Patents

Literature

55 results about "Green rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

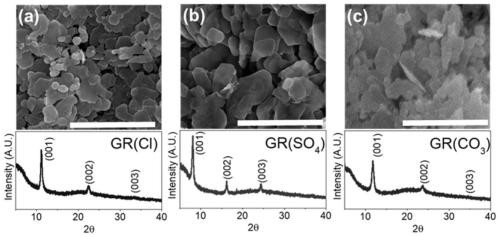

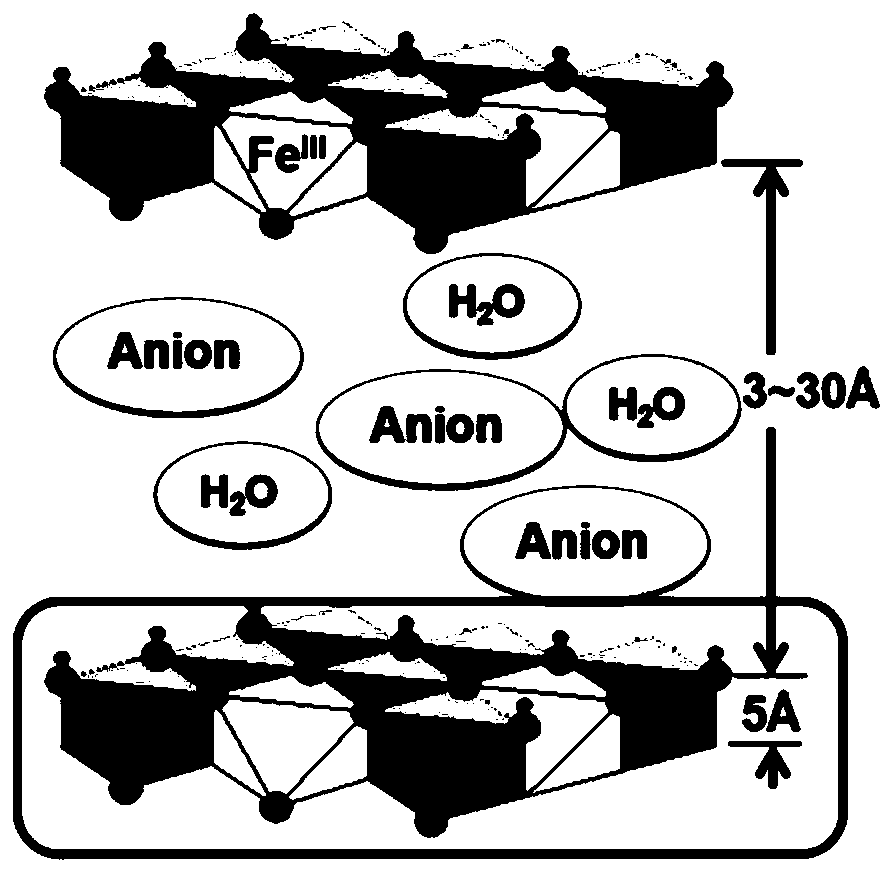

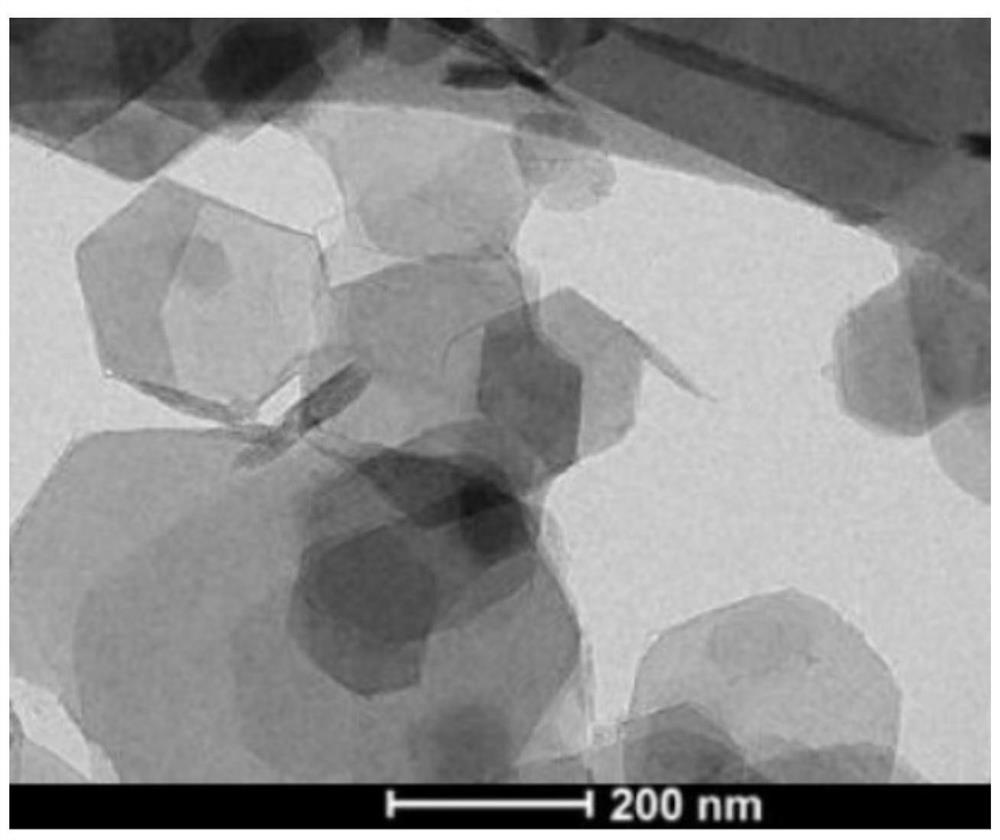

Green rust is a generic name for various green crystalline chemical compounds containing iron(II) and iron(III) cations, the hydroxide (HO⁻) anion, and another anion such as carbonate (CO²⁻₃), chloride (Cl⁻), or sulfate (SO²⁻₄), in a layered double hydroxide structure.

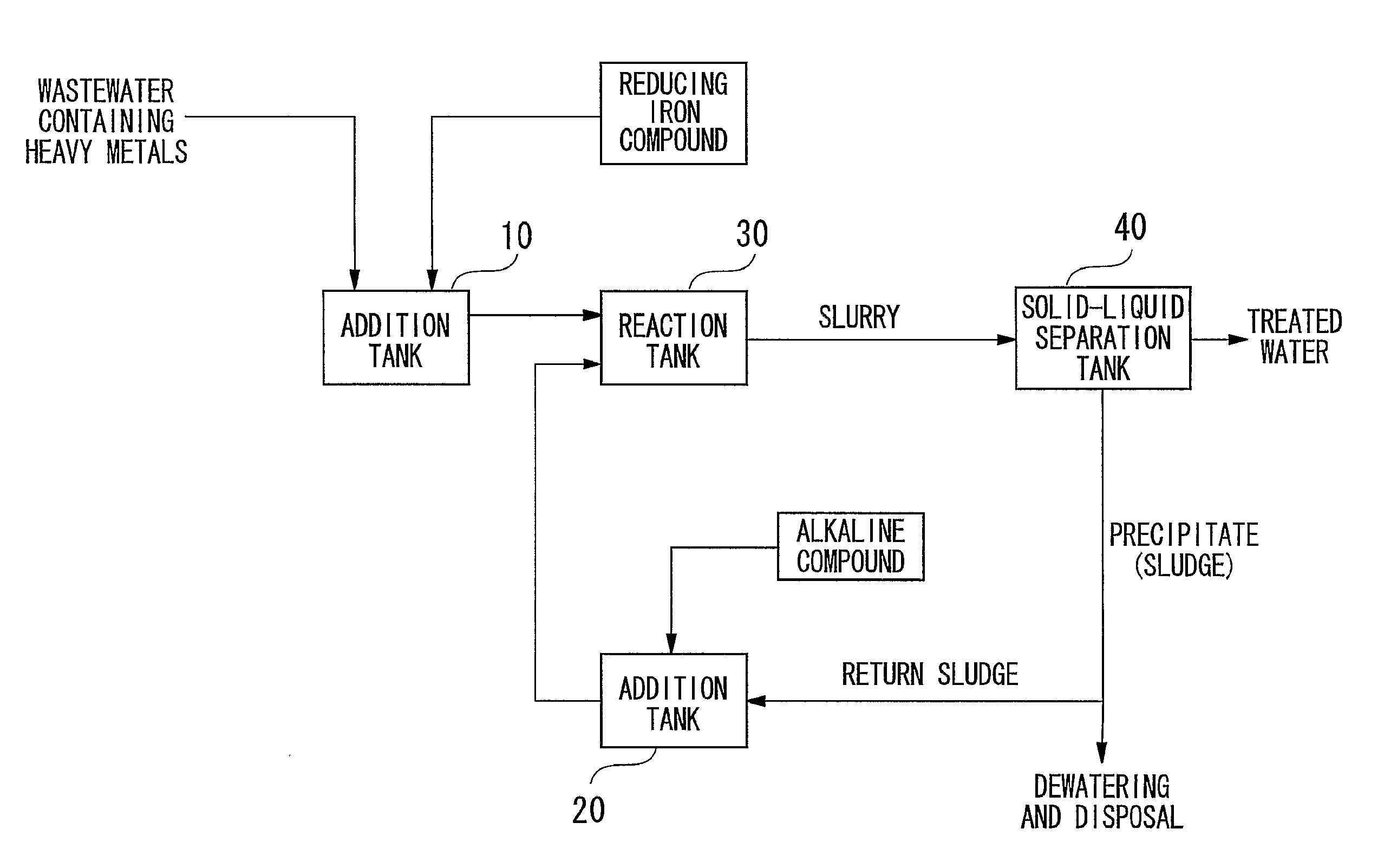

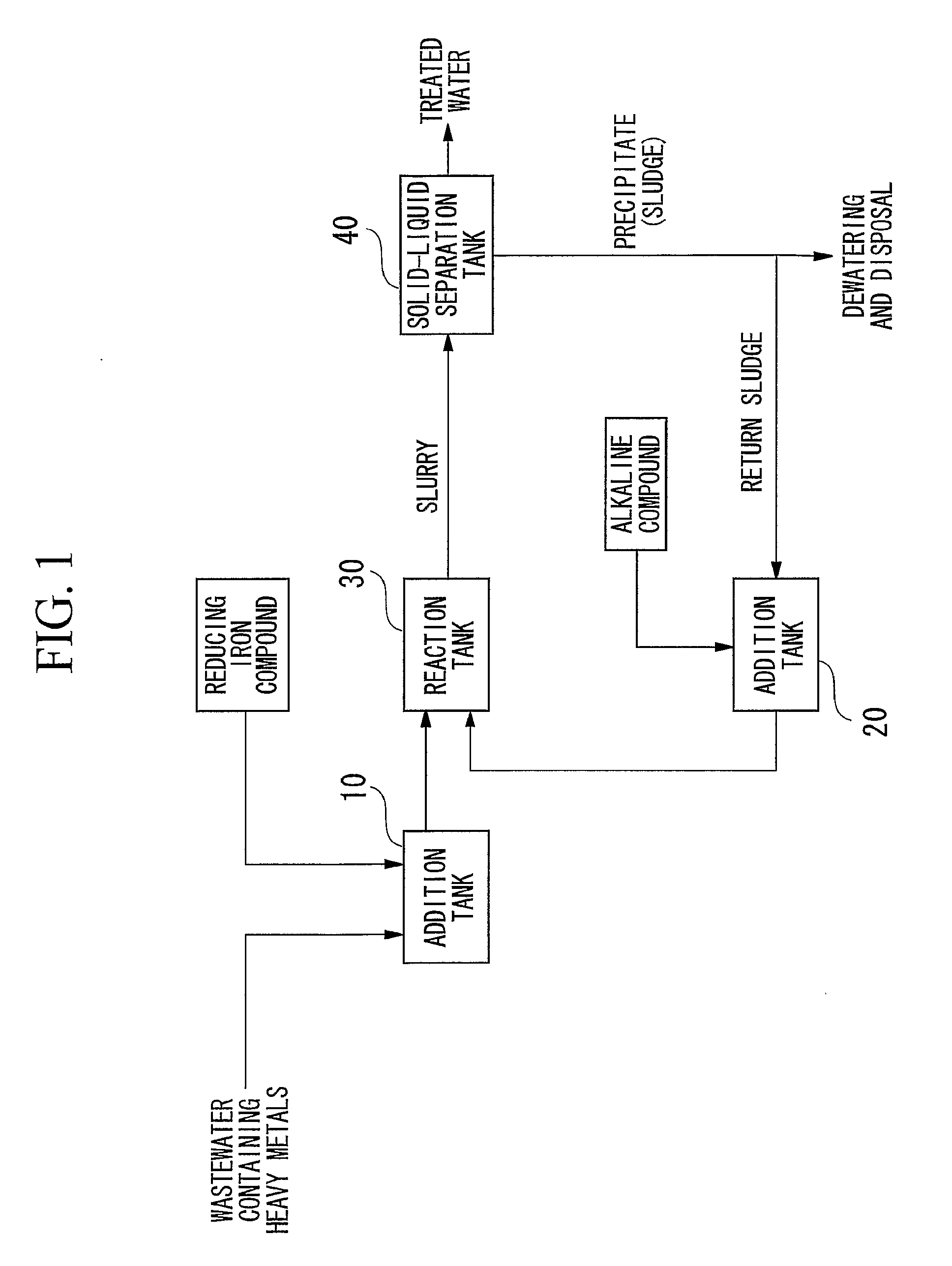

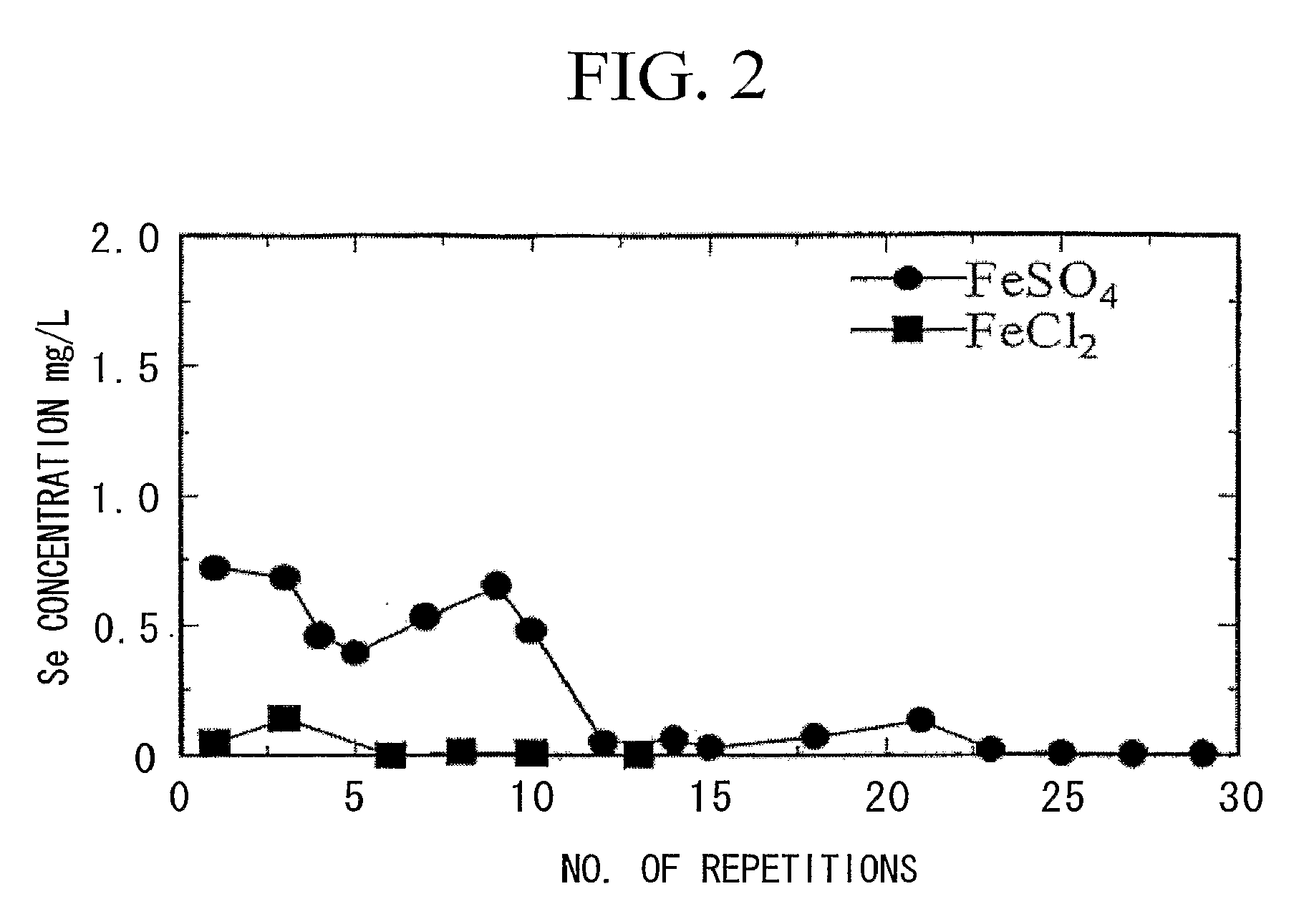

Reducing water purification material, method for producing reducing water purification material, method for treating wastewater, and wastewater treatment apparatus

ActiveUS20070209989A1Satisfactory separationImprove economyLiquid degasificationWater softeningSludgeFerric hydroxide oxide

