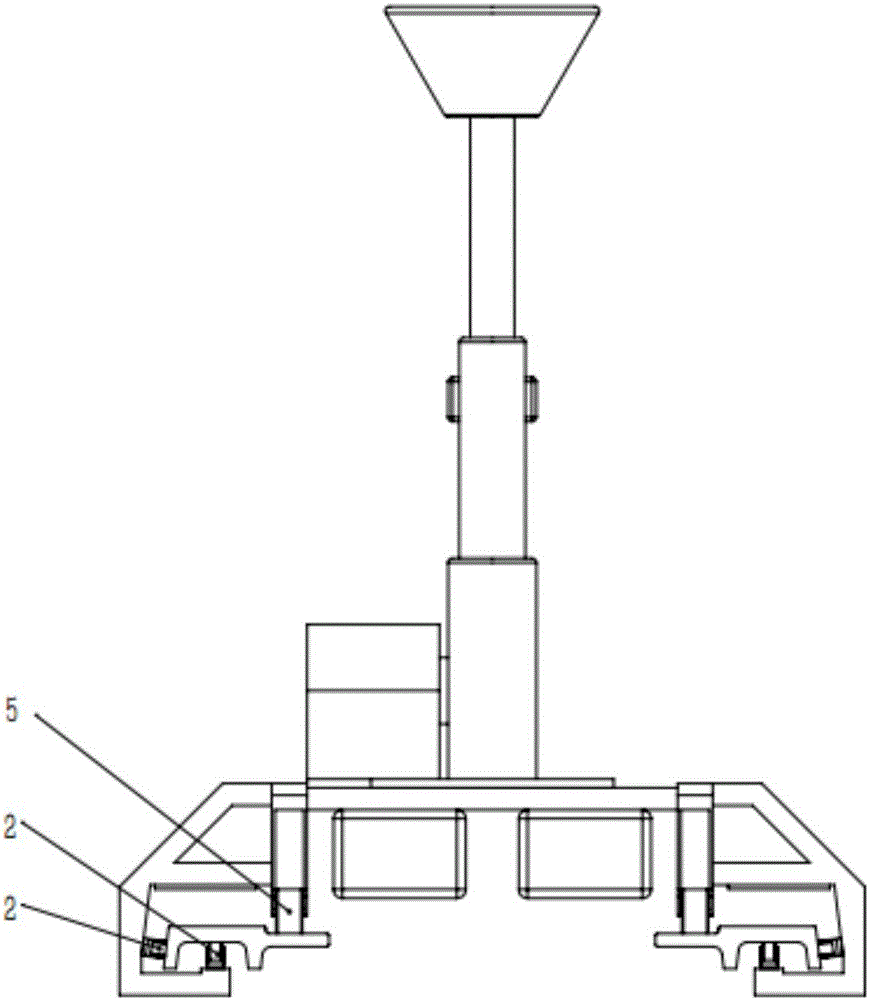

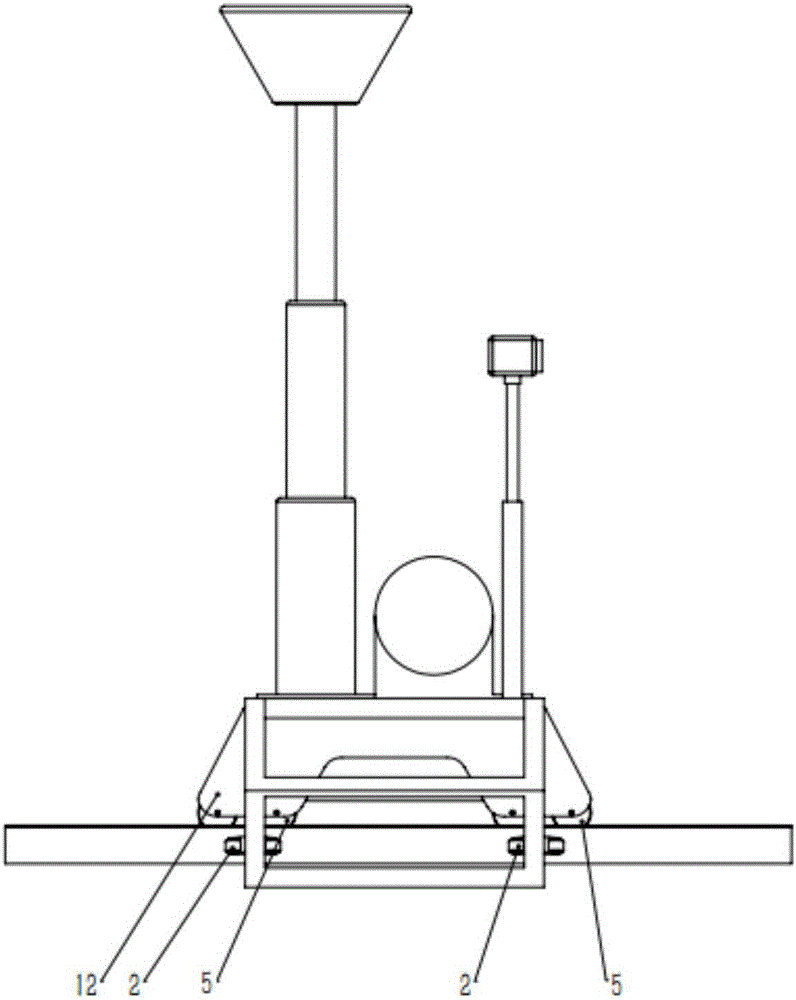

The invention discloses a middle-low-speed magnetic suspension rescue robot. The middle-low-speed magnetic suspension rescue robot comprises a rack, folding bending mechanisms, a detecting rescue mechanism and an autonomous cruise module; the rack stretches over two middle-low-speed magnetic suspension F rails to be detected; the two folding bending mechanisms are arranged at the two ends of the rack and are located above the F rails, and each folding bending mechanism is provided with a walking wheel pair and a clamping wheel pair; the detecting rescue mechanism comprises a distance measuring sensor, a camera and a rescue contact rod, the distance measuring sensor is arranged on the rack and located between the two F rails, the camera is arranged above the rack, and the rescue contact rod is horizontally mounted on the side face of the rack; the autonomous cruise module is mounted below the rack and used for achieving free walking of the rescue robot along the F rails. In-time rescue of the F-rail abnormal detection robot is achieved, and the beneficial effects of being simple in structure, convenient to operate and the like are achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

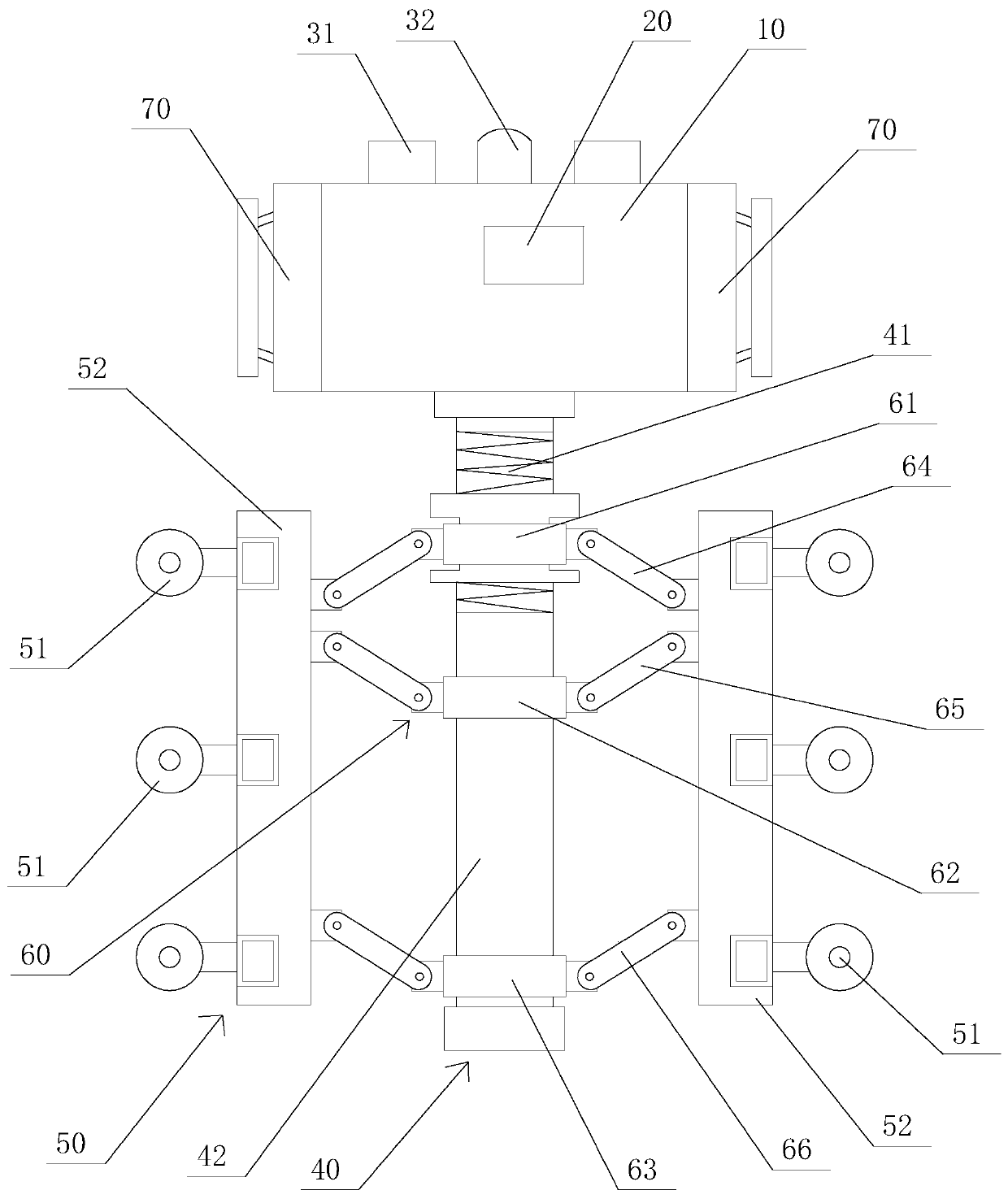

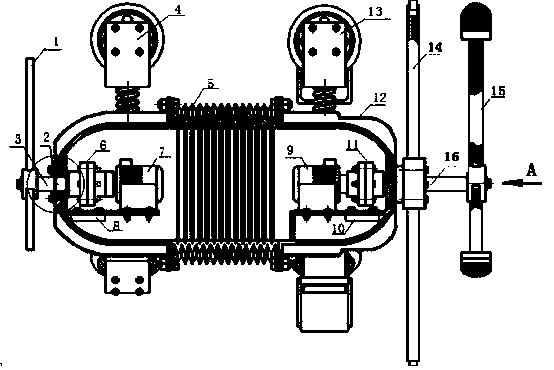

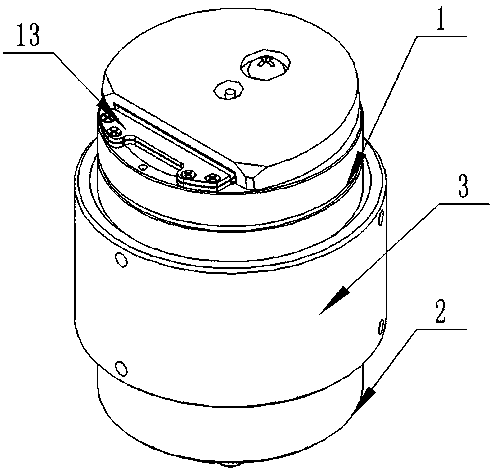

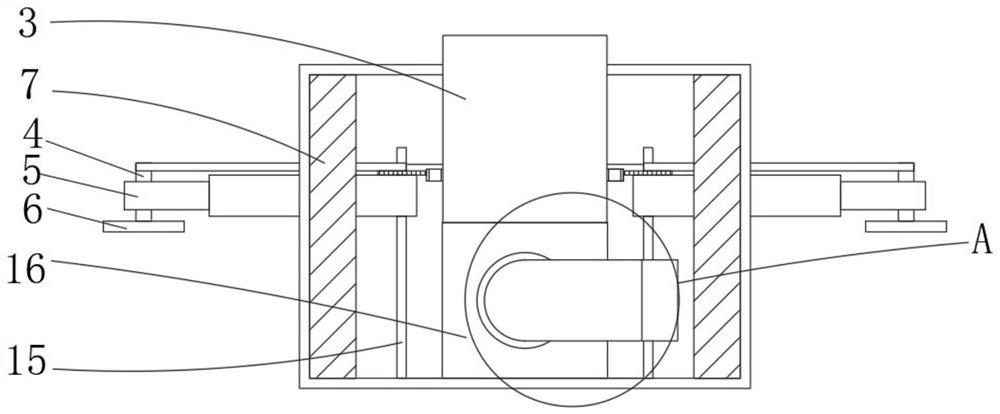

Pipe creeping robot

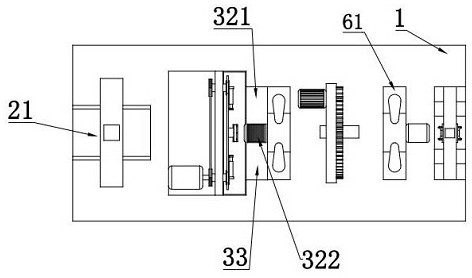

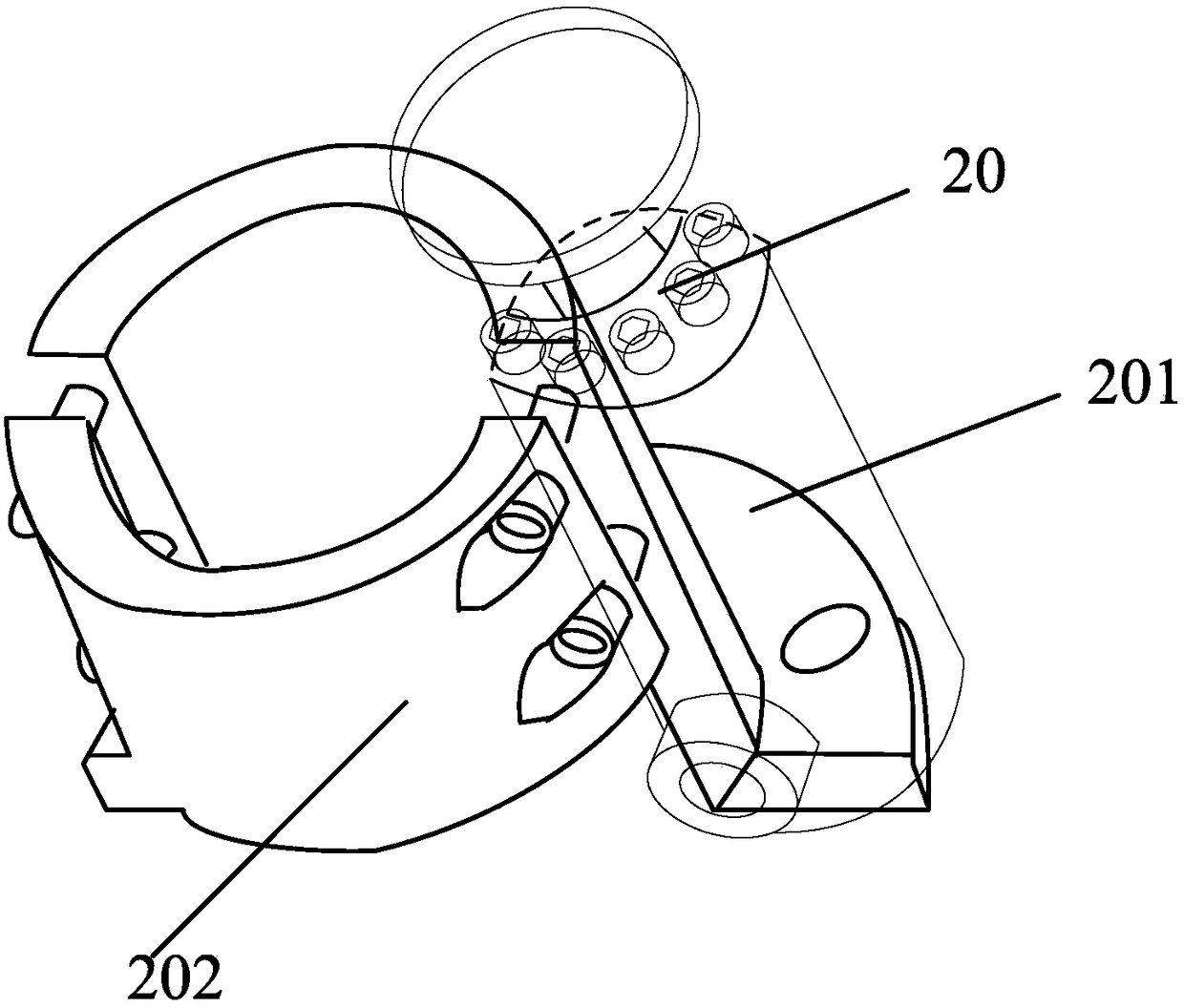

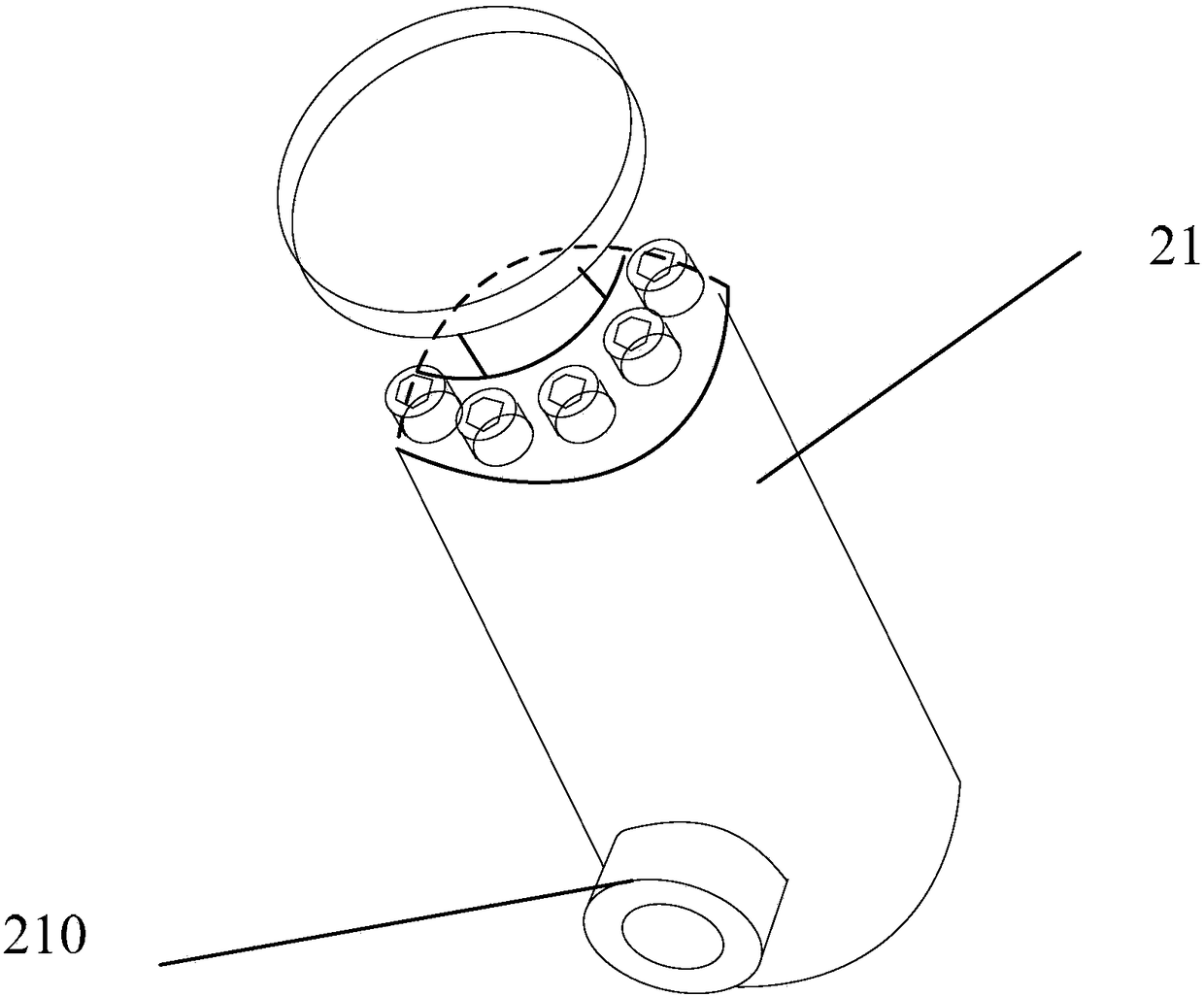

PendingCN110118290AImprove obstacle performanceAvoid obstructionPigs/molesEngineeringObstacle crossing

The invention discloses a pipeline creeping robot. The pipeline creeping robot comprises a box body, a control mechanism, a detection mechanism, a fixing column, multiple obstacle crossing creeping mechanisms, an extending-and-contracting connecting rod device and two detection fixing support brackets. The detection mechanism is mounted on the front end of the box body. The two detection fixing support brackets are mounted on the two sides of the box body correspondingly. The control mechanism is mounted inside the box body. The fixing column is mounted on the back end of the box body. The multiple obstacle crossing creeping mechanisms are connected with the fixing column through the extending-and-contracting connecting rod device. The detection mechanism, the obstacle crossing creeping mechanisms and the detection fixing support brackets are electrically connected with the control mechanism. The pipeline creeping robot is applicable to the size variation of the pipeline; barriers in the pipeline can be crossed; obstacle crossing ability is great; the problem that barrier obstruction is conducted in the pipeline walking process is avoided.

