Automatic detection frame for metal pipeline flaw detector

An automatic detection and metal pipeline technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of long building installation pipelines, labor and time consumption, installation location is not suitable for direct detection by personnel, etc., to ensure accuracy, The effect of reducing deviation and saving work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

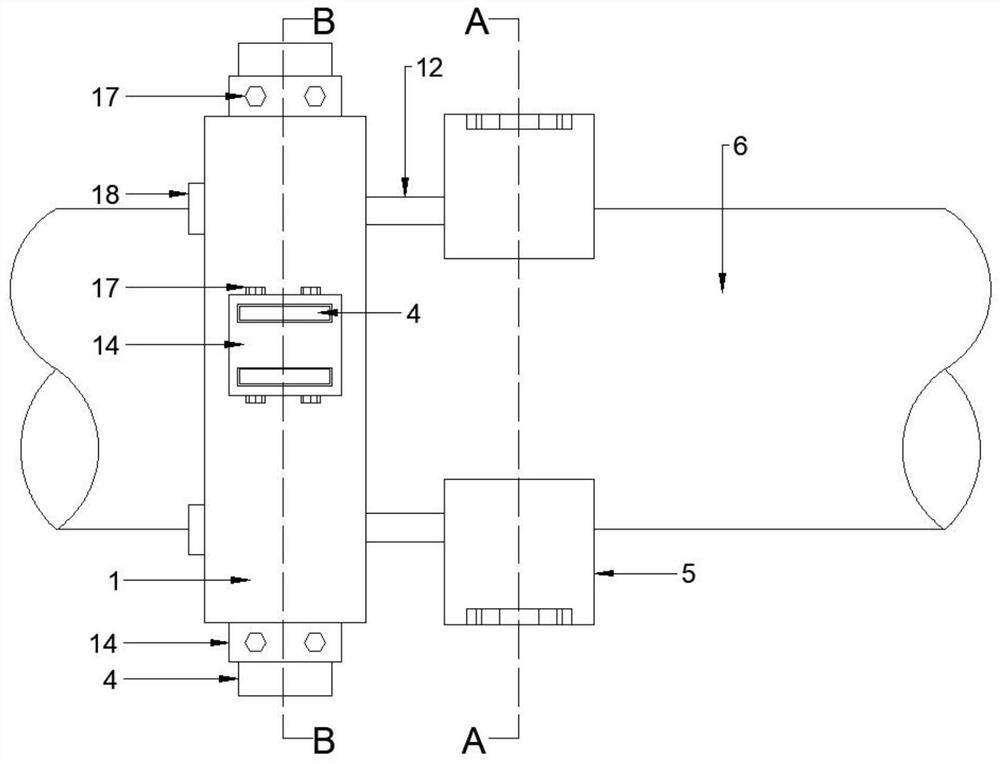

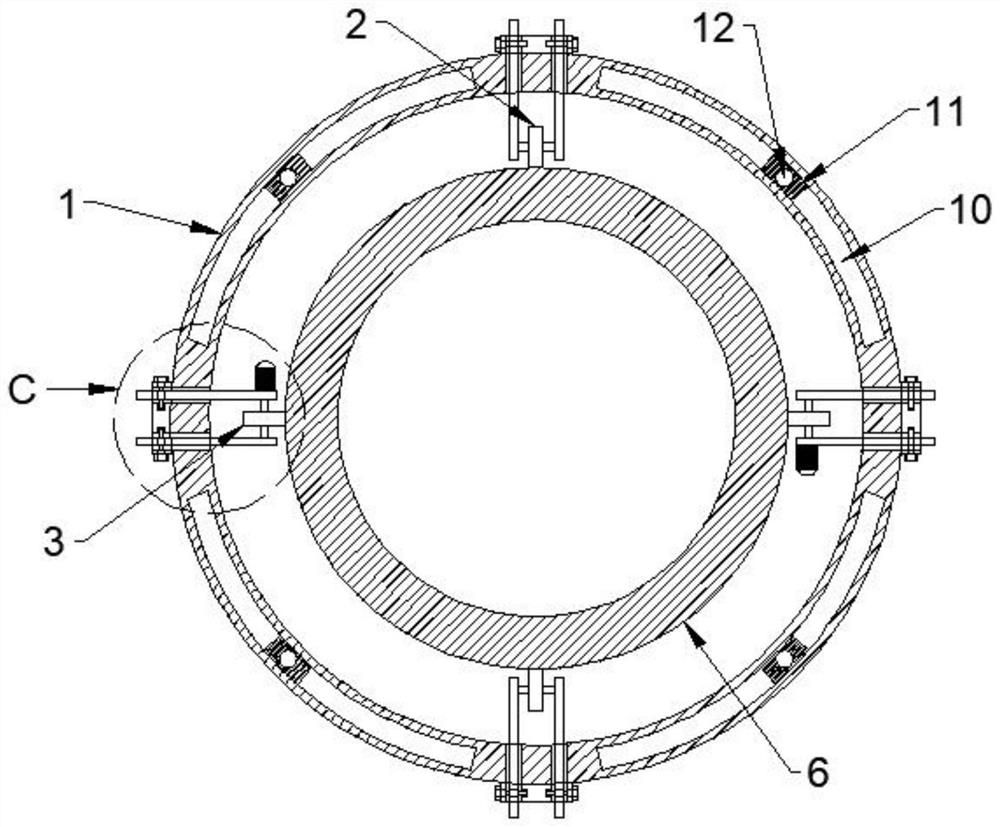

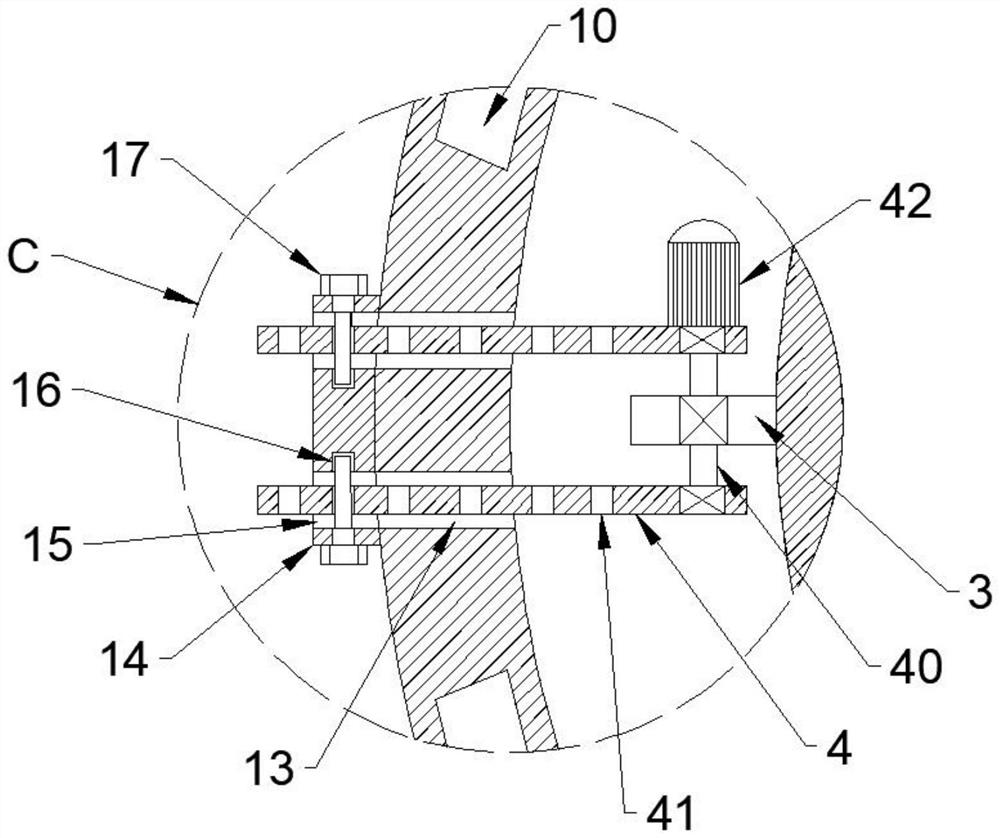

[0023] see Figure 1-6 , in an embodiment of the present invention, an automatic detection frame for a metal pipeline flaw detector includes an automatic push frame 1, a detection frame 5 and a metal pipe fitting 6, the automatic push frame 1 is integrally sleeved on the outer wall of the metal pipe fitting 6, and the The top and bottom of the inner wall of the automatic pushing frame 1 are provided with two pairs of follower pulleys 2 supported on the surface of the metal pipe fitting 6, and the left and right inner walls of the automatic pushing frame 1 are provided with two pairs of driving pulleys 3 supported on the surface of the metal pipe fitting 6, One side of the drive pulley 3 is provided with a micro motor 42 for driving the drive pulley 3 to rotate, and between the follow-up pulley 2, the drive pulley 3 and the automatic push frame 1 is provided with a metal pipe fitting 6 for adjusting the inner wall of the automatic push frame 1. The diameter adjustment device be...

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is:

[0031] Described micromotor 42 is a DC micromotor, and the outer surface of described automatic pushing frame 1 is provided with rechargeable battery pack and switch for micromotor 42 power supply.

[0032] The flaw detector fixing groove 50 is provided with a detection fixing plate 51 and an elastic splint 53 for fixing the flaw detector. A plurality of splint springs 54 are fixed between the elastic splint 53 and the inner wall of the flaw detector fixing groove 50. The 5 The left and right side walls are threaded with a plurality of detection fixing bolts 52, the detection fixing plate 51 is fixed on the inner side of the detection fixing bolts 52, and the center position of the groove bottom of the detection frame 5 is provided with a flaw detection hole for placing a flaw detector probe. The head hole 55 is facing the surface of the metal pipe 6 .

[0033] The working principle of the present invention:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com