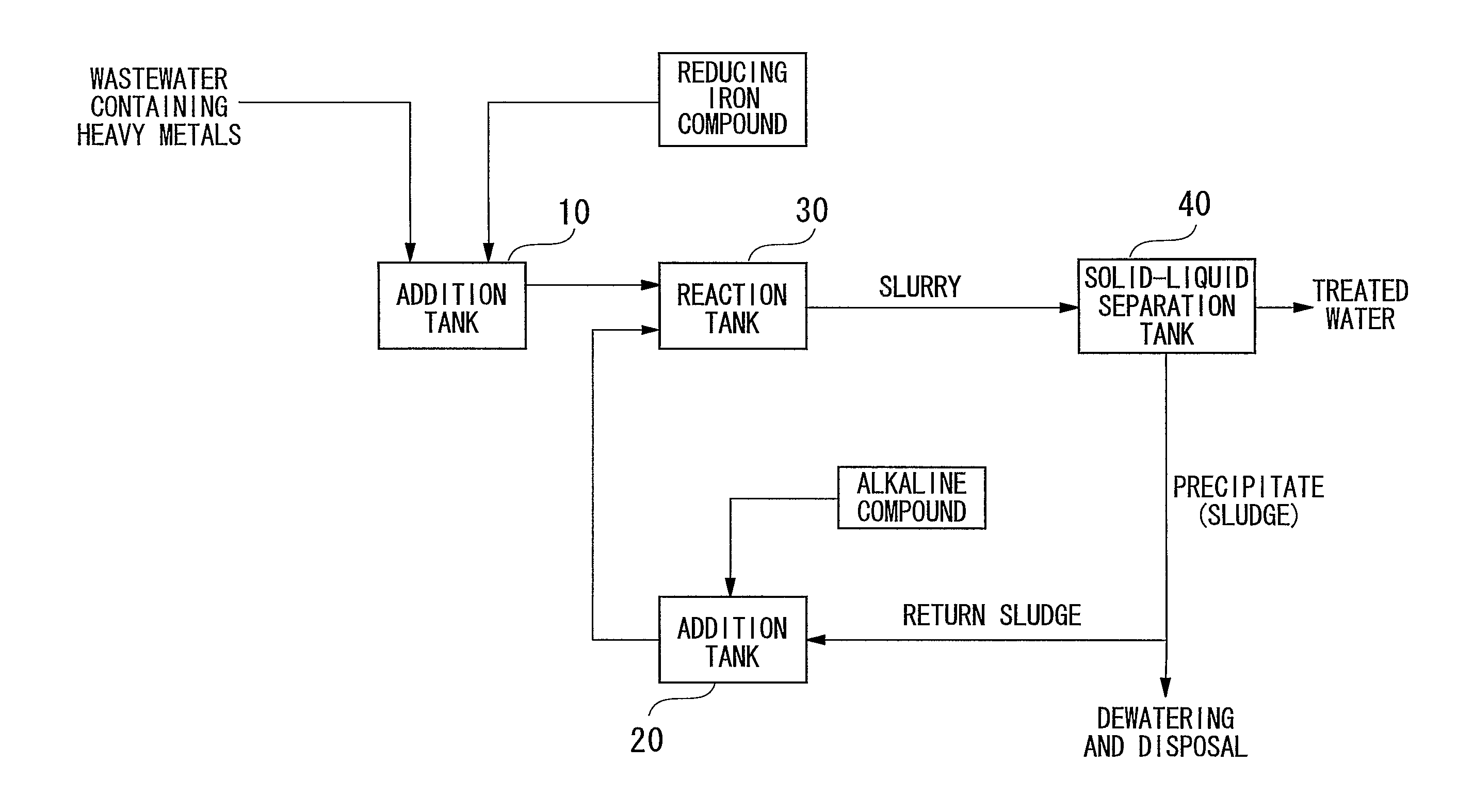

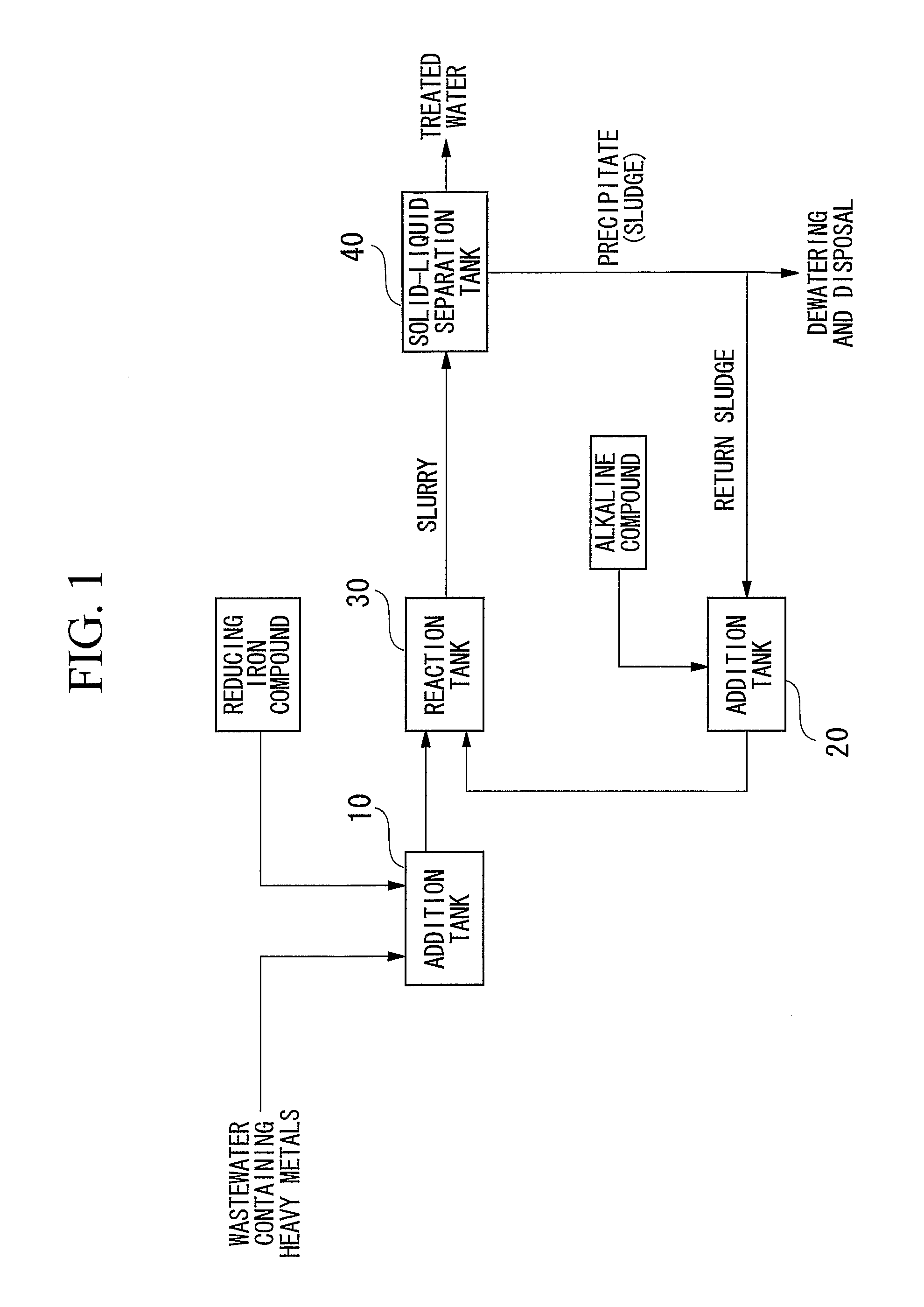

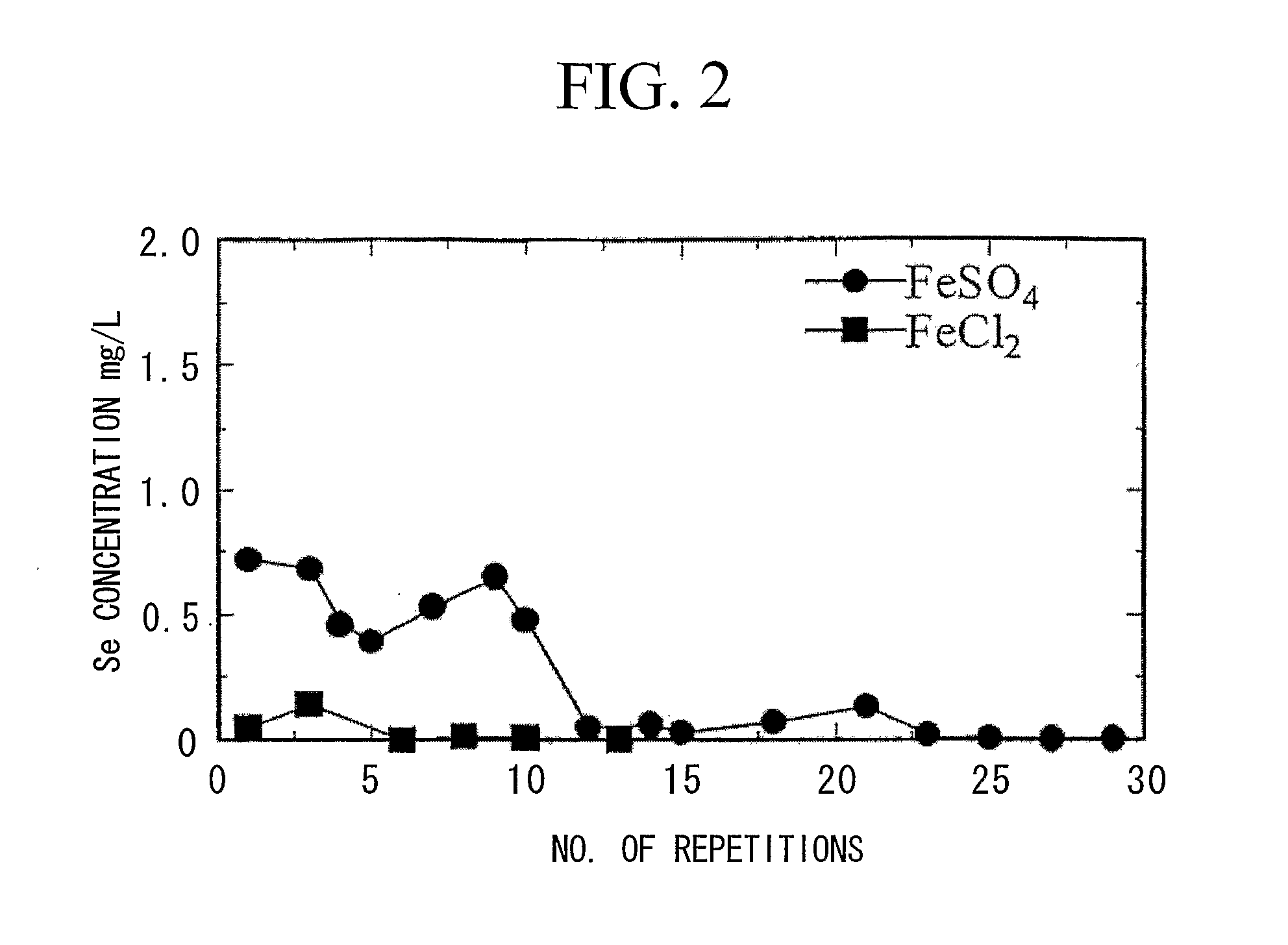

A reducing water purification material having a reducing iron-based precipitate selected from green rust, iron ferrite, reducing iron hydroxide, and a mixture thereof. A wastewater treatment process having steps of adding a reducing iron compound to wastewater, leading the wastewater to which the reducing iron compound is added to a reaction tank and forming a precipitate, separating the formed precipitate by a solid-liquid separation to obtain a sludge, and alkalinizing all or a portion of the separated sludge to form an alkaline sludge followed by returning to the reaction tank, wherein in the precipitation step, the wastewater to which the reducing iron compound is added and the alkaline sludge are mixed and are allowed to react in a non-oxidizing atmosphere under alkaline condition to form a reducing iron compound precipitate as the precipitate, thereby incorporating contaminants in the precipitate to remove the contaminants from the wastewater.

Owner:MITSUBISHI MATERIALS CORP

Chromium-free rust-inhibitive surface treatment agent for metal parts with zinc surfaces and metal parts with zinc surfaces coated with rust-inhibitive surface coated film

ActiveUS20090169875A1Improve adhesionImprove the immunityOther chemical processesSynthetic resin layered productsChromium freeOligomer

Disclosed is a chromium-free rust-inhibitive surface treatment agent to form a siliceous film that rarely cracks or peels off and yields an excellent rust-inhibitive performance on zinc surfaces of a metal part. The chromium-free rust-inhibitive surface treatment agent is an alcoholic solution of alkoxysilane oligomer having weight-averaged molecular weight of 1,000 to 10,000, and 2.5 to 15% of silicon in molecules of the alkoxysilane oligomer has been replaced with titanium. To prepare partly titanium-replaced alkoxysilane oligomer, titanium compound, in which about a half of alkoxy groups in titanium tetraalkoxide has been chelated, is reacted with tetraalkoxysilane monomer or alkoxysilane oligomer in the alcoholic solution.

Owner:HODEN SEIMITSU KAKO KENKYUSHO CO LTD

Reduction treatment method for nitrates in water

InactiveCN103570114AAccelerated settlementReduce the concentration of metal ionsWater/sewage treatment by reductionReduction treatmentPtru catalyst

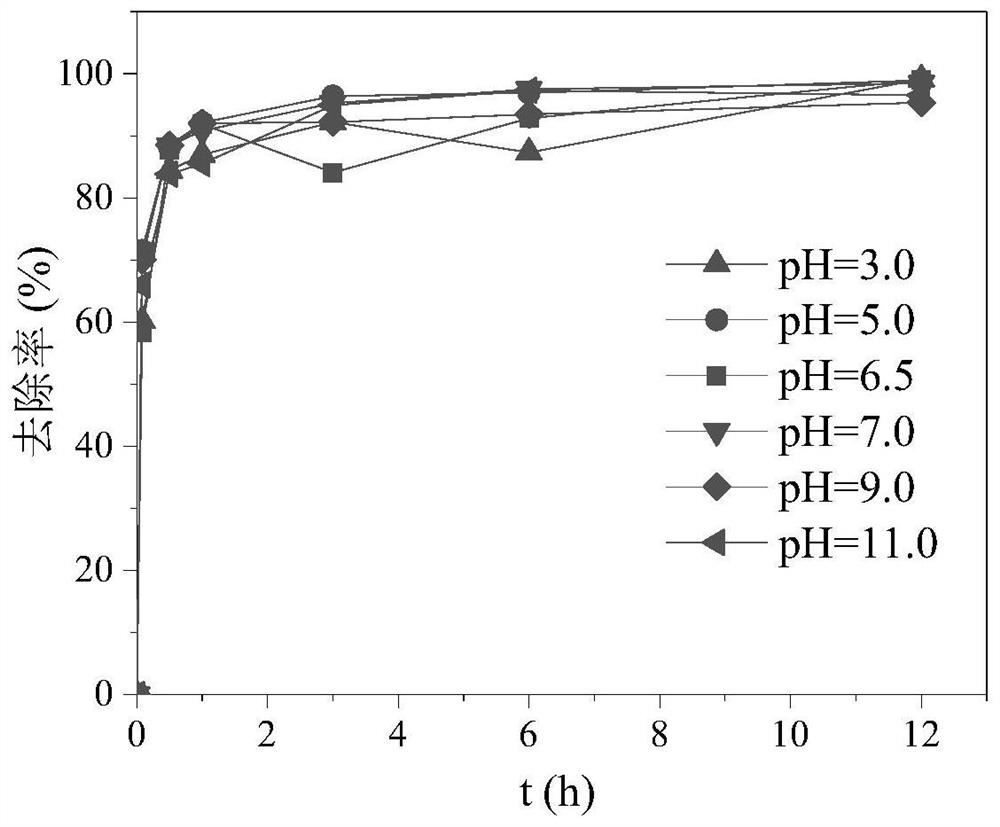

The invention belongs to the technical field of water treatment, and relates to a reduction treatment method for nitrates in water. Green rust LDH (Layered double hydroxides) are fed into nitrate-containing wastewater to react, so that the reaction rate thereof on reducing nitrates in water and the partial removal of total nitrogen are effectively improved. According to the invention, nitrates are subjected to reduction treatment by using the reducibility of green rusts, and then under the action of catalyst ions, part of the LDH is transferred into an environmental-friendly gas N2, so that the reaction time is short, and more than 95% of the nitrates can be removed within 4h; the removal rate of total nitrogen is more than 35%; the method is good in iron cement sedimentation and simple in operation, and has good economic and environmental benefits.