Owner:GUANGZHOU INST OF TECH

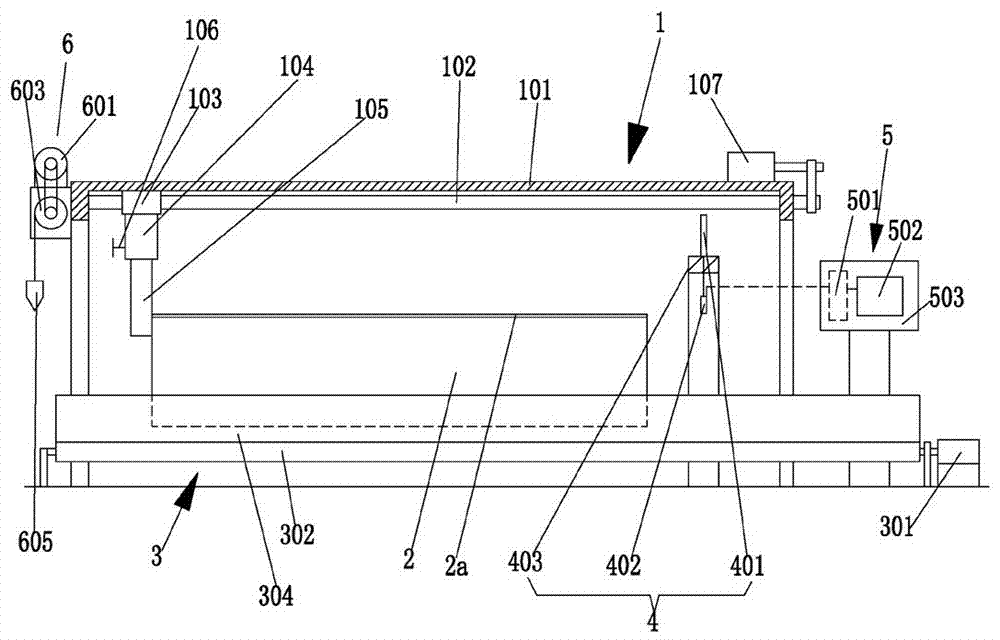

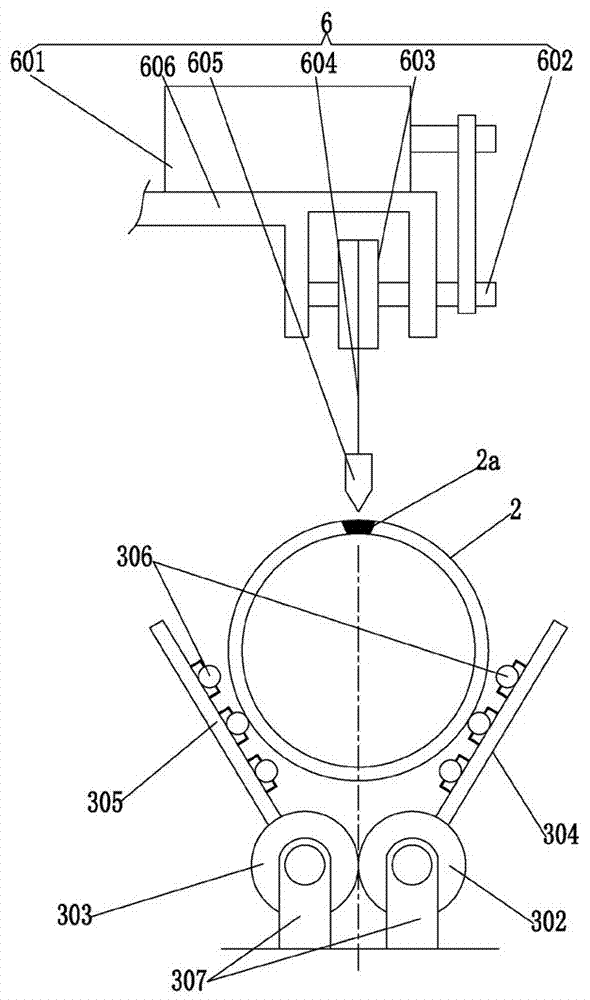

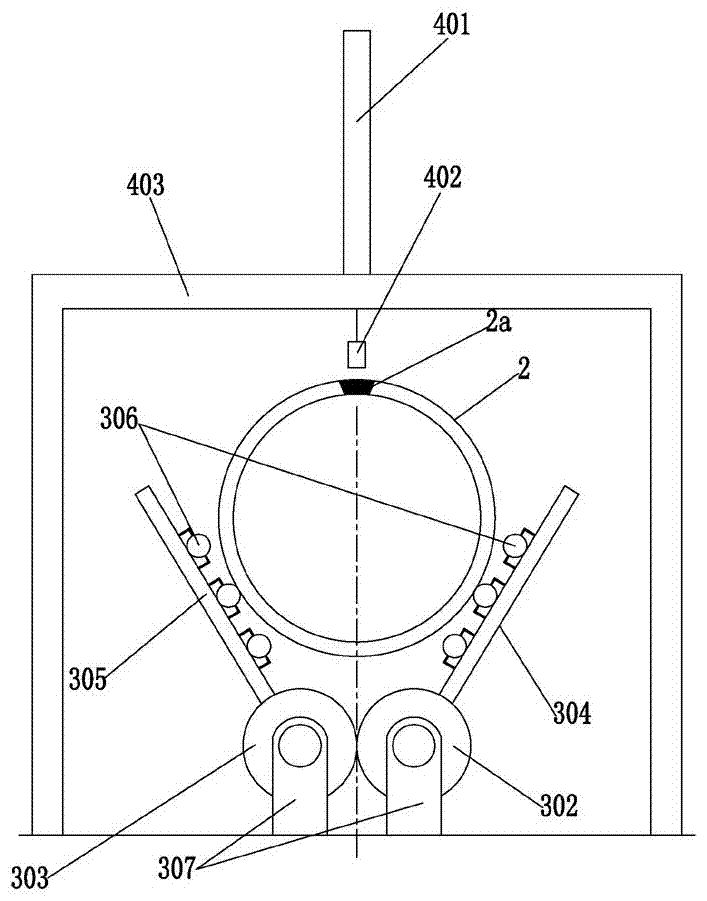

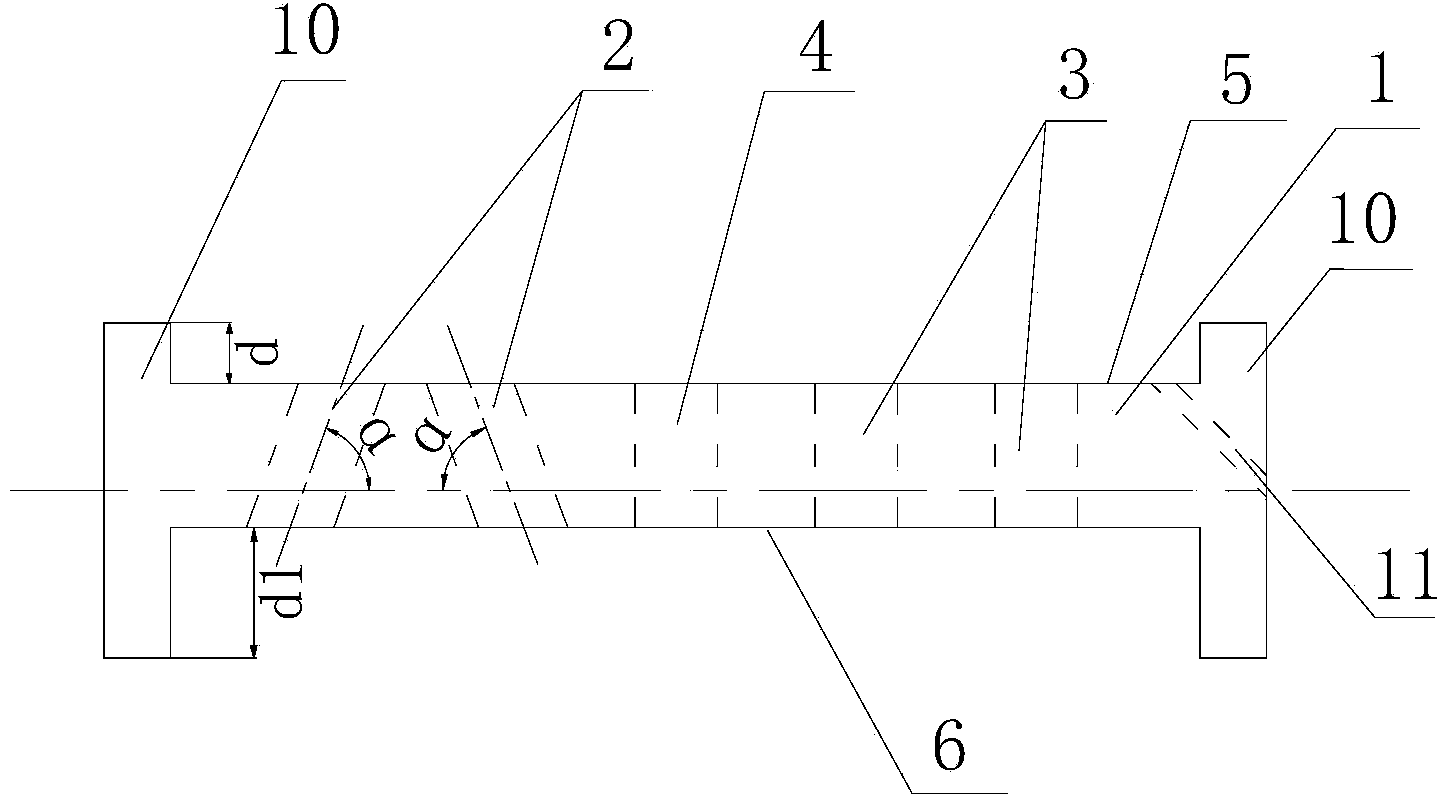

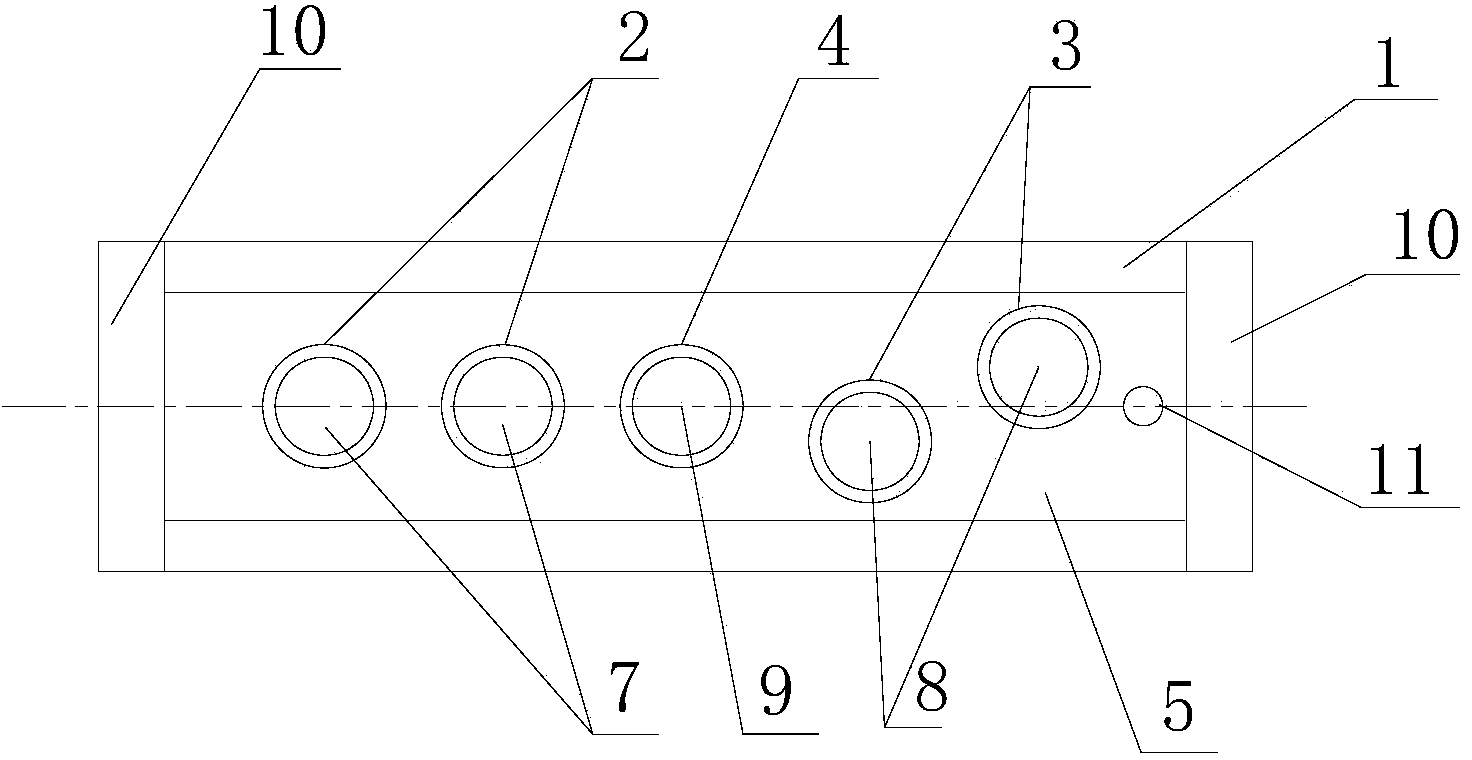

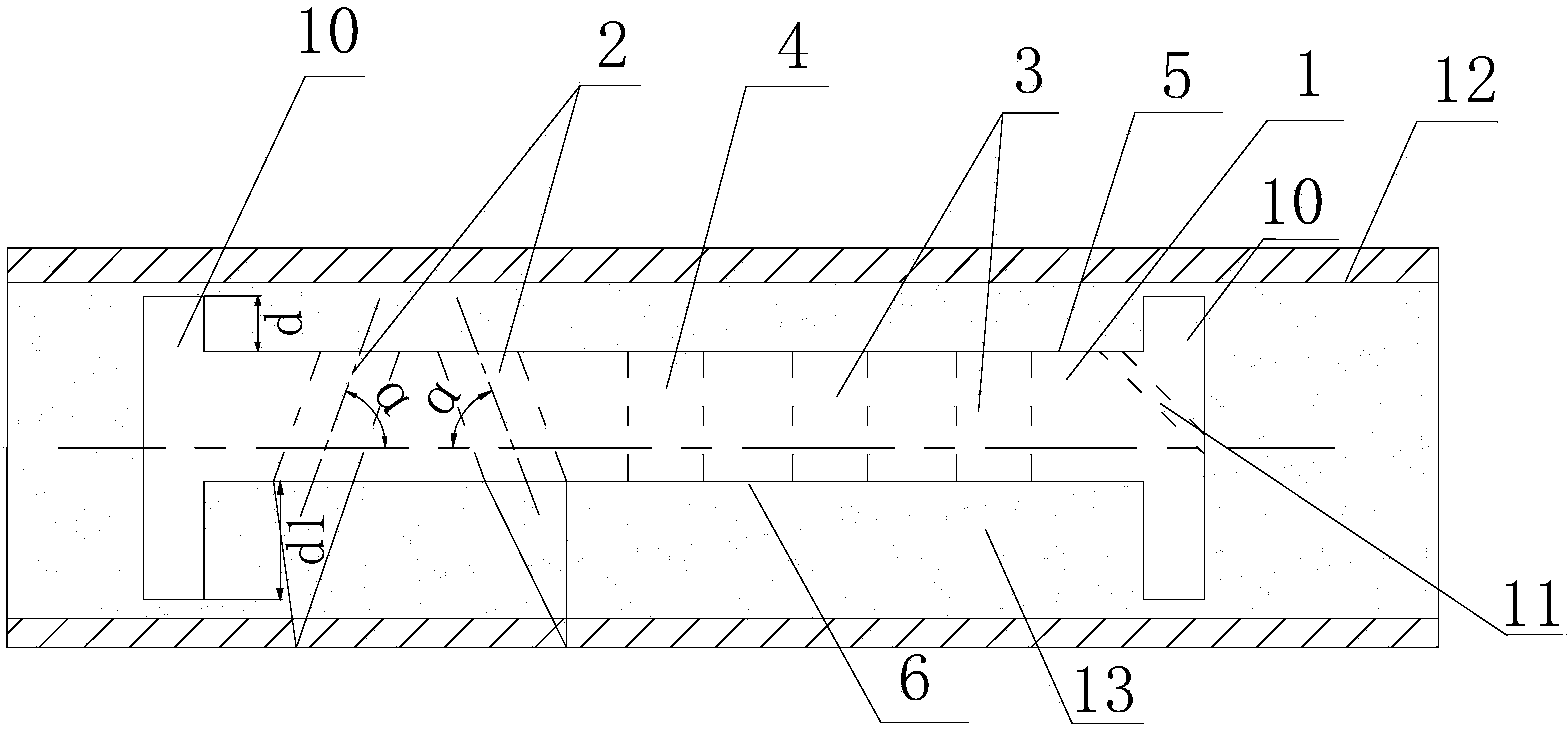

Ultrasonic pipe flaw detection device

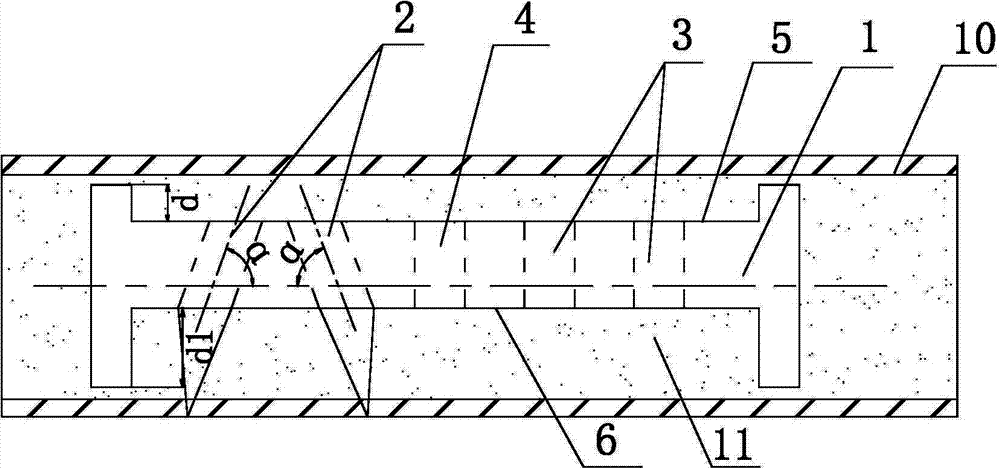

InactiveCN107764902AAccurate flaw detectionFlexibleMaterial analysis using sonic/ultrasonic/infrasonic wavesHollow article cleaningTask completionUnderwater

The invention discloses an ultrasonic pipeline flaw detection device, which has the function of completing flaw detection tasks for buried and underwater concealed pipelines, and can realize automatic turning especially for long-distance transmission pipelines, and can remove dirt on the inner wall of the pipeline to realize accurate flaw detection. At the same time, the device proposed by the invention can simultaneously realize efficient flaw detection in the liquid-filled pipeline and the empty pipeline, and solve the technical problem that the prior art cannot work uninterruptedly under variable working conditions.

Owner:宋欢

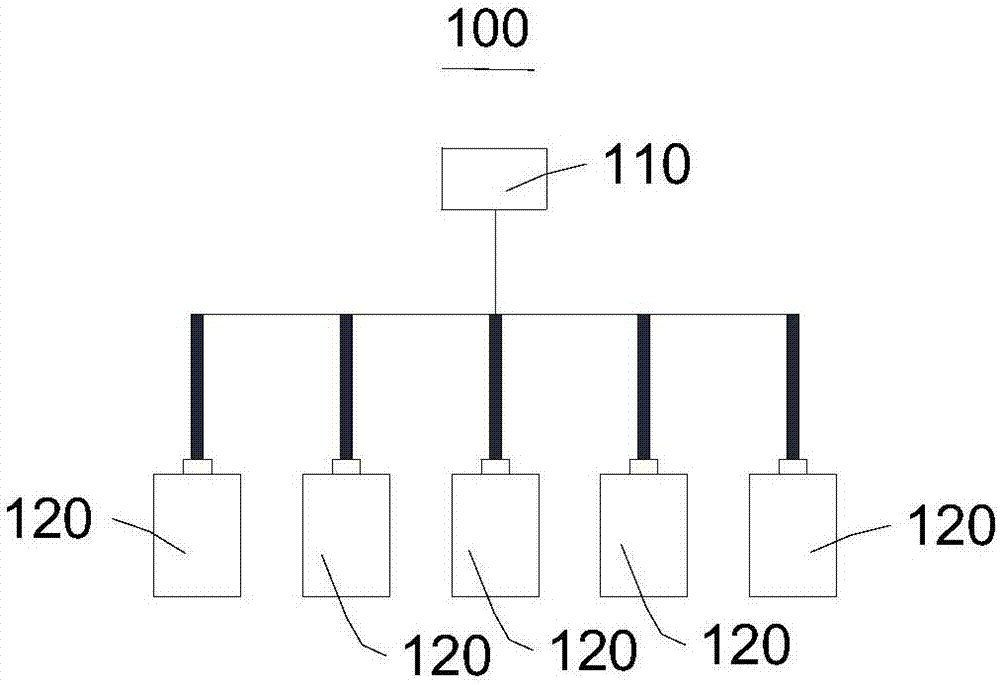

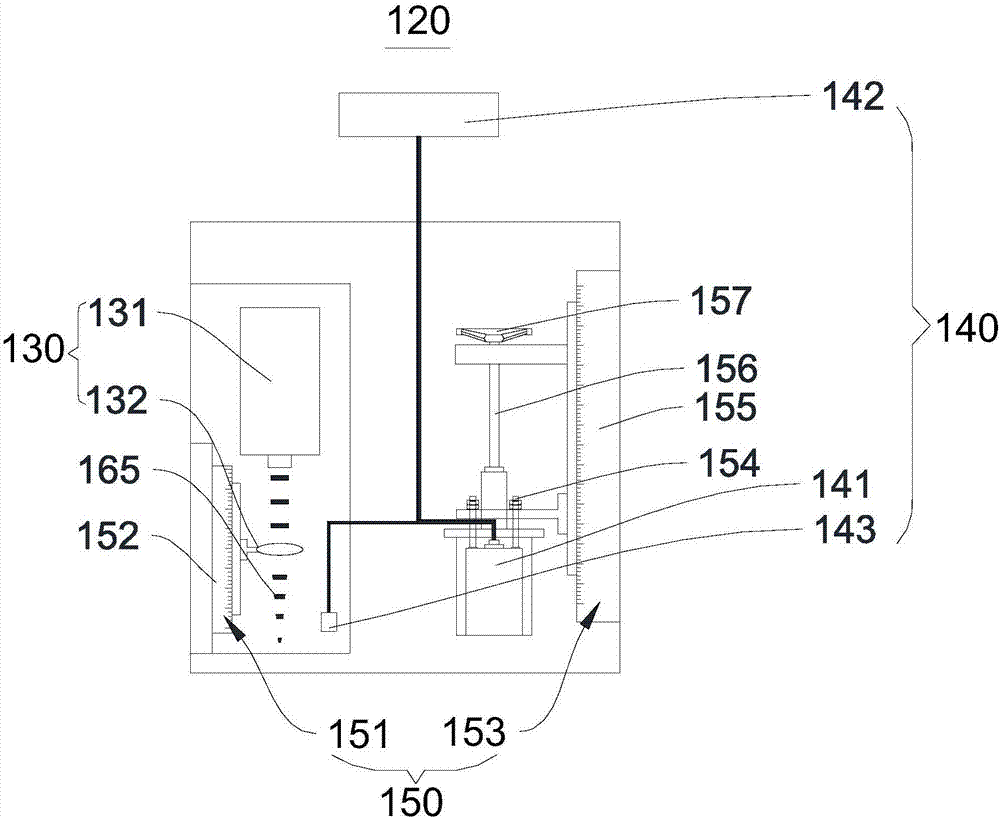

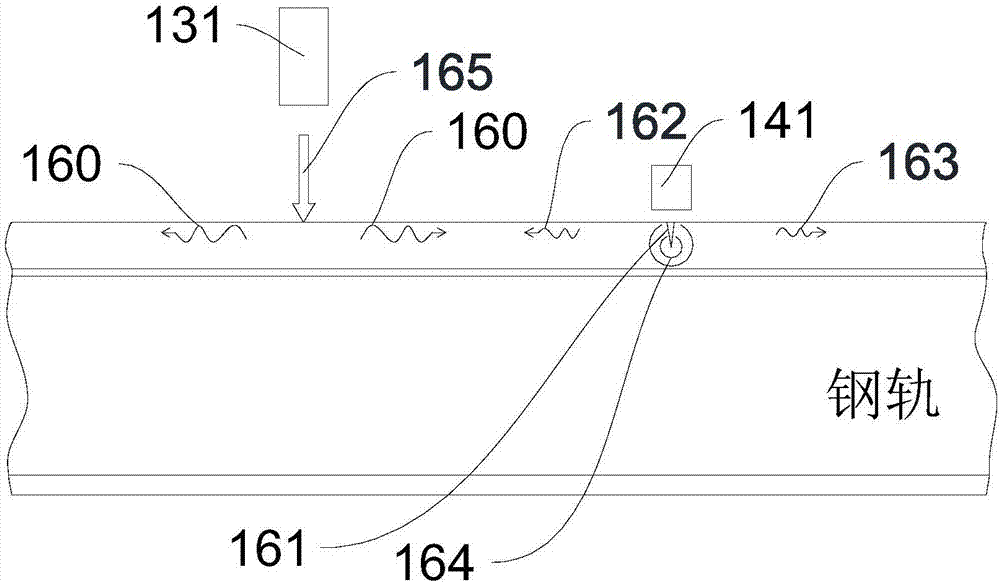

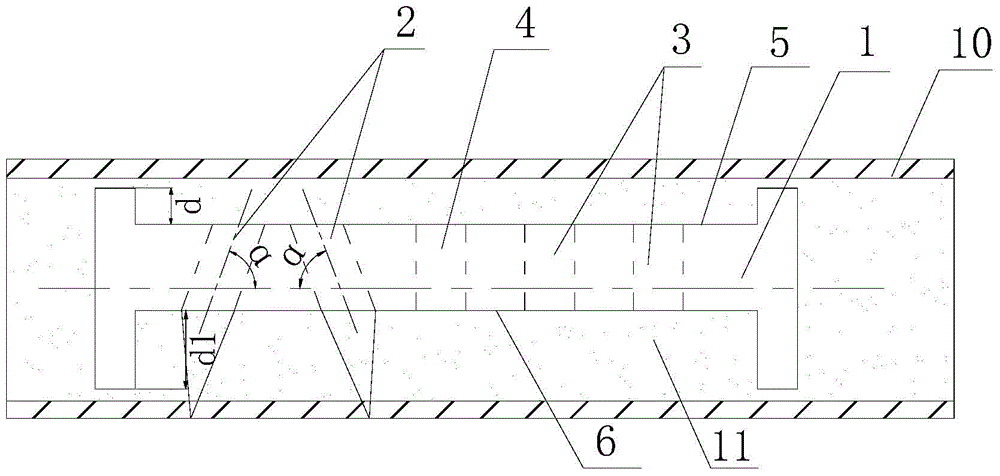

Laser acoustomagnetic steel rail surface defect rapid flaw detection system and method

PendingCN106994984AAccurate flaw detectionHigh speedOptically investigating flaws/contaminationRailway auxillary equipmentPulsed laser beamTransverse wave

The embodiment of the invention provides a laser acoustomagnetic steel rail surface defect rapid flaw detection system and method and relates to the technical field of flaw detection. The laser acoustomagnetic steel rail surface defect rapid flaw detection system comprises a control device and a plurality of laser acoustomagnetic flaw detectors electrically connected with the control device and arranged according to preset intervals. Each laser acoustomagnetic flaw detector comprises a laser ultrasonic excitation device, an ultrasonic diffraction transverse wave receiving device and an adjusting mechanism. The laser ultrasonic excitation devices and the ultrasonic diffraction transverse wave receiving devices are electrically connected with the control device. The ultrasonic diffraction transverse wave receiving devices are used for emitting focused pulse laser beams to the surface of an object to be detected. The ultrasonic diffraction transverse wave receiving devices are used for receiving ultrasonic diffraction transverse wave signals produced on the surface the object to be detected. The control device judges whether flaw signals exist or not according to the amplitude values of the ultrasonic diffraction transverse wave signals and locates the positions corresponding to the existing flaw signals, so that flaw positions are obtained. Rapid flaw detection can be achieved.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

