Eddy current coil center calibration device and calibration method

A center calibration, eddy current coil technology, applied in measuring devices, instruments, material analysis by electromagnetic means, etc., can solve the problem of uncontrollable length of time to adjust the sample tube, affecting the production rhythm, etc., to achieve high flaw detection efficiency and improve labor. Efficiency and convenient operation of flaw detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

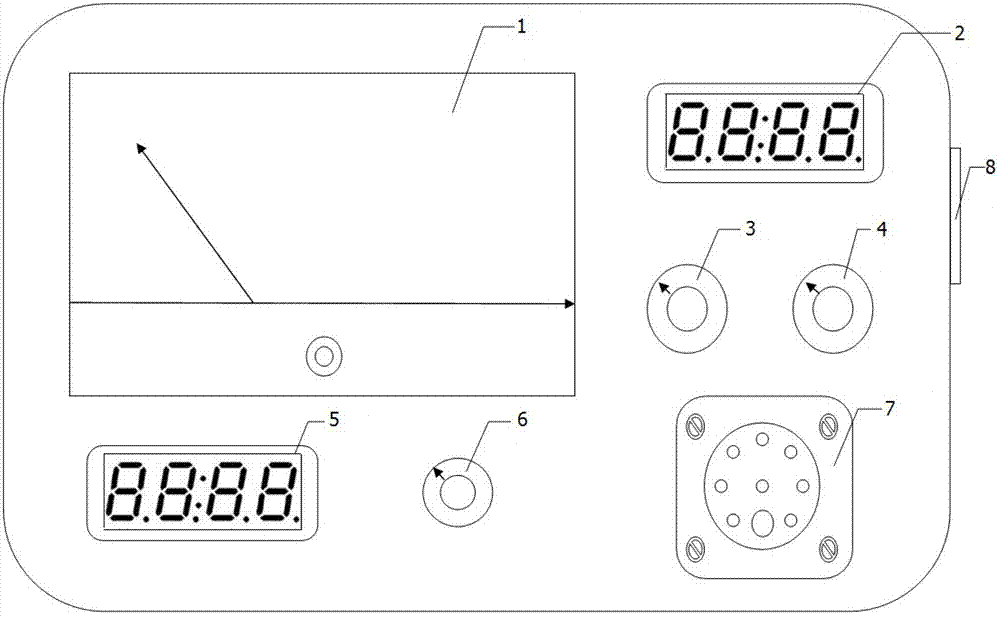

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

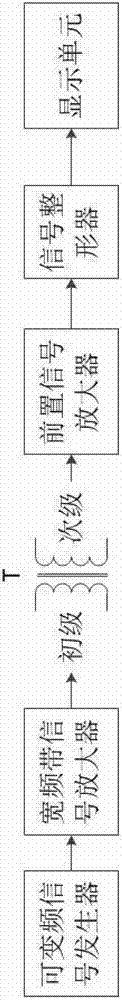

[0024] The present invention is based on the original mechanical center, and finds the mechanical center by repeatedly measuring geometric dimensions. The difference between the mechanical center and the electrical center of the coil can only be adjusted by experience, and human factors play a considerable role in the adjustment. In order to find a new and more scientific adjustment method, the present invention has developed a device that detects the intensity of electromagnetic induction to achieve the coincidence of the final center of the coil and the center of the steel pipe, and quickly complete the verification of the sample pipe, and finally to ensure that the through Type eddy current flaw detection equipment can detect flaws normally and reliably.

[0025] For this reason, the present invention utilizes the relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com