Owner:SHANGHAI UNIV

Process for preparing patina

InactiveCN101259970ARegular latticeImproved particle size distributionIron compoundsColor changesNitrogen gas

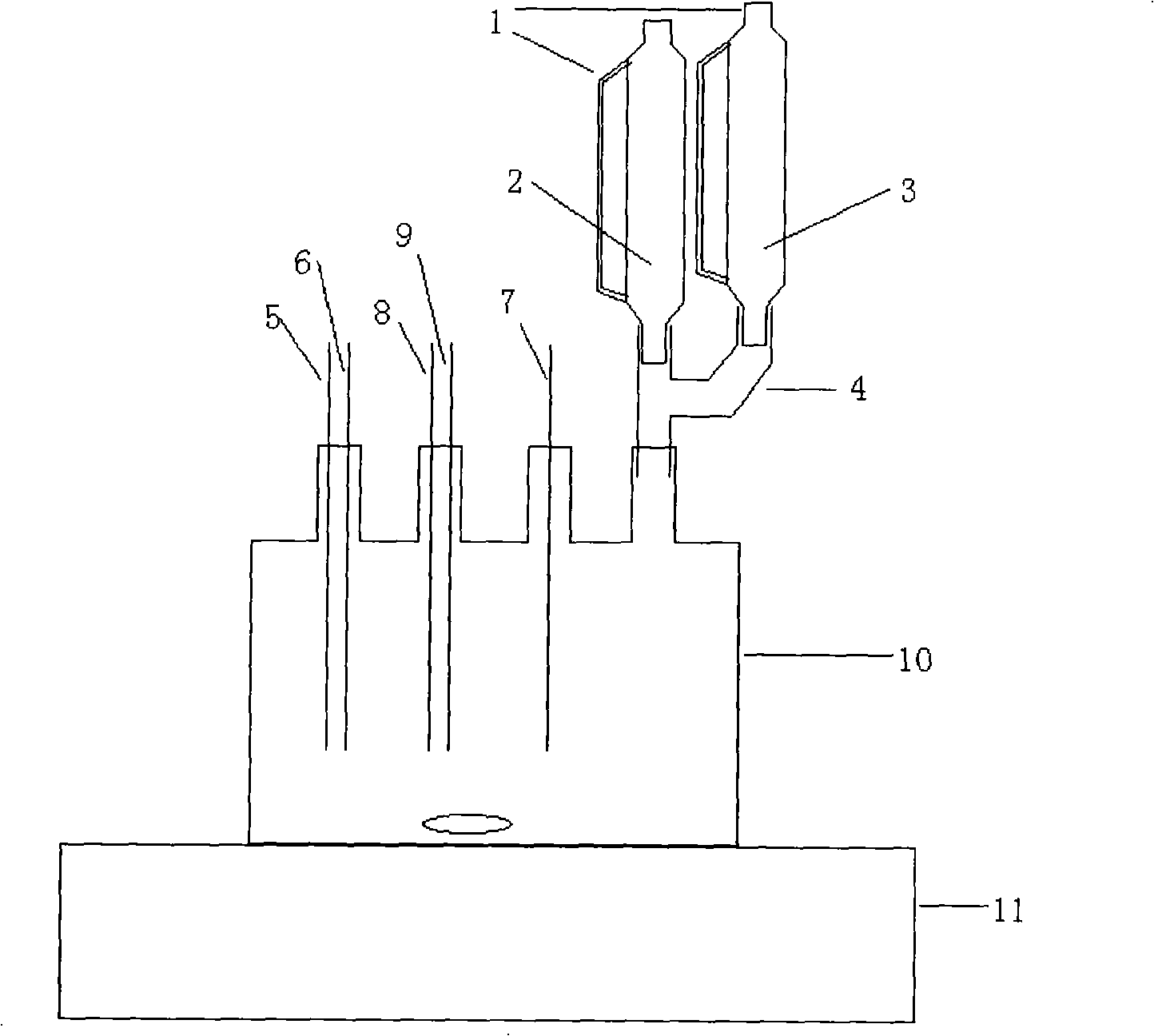

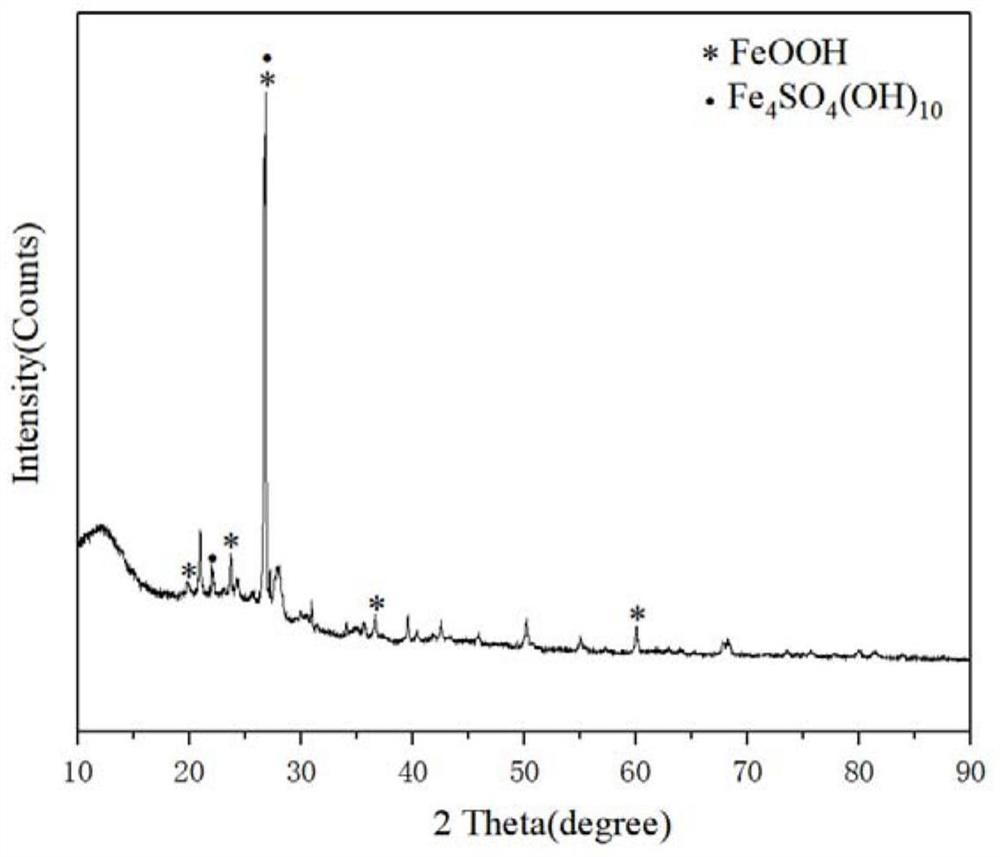

The invention belongs to the inorganic chemical technical field, in particular to a preparation method of important intermediate, namely green rust which is obtained in the process of generating various ferrites. The specific steps are as follows: a reaction device is built, and the ferrous solution is prepared by taking the ascorbic acid aqueous solution the mol concentration of which is 2.5x10<-4> to 7.5x10<-4>mol / l as the solvent and FeSO4 as the solute and is put in a four-mouth flask in nitrogen atmosphere; the alkaline solution is put in a pipe of a constant pressure titration funnel, and the Fe2(SO4)3 solution is put in the other pipe of the constant pressure titration funnel; the FeSO4 solution and the Fe2(SO4)3 solution are the same in mol concentration; the solution in the four-mouth flask are evenly stirred by the magnetic stirring until the PH value of the solution in the four-mouth flask is adjusted to 6, and the Fe2(SO4)3 solution is dropwise added and simultaneously the alkaline solution is dropwise added, which keeps the PH value of the solution to 6; after the Fe2(SO4)3 solution is completely added, the PH value of the solution is recorded, and the alkaline solution continues to be dropwise added, simultaneously the color change of the solution is observed, and the reaction is over until the PH value of the solution is 7; and the needed products are obtained after aging. The green rust prepared by the invention is high in purity, and the reaction conditions needed in the invention are mild.

Owner:TONGJI UNIV

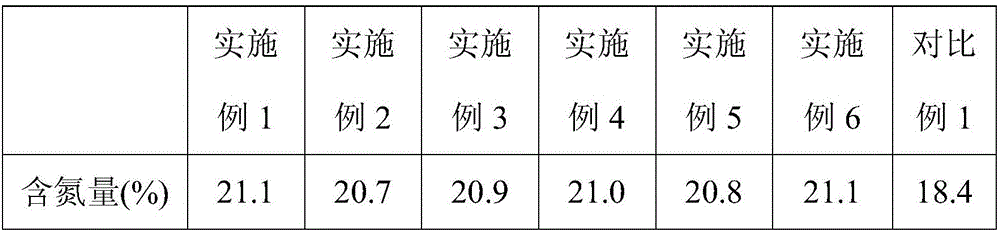

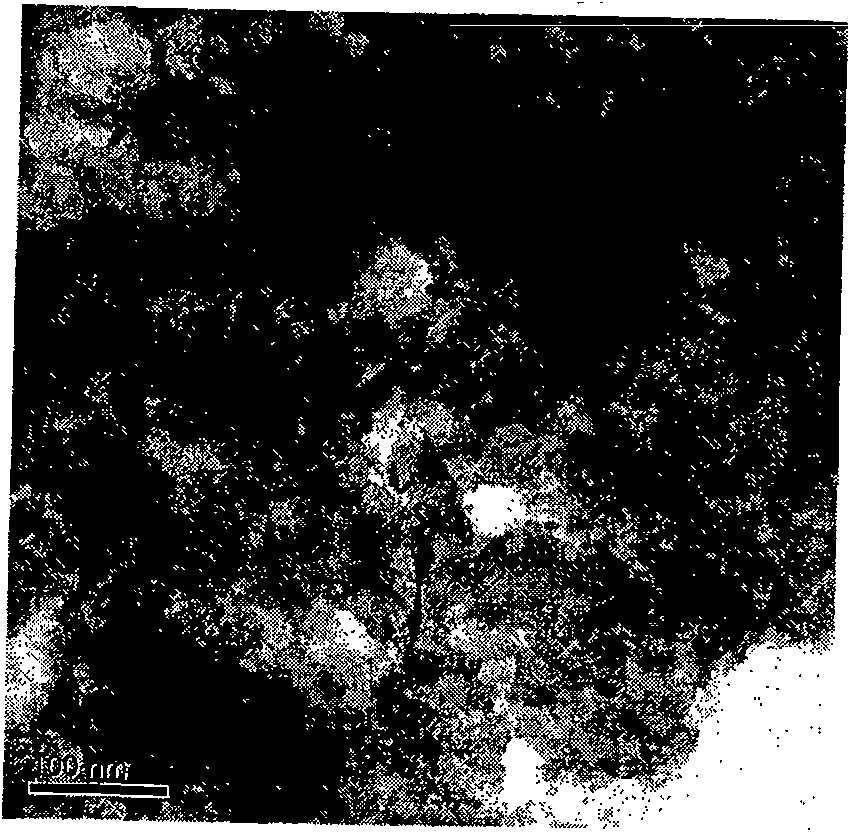

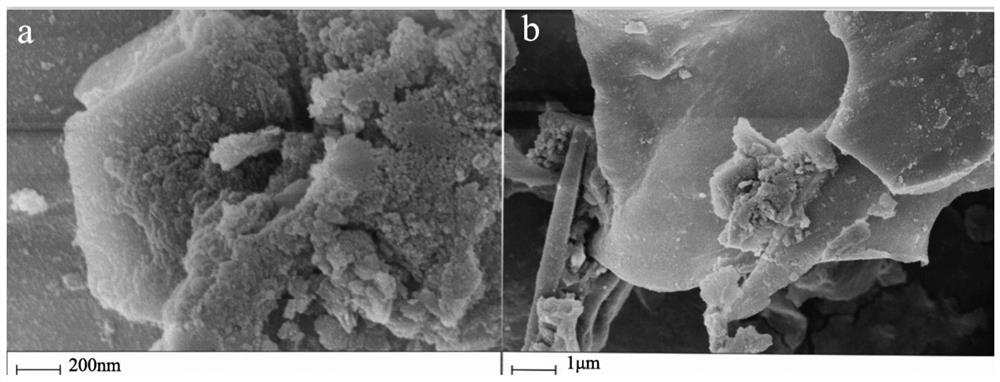

Technology for preparing iron hydroxide with high specific surface area and cooperatively producing ammonium sulfate

ActiveCN106185988ALarge specific surface areaImprove adsorption capacityIron oxides/hydroxidesWaste water treatment from plant processingDistillationDiammonium carbonate

The invention provides a technology for preparing iron hydroxide with a high specific surface area and cooperatively producing ammonium sulfate. The technology includes mixing and kneading solid ferrous sulfate, solid ammonium carbonate and / or solid ammonium bicarbonate which are used as raw materials, adding water into the raw materials in mixing and kneading procedures to form slurry and controlling a pH (potential of hydrogen) value of the slurry so that the pH value of the slurry is 6.5-7 in the mixing and kneading procedures and is 7-8 when the raw materials are completely mixed and kneaded; separating solid from liquid in the slurry, respectively collecting solid phases and liquid phases and drying the liquid phases by means of distillation to obtain the ammonium sulfate; preparing serous fluid from the solid phases by the aid of water, adding hydrogen peroxide into the serous fluid to carry out oxidation reaction to obtain products and filtering the products after the reaction is completely carried out to obtain filter cake which is the iron hydroxide. The technology has the advantages that green rust which is an intermediate product is oxidized by the aid of the hydrogen peroxide, and accordingly a final product is assuredly the amorphous iron hydroxide; the iron hydroxide prepared by the aid of the technology has the large specific surface area, is high in oxidation capacity and accordingly can be widely applied to the field of gas purification and sewage treatment.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Reducing water purification material, method for producing reducing water purification material, method for treating wastewater, and wastewater treatment apparatus

ActiveUS20090289016A1Satisfactory separationGood effectWater contaminantsSeparation devicesSludgeFerric hydroxide oxide

A reducing water purification material having a reducing iron-based precipitate selected from green rust, iron ferrite, reducing iron hydroxide, and a mixture thereof. A wastewater treatment process having steps of adding a reducing iron compound to wastewater, leading the wastewater to which the reducing iron compound is added to a reaction tank and forming a precipitate, separating the formed precipitate by a solid-liquid separation to obtain a sludge, and alkalinizing all or a portion of the separated sludge to form an alkaline sludge followed by returning to the reaction tank, wherein in the precipitation step, the wastewater to which the reducing iron compound is added and the alkaline sludge are mixed and are allowed to react in a non-oxidizing atmosphere under alkaline condition to form a reducing iron compound precipitate as the precipitate, thereby incorporating contaminants in the precipitate to remove the contaminants from the wastewater.

Owner:MITSUBISHI MATERIALS CORP

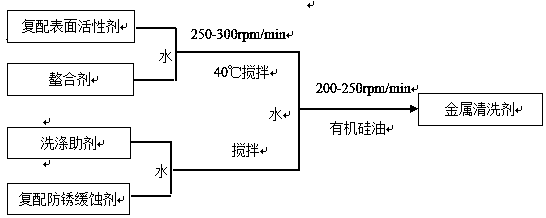

Phosphorus-free rust-proof metal cleaning agent and preparation method thereof

The invention relates to a phosphorus-free rust-proof metal cleaning agent and a preparation method thereof. The phosphorus-free rust-proof metal cleaning agent is composed of the following raw materials by weight: 10-15 parts of a non-ionic surfactant fatty alcohol polyoxyethylene ether, 10-15 parts of coconut fatty acid diethanolamide, 5-10 parts of an anionic surfactant sodium dodecylbenzene sulfonate, 10-15 parts of a washing assistant, 8-12 parts of a chelating agent, 2-5 parts of a rust and corrosion inhibitor, 1-4 parts of a defoaming agent and 80-100 parts of water. The phosphorus-freerust-proof metal cleaning agent provided by the design has the advantages of low price and wide sources of components, simple operation, good solubility, excellent detergency, low foaming performance, and no damage or corrosion to metal parts and the like; and more importantly, the metal cleaning agent does not contain phosphorus, nitrite, heavy metals and other harmful substances and the surfactants can be biodegraded, so subsequent sewage treatment is facilitated, and safety and environmental protection are obtained.