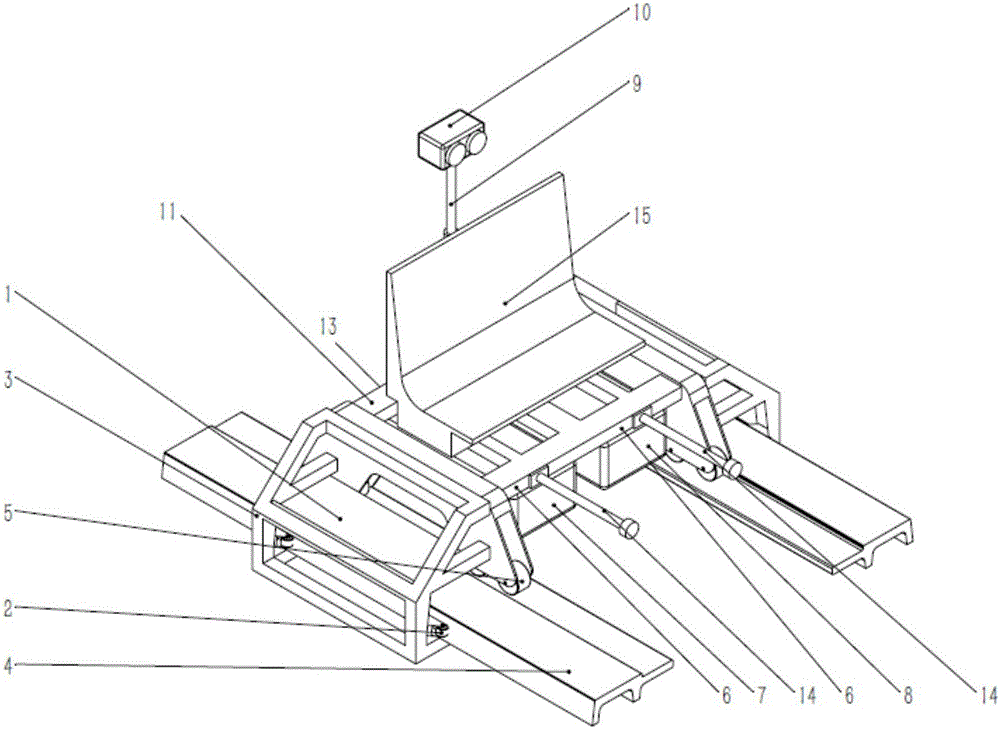

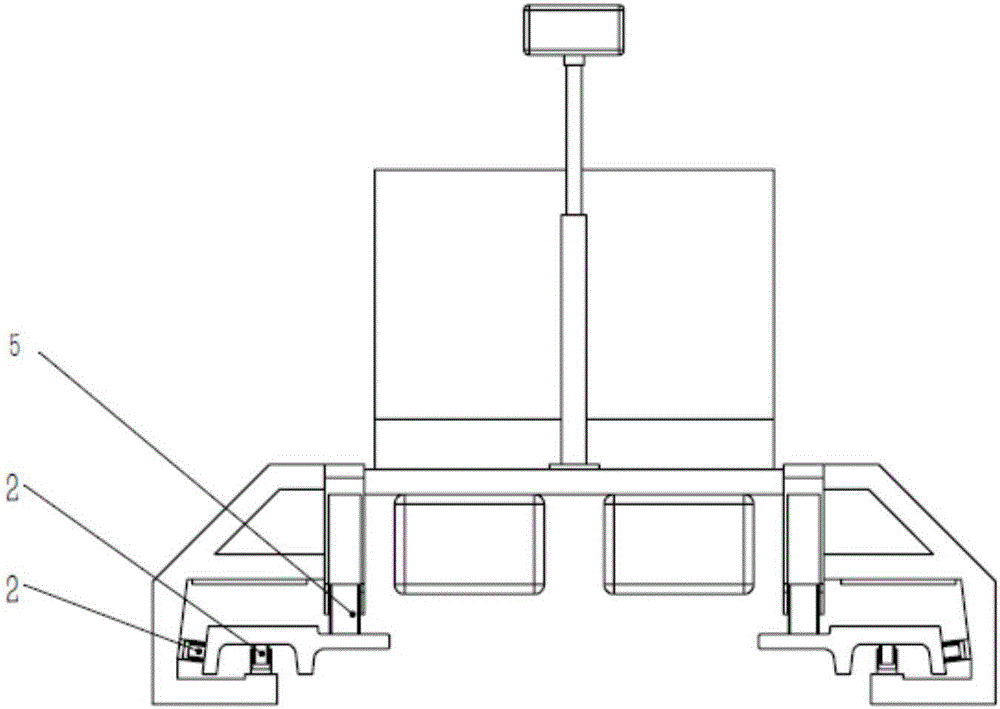

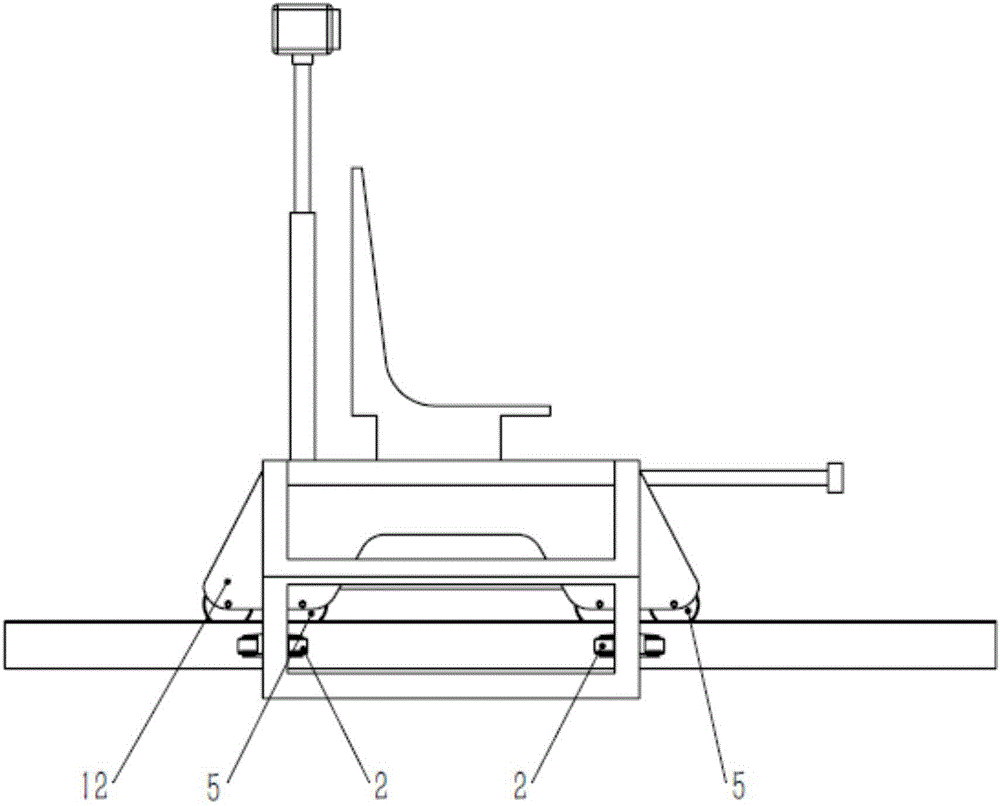

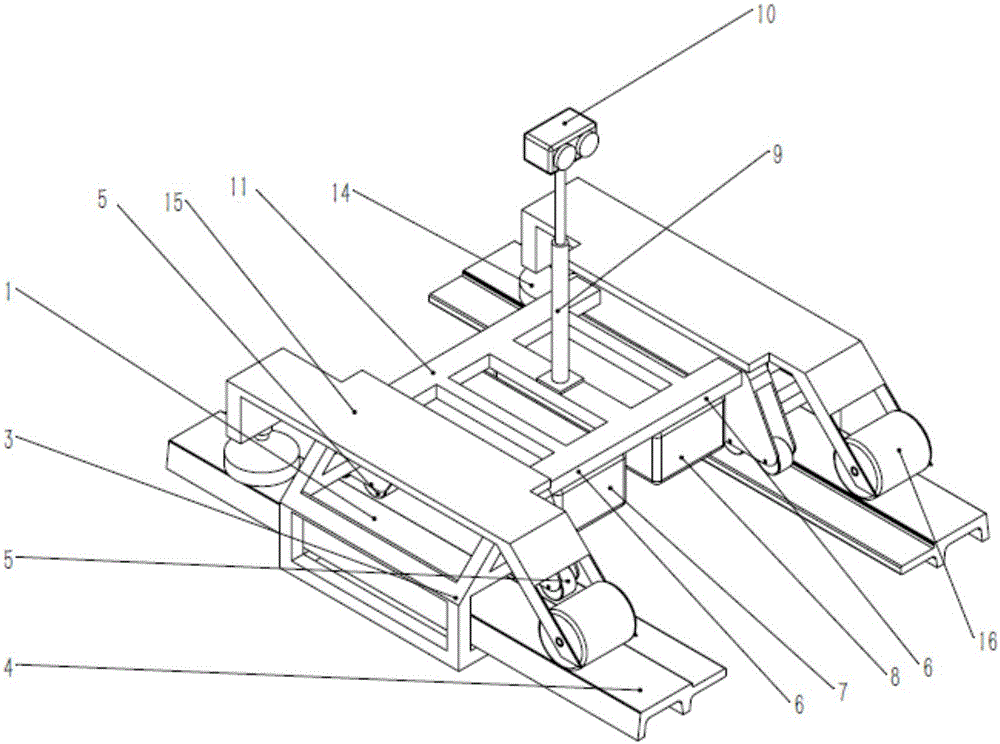

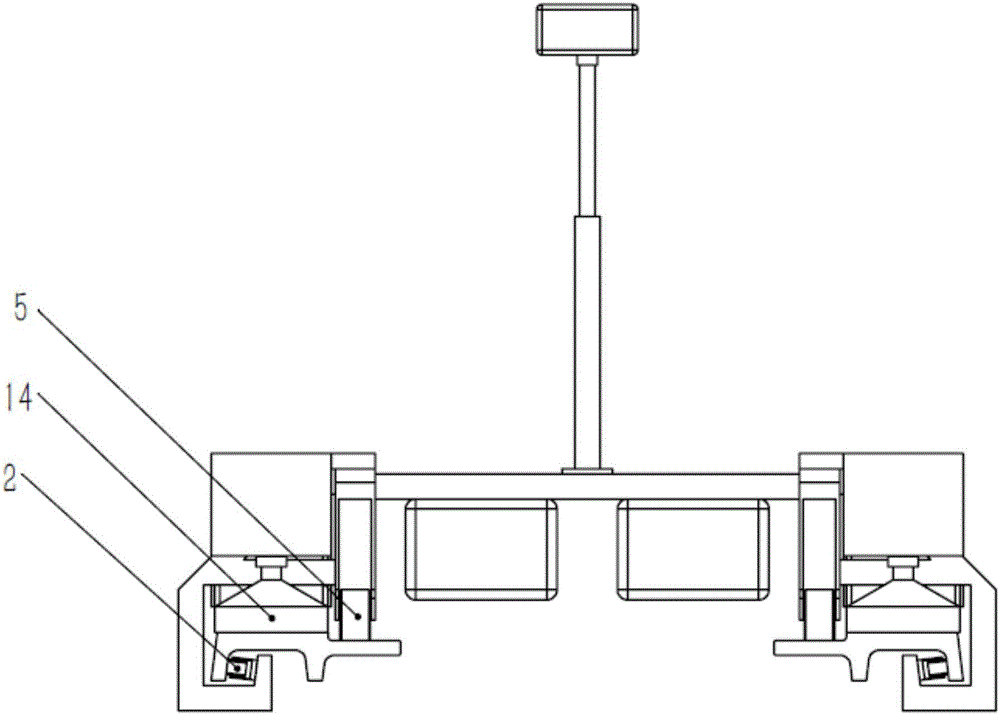

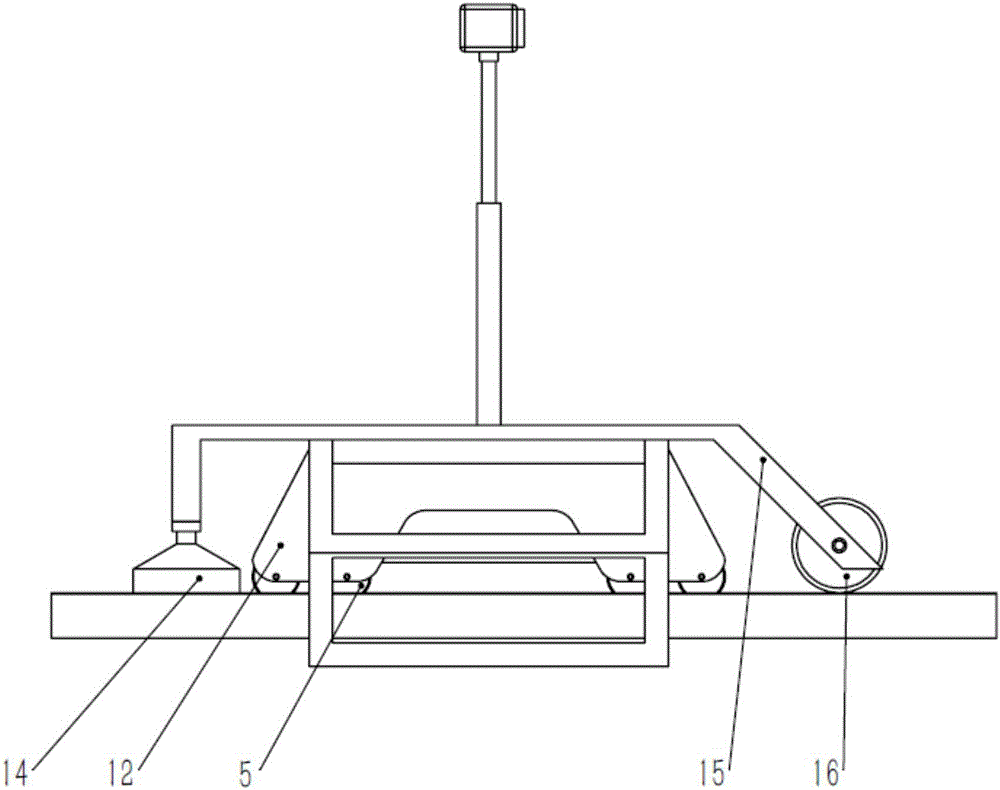

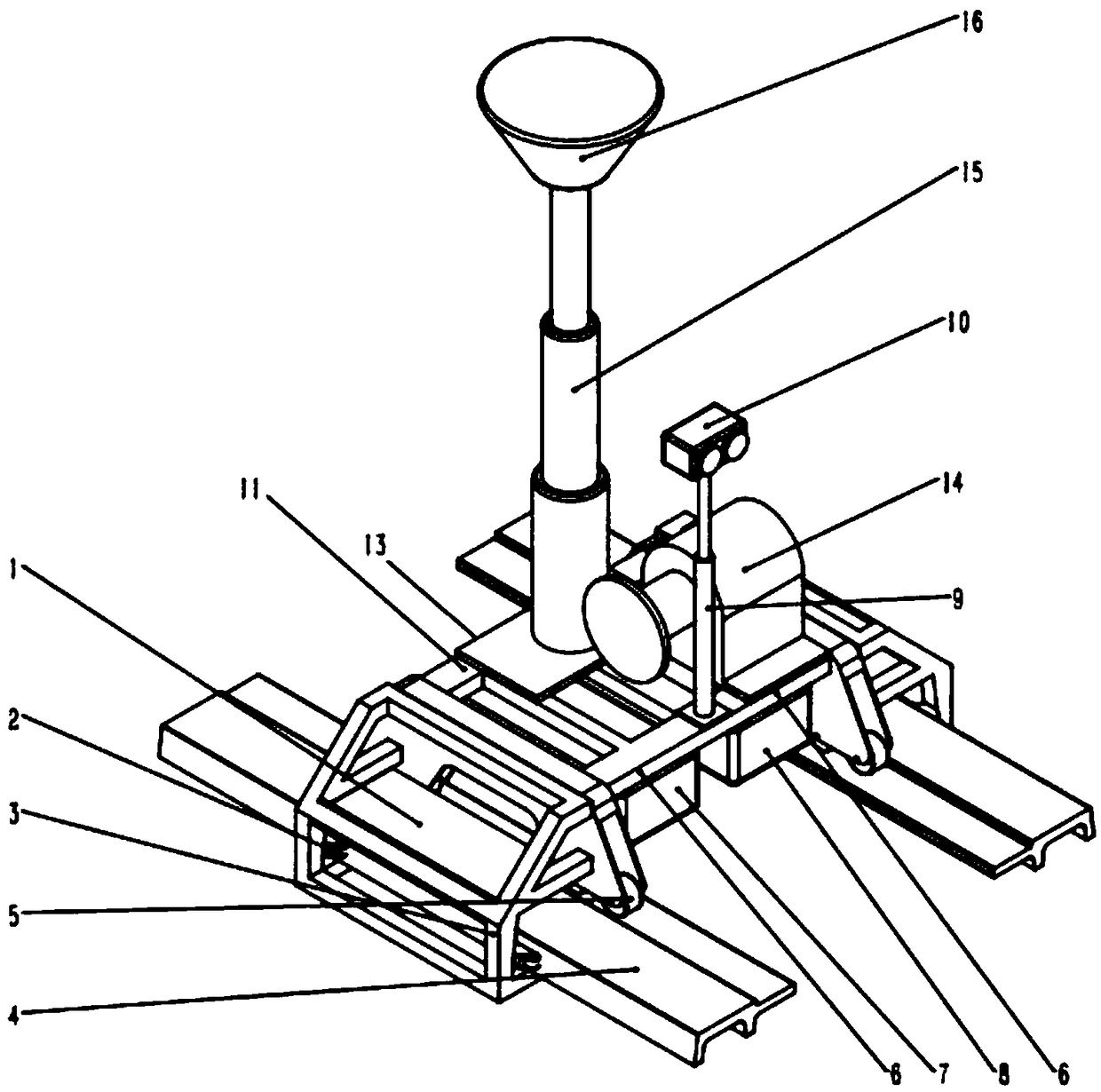

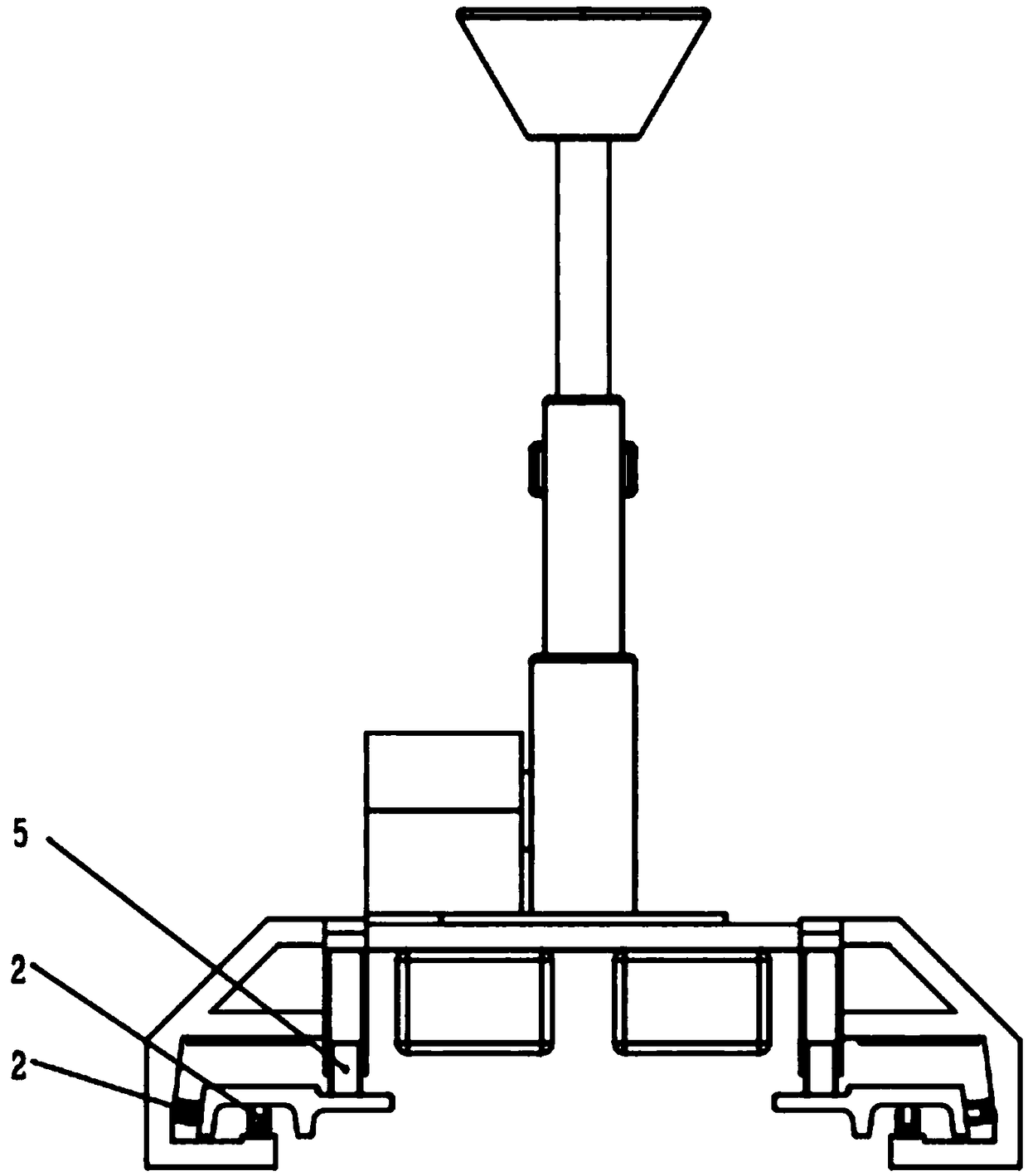

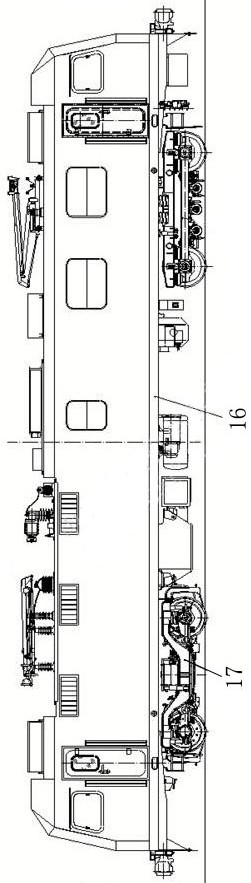

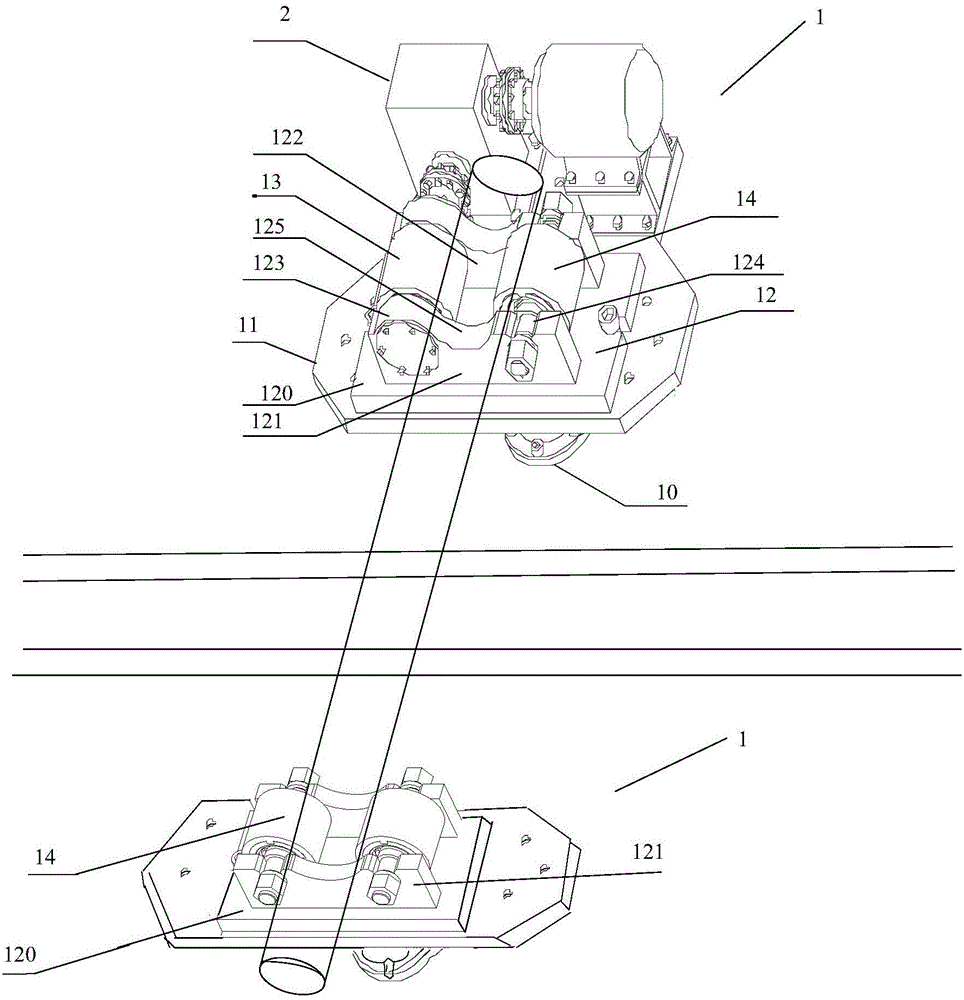

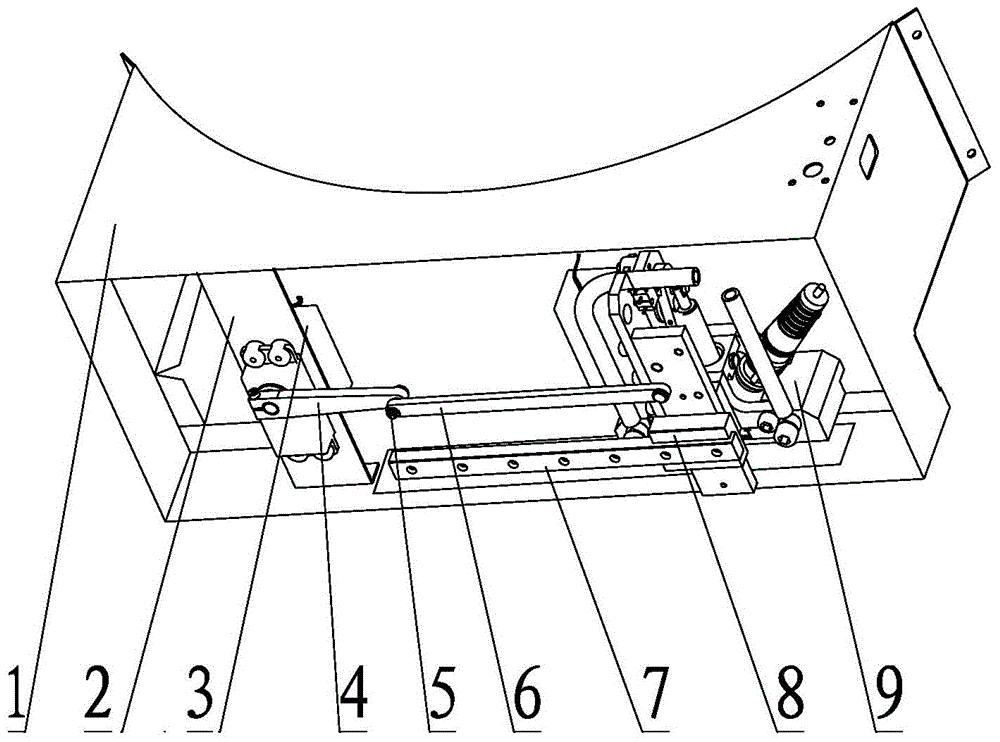

Low and medium speed magnetic levitation icebreaking and snow melting cleaning robot

ActiveCN106120636AEffective Public Works MaintenanceEffective Operational SecurityRailway cleaningFixed frameSnow melting