Owner:HEILONGJIANG UNIV

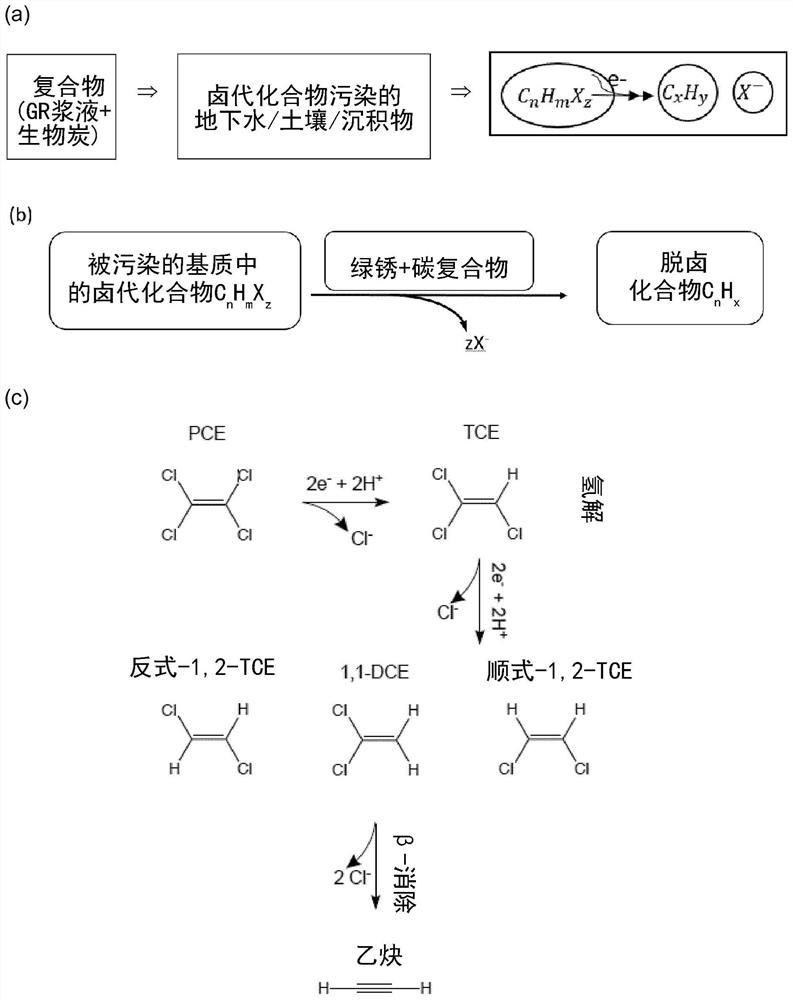

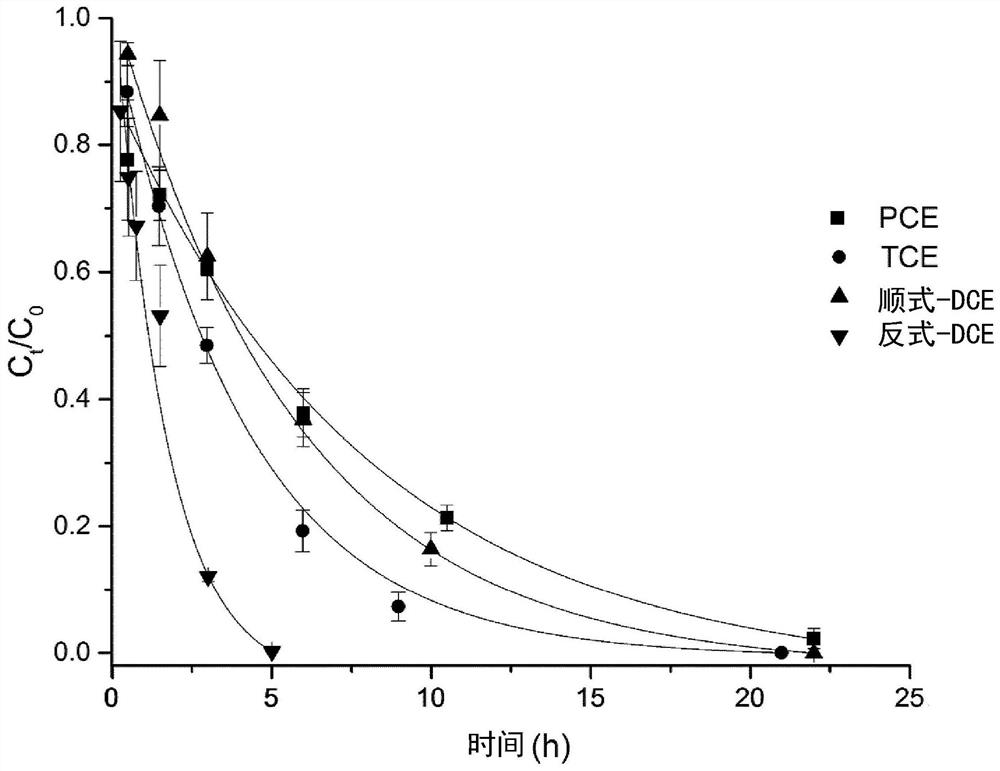

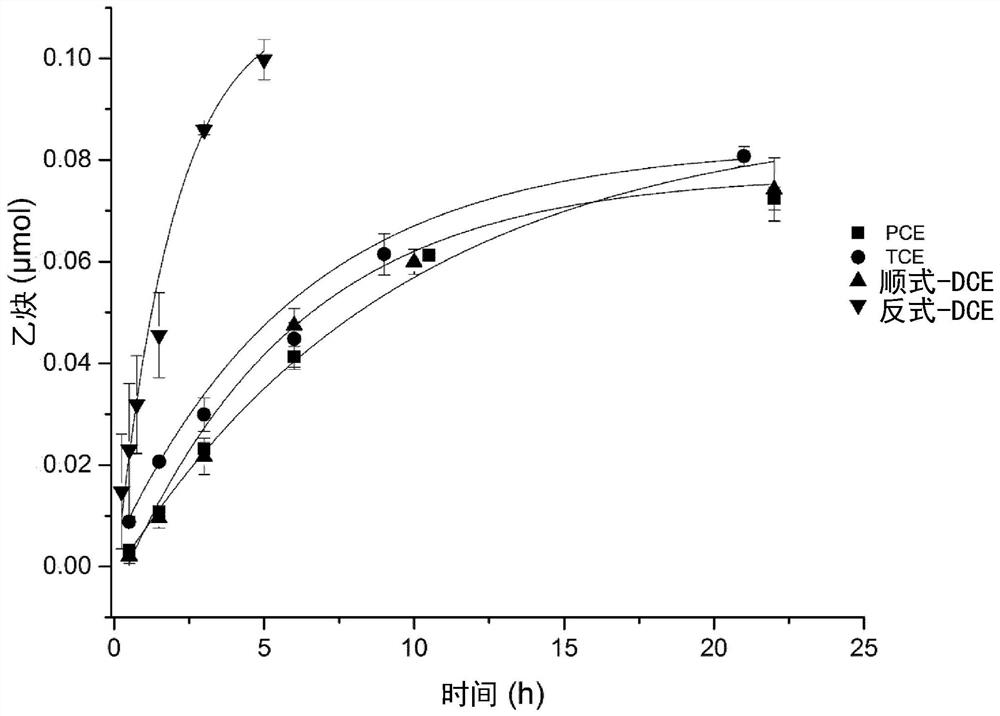

Composite comprising green rust and carbon for environmental remediation

InactiveCN111712333AImprove stabilityImprove mobilityWater contaminantsContaminated soil reclamationEnvironmental engineeringEnvironmental remediation

The invention regards a composite for environmental remediation, comprising: one or more green rust compound(s) or green rust precursor(s), and one or more biochar(s).

Owner:UNIVERSITY OF COPENHAGEN

Environment-friendly chromium-free rust-proof passivation solution and preparation method thereof

InactiveCN107699883AImprove the effect of surface treatmentImprove adhesionMetallic material coating processesCerium nitrateCerium nitrate hexahydrate

The invention discloses an environment-friendly chromium-free rust-proof passivation solution. The rust-proof passivation solution is prepared from the raw materials of, by weight, 100 parts of deionized water, 2-10 parts of salicylic acid, 4-10 parts of benzotriazole, 3-10 parts of sodium citrate, 2-10 parts of 2-chlorine-4,5-dihydro-1H-imidazole sulfonate, 1-10 parts of hexafluorotitanic acid, 1-5 parts of sodium gluconate, 1-5 parts of zinc oxide, 4-10 parts of cerium nitrate, 3-10 parts of silane-modified polyphosphazene-polyethersulfone block copolymers, 5-10 parts of silver nitrate, 1-10parts of n-butanol, 1-5 parts of sodium silicate, 1-5 parts of 2-mercapto benzimidazole-5-sodium sulfonate dehydrate, 1-10 parts of oxalic acid, 1-5 parts of ethyl alcohol and 1-5 parts of 3-[(methylol)methylamine] ethanesulfonic acid. The obtained environment-friendly chromium-free rust-proof passivation solution can be used for low-temperature surface treatment, is high in surface treatment efficiency, environmentally friendly and good in rust-proof performance and has good market prospects.

Owner:JINGMEN TUODA TECH CO LTD

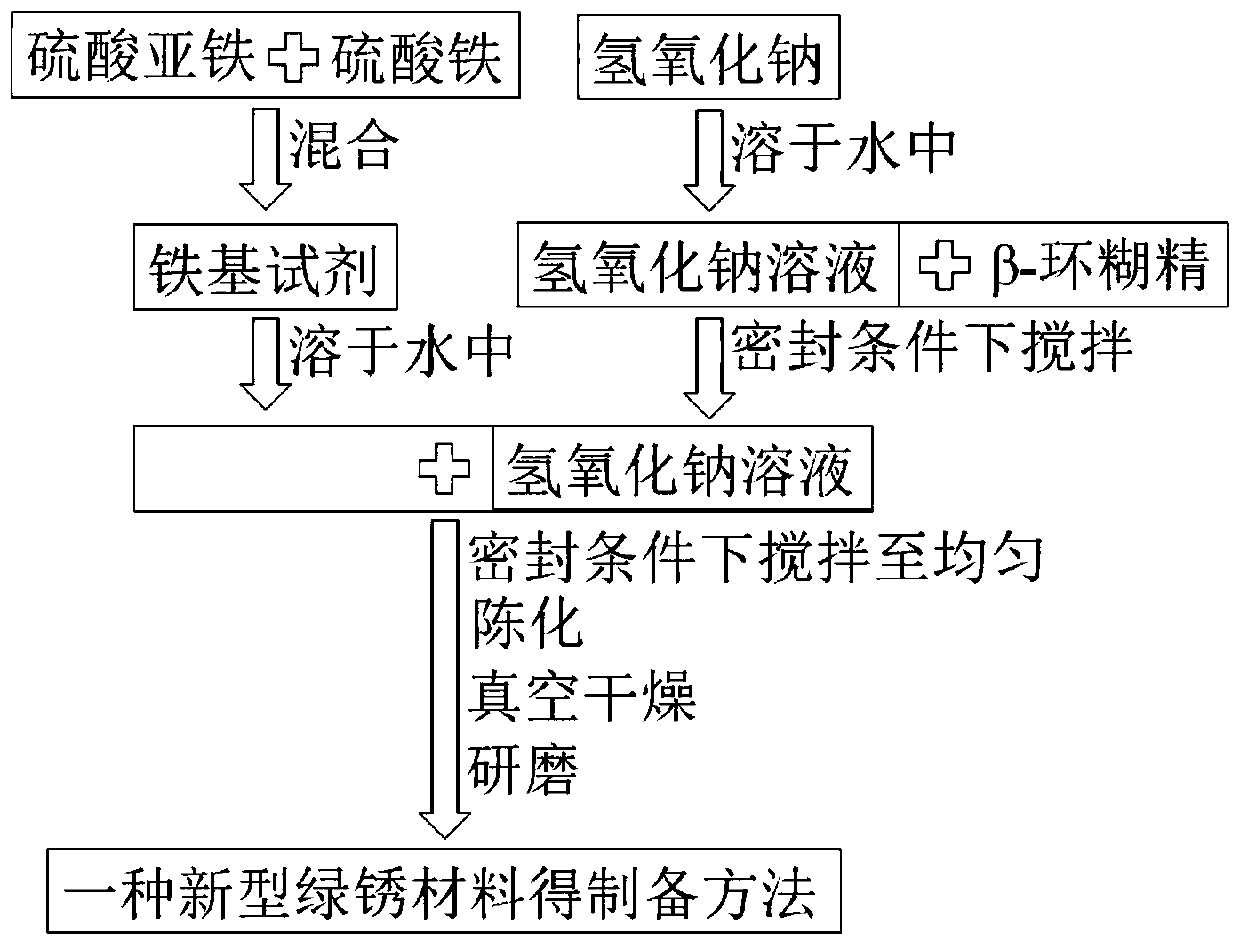

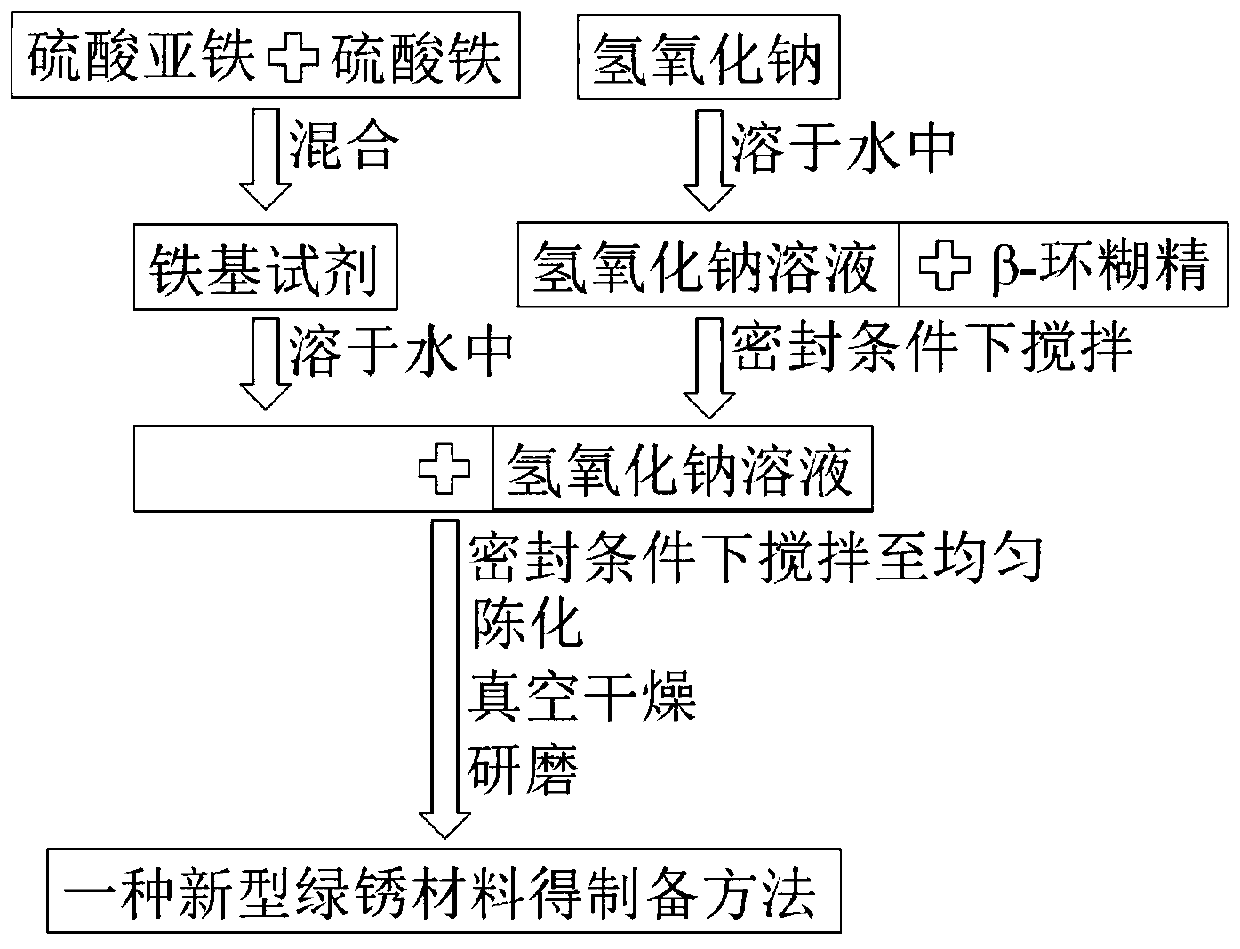

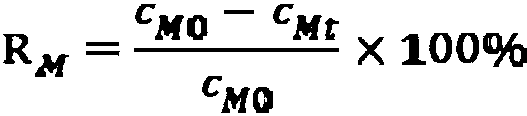

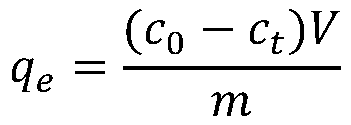

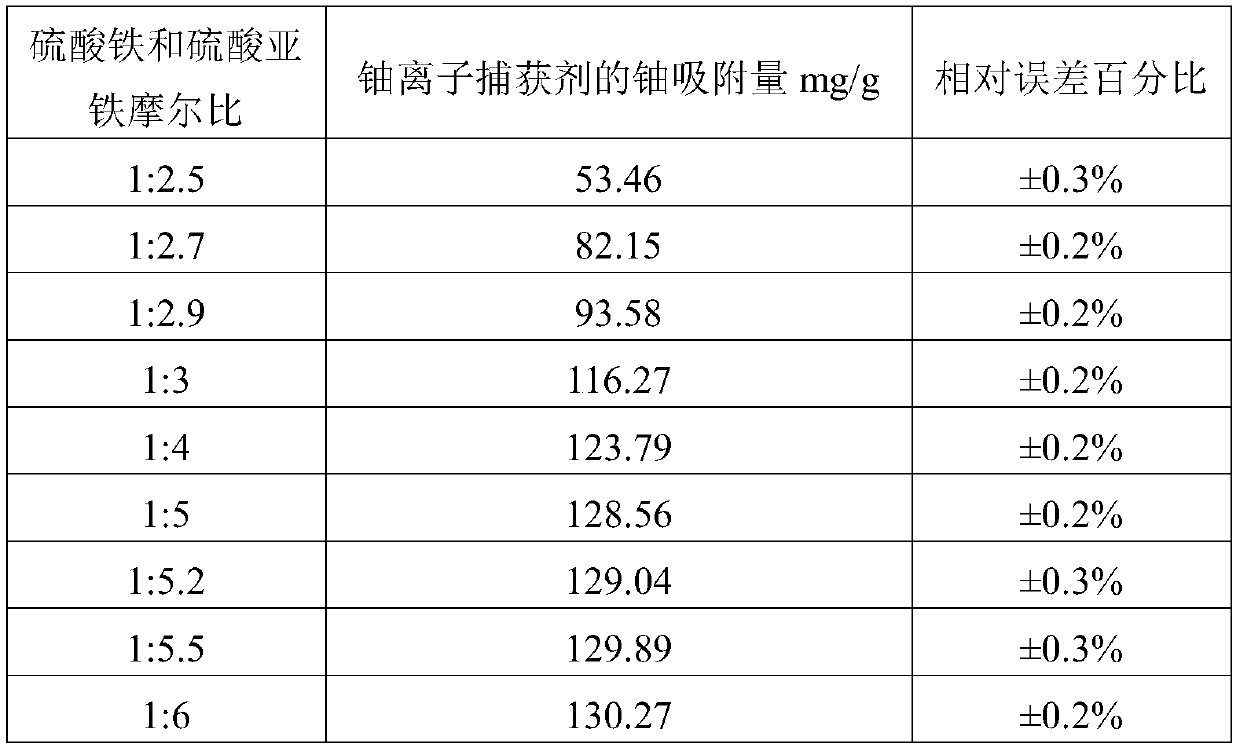

Green rust material and preparation method and application thereof

ActiveCN111135798AWide variety of sourcesHigh recovery rateOther chemical processesWater contaminantsIron sulfateFerrous sulfate iron