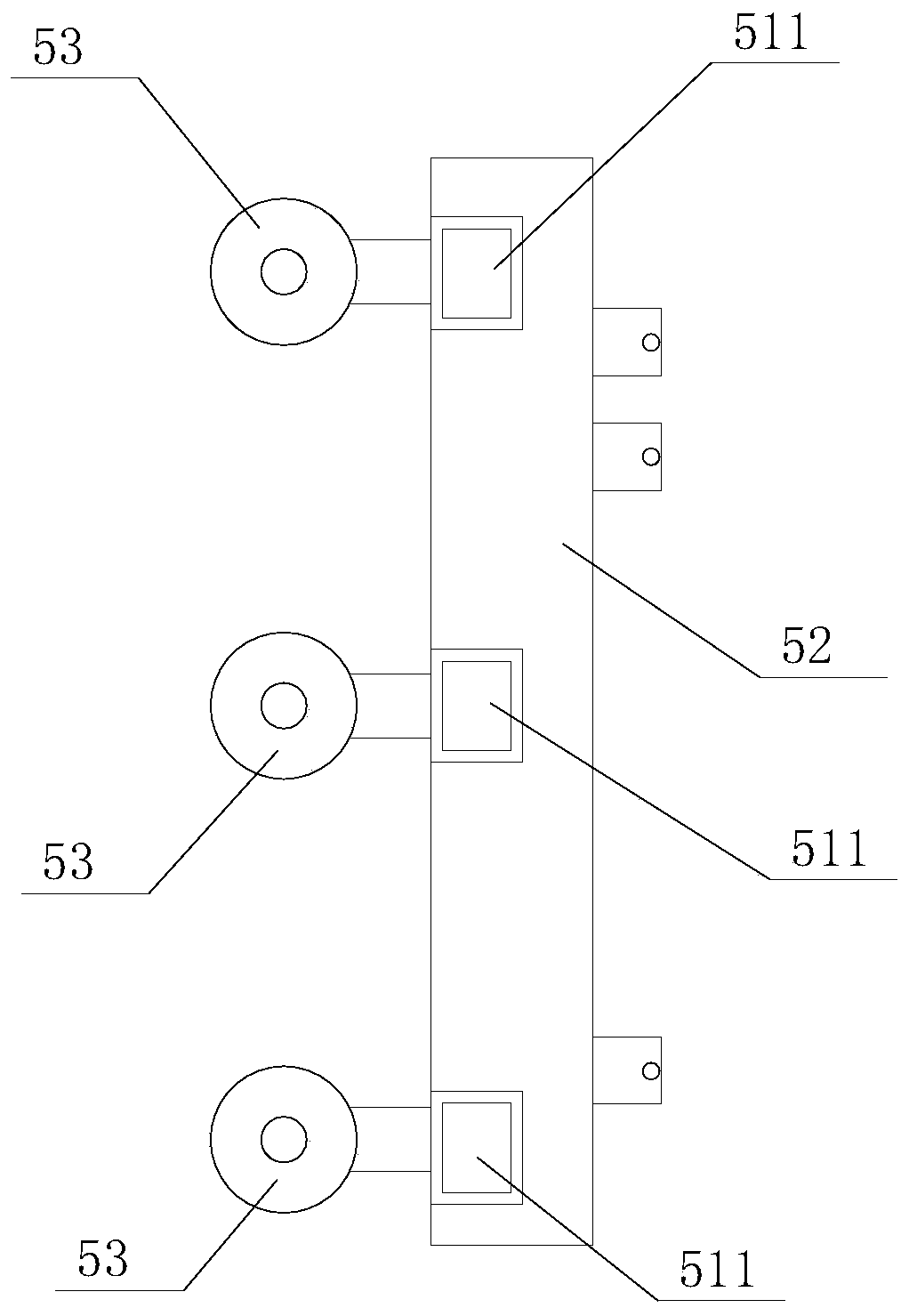

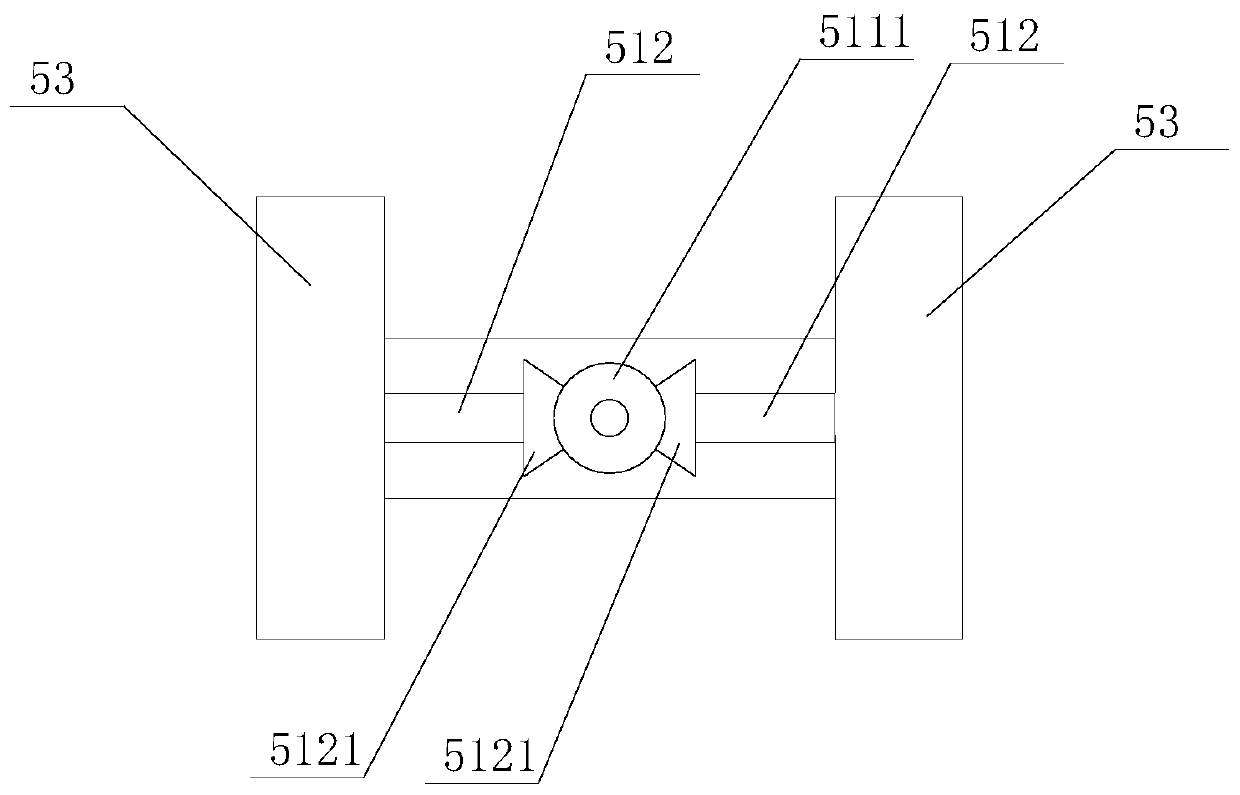

The invention discloses a low and medium speed magnetic levitation icebreaking and snow melting cleaning robot which comprises a machine frame, two folding bending mechanisms, an ice melting cleaning mechanism and an autonomous cruising module. The machine frame stretches over two rails F of low and medium speed magnetic levitation to be detected. The two folding bending mechanisms are arranged at the two ends of the machine frame and located above the rails F. Each folding and bending mechanism is provided with a walking wheel pair and a clamping wheel pair. The snow melting cleaning mechanism comprises a fixed frame, a rail F obstacle removal cleaning unit and an ice melting heating unit. The fixing frame is installed on the machine frame and located above the folding bending mechanisms and arranged in the extending direction of the rails F. The rail F obstacle removal cleaning unit and the ice melting heating unit are arranged at the two ends of the fixing frame. The autonomous cruising module is installed below the machine frame. Rail F ice and snow melting and cleaning can be achieved, and the low and medium speed magnetic levitation icebreaking and snow melting cleaning robot has the advantages of being simple in structure, convenient to operate and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

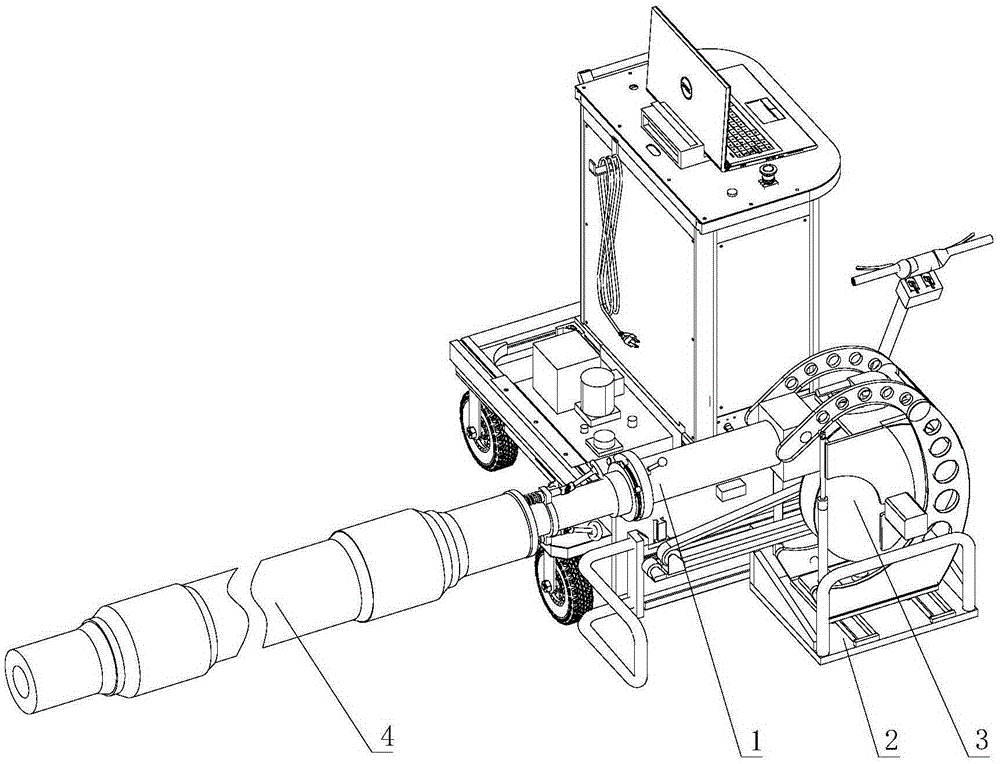

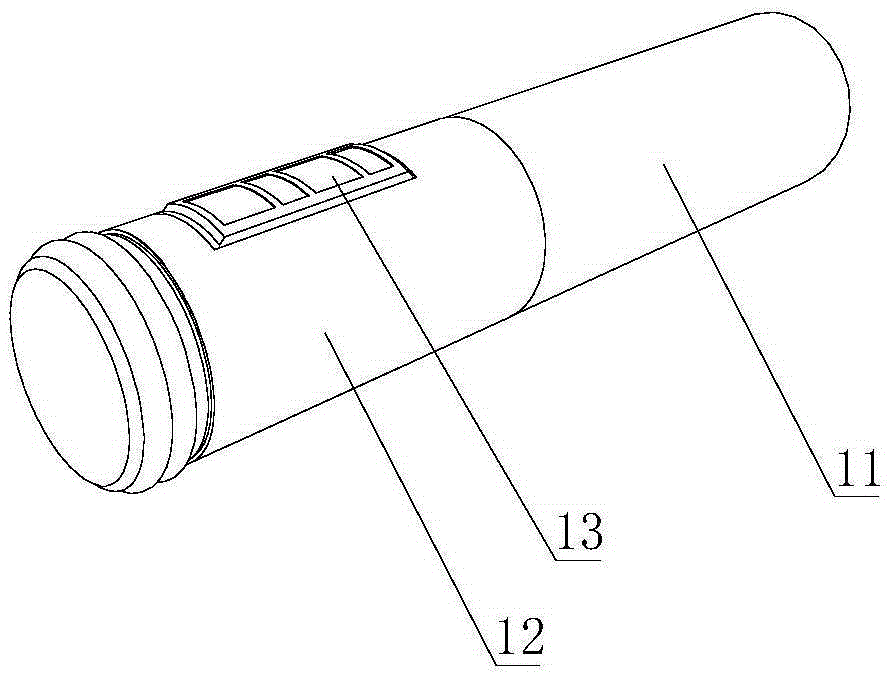

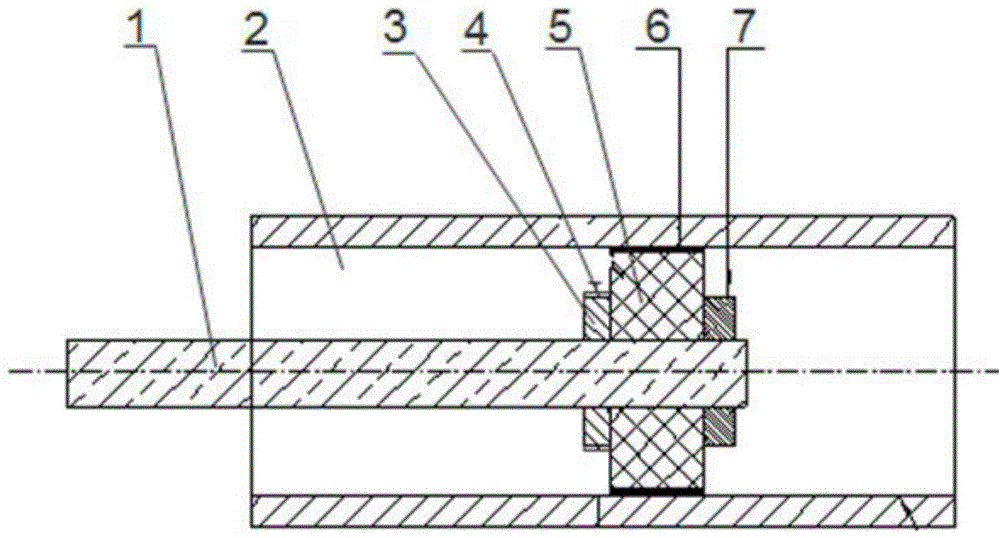

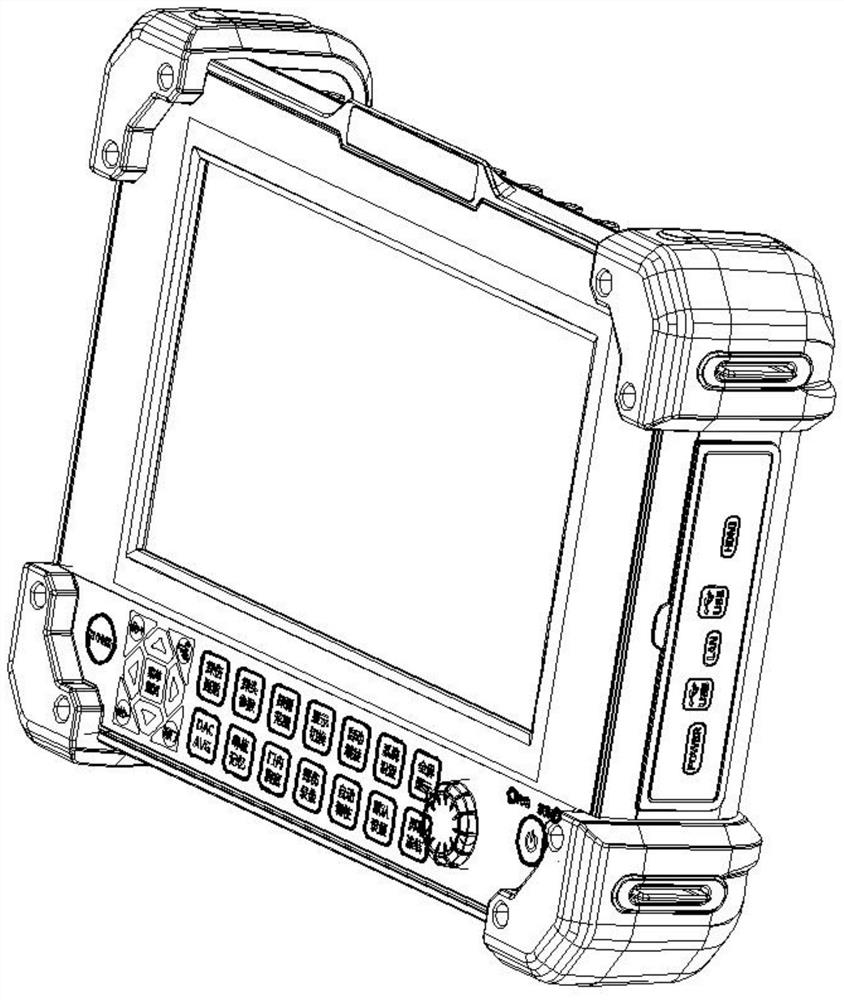

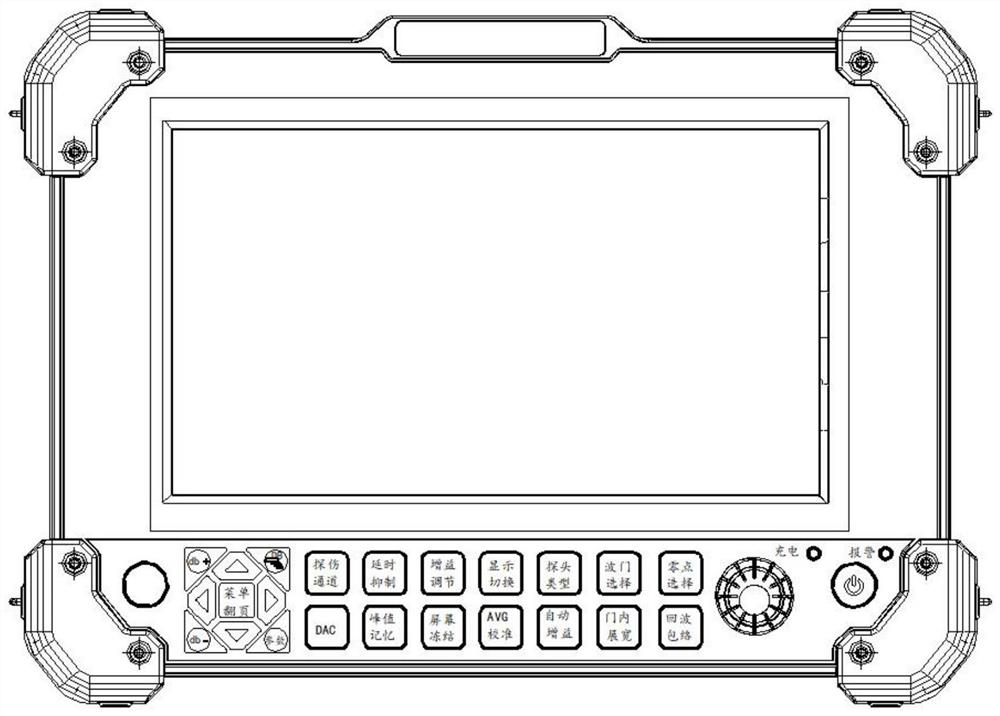

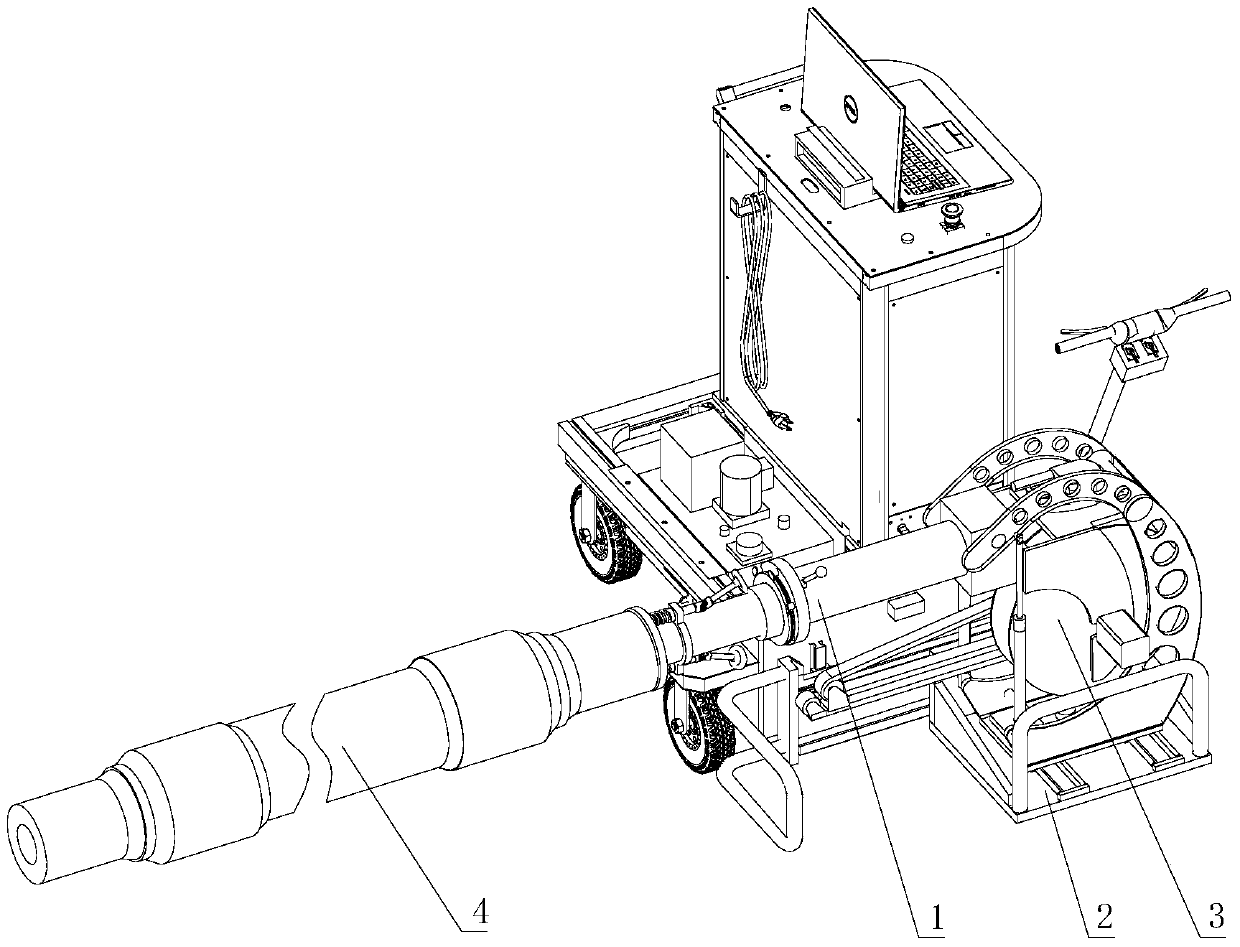

Hollow axle ultrasonic flaw detector

ActiveCN105424815ALabor savingAvoid elevationMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringTurbine

The invention relates to the technical field of ultrasonic flaw detection, in particular to a hollow axle ultrasonic flaw detector, which includes a flaw detection assembly, a docking platform and a feeding device. The flaw detection assembly is in butt joint with a hollow axle through the docking platform, and is driven by the feeding device to enter the hollow axle to perform detection. The hollow axle ultrasonic flaw detector no longer uses a line type balancer while installing the flaw detection assembly to the axle, but uses the docking platform to bear the flaw detection assembly, thus alleviating the labor force needed for left-right movement and up-down movement of the flaw detection assembly. In addition, an ultrasonic probe adjusts the gap between the outer surface of the ultrasonic probe and the inner surface of the hollow axle through a self-adaptive adjustment device, so that the gap between the ultrasonic probe surface and the hollow axle inner surface can always keep consistent during high-speed rotating flaw detection by the universal probe, thus preventing a supplied turbine oil membrane on the ultrasonic probe surface from thickening, and ensuring accurate time and locations for ultrasonic wave emission and ultrasonic wave receiving during ultrasonic probe detection.

Owner:常州常瑞轨道交通科技有限公司

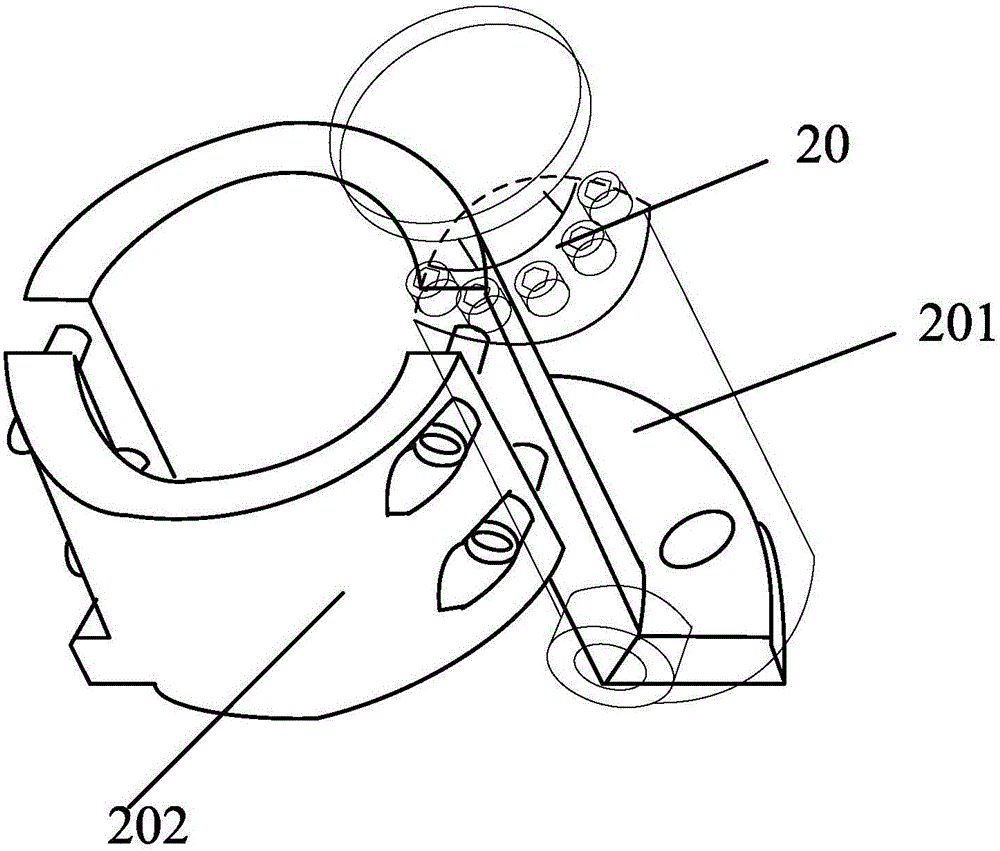

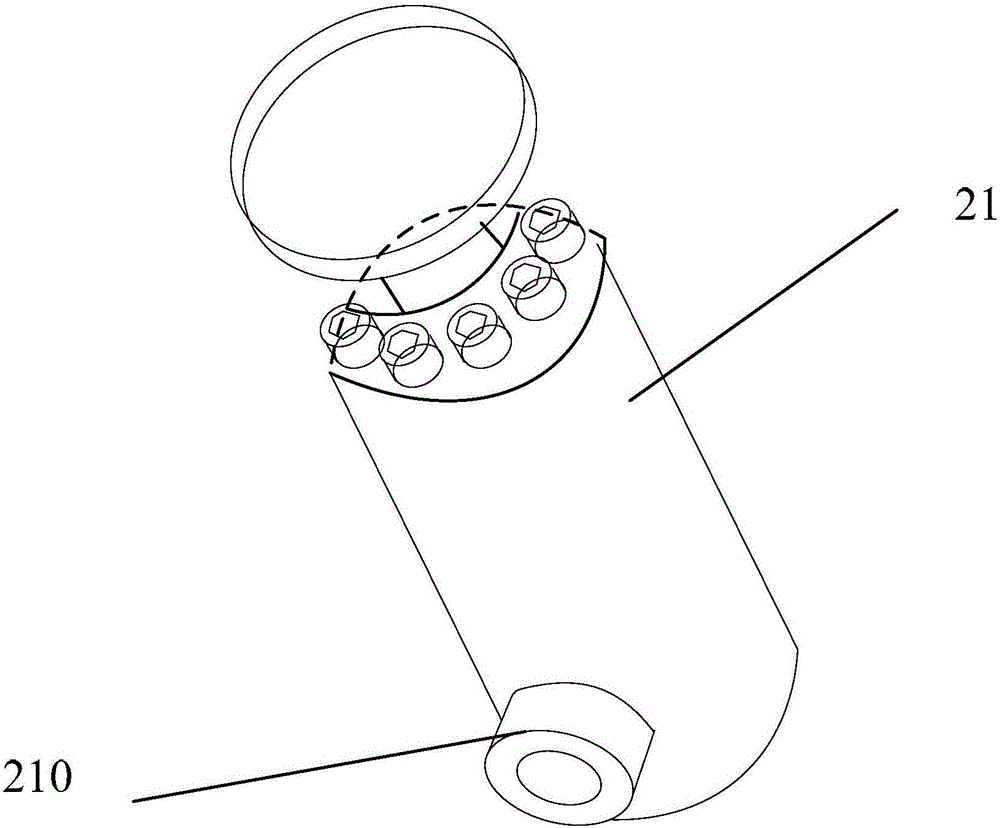

Medium-low speed magnetic levitation auxiliary work robot

InactiveCN109131430AEffective Public Works MaintenanceEffective Operational SecuritySatellite radio beaconingElectromagnetic wave reradiationLow speedComputer module

The invention discloses a medium-low speed magnetic suspension auxiliary working robot, which comprises a frame, two sets of folding and bending mechanisms, an auxiliary working mechanism and an autonomous cruising module. The frame spans between two F rails of medium-low speed magnetic suspension to be detected. The two sets of folding and bending mechanisms are respectively arranged at two endsof the frame and above the F rail, and each group of the folding and bending mechanism is provided with a traveling wheel pair and a clamping wheel pair. The auxiliary work mechanism comprises an auxiliary work platform and an auxiliary work equipment, wherein the auxiliary work platform is installed on the machine frame and the auxiliary work equipment is installed on the auxiliary work platformfor completing the auxiliary work. The autonomous cruise module is installed under the rack, which is used to realize the free walking of the auxiliary robot along the F-track. The invention can realize auxiliary operation of field maintenance and can realize autonomous cruising, and has the advantages of simple structure, convenient operation and the like.

Owner:陈友林

Medium and low speed maglev auxiliary operation robot

ActiveCN106320112AEffective Public Works MaintenanceEffective Operational SecurityRailway track constructionLow speedDetent

The invention discloses a medium and low speed maglev auxiliary operation robot. The auxiliary operation robot comprises a rack, folding and bending mechanisms, an auxiliary operation mechanism and an autonomous cruise module. The rack stretches across two F rails of a medium and low speed maglev; the two folding and bending mechanisms are arranged at the two ends of the rack respectively and located on the F rails, and each folding and bending mechanism is provided with a walking wheel pair and a detent wheel pair; the auxiliary operation mechanism comprises an auxiliary operation platform and auxiliary operation equipment, wherein the auxiliary operation platform is installed on the rack, the auxiliary operation equipment is installed on the auxiliary operation platform and used for completing auxiliary operation; the autonomous cruise module is installed below the rack and used for making the auxiliary operation robot walk along the F rails freely. Auxiliary operation of on-site maintenance and autonomous cruise can be achieved, and the medium and low speed maglev auxiliary operation robot has the advantages of being simple in structure, convenient to operate and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

Ultrasonic flaw detector for measuring metal workpiece

InactiveCN107478727AReduce workloadAccurate flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasoundPhysics

The invention discloses an ultrasonic flaw detector for measuring a metal workpiece and belongs to the technical field of ultrasonic flaw detection. The ultrasonic flaw detector comprises a detection executing mechanism used for detecting a weld joint of a pipeline, a monitoring device correlated to the detection executing mechanism, a conveying mechanism used for moving the pipeline to the detection executing mechanism along axial direction, a lifting mechanism used for lifting the pipeline, a correcting component used for monitoring if the weld joint is upward and a remote controller. The workload of flaw detection is greatly relieved, the flaw detection is more accurate and the efficiency is higher.

Owner:镇江龙逸电子科技有限公司

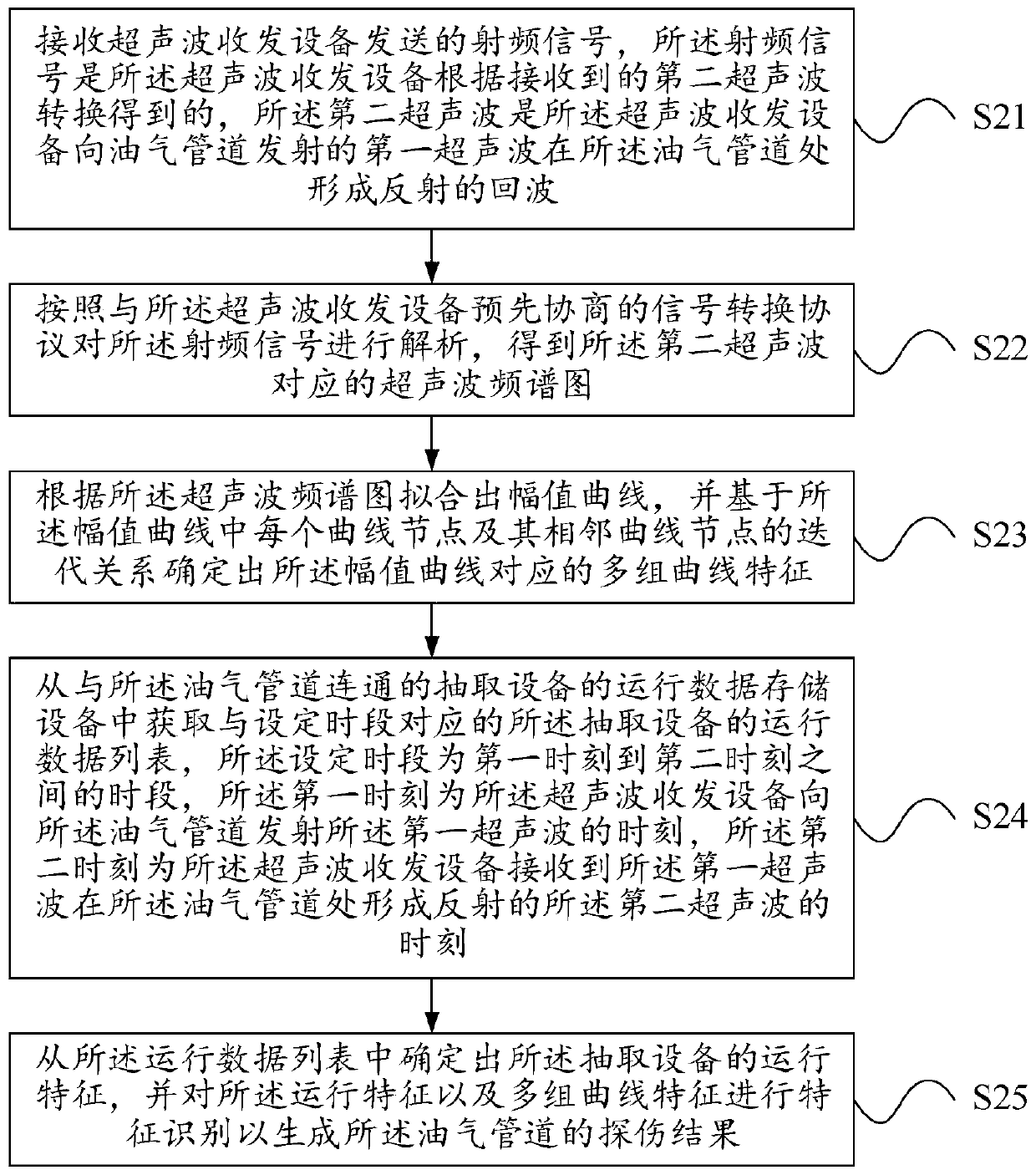

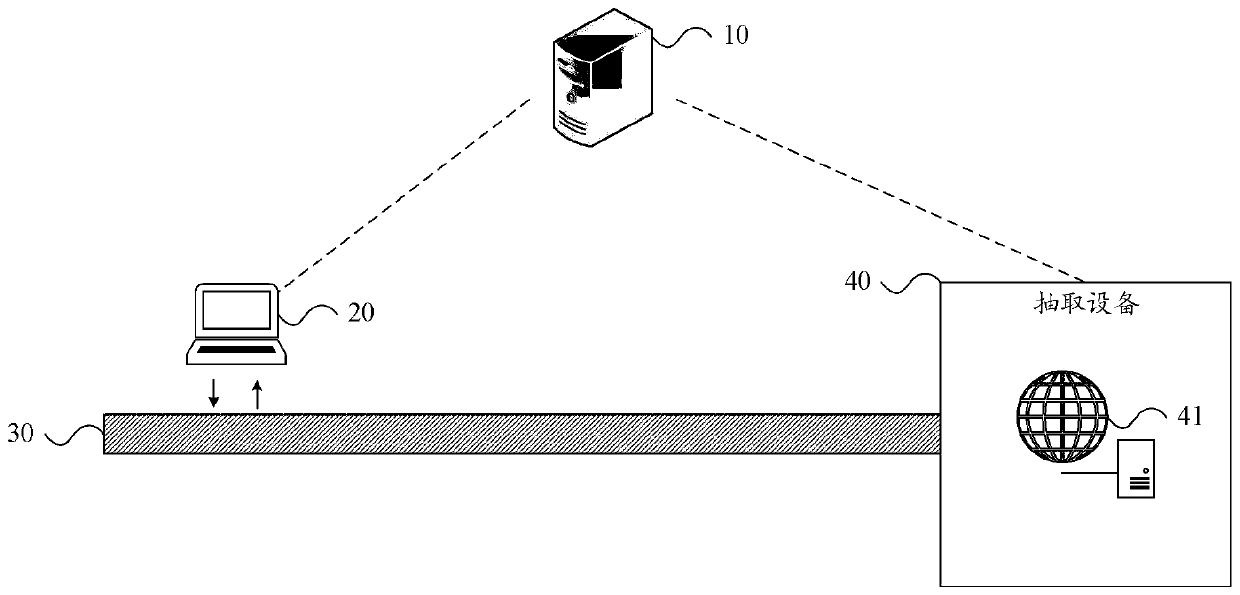

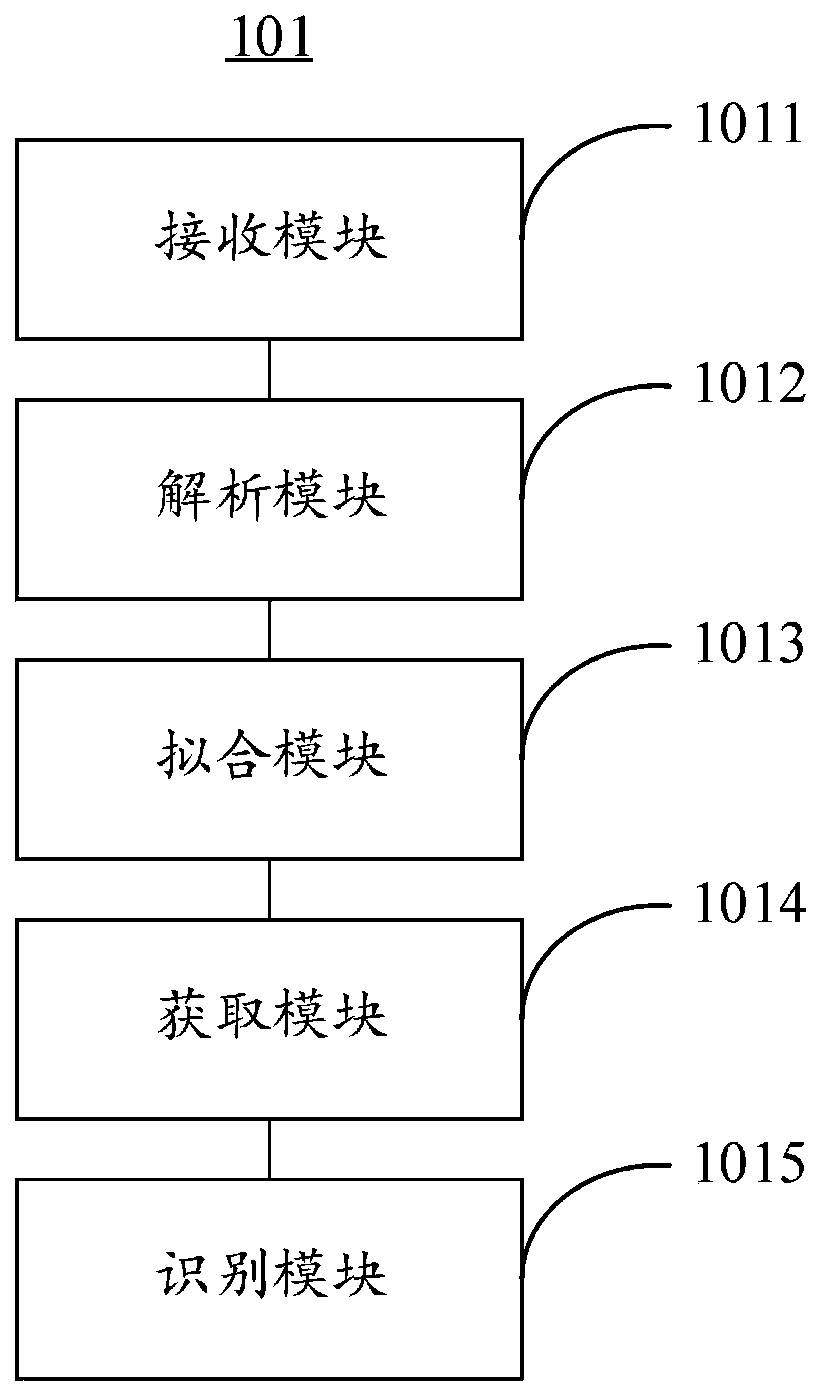

Drilling platform safety detection method and device and detection equipment

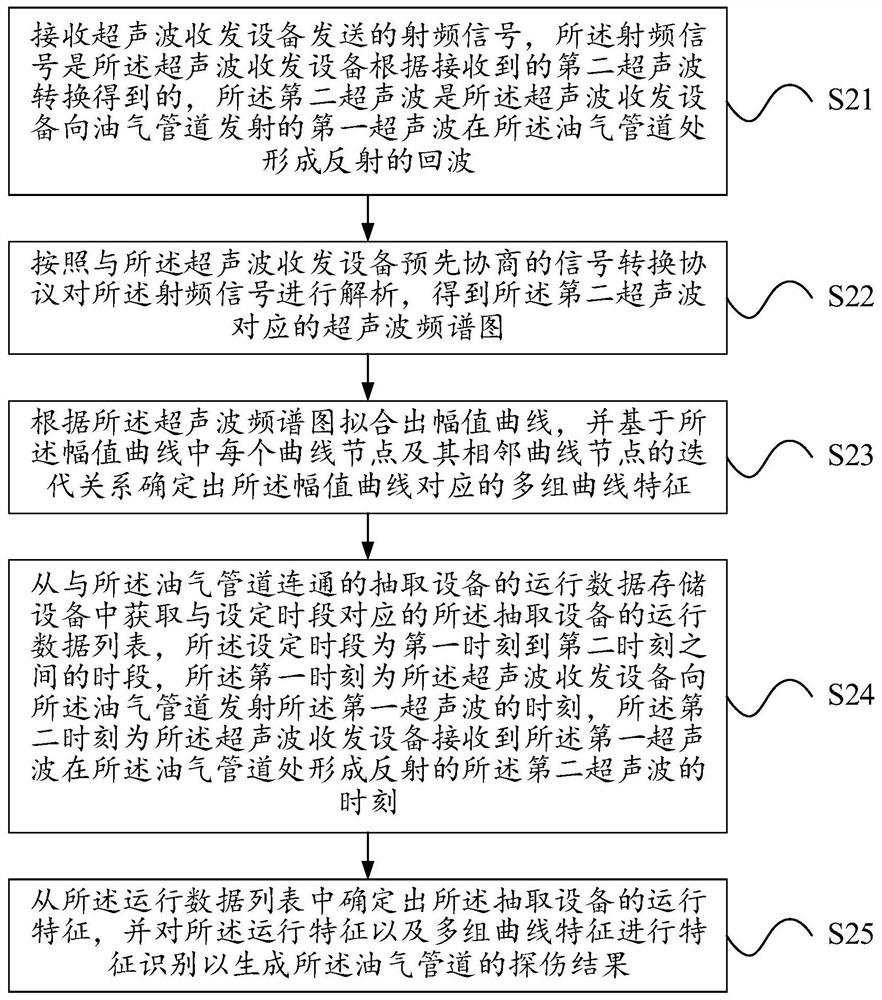

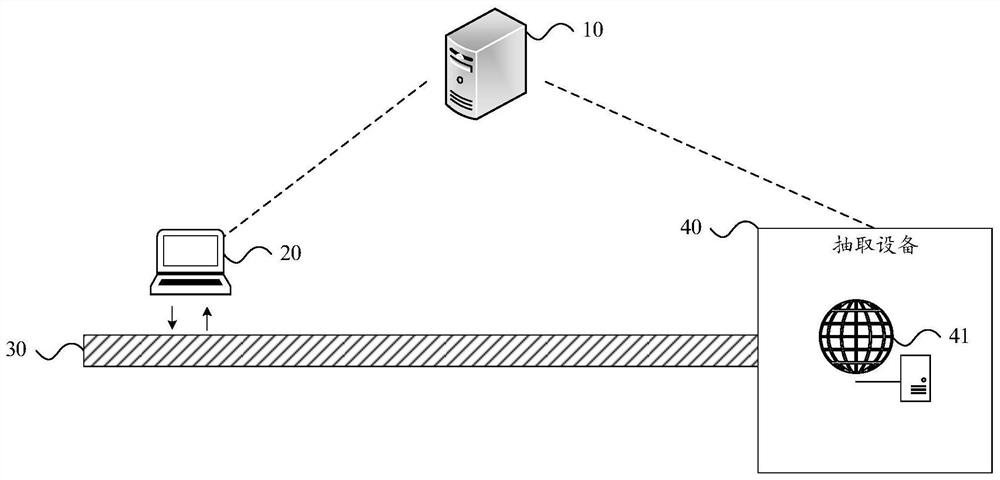

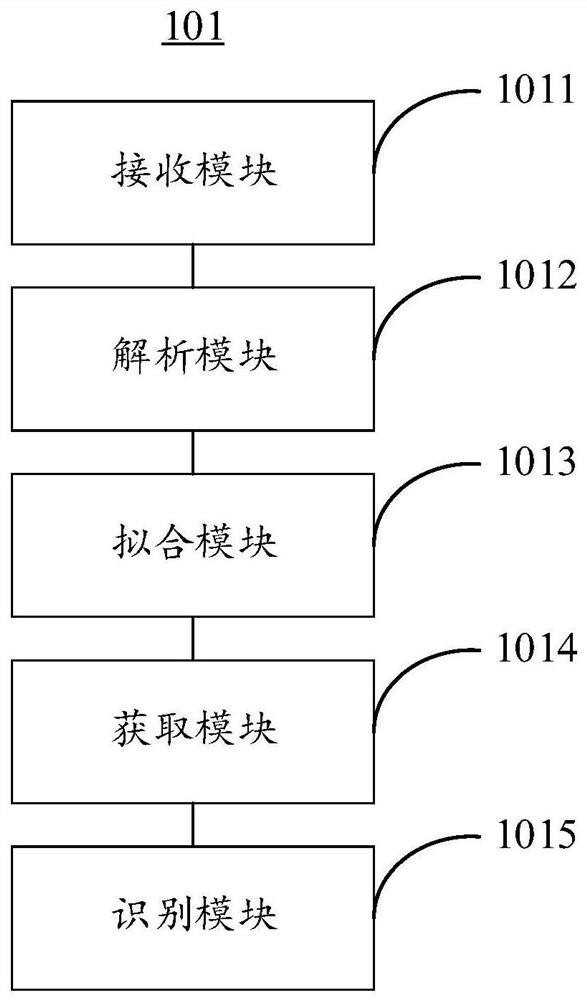

ActiveCN111322524ARealization of flaw detectionAccurate flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalTransceiverFrequency spectrum

The invention provides a drilling platform safety detection method and device and detection equipment. A radio frequency signal sent by ultrasonic transceiver equipment can be analyzed to obtain an ultrasonic spectrogram, then an amplitude curve is fitted, multiple groups of curve characteristics of the amplitude curve are determined, then characteristic recognition is carried out by combining operating characteristics corresponding to an operating data list of extraction equipment communicated with an oil and gas pipeline, and thus a flaw detection result of the oil and gas pipeline is generated. Therefore, flaw detection of the oil and gas pipeline can be realized on the ultrasonic level, and then slight damage in the oil and gas pipeline is recognized, so that even if no oil and gas leakage occurs in the oil and gas pipeline, accurate flaw detection can still be carried out on the oil and gas pipeline through the scheme.

Owner:四川盐业地质钻井大队

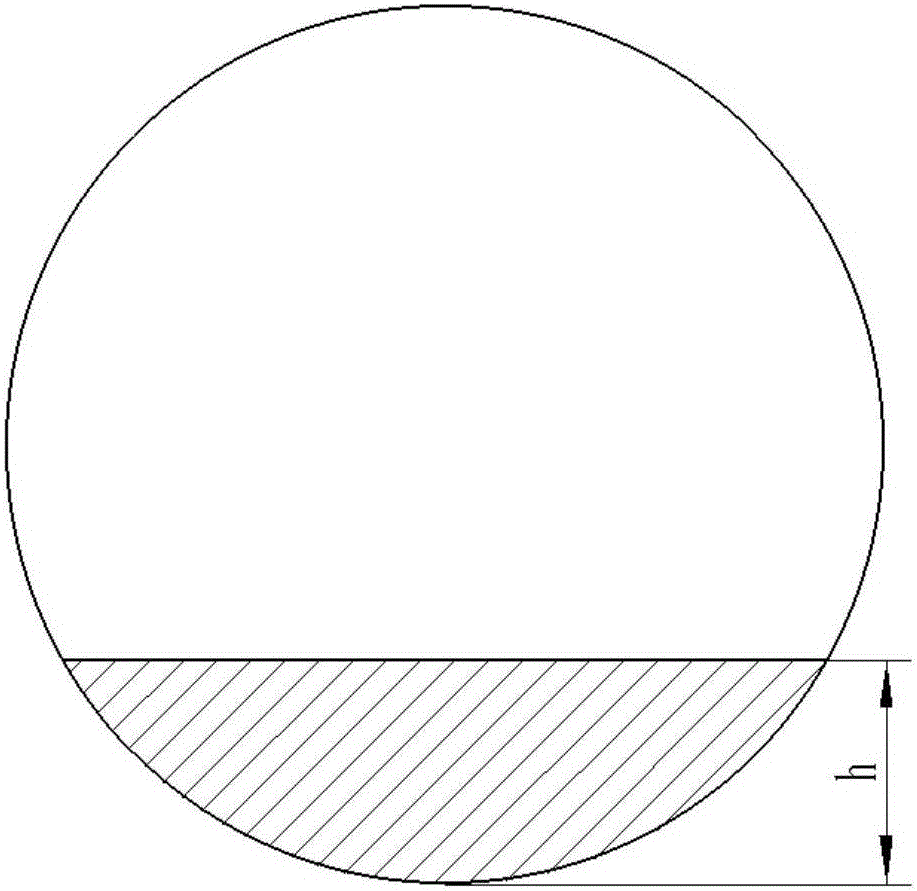

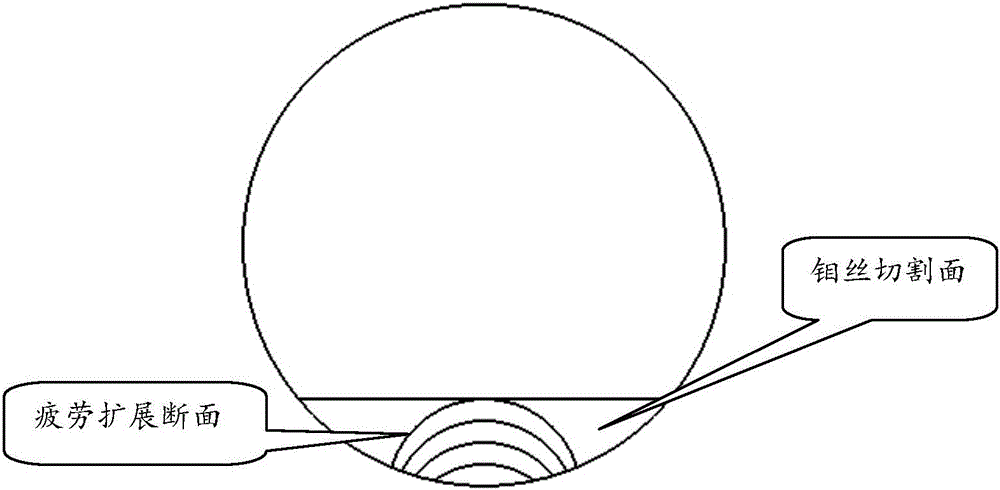

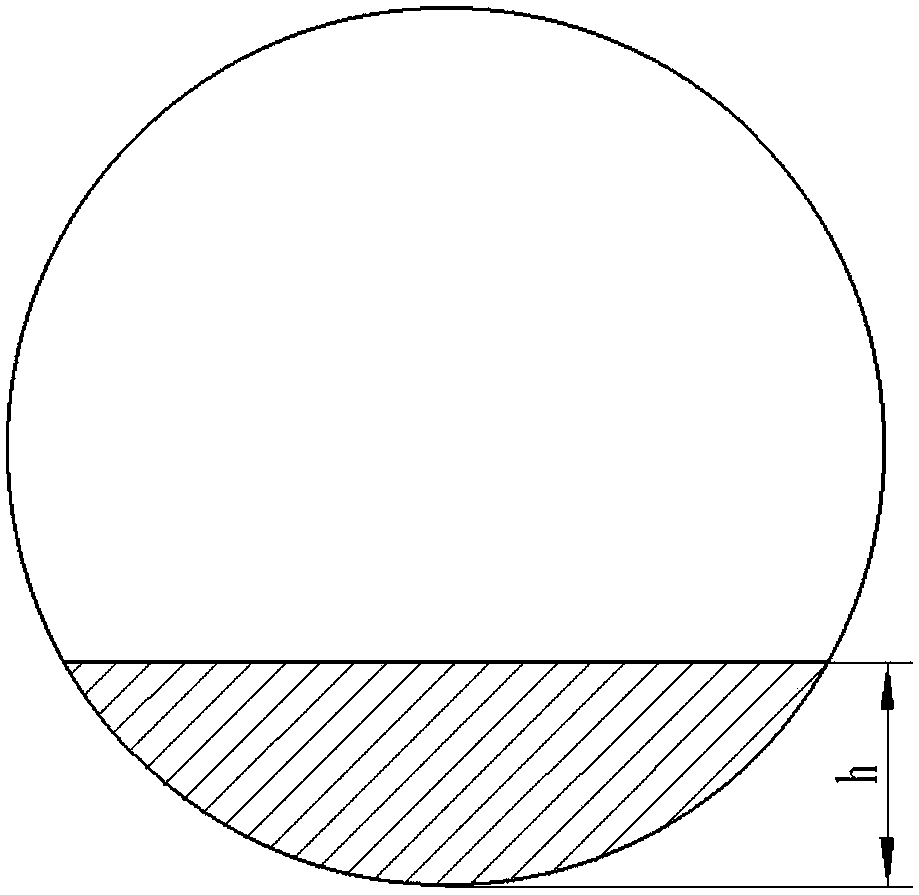

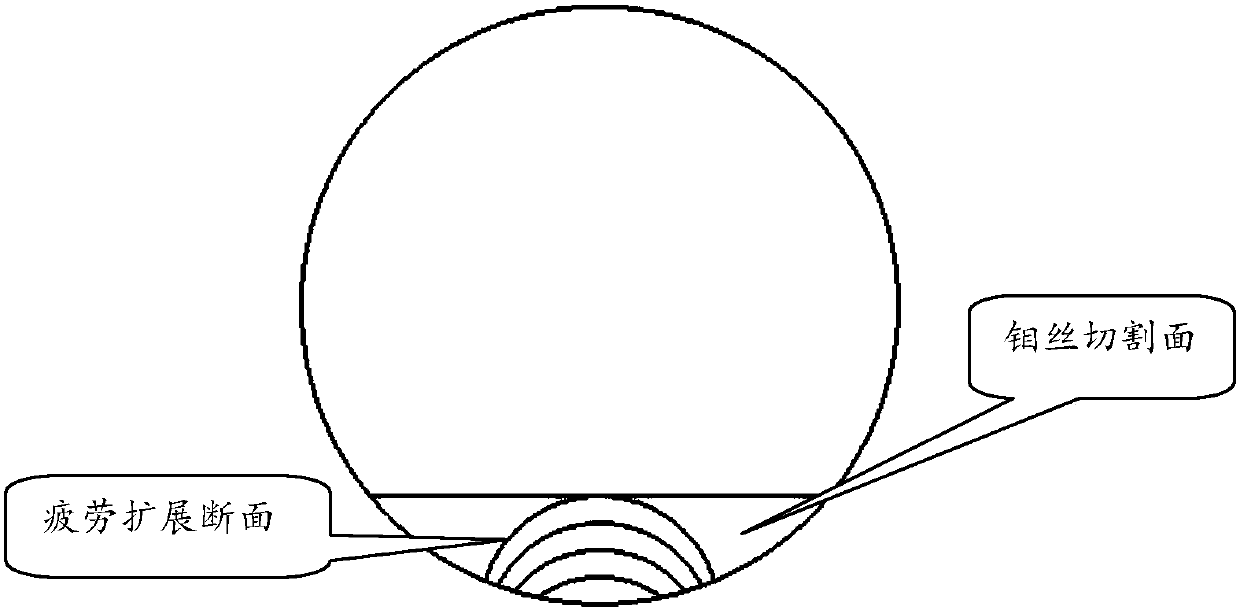

Method for manual simulation of fatigue cracks of reference block of bolt

ActiveCN106153735AAccurate flaw detectionEasy to processMaterial analysis using sonic/ultrasonic/infrasonic wavesCrazingFatigue cracking

The invention relates to a method for manual simulation of fatigue cracks of a reference block of a bolt. The bolt is processed with a central rotating circle or circular arc cutter, and an arc fatigue crack section which is same as a fatigue section is processed. By means of the method for manual simulation of the fatigue cracks of the reference block of the bolt, a natural crack reflection surface at a bolt fracture can be really and effectively simulated, crack detection of the bolt is more accurate, and the method has the advantages of being simple, accurate and easy to process and the like.