The invention discloses a green rust material and a preparation method and application thereof. The preparation method comprises the following steps: separately weighing ferrous sulfate and ferric sulfate, and carrying out mixing and uniform stirring to obtain an iron-based reagent; dissolving the iron-based reagent in water, and carrying out stirring under a sealed condition until the iron-basedreagent is completely dissolved to obtain an iron-based solution; adding beta-cyclodextrin into a sodium hydroxide solution, and carrying out stirring under a sealed condition until beta-cyclodextrinis completely dissolved to obtain cyclodextrin alkali liquor; and mixing the cyclodextrin alkali liquor with the iron-based solution, carrying out uniform stirring under a sealed condition, performingaging for 5-15 minutes, and conducting centrifuging, drying in vacuum and grinding into powder to obtain the green rust material. Compared with a traditional green rust adsorption material, the novelgreen rust adsorption material prepared by the preparation method disclosed by the invention has a larger specific surface area, more excellent heavy metal adsorption performance, applicability to awide range of pH values and a higher material recovery rate.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

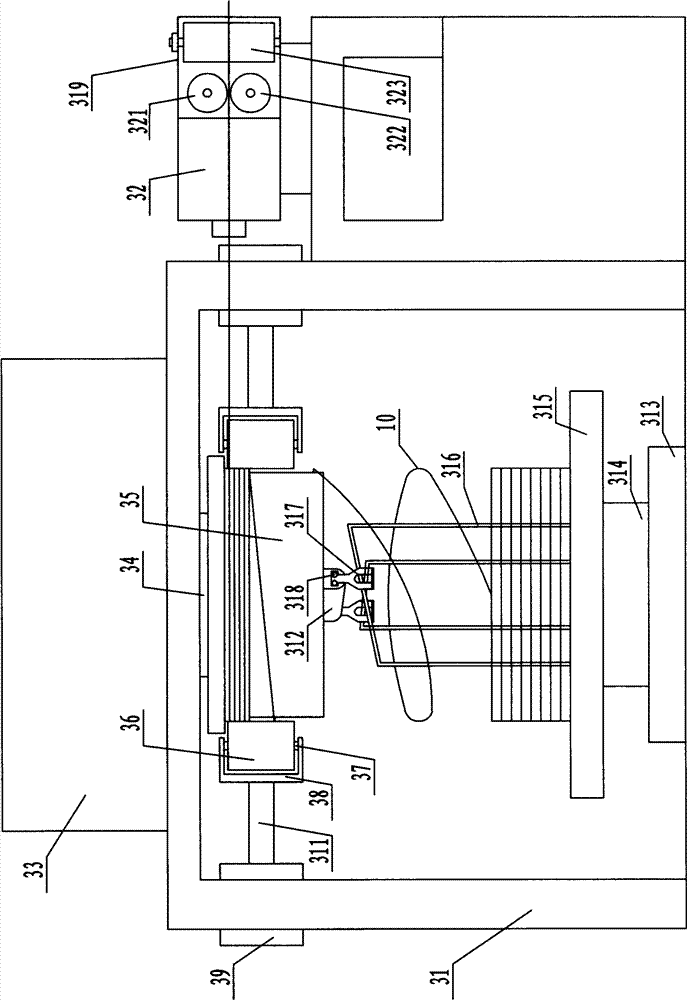

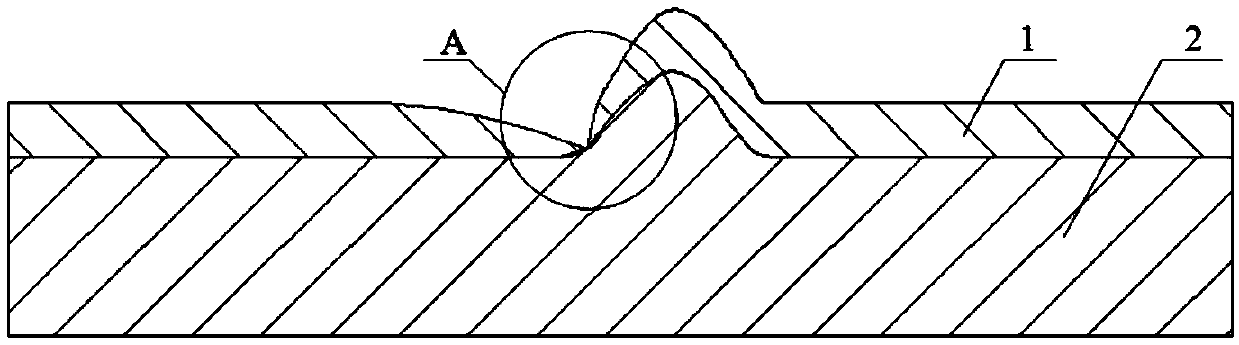

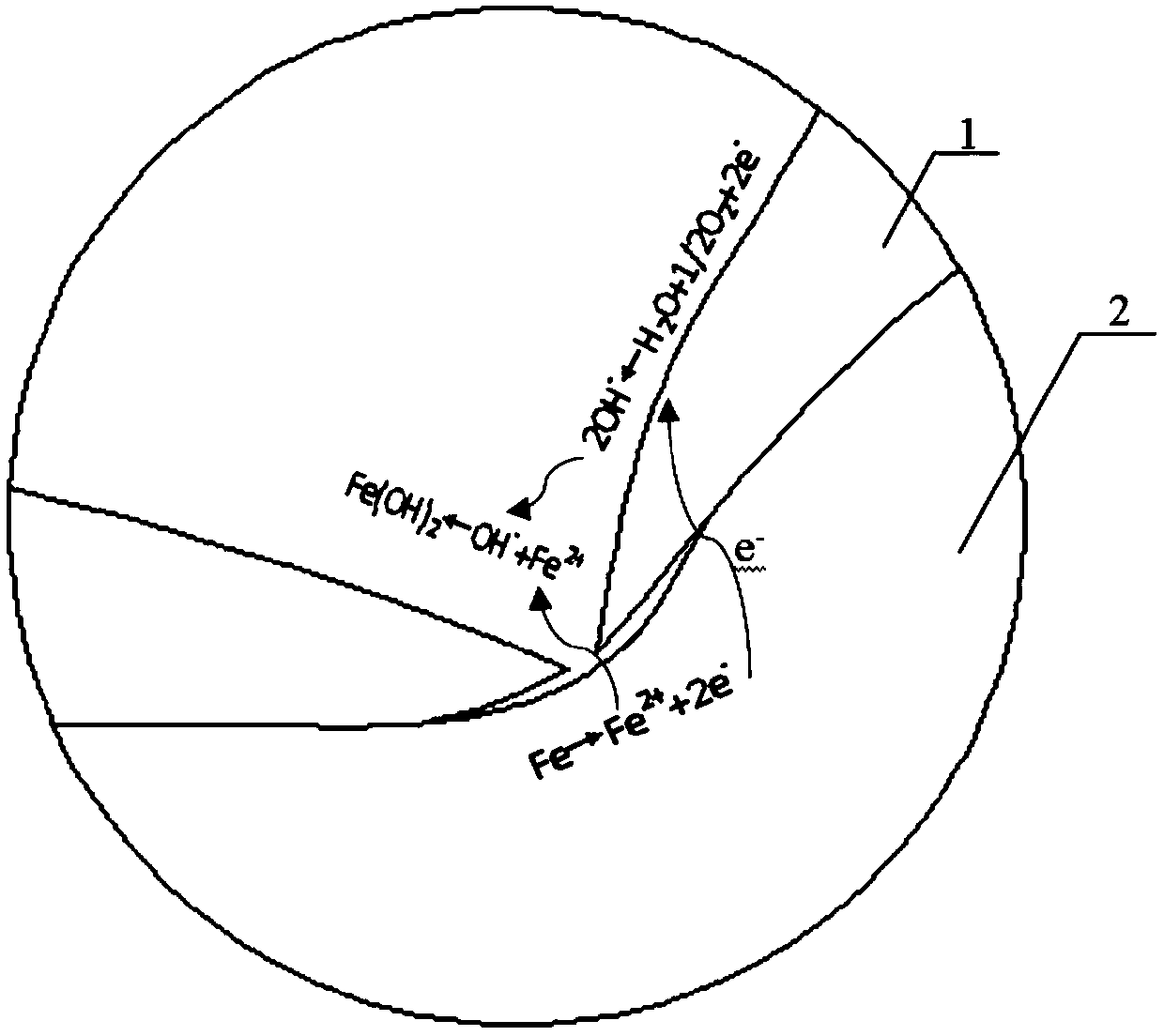

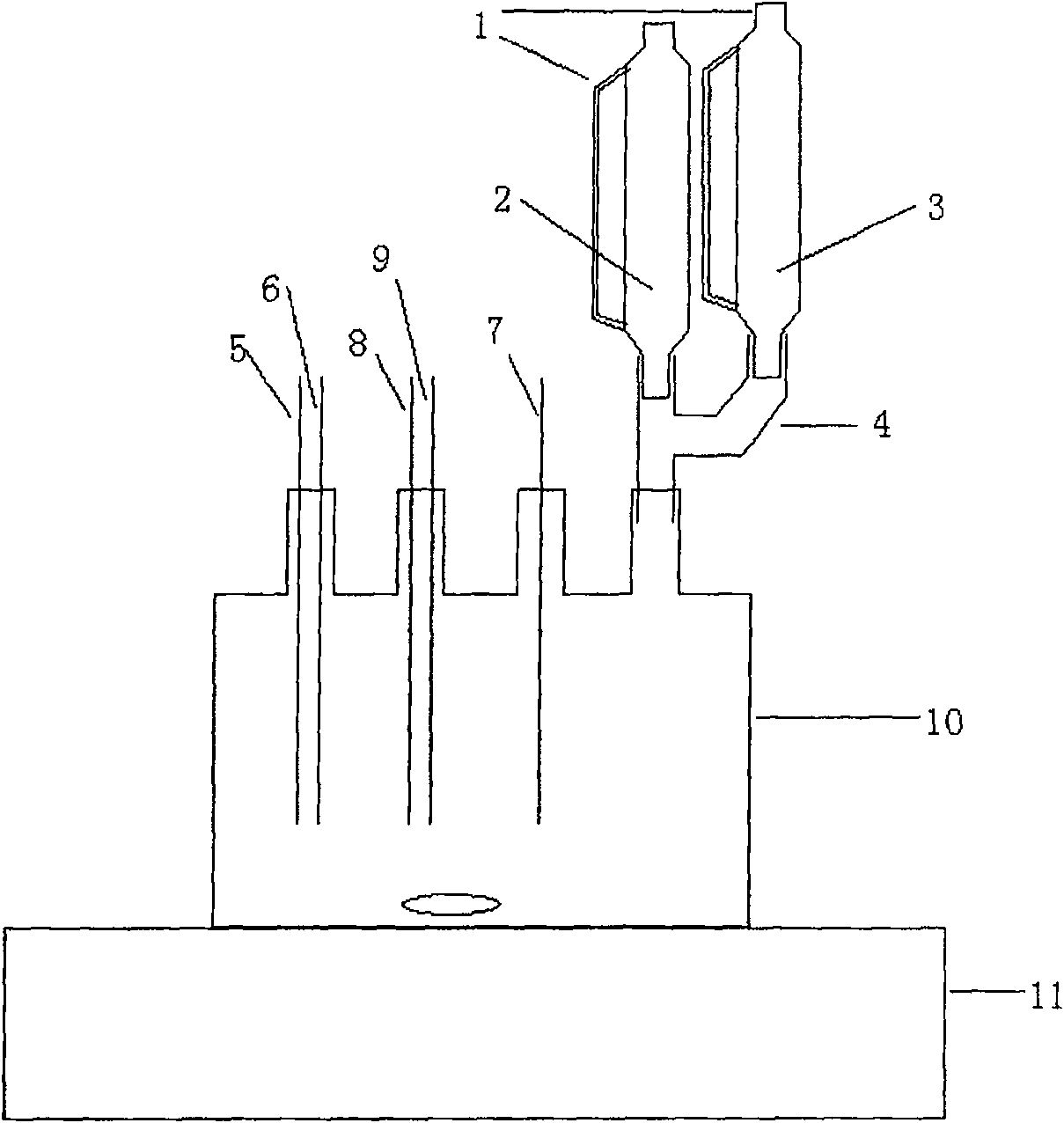

Pickling-free rust removing device for steel wires

InactiveCN103934308ARemove comprehensivelyEasy to cleanExtrusion cleaning devicesEngineeringGreen rust

The invention discloses a pickling-free removing device with a low cost for steel wires. The device comprises a frame and a reeling device; the upper end of one side of the frame is provided with a guiding device and a lubricant tank; the upper end of the frame is provided with a driving device; the rotation shaft of the driving device is connected to an extruding rust-removing central roller; the two sides of the extruding rusting-removing central roller are both provided with an extruding small roller that cooperates with the central roller; each extruding small roller is rotatingly arranged on an extruding small roller support through a rotation shaft; each extruding small roller support is connected to a position rod of an extruding cylinder; the extruding cylinder is fixedly arranged on the frame; and the lower end of the extruding rust-removing central roller is provided with a fixing seat.

Owner:JIANGSU YAFENG TECH GRP CO LTD

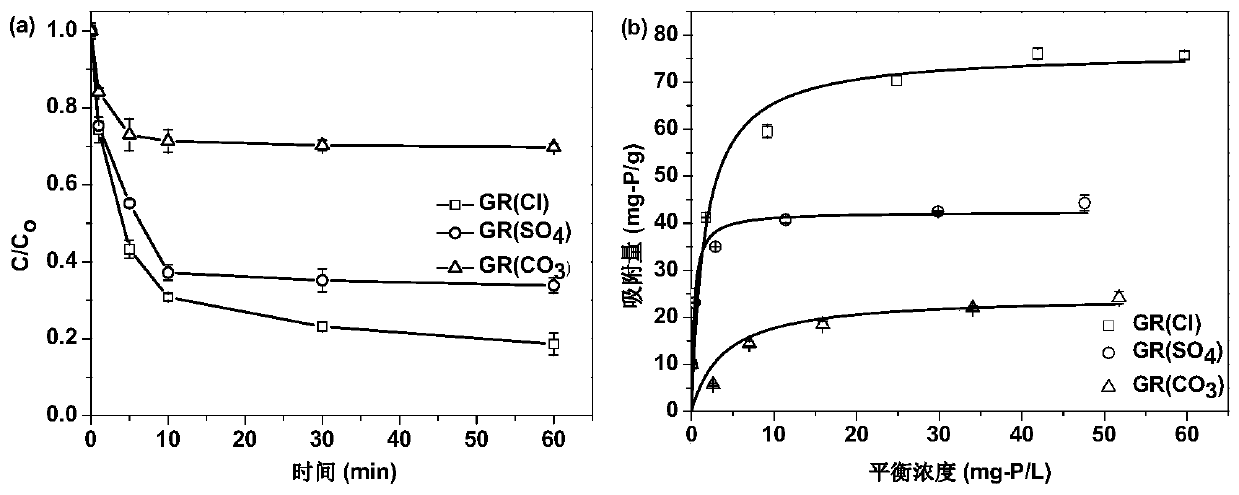

Green rust material for fixing anaerobic lake sediment phosphate as well as preparation method and application thereof

PendingCN111153492AEfficient remediation of pollutionRepair pollutionTreatment with anaerobic digestion processesSoil sciencePhosphate

The invention belongs to the technical field of sewage treatment, and particularly discloses a green rust material for fixing anaerobic lake sediment phosphate as well as a preparation method and application thereof. The method comprises the following steps: stirring Fe(OH)2 turbid liquid to oxidize Fe(OH)2 to obtain turbid liquid containing Fe(OH)2 and Fe(OH)3; continuously stirring in an oxygen-free environment to remove O2 in the turbid liquid, and filtering and washing the turbid liquid to obtain the green rust material. The prepared green rust can stably exist under an anaerobic condition; the green rust has a strong performance on combining phosphate, meanwhile, the structure of the green rust under the anaerobic condition is further stabilized through adsorption of phosphate, and the long-term fixing effect on phosphorus in the bottom mud can be achieved. Therefore, the problem that other ferric minerals are reduced under anaerobic conditions to release iron and phosphorus is solved; and the green rust is an iron-based ore and has the characteristic of selectively adsorbing phosphate, so that the green rust is not easily influenced by other interfering ions.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Lubricating grease rust-inhibiting additive

InactiveCN101988006AImproved anti-rust and anti-corrosion functionImprove anti-rust and anti-oxidationAdditivesPhenolPolypropylene

The invention relates to a lubricating grease rust-inhibiting additive which comprises the following components in percent by weight: 50-54 percent of alkylsuccinate derivative, 3-5 percent of hindered phenol, 3-5 percent of bis(salicylidene) propanediamine, 6-8 percent of alkyl phosphate salt, 3-5 percent of lead naphthenate, 2-4 percent of metal borates, 3-5 percent of polyisobutene, 2-4 percent of random polypropylene and the balance of base oil. The lubricating grease rust-inhibiting additive has the advantages of simple preparation method, economic and practical preparation scheme and low cost, can ensure that the rust-inhibiting and corrosion-preventing functions of common lubricating grease are greatly improved, improves various comprehensive properties of the lubricating grease while improving the rust-inhibiting and corrosion-preventing functions of the lubricating grease, can prolong the service period of the lubricating grease, and plays a role of protecting various machines and devices.

Owner:TIANJIN GONGBO SCI TECH DEV

Flaw detecting method for stainless steel/carbon steel composite material

InactiveCN109557107AAccurate flaw detectionEasy to detectPreparing sample for investigationOptically investigating flaws/contaminationCarbon steelGreen rust

The invention discloses a flaw detecting method for a stainless steel / carbon steel composite material. Dark green rust spots appear after the stainless steel / carbon steel composite material is immersed in a sodium chloride solution for a period of time. The portion where the dark green rust spot are located is a damaged portion. Compared with the conventional flaw detecting method, the invention has the advantages of accuracy and low cost.

Owner:南工大溧阳新材料研发中心有限公司

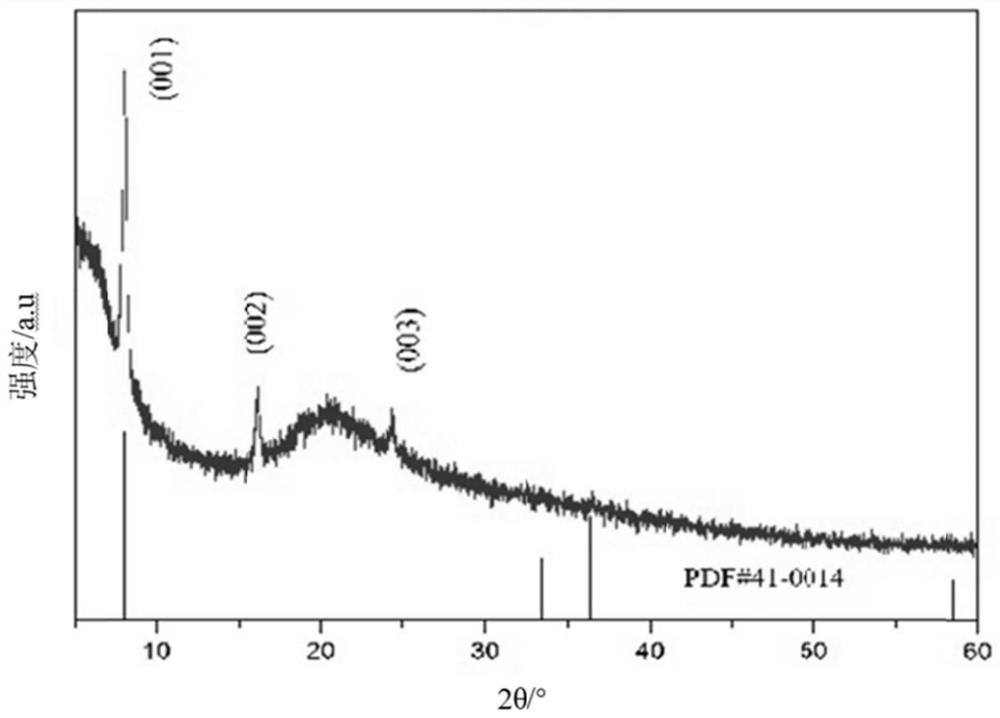

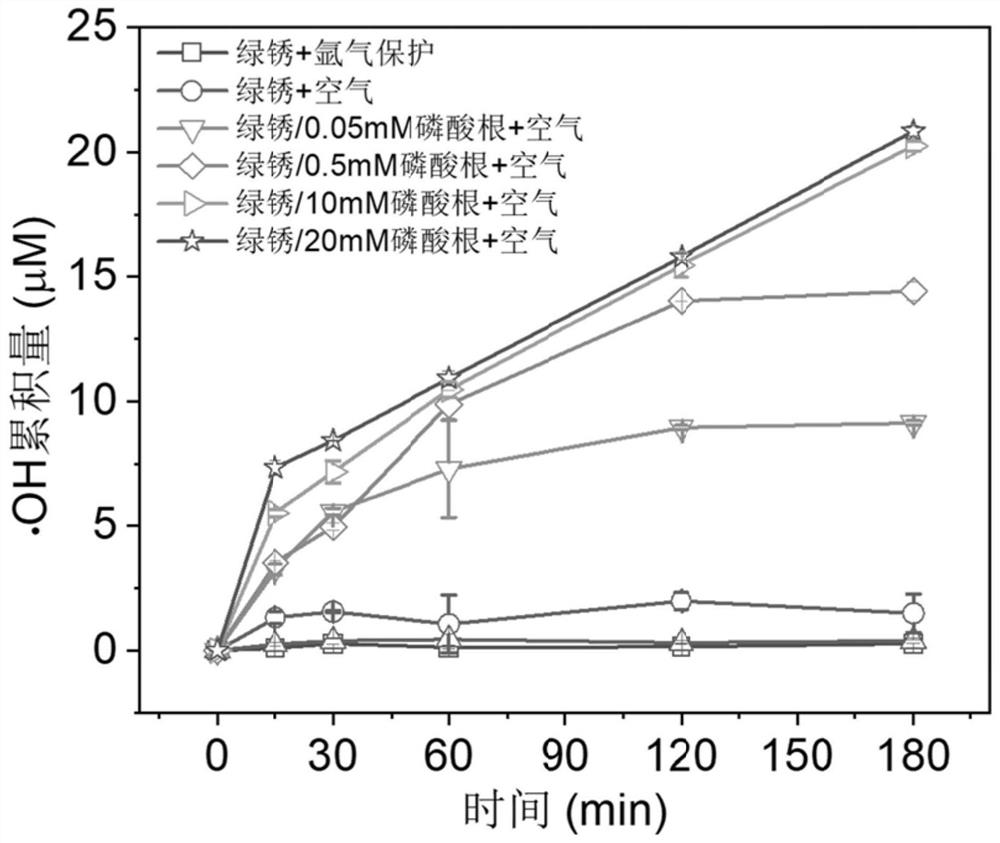

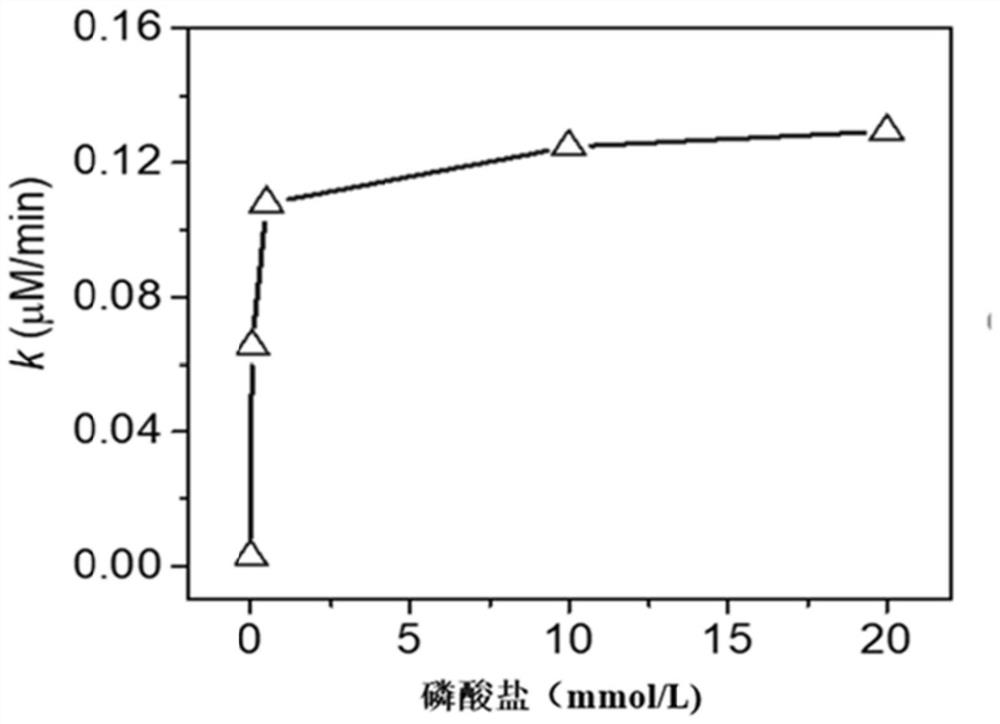

Application of phosphate to promotion of green rust to activate molecular oxygen

InactiveCN112340829ALow costEfficient use ofWater treatment compoundsWater contaminantsSulfate radicalsPhosphate

The invention relates to the technical field of environmental protection, and discloses application of a phosphate to promotion of green rust to activate molecular oxygen. The phosphate is a soluble phosphate; the green rust is at least one of chloride ion intercalation green rust, sulfate radical intercalation green rust and carbonate ion intercalation green rust; the molar ratio of the phosphorus element of the phosphate to the iron element of the green rust is (0.2-80):1; and the pH value of a mixture of the phosphate and the green rust is 6-8. Compared with single green rust, by adding thephosphate, green rust can be remarkably promoted to activate molecular oxygen, and the oxidative detoxification effect on various pollutants is achieved.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Food-grade rust-proof biaxially-oriented polypropylene film and preparation method thereof

InactiveCN109232938AMeet packaging requirementsGood water vapor barrierAnti-corrosive paintsFlat articlesPolymer sciencePolyvinyl alcohol

The invention relates to a food-grade rust-proof biaxially-oriented polypropylene film. The food-grade rust-proof biaxially-oriented polypropylene film comprises a substrate and a coating layer on thesubstrate surface, wherein a primer layer is arranged between the coating layer and the substrate; the coating layer is a modified polypropylene coating formed by applying modified barrier polypropylene latex to the surface of the primer layer and drying the latex; the ultrahigh vapor-barrier polypropylene latex is prepared from raw materials in parts by weight as follows: 52-95 parts of deionized water, 0.9-1.9 parts of sodium percarbonate, 0.5-2.3 parts of vinyl chloride, 37-40.9 parts of polypropylene, 2.9-3.9 parts of polyvinyl alcohol, 6-8 parts of propionamide and 1-2 parts of polytetrafluoroethylene propyl ester. The traditional food-grade rust-proof biaxially-oriented polypropylene film is modified, so that the food-grade rust-proof biaxially-oriented polypropylene film is endowedwith ultrahigh vapor barrier performance while keeping original characteristics.

Owner:SICHUAN GAOSHENG PACKAGING PROD

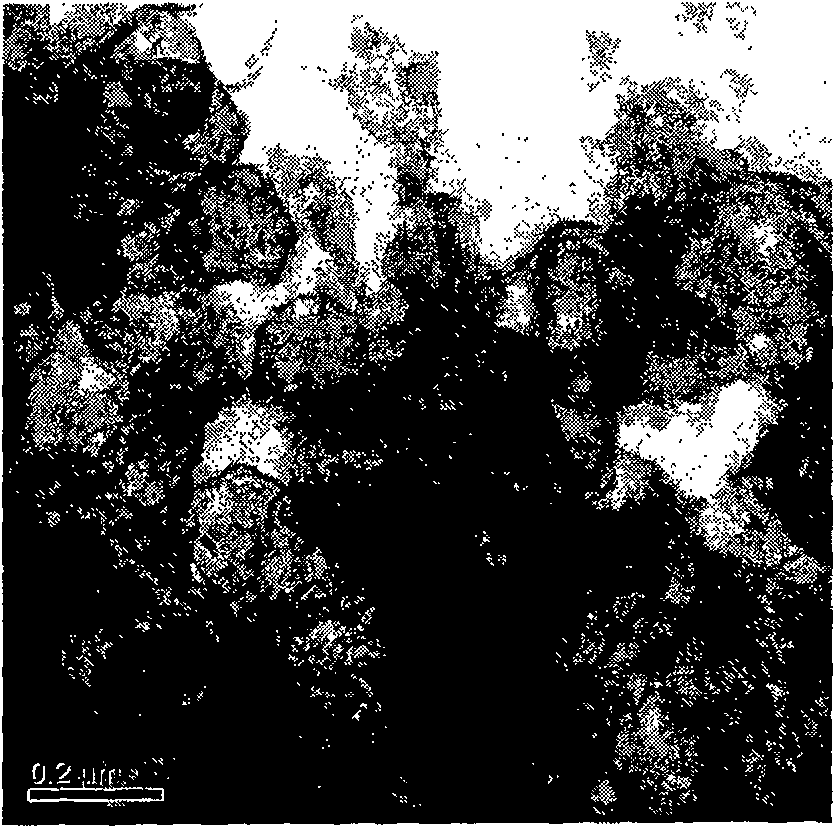

Process for preparing patina

InactiveCN100567168CRegular latticeImproved particle size distributionIron compoundsColor changesSolvent

The invention belongs to the technical field of inorganic chemical industry, and in particular relates to a preparation method of green rust, an important intermediate produced in various ferrite production processes. The specific steps are as follows: build a reaction device, use ascorbic acid aqueous solution with a molar concentration of 2.5×10-4 to 7.5×10-4 mol / L as a solvent, and FeSO4 as a solute to prepare a ferrous solution, and place it in a four-necked flask under a nitrogen atmosphere; Place the alkaline solution in one tube of the constant pressure titration funnel, and place the Fe2(SO4)3 solution in another tube of the constant pressure titration funnel; the molar concentrations of FeSO4 and Fe2(SO4)3 solutions are equal; Using magnetic stirring, the solution in the four-necked flask is stirred evenly, the pH value of the solution in the four-necked flask is adjusted to 6, Fe2(SO4)3 solution is added dropwise, and the alkaline solution is added dropwise at the same time, so that the pH value of the solution is maintained at 6; after the Fe2(SO4)3 solution is dripped, record the pH value of the solution, continue to drop the alkaline solution in the solution, and observe the color change of the solution at the same time, until the pH value of the solution is 7, the reaction ends; aging, that is get the desired product. The green rust prepared by the invention has high purity and mild reaction conditions.

Owner:TONGJI UNIV

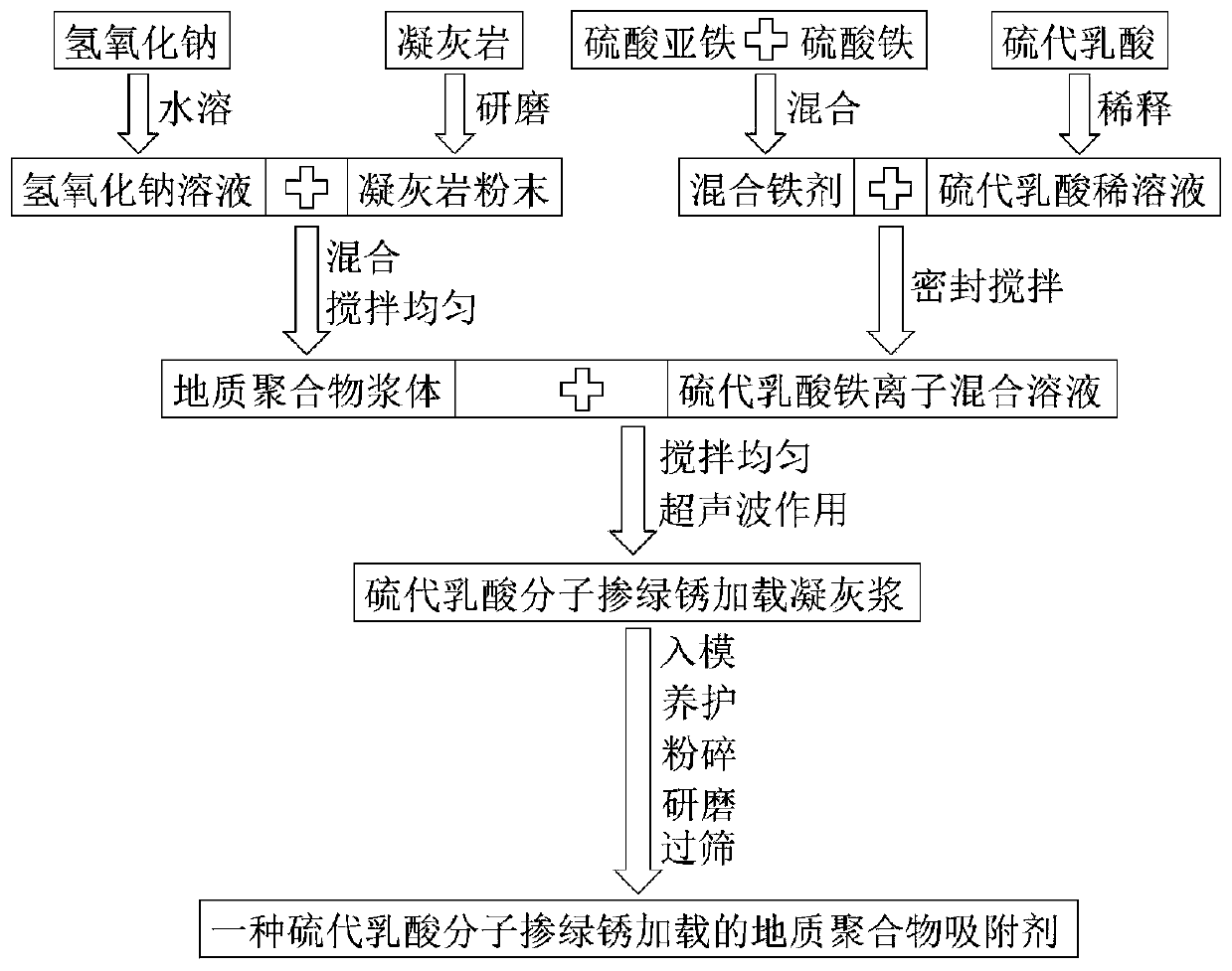

Thiolactic acid doped green rust geopolymer adsorbent and preparation method and application thereof