Owner:CHINA AIRPLANT STRENGTH RES INST

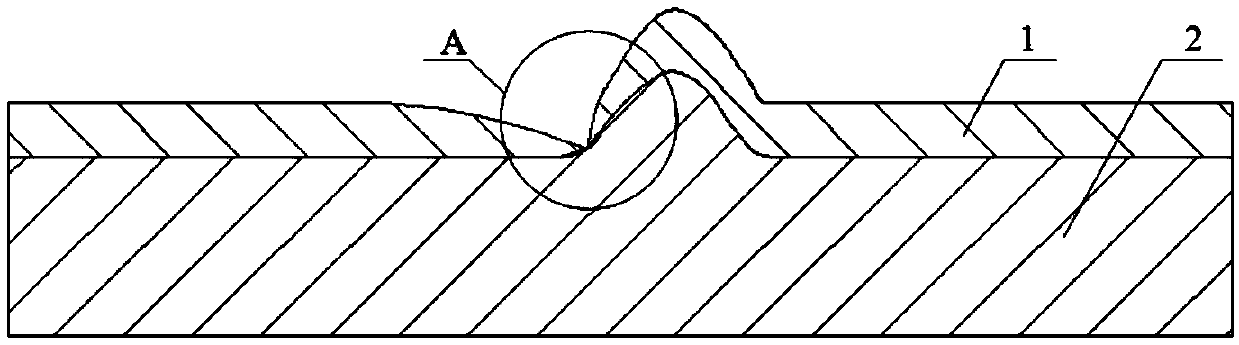

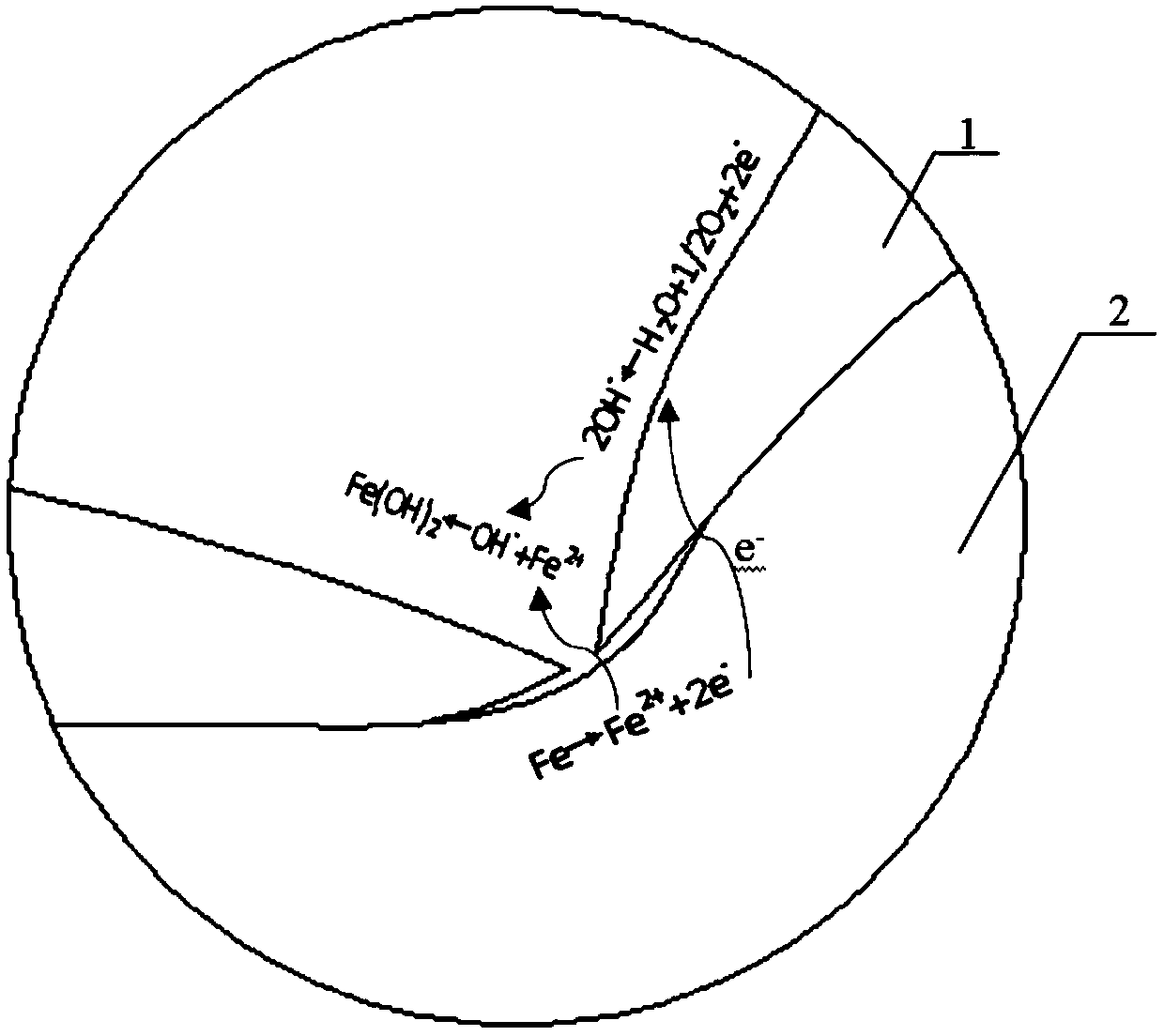

Flaw detecting method for stainless steel/carbon steel composite material

InactiveCN109557107AAccurate flaw detectionEasy to detectPreparing sample for investigationOptically investigating flaws/contaminationCarbon steelGreen rust

The invention discloses a flaw detecting method for a stainless steel / carbon steel composite material. Dark green rust spots appear after the stainless steel / carbon steel composite material is immersed in a sodium chloride solution for a period of time. The portion where the dark green rust spot are located is a damaged portion. Compared with the conventional flaw detecting method, the invention has the advantages of accuracy and low cost.

Owner:南工大溧阳新材料研发中心有限公司

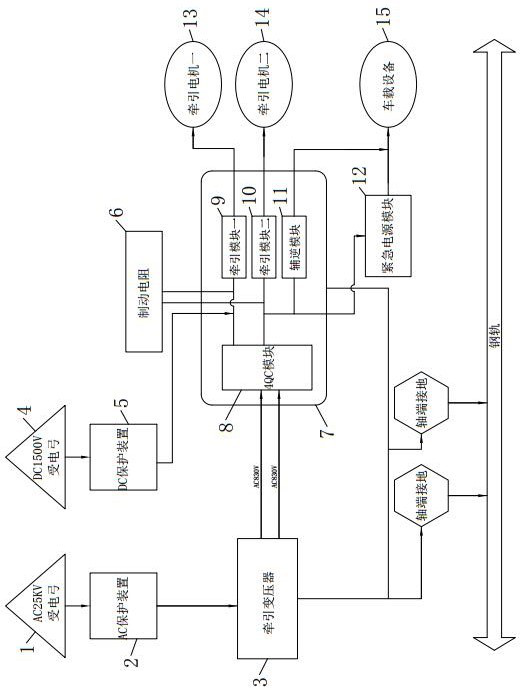

Alternating-current contact network and direct-current contact network double-power-supply steel rail flaw detection vehicle

PendingCN111645718AImprove efficiency and scopeImprove securityRailway inspection trolleysAc-dc conversionAutomotive engineeringTraction transformer

The invention discloses an alternating-current contact network and direct-current contact network double-power-supply steel rail flaw detection vehicle. The vehicle comprises a vehicle body and a traction power supply system installed in the vehicle body. The traction power supply system comprises an alternating current pantograph and a direct current pantograph, the output end of the alternatingcurrent pantograph is connected with an AC protection device, the output end of the AC protection device is connected with a traction transformer, and the output end of the traction transformer outputs two paths of AC830V and then is connected with a traction converter cabinet; the output end of the direct current pantograph is connected with a DC protection device, and the output end of the DC protection device is connected with a traction current transformer cabinet. The vehicle can perform high-speed, comprehensive and accurate flaw detection on subway steel rails, can be suitable for powersupply of an alternating-current contact network and a direct-current contact network, improves the flaw detection efficiency of the steel rails, widens the application range of the steel rails, andimproves the operation safety of subways.

Owner:CRRC LUOYANG CO LTD

Grinding device for inner wall of large shaft central hole of power generator unit

InactiveCN104589188AEfficient couplingGuaranteed grinding effectGrinding feed controlPortable grinding machinesCouplingEngineering

The invention relates to a grinding device for an inner wall of a large shaft central hole of a power generator unit. The grinding device comprises a handheld device round bar, wherein a fixed retainer ring is fixedly installed on the right side end part of the round bar, the round bar at the left side of the fixed retainer ring is sleeved by a hard sponge sleeve, a layer of grinding abrasive paper is fixedly installed on the outer side of the circumference of the hard sponge sleeve, a fixed stop ring sleeves the round bar at the left side of the hard sponge sleeve, and the fixed stop ring is fixed by a clamping hoop at the outer side of the circumference of the fixed stop ring. The grinding abrasive paper elastically contacts with the inner wall of the central hole, the elastic contact is different from the rigid contact between the traditional mechanical grinding block and the inner wall of the central hole, the abrasive paper in different fineness degree can be replaced at any time, the grinding effect can be guaranteed, the grinding efficiency can be improved, and the good coupling of an ultrasonic probe is guaranteed, so that accuracy in ultrasonic flaw detection can be realized, and leak detection can be avoided.

Owner:STATE GRID CORP OF CHINA +1

Automatic flaw detection device for steel wire rope

InactiveCN114689815AAffect accuracyAccurate flaw detectionPreparing sample for investigationDrying gas arrangementsWire rope

The invention discloses an automatic steel wire rope flaw detection device, which belongs to the technical field of steel wire rope flaw detection, and comprises a mounting table, and a steel wire rope leveling assembly, a steel wire rope cleaning assembly, a steel wire rope flaw detection assembly, a steel wire rope moving assembly and two steel wire rope fixing assemblies which are arranged on the mounting table, the steel wire rope leveling assembly is located at the feeding end of the mounting table, the steel wire rope cleaning assembly is located beside the steel wire rope leveling assembly, the steel wire rope flaw detection assembly is located in the middle of the mounting table, the two steel wire rope fixing assemblies are symmetrically arranged, and the two steel wire rope fixing assemblies are located between the steel wire rope flaw detection assemblies. The steel wire rope moving assembly is located at the discharging end of the mounting table. Through the steel wire rope flaw detection assembly, all-directional flaw detection operation can be conducted on the steel wire rope in the circumferential direction, the applicability of the device is improved, and flaw detection operation can be conducted on steel wire ropes of different sizes.

Owner:南通市江海钢绳有限公司

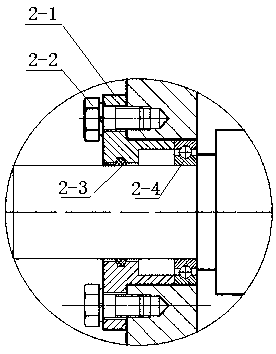

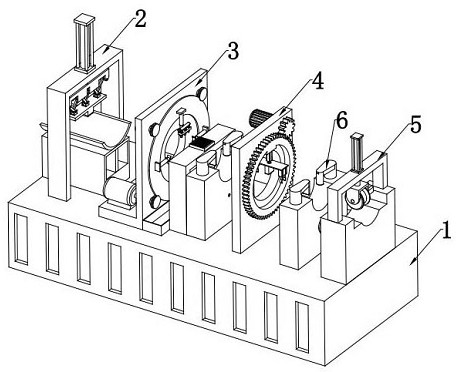

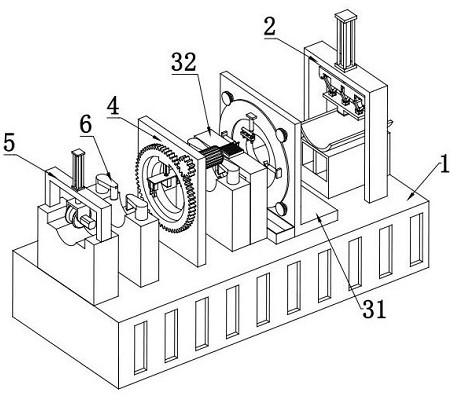

Wheel-set flaw detection driving device

Owner:CRRC TANGSHAN CO LTD

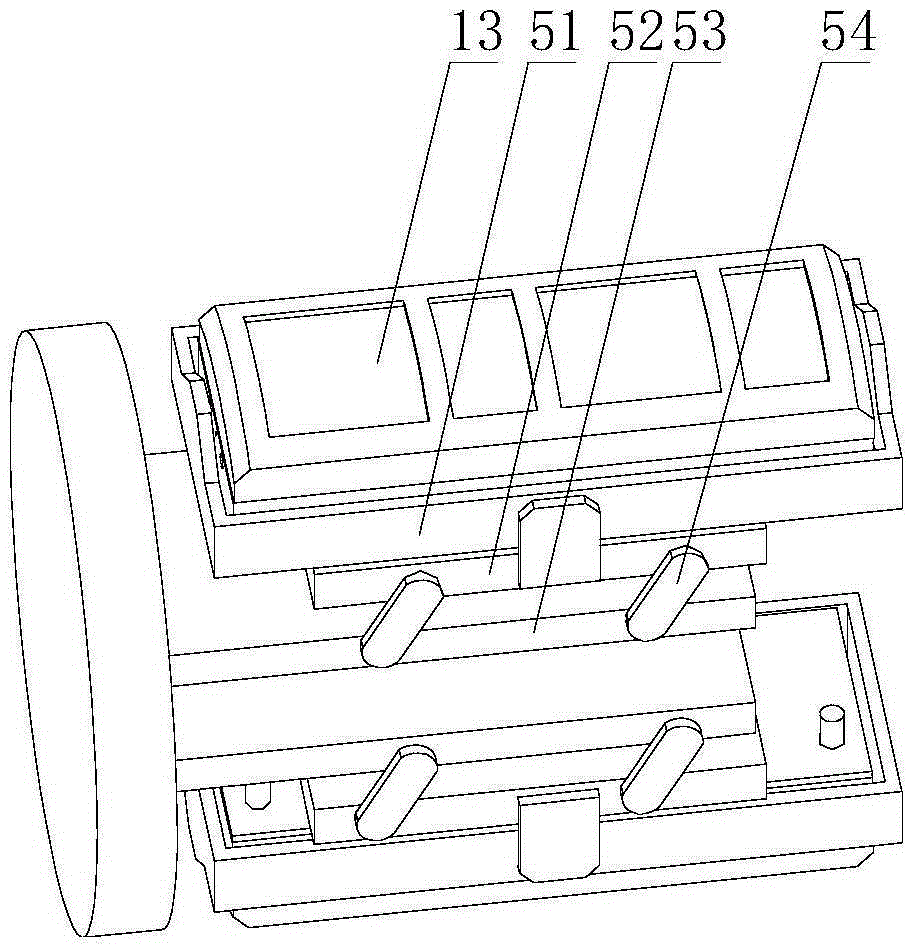

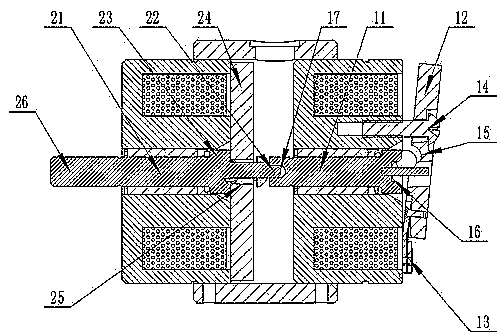

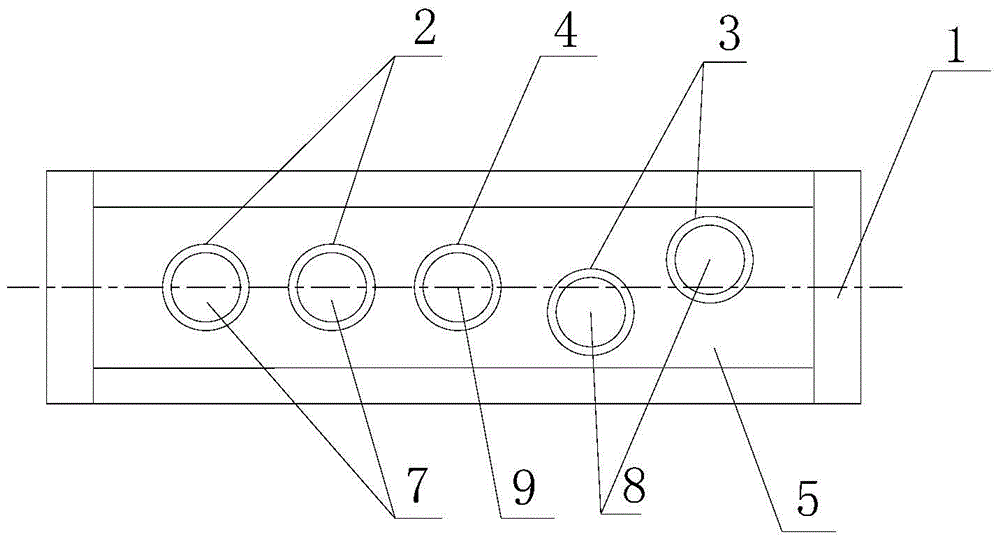

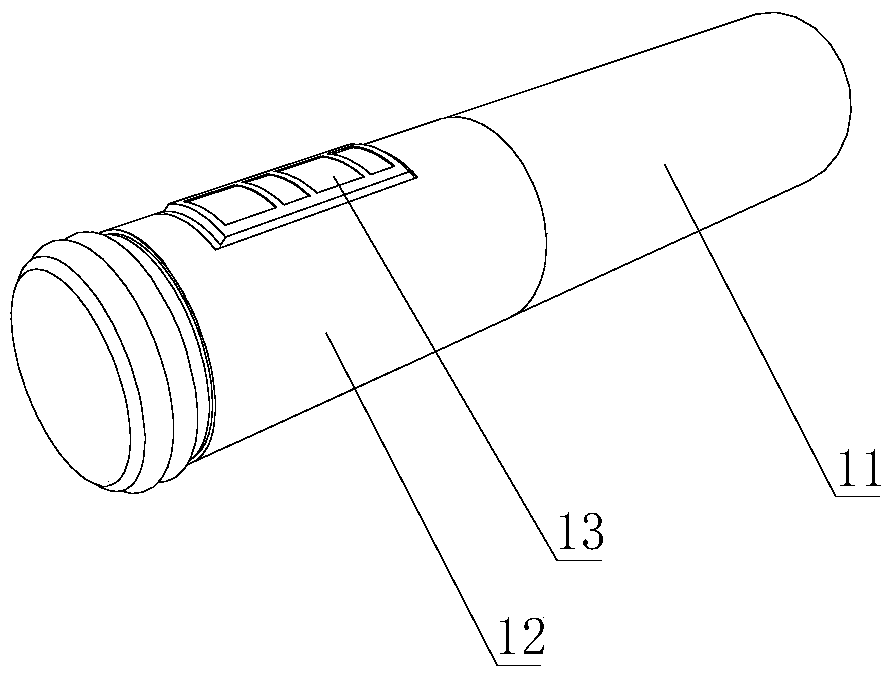

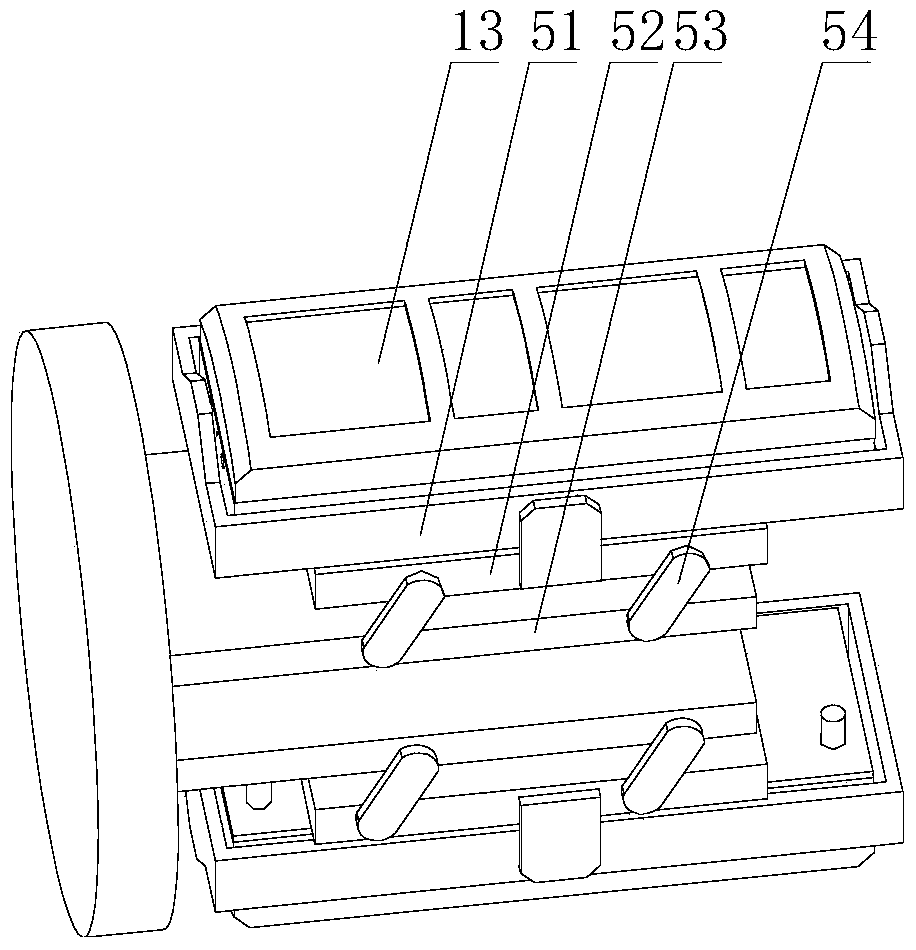

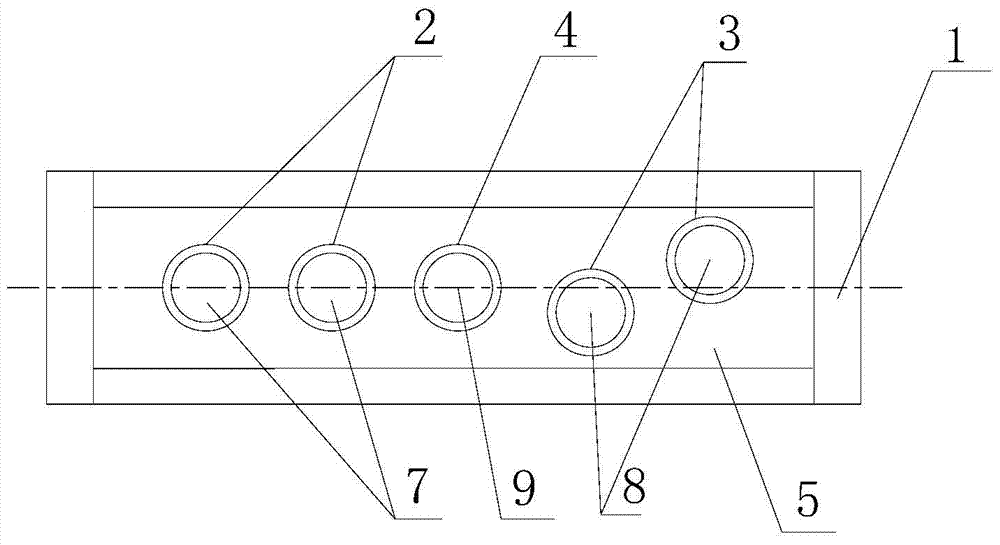

Nuclear evaporator heat transfer pipe inner hole crack detection device with convenient wire arrangement

ActiveCN103928067AImprove accuracyImprove work efficiencyNuclear energy generationNuclear monitoringEngineeringHeat transfer tube

A nuclear evaporator heat transfer pipe inner hole crack detection device with convenient wire arrangement comprises a seat body and probes arranged on the seat body. The seat body is a cylinder, a first concave table board and a second concave table board are formed on the side face of the cylinder, the first concave table board is parallel to the second concave table board, the structure with cylindrical end faces at the two ends and the two parallel concave table boards in the middle is formed, five through holes are formed in the two parallel concave table boards and comprise two first through holes used for mounting crack detection point focusing probes, two second through holes used for mounting linear focusing probes and one third through hole used for mounting a thickness detecting point focusing probe, and a probe emission end is arranged on the second concave table board. The first concave table board face is provided with a wire arrangement hole communicated with the cylindrical end face at one end of the seat body. The nuclear evaporator heat transfer pipe inner hole crack detection device with convenient wire arrangement is located in a heat transfer pipe in the crack detection process, leading wires of the five probes are connected to the outside by penetrating through the wire arrangement hole, and therefore the interference of the leading wires to detection is avoided.