ActiveCN111135797AImprove adsorption capacityEasy to makeOther chemical processesWater contaminantsThiolactic acidIron sulfate

The invention discloses a thiolactic acid doped green rust geopolymer adsorbent, and a preparation method and application thereof. The preparation method comprises the following steps: mixing tuff powder and a sodium hydroxide solution and carrying out uniform stirring to obtain geopolymer slurry; introducing nitrogen into a dilute solution of thiolactic acid, then adding a mixed iron agent into the dilute solution of thiolactic acid, and carrying out stirring under a sealed condition until ferrous sulfate and ferric sulfate are completely dissolved to prepare a thiolactic acid-iron ion mixedsolution; mixing the thiolactic acid- iron ion mixed solution with the geopolymer slurry, conducting uniform stirring, and carrying out ultrasonic treatment to obtain thiolactic acid doped green rustloaded tuff slurry; and carrying out aging, crushing, grinding and sieving on the thiolactic acid doped green rust loaded tuff slurry to obtain the thiolactic acid doped green rust loaded geopolymer adsorbent. The preparation method is simple in process; and compared with a geopolymer adsorbent, the prepared thiolactic acid doped green rust loaded geopolymer adsorbent has the advantages of higherheavy metal adsorption capacity, applicability to a wide range of pH values and capability of efficiently absorbing various heavy metals.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

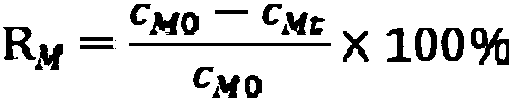

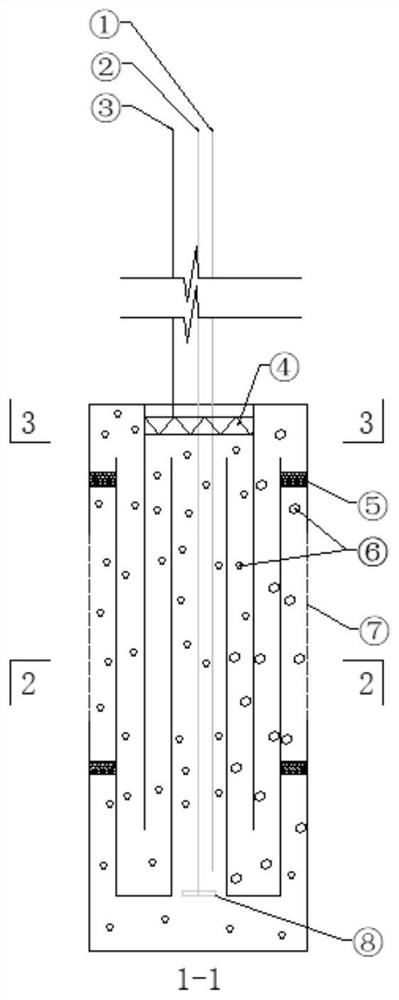

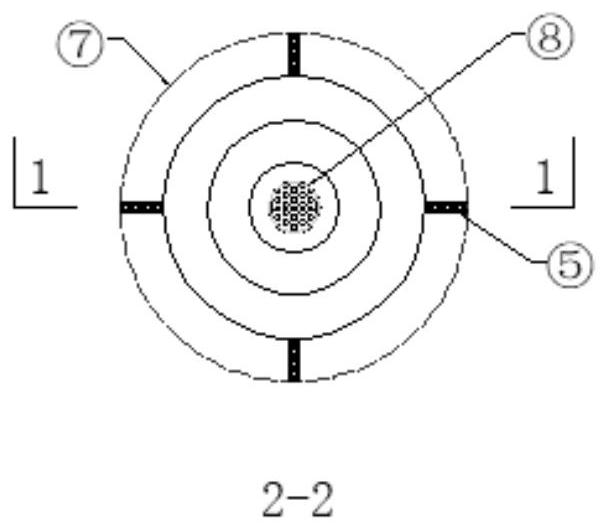

Method for preparing uranium ion trapping agent

ActiveCN110152616AQuick removalLarge adsorption capacityOther chemical processesRadioactive decontaminationLow temperature plasmaIron(III) sulfate

The invention discloses a method for preparing a uranium ion trapping agent. The method comprises the following steps: (1) dissolving ferric sulfate and ferrous sulfate into water, sealing and stirring to obtain an iron-based solution; dissolving sodium hydroxide and sodium thioglycolate into water, sealing and stirring to obtain a basic thiol solution; mixing the iron-based solution and the basicthiol solution, sealing and stirring, separating, filtering, drying and grinding to obtain thiol green-rust doped powder; (2) adding the thiol green-rust doped powder into a low temperature plasma apparatus to perform glow discharge treatment so as to obtain thiol green-rust doped powder subjected to plasma treatment; and (3) adding the thiol green-rust doped powder subjected to plasma treatmentinto a test tube filled with a chelating agent solution, sealing and carrying out a grafting reaction to obtain a chelating agent enhanced thiol green-rust doped mixture, separating, filtering, dryingand grinding, thereby obtaining the uranium ion trapping agent. According to the method disclosed by the invention, uranium ions in uranium-containing waste liquor can be rapidly removed, and the adsorbed uranium ions can be stabilized inside particles.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Slow-release Fenton-like system based on immobilized enzyme and method for in-situ remediation of groundwater pollution by slow-release Fenton-like system

ActiveCN112624508AImprove controllabilityAchieve mineralization degradationWater contaminantsMultistage water/sewage treatmentIn situ remediationEnvironmental engineering

The invention discloses a slow-release Fenton-like system based on an immobilized enzyme, and provides a method for in-situ remediation of groundwater pollution. The method mainly comprises the following steps: 1) selecting a central well and a plurality of peripheral chemical adding wells in a pre-remediated groundwater pollution area; 2) adding green rust into the chemical adding wells, then pumping water from the central well, recharging the water into underground water through the chemical adding well, and continuously pumping water until green rust appears; and 3) arranging an immobilized enzyme reactor in each chemical adding well, conducting aerating, introducing a glucose solution, pumping a small amount of water in the central well, recharging the water into underground water through the chemical adding wells, and pumping water until the concentration of effluent pollutants reaches the standard. The slow-release Fenton-like system has a pH range close to the environment where underground water is located, lasting slow release of free radicals and controllability of a degradation area can be achieved in the whole process, other pollutants cannot be introduced into the underground water, and non-toxicity and harmlessness can be achieved.

Owner:WUHAN UNIV OF TECH

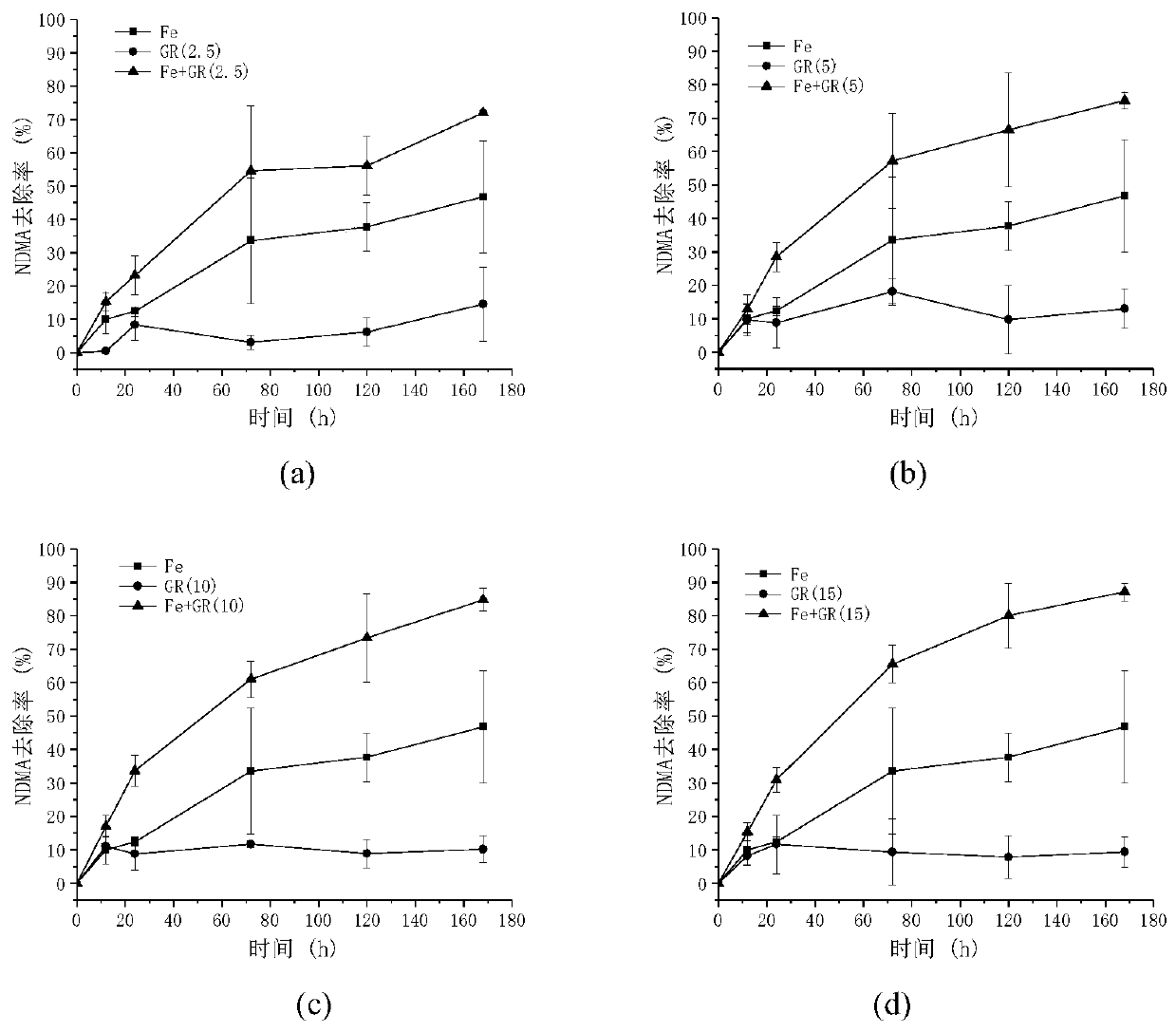

Water treatment method for reducing nitrosodimethylamine in water by green rust and zero-valent iron

ActiveCN110357240AEfficient removalWater contaminantsWater/sewage treatment by reductionSyringeGreen rust

A water treatment method for reducing nitrosodimethylamine in water by green rust and zero-valent iron comprises the following steps: 1) preparing a preset volume of deionized oxygen-free water with an initial pH of 7.0, adding 10 g.L<-1> of iron powder, adding 2.5-15 g.L<-1> of green rust, finally adding 100 [mu]g.L<-1> of NDMA, tightly covering with a bottle cap, placing the covered bottle in arotary incubator, and rotating the bottle in a dark place; and 2) carrying out timing sampling, carrying out pressure filtration on the obtained sample by a syringe through a 0.22-0.45 [mu]m filter toseparate unreacted iron powder and green rust in order to terminate a reaction, and analyzing the NDMA concentration of the obtained water sample. The method increases the degradation rate of NDMA.

Owner:ZHEJIANG UNIV OF TECH

Cleaning-free rust-preventative oil composite additive and preparation method thereof

The invention discloses a cleaning-free rust-preventative oil composite additive and a preparation method thereof. The cleaning-free rust-preventative oil composite additive comprises 5 to 20% of benzotriazole, 10 to 45% of heptadecenylimidazoline alkenylamine succinate, 10 to 45% of barium petroleum sulfonate, 15 to 55% of low-base number calcium petroleum sulfonate, 15 to 55% of zinc didecylnaphthalene sulfonate and 5 to 15% of flux oil. The preparation method comprises the following steps: heating the flux oil to 65 to 85 DEG C; then successively adding benzotriazole, heptadecenylimidazoline alkenylamine succinate, barium petroleum sulfonate, low-base number petroleum calcium sulfonate and zinc didecylnaphthalene calcium sulfonate; and carrying out stirring at a constant temperature of 65 to 85 DEG C for no less than 95 min so as to obtain the composite additive. 1 to 20% of the composite additive is added into corresponding base oil so as to obtain thin-film rust preventive oil, so the purposes of rust prevention during sealed storage and rust prevention among machining procedures are achieved; and since the composite additive has good compatibility and implements thin-film rust prevention, cleaning-free assembling can be realized.

Owner:上海润祥化工有限公司 +1

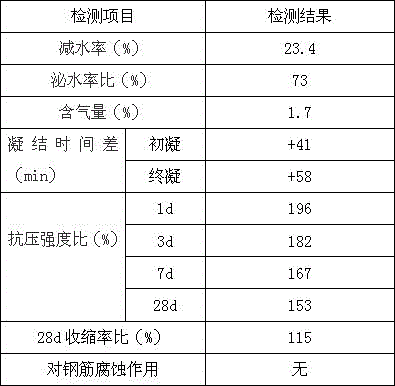

Chlorine-free rust-proof concrete early strength water-reducing agent and preparation method thereof

InactiveCN106242357AHigh water reduction rateGood early strength effectMelamine formaldehyde resinSodium sulfate

The invention discloses a chlorine-free rust-proof concrete early strength water-reducing agent and a preparation method thereof. The chlorine-free rust-proof concrete early strength water-reducing agent is made from, by weight, 12-18 parts of sulfonated melamine formaldehyde resin, 10-15 parts of sulfanilate, sulfonated acetone and formaldehyde condensate, 8-12 parts of starch and acrylic acid grafted copolymer, 4-8 parts of calcium butyrate, 6-9 parts of anhydrous sodium sulfate, 4-8 parts of magnesium chromate, 10-15 parts of poly(4-styrenesulfonic acid-co-maleic acid) sodium salt, 7-11 parts of Pulullan, 3-6 parts of urea, and 5-7 parts of sodium polyacrylate. The calcium butyrate, anhydrous sodium sulfate, Pulullan, urea and sodium polyacrylate replace chloride early strength agents to be used with the water-reducing agents such as sulfonated melamine formaldehyde resin, sulfanilate, sulfonated acetone and formaldehyde condensate, and poly(4-styrenesulfonic acid-co-maleic acid) sodium salt, and the water-reducing agent has high water-reducing rate and good early strength effect, is free of chlorine ions, is rust-free for reinforcement and is good in anti-cracking effect.

Owner:安徽海洋新型建材科技有限公司

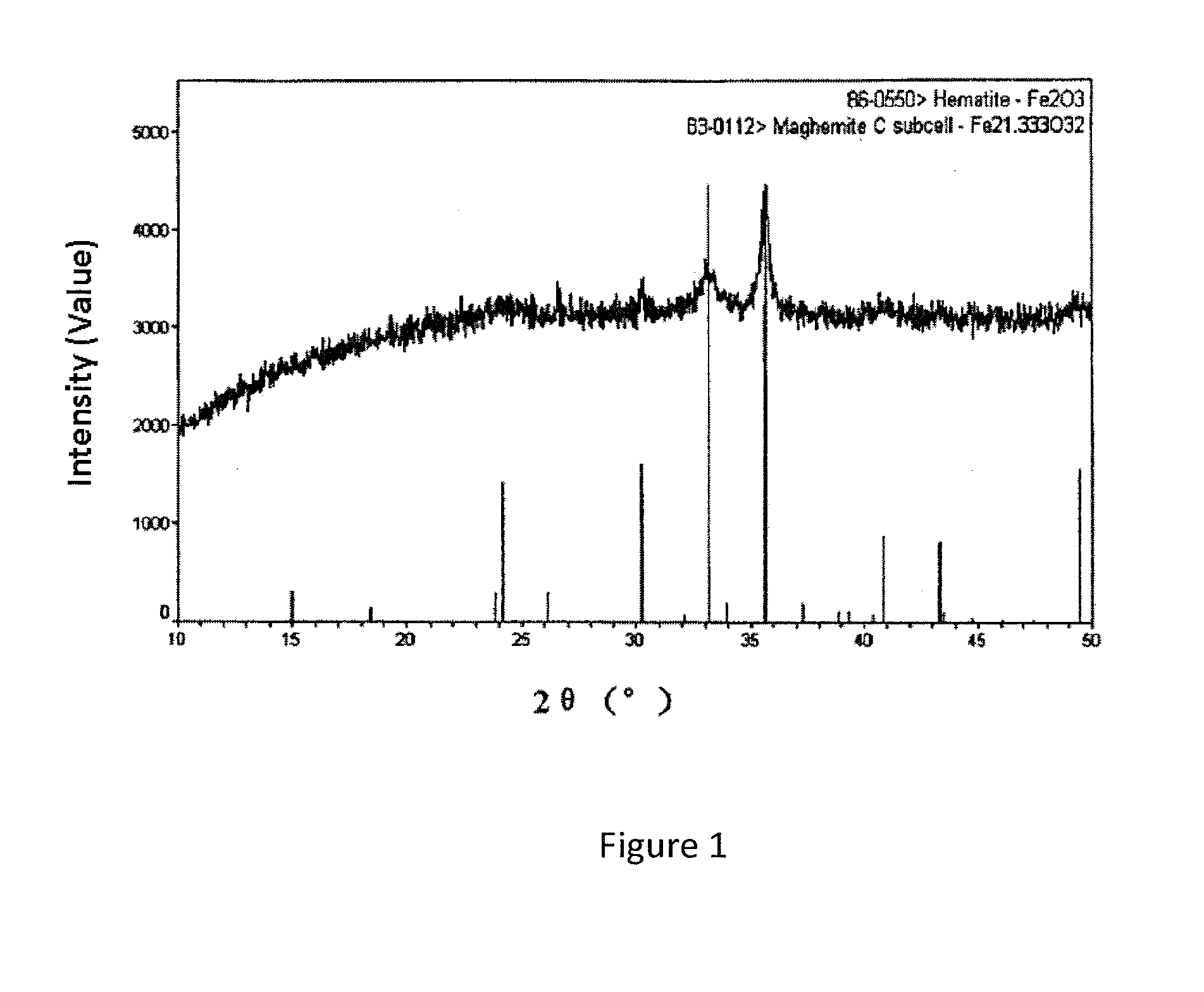

Preparation method and application of magnetic iron oxide and desulfurizer containing the magnetic iron oxide as active component