Owner:CHANGZHOU CHANGCHAO ELECTRONICS RES INSTCO

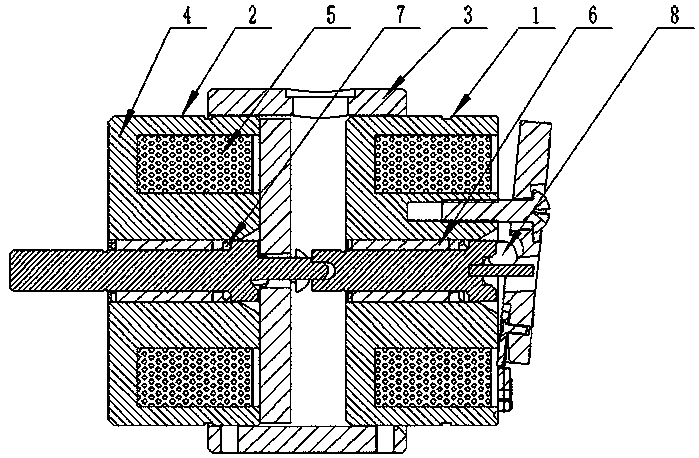

A superimposed rotating electromagnet with a curved surface rotating shaft

ActiveCN107316730BAccurate flaw detectionElectromagnets without armaturesStructural engineeringElectromagnet

A curved-surface rotation axis superposed rotation electromagnet comprises a main rotation electromagnet, wherein the main rotation electromagnet comprises a yoke, coils, a main shaft, a cover plate and an universal ball, a bearing is fixedly arranged in the center of the yoke, the main shaft is arranged on the bearing, one end of the main shaft penetrates through a bottom end of the yoke and is provided with an engagement bayonet, the other end of the main shaft extends to a central round hole of the cover plate, a main shaft curved-surface sliding groove is formed in the main shaft at a lower side of the cover plate, a cover plate curved-surface sliding groove is formed in one side, near to the yoke, of the cover plate, the cover plate curved-surface sliding groove and the main shaft curved-surface sliding groove are matched to form a limitation groove, the universal ball is arranged in the limitation groove, and the main shaft curved-shaft sliding groove is an irregularly-shaped curved-shaft sliding groove of which the curvature of a curved surface is gradually changed. By the curved-surface rotation axis superposed rotation electromagnet, a large torque is provided, and flaw detection and check can be accurately performed on a steel material in a high-temperature temperature; and after the electromagnets in two different working directions are combined, the detection mechanism is automatically opened and closed by circuit control.

Owner:GUANGZHOU WAYTOP ELECTRONICS

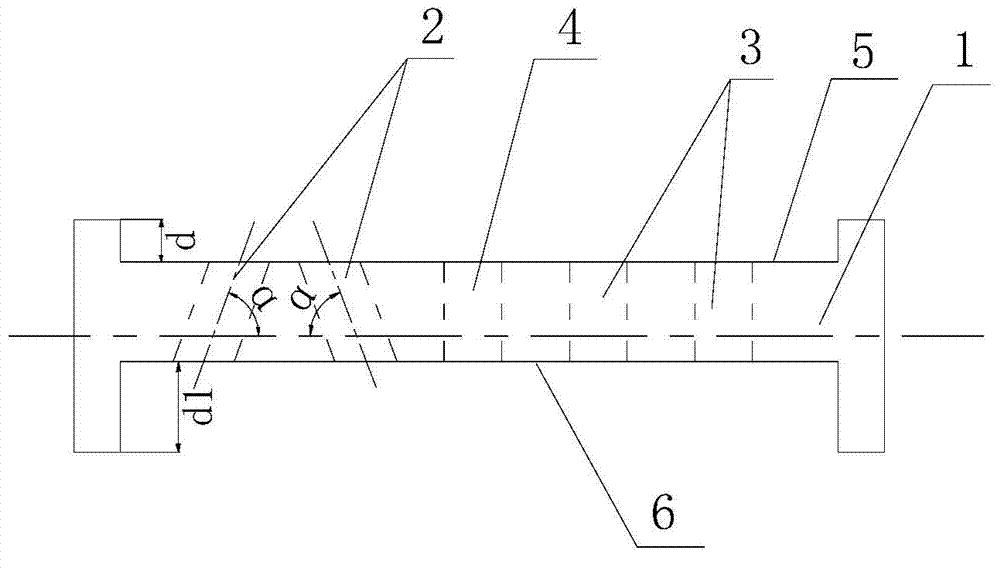

Inner hole flaw detection device of heat transfer tube of nuclear power evaporator with thickness measurement function

ActiveCN103943156BAccurate flaw detectionAvoid detectionNuclear energy generationNuclear monitoringNuclear powerEngineering

The invention discloses a flaw detection device with a thickness measuring function of an inner hole of a heat conduction tube of a nuclear power evaporator. A first concave tabletop and a second concave tabletop are formed in the side surface of a column to form a base body; five through holes, namely two through holes I, two through holes II and a through hole III, are formed in the two concave tabletops in parallel; the axes of the two through holes I are intersected with each other on one side of the first concave tabletop and are both intersected with the axis of the base body; a plane in which the axes of the two through holes I are located is perpendicular to the first concave tabletop; the axes of the two through holes II are positioned on two sides of the axis of the base body and are in one same plane; the plane in which the axes of the two through holes II are located is perpendicular to the first concave tabletop; the axis of the through hole III and the axes of the through holes I are positioned in one same plane; the axis of the through hole III is perpendicular to the axis of the base body. The device can be used for detecting the inner hole in the axial direction, the circumferential direction and the thickness simultaneously, the problems that some flaw is neglected and cracks cannot be detected are avoided, the accuracy and the working efficiency of flaw detection are improved, and the flaw detection is reliable.

Owner:CHANGZHOU CHANGCHAO ELECTRONICS RES INSTCO

An Artificial Simulation Method for Fatigue Cracks of Bolt Comparison Test Blocks

ActiveCN106153735BAccurate flaw detectionEasy to processMaterial analysis using sonic/ultrasonic/infrasonic wavesFatigue crackingMaterials science

The invention relates to a method for manual simulation of fatigue cracks of a reference block of a bolt. The bolt is processed with a central rotating circle or circular arc cutter, and an arc fatigue crack section which is same as a fatigue section is processed. By means of the method for manual simulation of the fatigue cracks of the reference block of the bolt, a natural crack reflection surface at a bolt fracture can be really and effectively simulated, crack detection of the bolt is more accurate, and the method has the advantages of being simple, accurate and easy to process and the like.

Owner:CHINA AIRPLANT STRENGTH RES INST

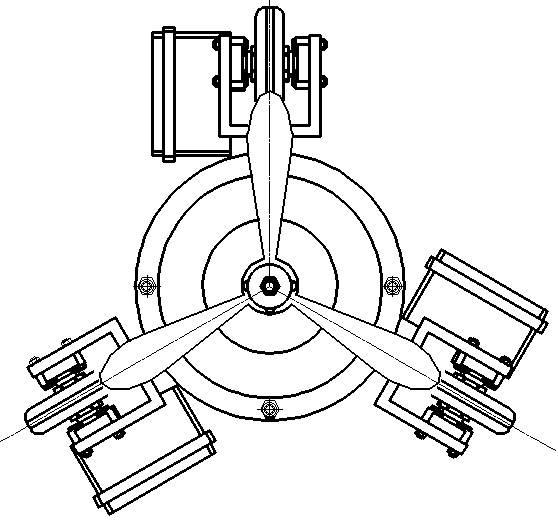

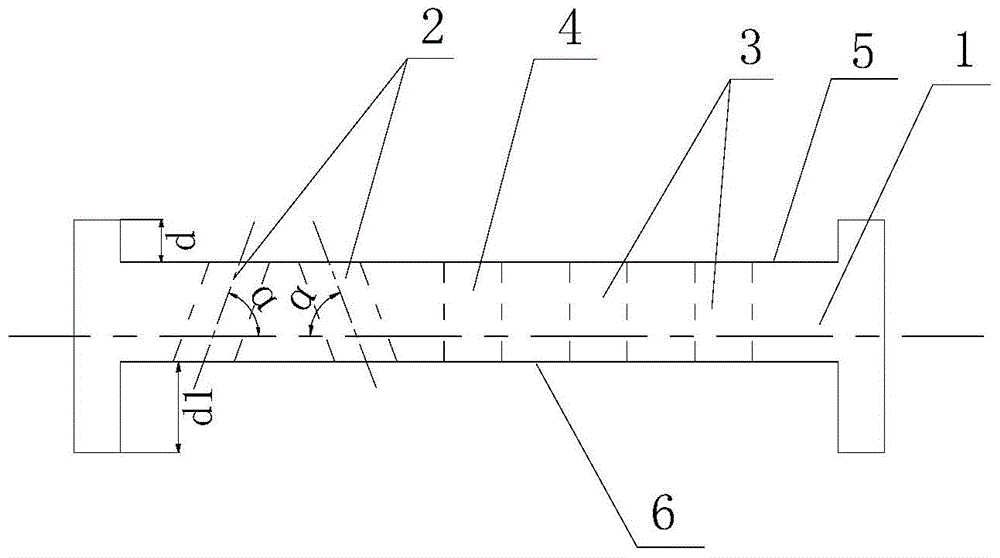

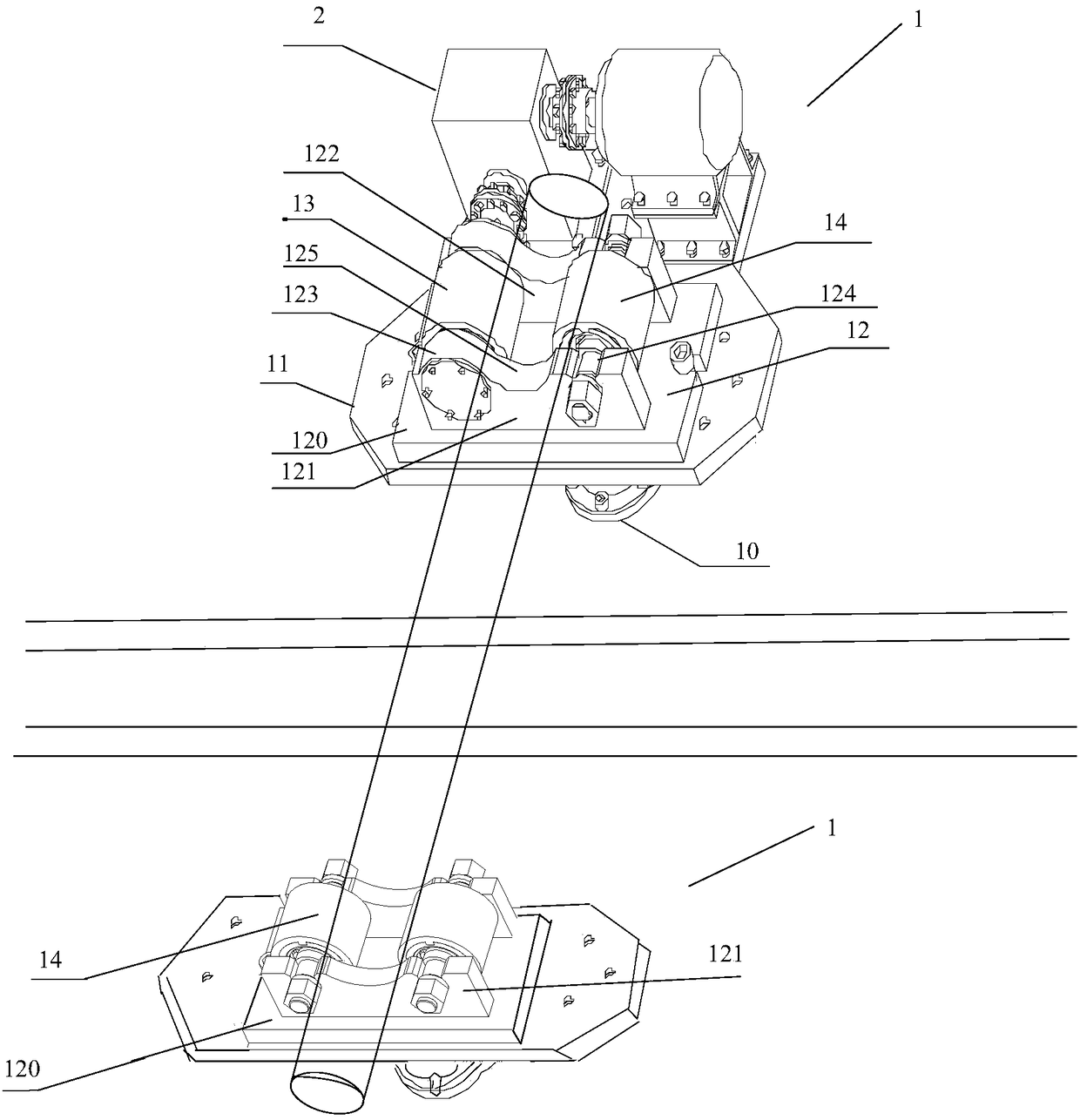

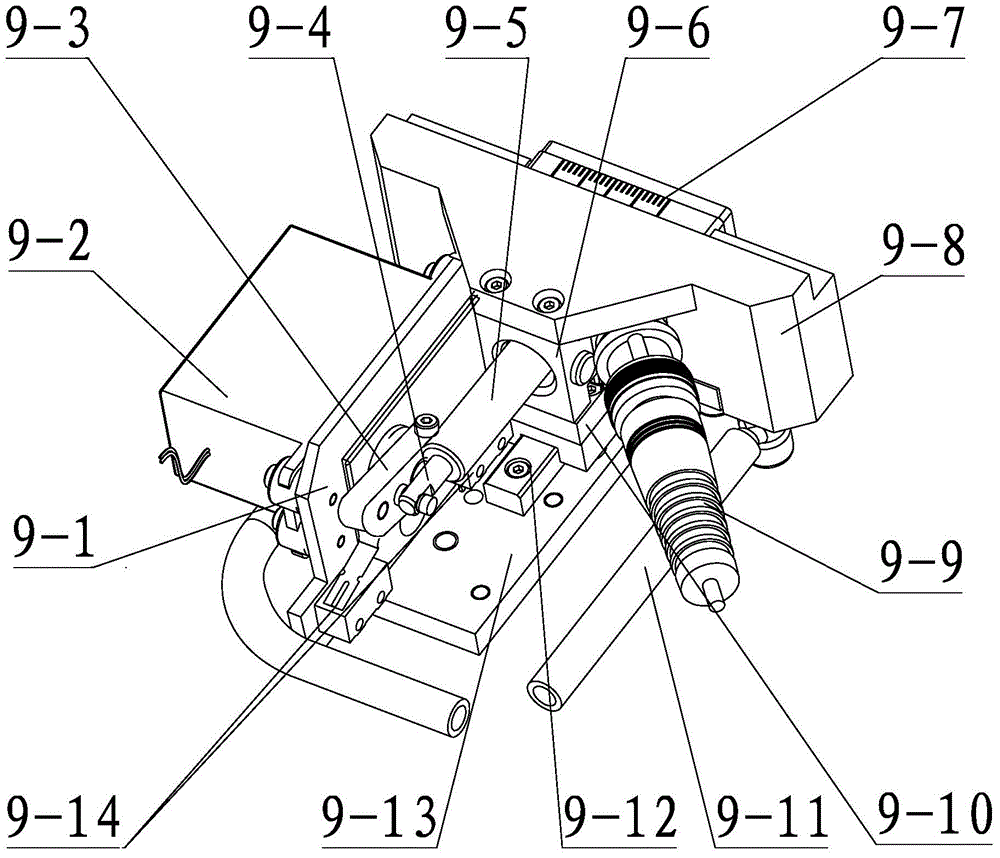

Wheelset flaw detection drive

ActiveCN106290717BAccurate flaw detectionSmooth rotationMaterial analysisDrive wheelElectric machinery

The wheel pair flaw detection driving device provided by the invention includes two driving components and a driving motor. Each driving component includes a supporting component, a supporting plate, a runner mounting seat, a driving wheel and a driven wheel. The runner mounting seat includes a first Bottom plate, first side wing and second side wing. The first side wing and the second side wing each include a first through hole for installing the driving wheel, a first slot hole for installing the driven wheel and a wheel pair shaft for clamping The first slotted hole, the supporting component is installed at the bottom of the supporting plate, and the driving motor is drivingly connected to the central axis of the driving wheel. The wheel set flaw detection driving device provided by the invention supports the tread of the wheel pair off the ground through the supporting component, drives the motor to drive the driving wheel to rotate and drives the wheel pair shaft of the wheel pair to rotate, thereby reducing the wear caused by the contact between the tread of the wheel set and the ground. , thus ensuring the smooth rotation of the wheelset, allowing the flaw detection equipment to accurately detect flaws in the wheelset.

Owner:CRRC TANGSHAN CO LTD

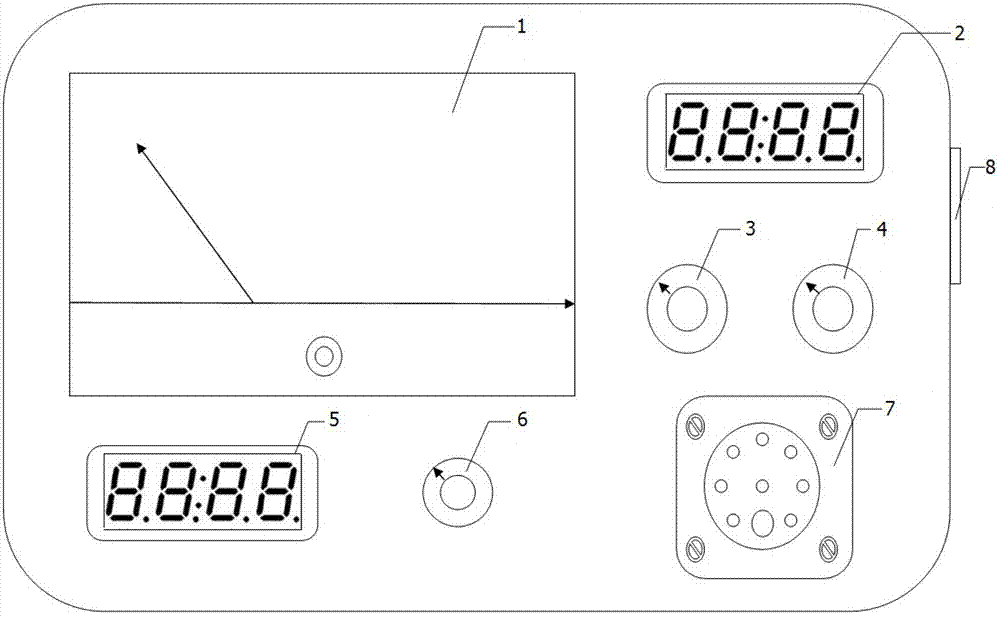

Eddy current coil center calibration device and calibration method

ActiveCN104062355BImprove flaw detection efficiencyEasy to detect flawsMaterial magnetic variablesElectricityEngineering

The present invention discloses a device for calibrating the electric center of the eddy current coil, which works on the normal calibration sample tube during the use of the original through-type eddy current, and a very critical step in this work is to measure the electric center and the electric center of the coil Check the coincidence adjustment of the steel tube mechanical center. The device changes the original two-step method of first finding the coil mechanical center and then the coil electrical center into the present one-step method of directly finding the coil electrical center through a method of utilizing electromagnetic induction. From the original mechanical adjustment to the measurement of electromagnetic induction. Moreover, because of the adoption of digital display technology, the final result is digitized, which is beneficial to future statistics, reduces labor intensity, and improves labor efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

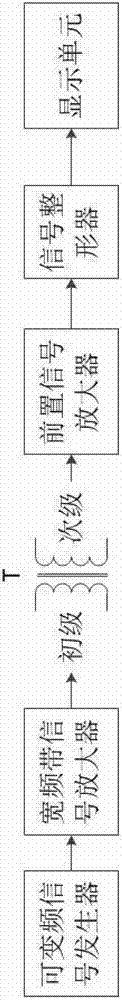

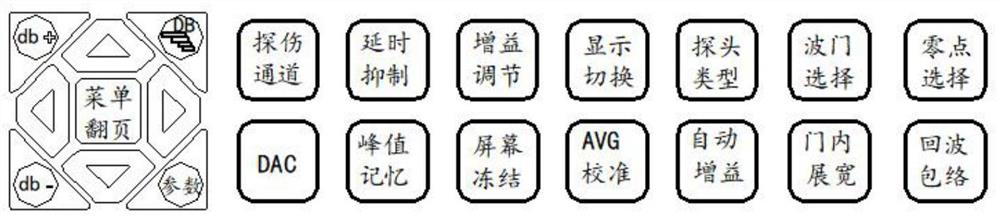

Gain control circuit of ultrasonic flaw detector

PendingCN112051338AGood directionSure easyProcessing detected response signalCapacitanceSoftware engineering

The invention discloses a gain control circuit of an ultrasonic flaw detector. The circuit comprises a single-to-double gain circuit and a gain adjusting circuit, the single-to-double gain circuit isprovided with a gain amplifier with a fixed 6db, and the positive input terminal of the gain amplifier is electrically connected with the output terminal of an ultrasonic receiving loop through an LCfilter circuit consisting of an inductor L5 and a blocking capacitor C23; the gain adjusting circuit comprises a DAC for converting analog signals, and a D-end control pin of the DAC is electrically connected with an FPGA. And the DAC converts a digital signal of the FPGA into an analog signal for controlling the VGA through the D-end control pin. Gain adjustment is further performed on the VGA1 and the VGA2 through the analog signal, and the gain amplifier converts an ultrasonic receiving loop reflection signal at the input terminal into a differential gain signal and outputs the differentialgain signal to the VGA1, so that the noise of the ultrasonic reflection signal is effectively reduced; and the repetition frequency of the negative pulse in the ultrasonic transmitting circuit is suppressed.

Owner:青岛汉泰智能科技有限公司

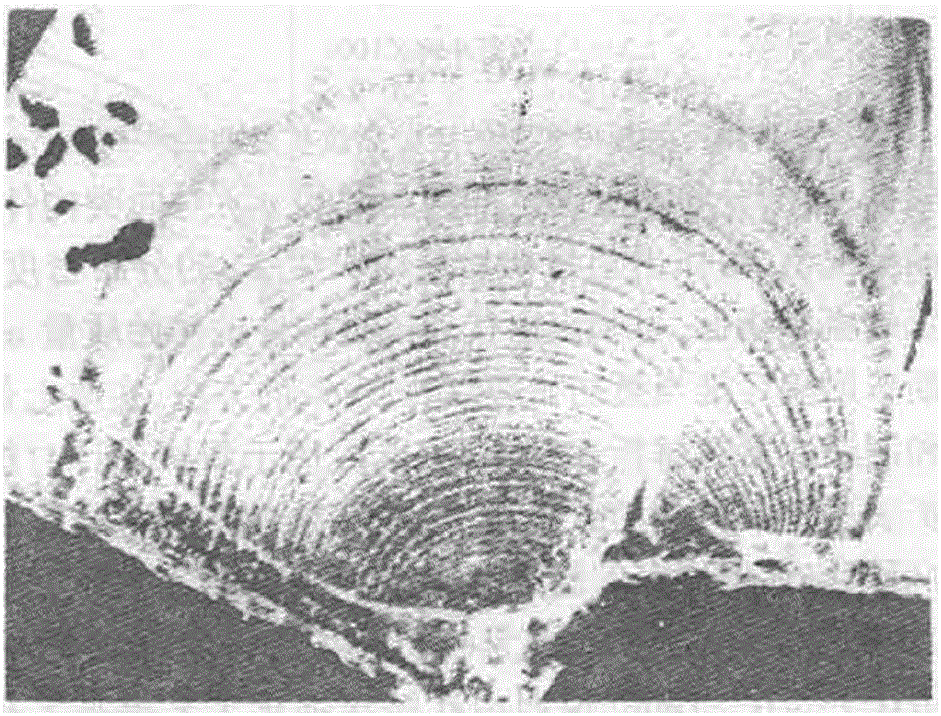

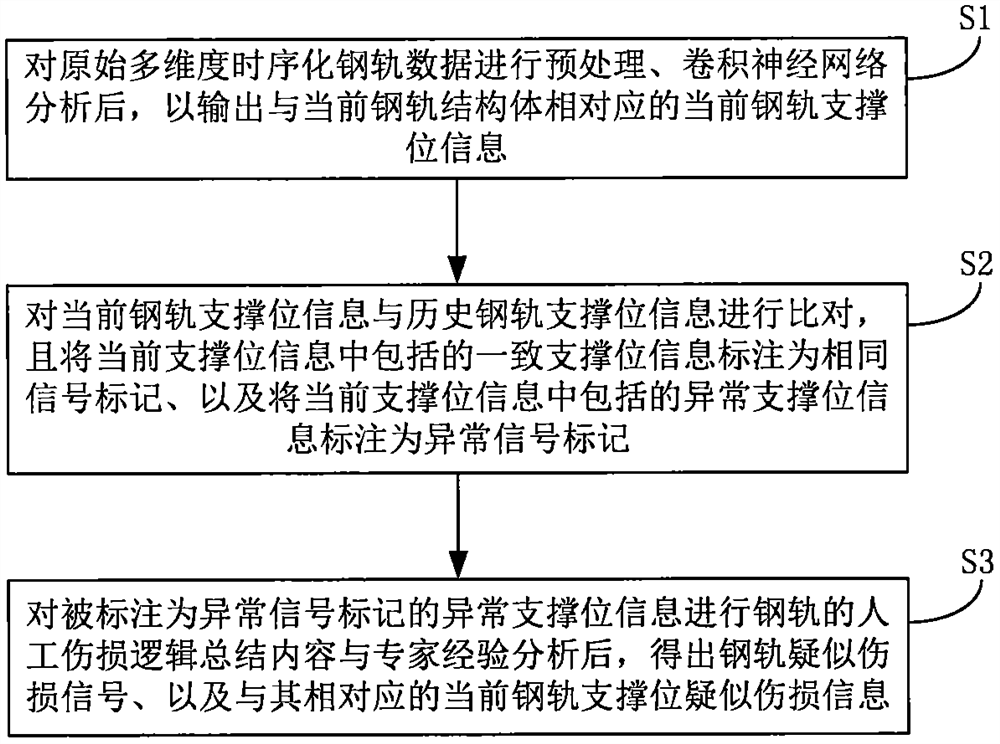

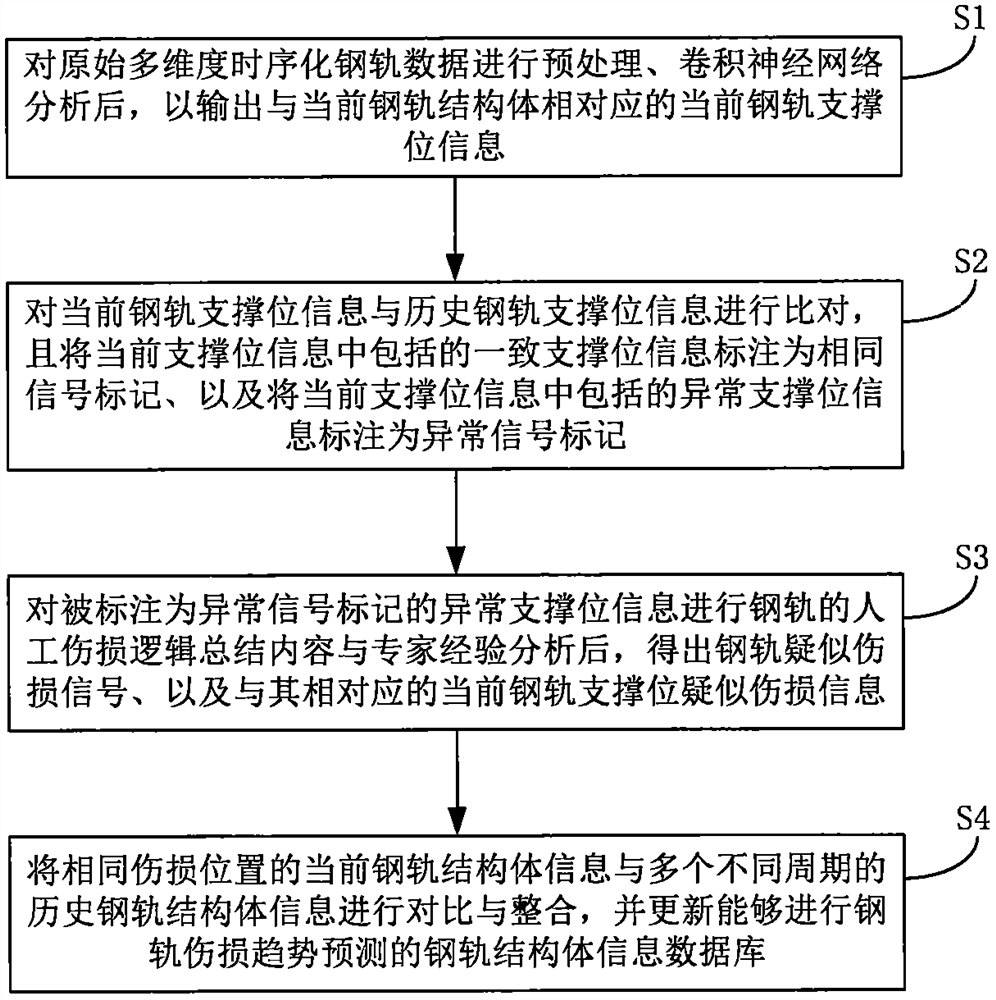

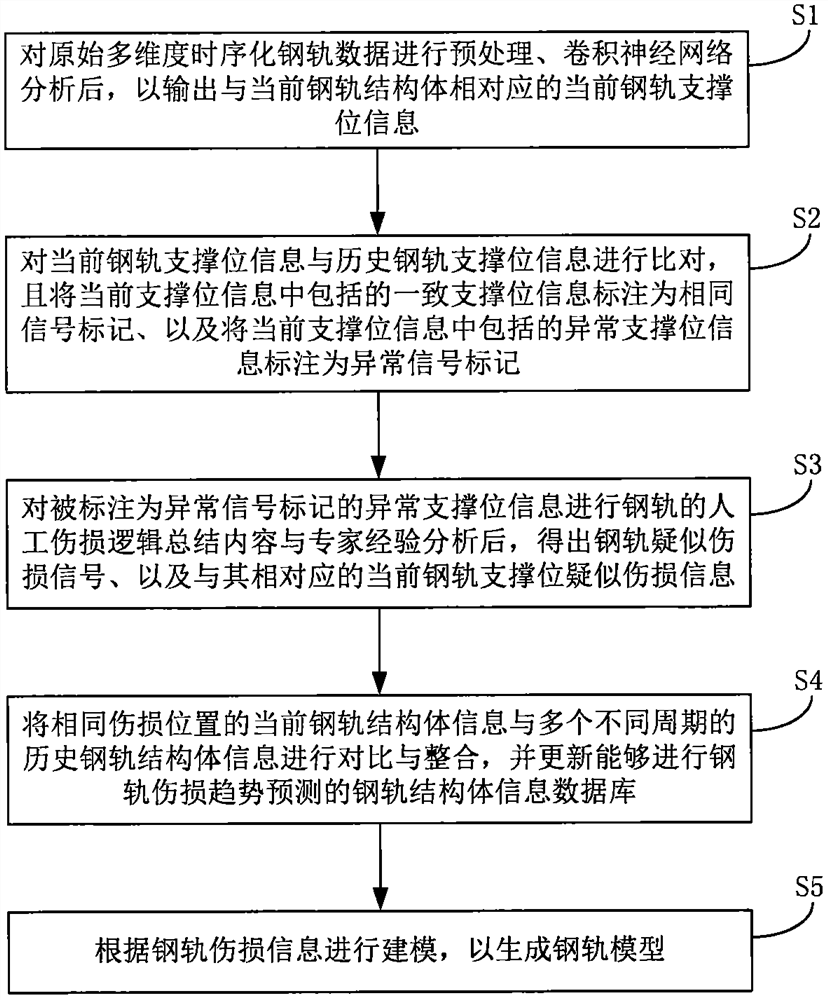

Steel rail damage determination method and determination system based on convolutional neural network

PendingCN114862743AAccurate flaw detectionGuaranteed uptimeImage enhancementImage analysisNeural network analysisInformation analysis

The invention provides a steel rail damage determination method based on a convolutional neural network, and the method comprises the steps: carrying out the preprocessing of original multi-dimensional time sequence steel rail data, and outputting the current steel rail supporting position information after the analysis of the convolutional neural network; after the current steel rail supporting position information is compared with the historical steel rail supporting position information, the consistent supporting position information is marked as the same signal mark, and the abnormal supporting position information is marked as the abnormal signal mark; and carrying out steel rail artificial injury logic summary content and expert experience analysis on the abnormal supporting position information marked as the abnormal signal mark to obtain a steel rail suspected injury signal and current steel rail supporting position suspected injury information corresponding to the steel rail suspected injury signal. The determination system applying the method comprises a current steel rail supporting position information acquisition part, a supporting position information signal marking part and a steel rail suspected damage information analysis part. According to the invention, more accurate and rapid steel rail flaw information can be provided for steel rail flaw detection.

Owner:北京洞微科技发展有限公司

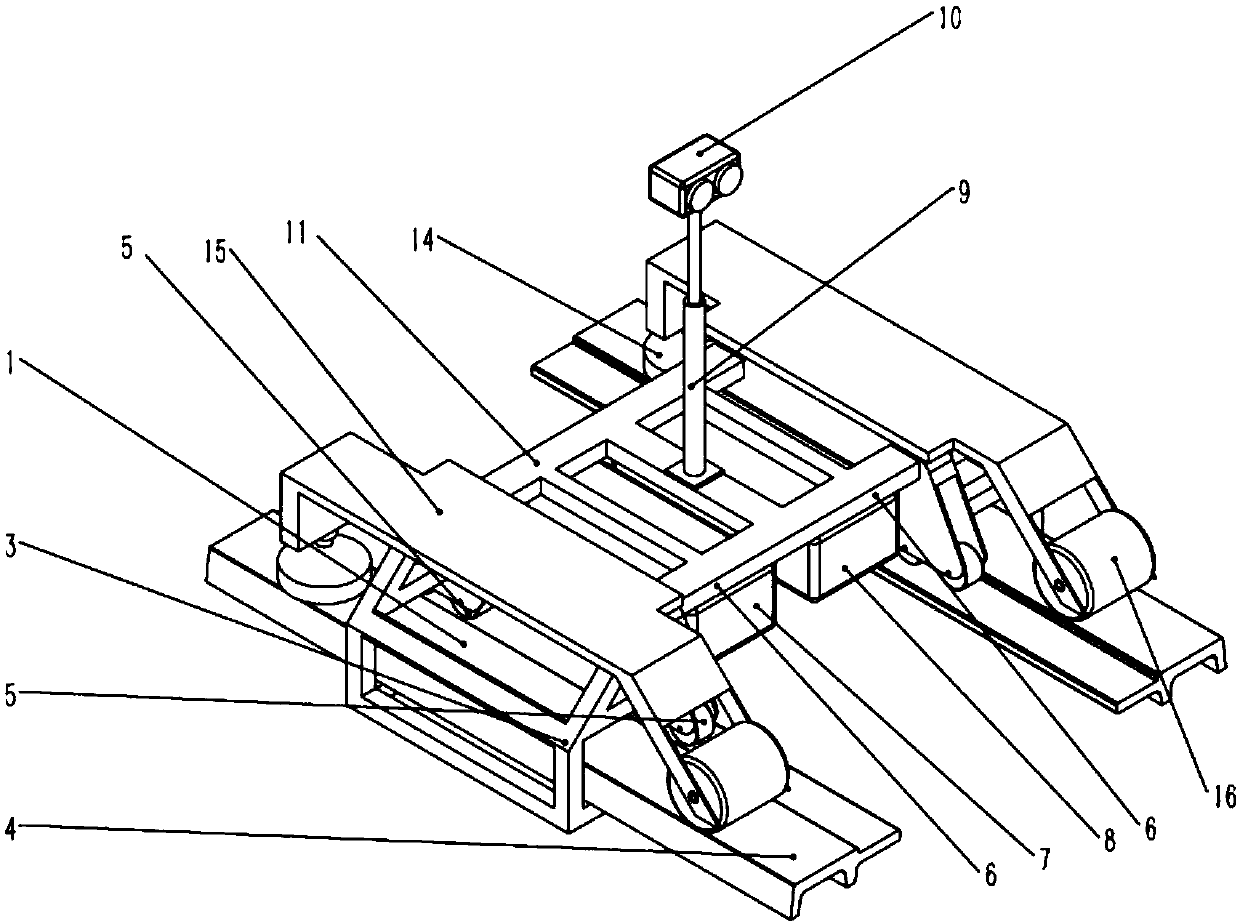

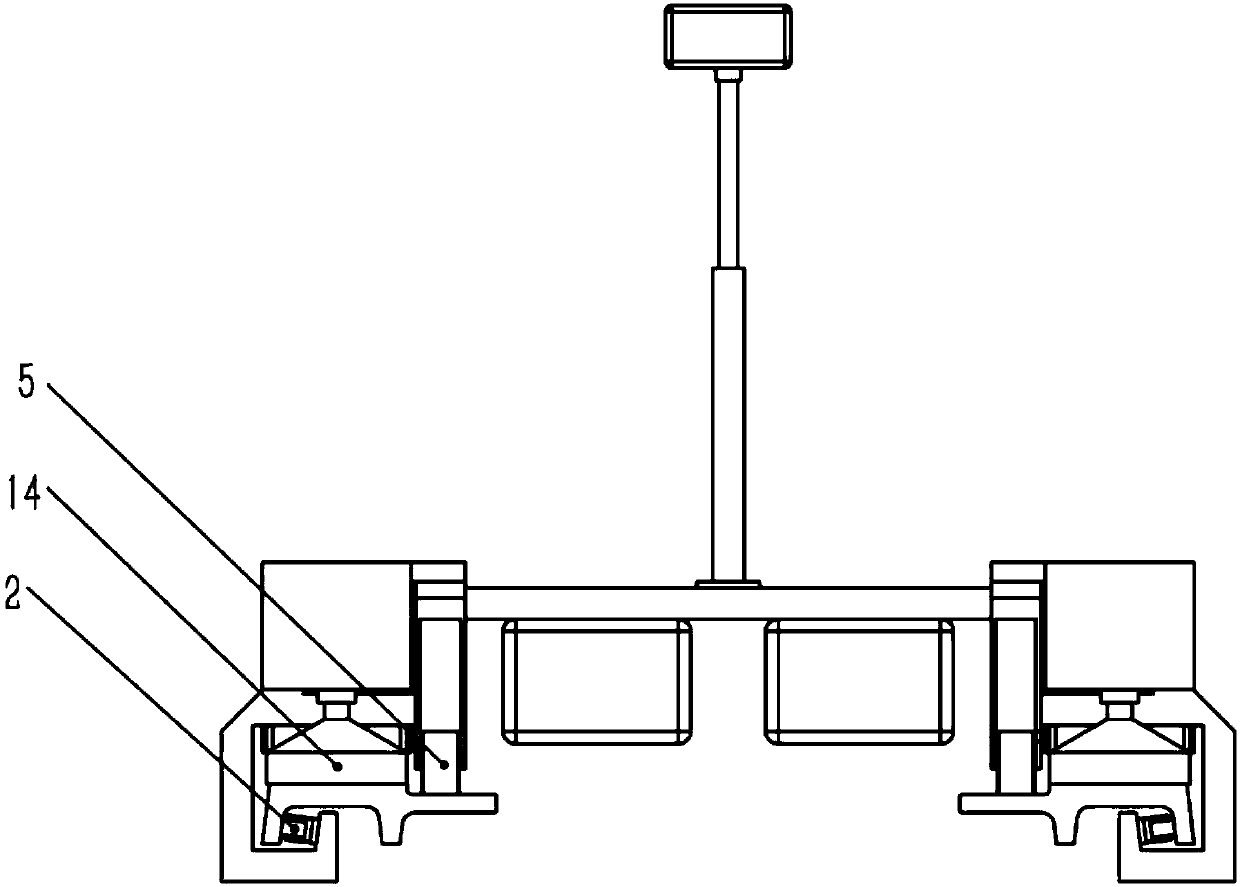

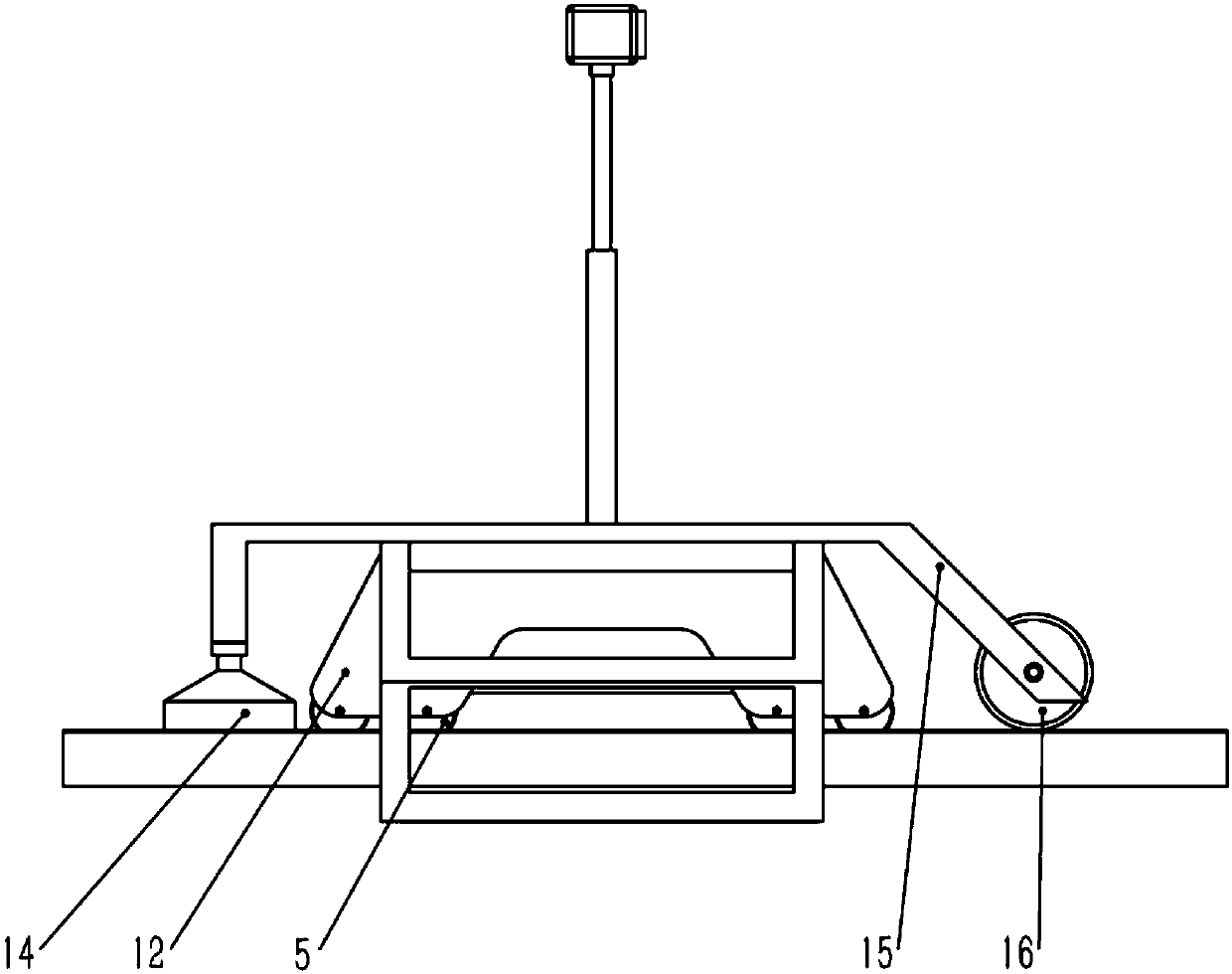

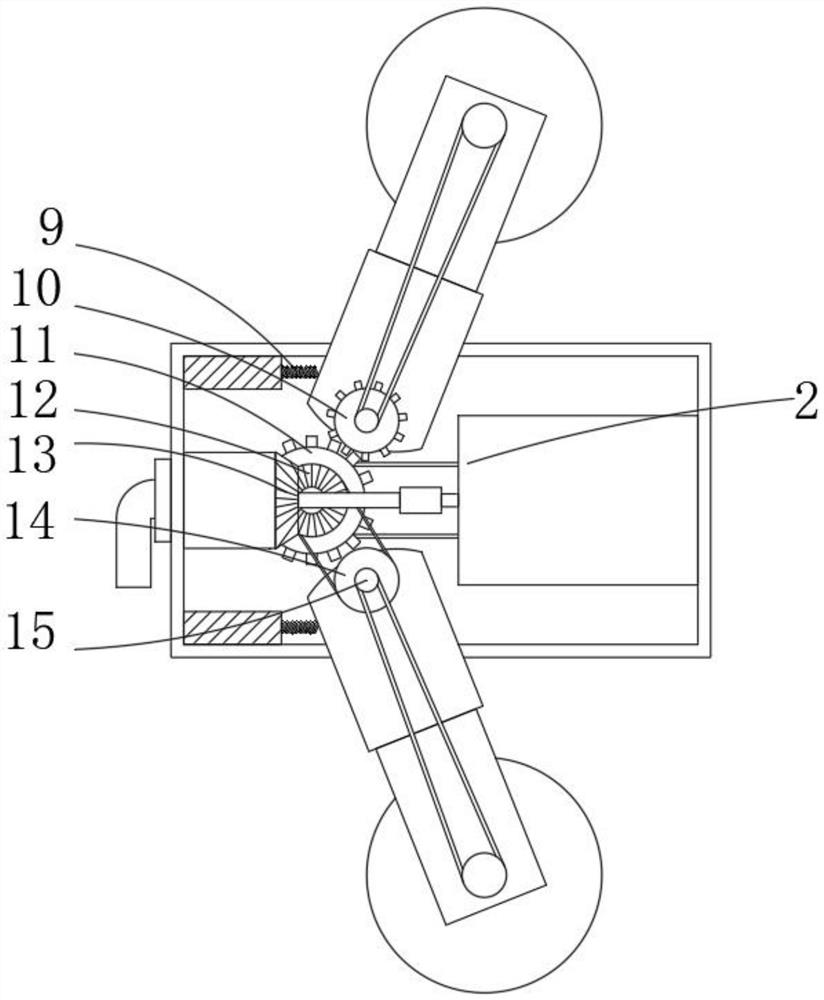

A low-to-medium-speed magnetic levitation ice-breaking and snow-melting cleaning robot

An ice-breaking and snow-melting cleaning robot for a medium and low speed maglev, comprising a rack (11), folding bending mechanisms, an ice-melting and cleaning mechanism, and an autonomous cruise module (7). The rack (11) spans between two F rails of a low and medium speed maglev to be detected. There are two groups of folding bending mechanisms, which are disposed at two ends of the rack (11) respectively and are located above the F rails. Each group of folding bending mechanisms is provided with a walking wheel pair (5) and a detent wheel pair (2). The snow-melting and cleaning mechanism comprises a fixing frame (15), an F rail obstacle-removal and cleaning unit (14), and an ice-melting heating unit (16). The fixing frame (15) is mounted on the rack (11), located above the folding bending mechanisms, and deployed along the extension direction of the F rails. The F rail obstacle-removal and cleaning unit (14) and the ice-melting heating unit (16) are disposed at two ends of the fixing frame (15) respectively. The autonomous cruise module (7) is mounted below the rack (11). The cleaning robot can melt and clean ice and snow on the F rails, and is simple in structure and convenient to operate.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

Drilling platform safety detection method and detection equipment

InactiveCN112326791ARealization of flaw detectionAccurate flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFrequency spectrumWell drilling

The invention provides a drilling platform safety detection method and detection equipment, which can analyze a radio frequency signal sent by ultrasonic transceiving equipment to obtain an ultrasonicspectrogram so as to fit an amplitude curve and determine multiple groups of curve characteristics of the amplitude curve. And then characteristic recognition is carried out in combination with the operation characteristics corresponding to the operation data list of extraction equipment communicated with an oil and gas pipeline, so that a flaw detection result of the oil and gas pipeline is generated. Thus, the flaw detection of the oil and gas pipeline can be achieved on the ultrasonic level, then slight damage in the oil and gas pipeline is recognized, and even if oil and gas leakage doesnot occur to the oil and gas pipeline, accurate flaw detection can still be conducted on the oil and gas pipeline through the scheme.

Owner:周红

A Hollow Axle Ultrasonic Flaw Detector

ActiveCN105424815BLabor savingAvoid elevationMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringTurbine

Owner:常州常瑞轨道交通科技有限公司

Robot for flaw detection of tap water pipeline

PendingCN114280162AAccurate flaw detectionPrevent uneven ultrasonic detectionMaterial analysis using sonic/ultrasonic/infrasonic wavesLiquid spraying apparatusTap waterSimulation

The invention discloses a robot for flaw detection of a tap water pipeline, and relates to the technical field of pipeline flaw detection, the robot comprises a shell, the upper surface of the shell is fixedly connected with an ultrasonic flaw detection device, the back of the shell is provided with a rotary spraying device, and the rear end of the inner surface of the shell is provided with a stirring device; the lower end of the inner surface of the shell is rotationally connected with a first rotating shaft. The robot for flaw detection of the tap water pipeline is provided with the moving wheels, when the robot is placed in the pipeline, the moving wheels on the two sides can make contact with the inner wall of the pipeline, certain pressure can be provided for the interior of the pipeline under the action of the limiting springs, and then the transverse center lines of the moving wheels coincide with the center line of the cross section of the pipeline; therefore, the ultrasonic flaw detection device is always located in the center of the pipeline, flaw detection can be accurately carried out on the inner wall of the pipeline, ultrasonic detection nonuniformity caused when the device is located on the bottom face or the upper end of the pipeline is prevented, and the measurement accuracy of the device is better.

Owner:CHANGSHA AERONAUTICAL VACATIONAL AND TECHNICAL COLLEGE

Flaw detection device with thickness measuring function of inner hole of heat conduction tube of nuclear power evaporator

ActiveCN103943156AAvoid detectionEliminate omissionsNuclear energy generationNuclear monitoringNuclear powerEngineering

The invention discloses a flaw detection device with a thickness measuring function of an inner hole of a heat conduction tube of a nuclear power evaporator. A first concave tabletop and a second concave tabletop are formed in the side surface of a column to form a base body; five through holes, namely two through holes I, two through holes II and a through hole III, are formed in the two concave tabletops in parallel; the axes of the two through holes I are intersected with each other on one side of the first concave tabletop and are both intersected with the axis of the base body; a plane in which the axes of the two through holes I are located is perpendicular to the first concave tabletop; the axes of the two through holes II are positioned on two sides of the axis of the base body and are in one same plane; the plane in which the axes of the two through holes II are located is perpendicular to the first concave tabletop; the axis of the through hole III and the axes of the through holes I are positioned in one same plane; the axis of the through hole III is perpendicular to the axis of the base body. The device can be used for detecting the inner hole in the axial direction, the circumferential direction and the thickness simultaneously, the problems that some flaw is neglected and cracks cannot be detected are avoided, the accuracy and the working efficiency of flaw detection are improved, and the flaw detection is reliable.

Owner:CHANGZHOU CHANGCHAO ELECTRONICS RES INSTCO

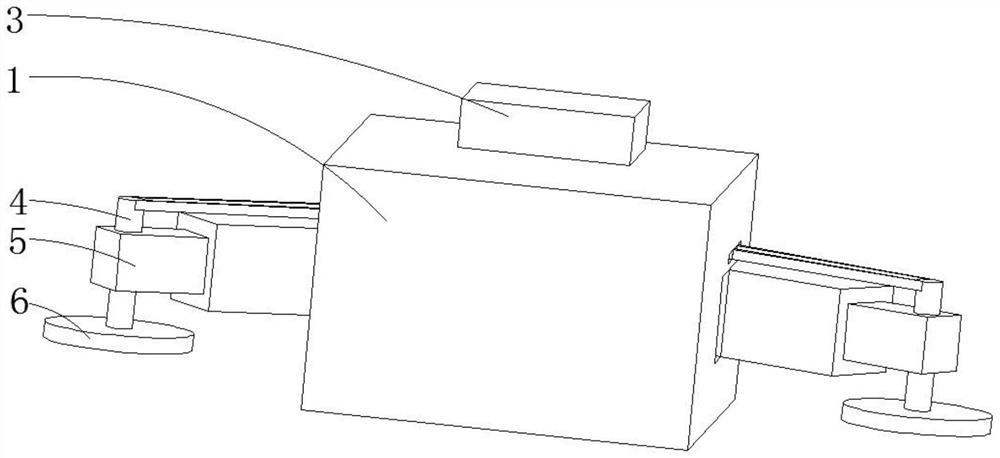

Self-search flaw-detection mechanism

ActiveCN104374824AFew jointsImprove flaw detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesSupersonic wavesEngineering

The invention discloses a self-search flaw-detection mechanism. The self-search flaw-detection mechanism comprises a base, a guide device which is fixedly installed on the base and is used for providing a flaw-detection driving force, and a flaw-detection module which is connected to the guide device, is used for receiving a driving force from the guide device and contacting with a surface to be detected back and forth under the action of the driving force to detect flaw cases of the surface to be detected. Compared with the prior art, the self-search flaw-detection mechanism accords with a lightweighting design idea, has less joints and a high flaw detection precision, can buffer impact caused by uneven surfaces in movement, can continuously supply oil to a supersonic wave instrument, and can fill gaps between the supersonic wave instrument and the surface to be subjected to flaw-detection thereby guaranteeing accurate flaw detection based on a supersonic wave instrument.

Owner:顿向明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com