ActiveUS20140124697A1Improve magnetic propertiesHigh desulfurization activityGas treatmentDispersed particle separationSuperparamagnetic iron oxide nanoparticlesMetallurgy

Owner:BEIJING HAIXIN ENERGY TECH CO LTD

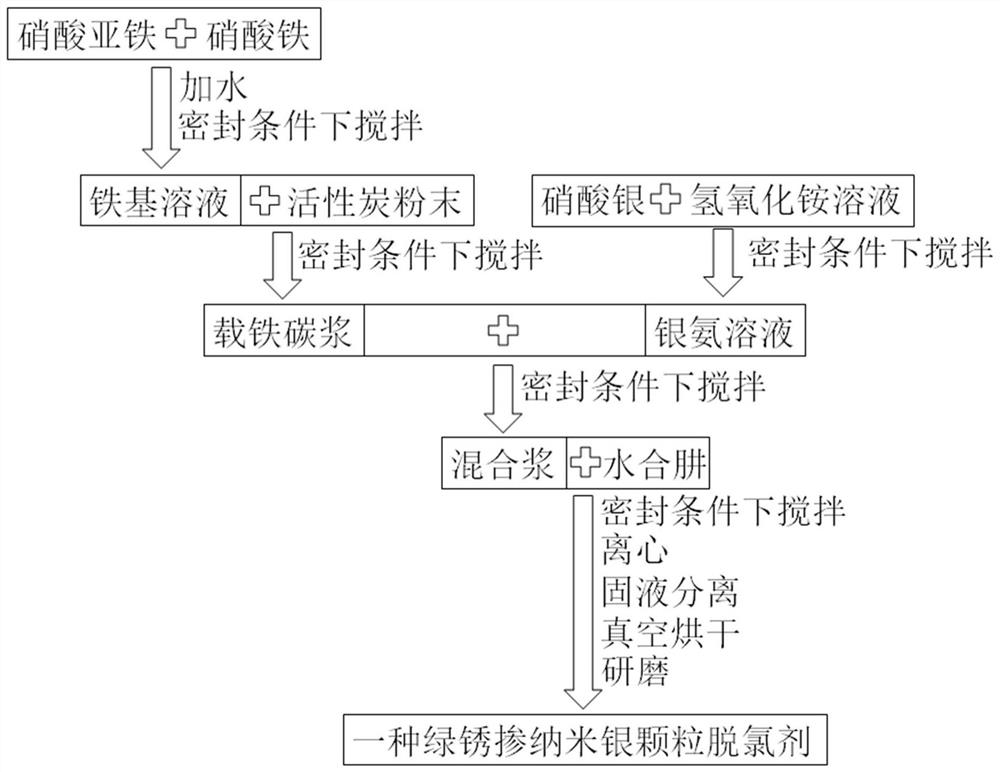

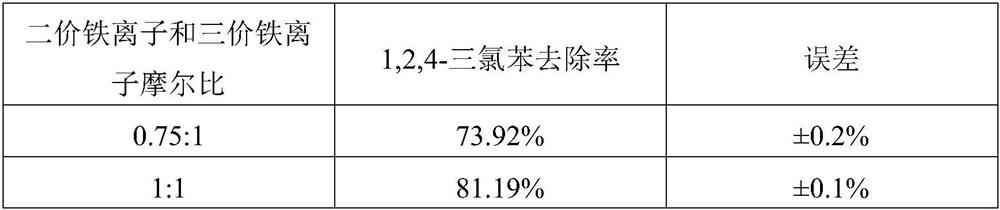

A green rust mixed with nano-silver particle dechlorination agent and its preparation method and application

ActiveCN111547831BImprove reaction efficiencySimple preparation processWater contaminantsWater/sewage treatment by sorptionActivated charcoal powderChlorobenzene

The invention discloses a green rust-doped nano-silver particle dechlorination agent and a preparation method and application thereof, comprising the following steps: adding ferric nitrate and ferrous nitrate into water, stirring under sealing conditions until the ferric nitrate and ferrous nitrate are completely dissolved, and obtaining iron base solution; mix the iron-based solution with activated carbon powder, and stir under sealing conditions to obtain iron-loaded carbon slurry; mix silver nitrate into ammonium hydroxide solution with a pH of 10-12, and stir under sealing conditions until the silver nitrate is completely dissolved to obtain Silver ammonia solution; mix the silver ammonia solution and iron-carrying carbon slurry, stir evenly under sealed conditions to obtain a mixed slurry, then add hydrazine hydrate to the mixed slurry, and stir evenly under sealed conditions to obtain a dechlorination agent doped with nano-silver rust. The preparation process of the invention is simple, and the raw materials and reagents involved are simple and easy to obtain. Compared with the traditional green rust material, the reaction efficiency of the green rust-doped nano-silver particle dechlorination agent of the present invention is higher, and it can be applied to the water environment with pH equal to 6-12, and can achieve a maximum of 99% 1,2,4-trichlorobenzene remove.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

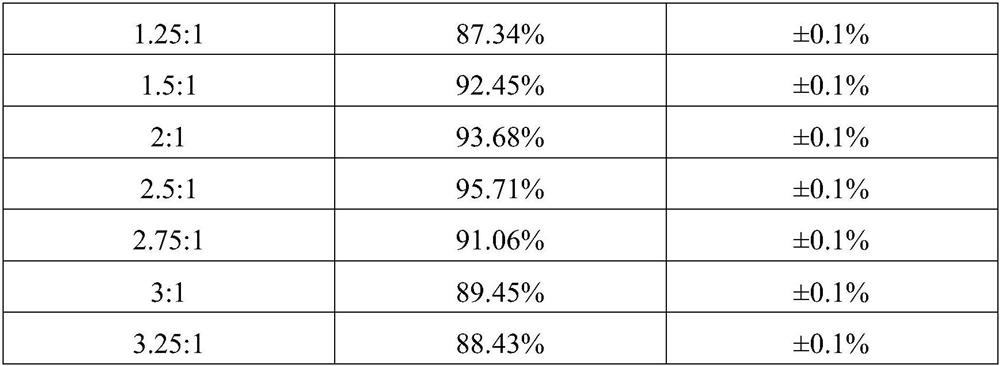

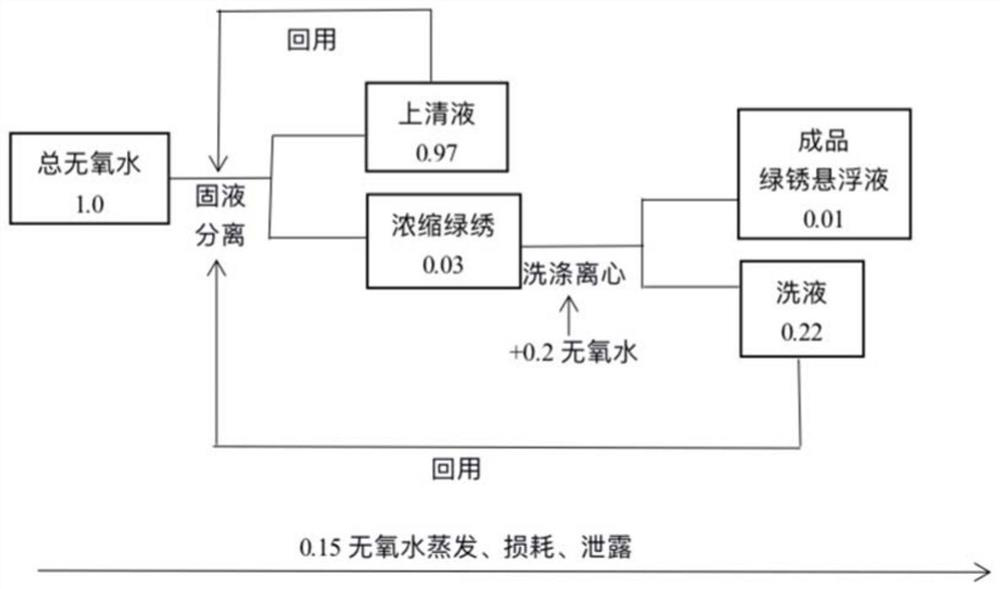

Method for preparing layered iron oxide green rust in zero-emission mode

InactiveCN112429778ASynthesis fastHigh purityIron compoundsOrganic fertilisersWastewaterEnvironmental remediation

The invention relates to the field of preparation of environmental remediation agents, in particular to a method for preparing layered iron oxide green rust in a zero-emission mode. Glycine is used asan auxiliary agent, a large amount of green rust is rapidly synthesized through a homogeneous precipitation method, and zero emission of waste water and waste in the synthesis process is achieved. Glycine, ferric iron and ferrous iron are used as raw materials, green rust is synthesized under the weakly alkaline condition, supernatant and washing liquid in the process are recycled, chemicals areadded, then the mixture is reused in the synthesis process, and zero emission in the production process is achieved. The production process does not generate waste, the raw materials are cheap and easy to obtain, the process is simple and easy to implement, large-scale synthesis can be realized, oxygen-free water is theoretically and completely recycled, the oxygen removal energy consumption is greatly reduced, and the production process has very high practical value and popularization value.

Owner:JINAN UNIVERSITY

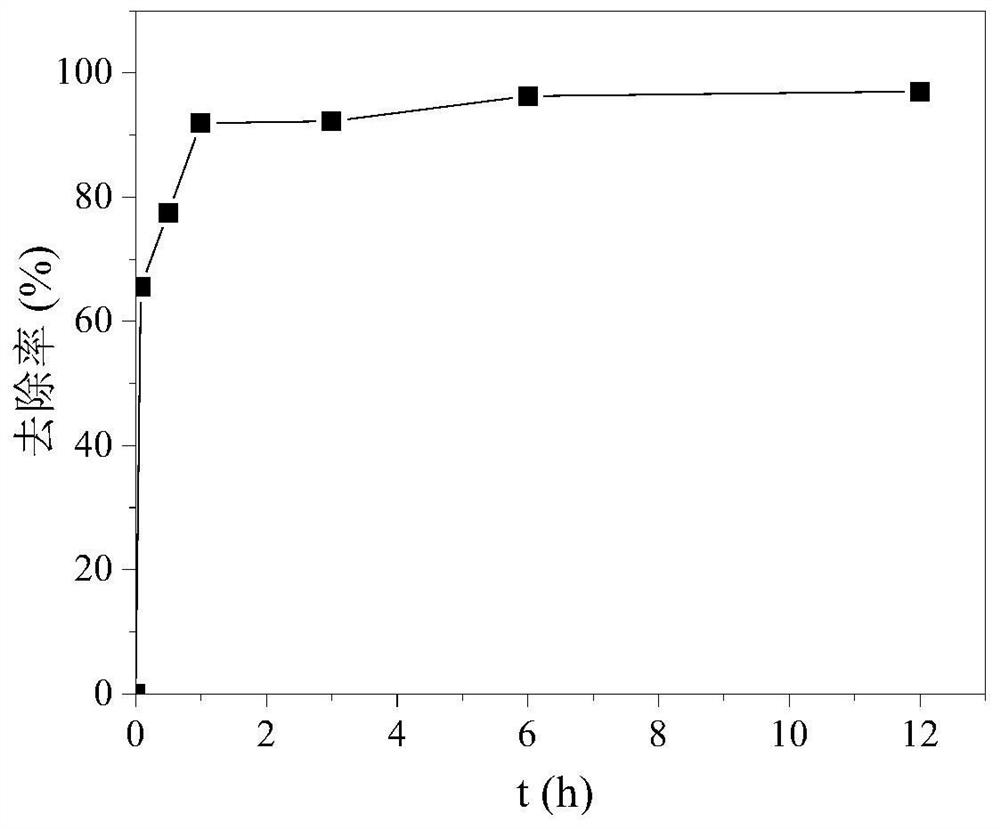

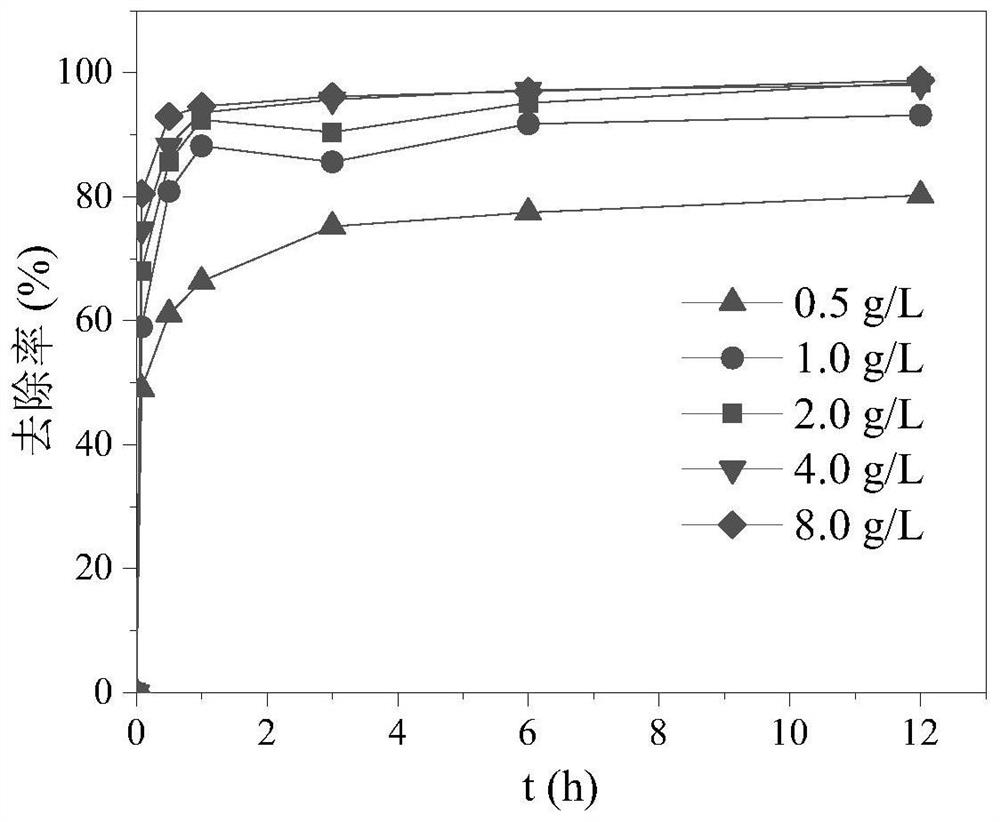

Method for adsorbing tetracycline in underground water by using green rust

PendingCN111977737AEnsure safetyControl Toxic Substances TCWater treatment parameter controlOther chemical processesPotable waterWater source

The invention discloses a method for adsorbing tetracycline in underground water by using green rust. The method comprises the following steps: adding 0.5-8g / L green rust into a reaction bottle filledwith a solution with TC initial concentration of 1-80mg / L in an anaerobic incubator, tightly capping the bottle, placing the bottle on a rotary incubator to rotate away from light at a rotating speedof 30-70 r / min, performing timing sampling, and performing solid-liquid separation on obtained samples through a 0.45-micron filter membrane so as to achieve tetracycline adsorption. The method provided by the invention for adsorbing tetracycline in underground water by using green rust can effectively control the potential toxic substance TC in the underground water and ensure the safety of thedrinking water source of the underground water.

Owner:ZHEJIANG UNIV OF TECH

Novel environment-friendly anti-rust paint and preparation method thereof

The invention provides a novel environment-friendly antirust paint and a preparation method thereof, and relates to the field of antirust paints. Prepared from the following raw materials in parts by weight: 40-50 parts of water-based epoxy resin, 10-15 parts of talcum powder, 5-10 parts of titanium dioxide, 5-10 parts of aluminum tripolyphosphate, 20-25 parts of deionized water, 10- 15 parts of plant starch, 3-5 parts of ceramic hollow microspheres, 3-5 parts of titanium dioxide, 0.5-1 part of defoamer, 0.5-1 part of dispersant, 2-4 parts of film-forming aids, 10-15 parts of tung oil . The invention provides a novel environment-friendly antirust paint and a preparation method thereof. The raw materials used are environment-friendly, and have the characteristics of low toxicity, low cost and good performance.

Owner:合肥华福土工合成材料有限公司

Water-in-water type environment-friendly rust-resistant coating

InactiveCN107022217AImprove corrosion resistanceCreate pollutionAnti-corrosive paintsWater solubleGreen rust

The invention relates to a coating, in particularly to a water-in-water type environment-friendly rust-resistant coating. The water-in-water type environment-friendly rust-resistant coating comprises a film-forming adhesive, and 0.1 g / l or more of water-soluble rust spot reaction solid matter; the solid matter can be chelated with iron. The water-in-water type environment-friendly rust-resistant coating provided by the invention can further improve corrosion resistance and increase reliability of outdoor buildings.

Owner:南通市乐佳涂料有限公司

Composite catalyst as well as preparation method and application thereof

ActiveCN113457694AEasy to handleGood catalytic degradation activitySolid waste disposalCatalyst activation/preparationPtru catalystIron chloride

The invention belongs to the technical field of garbage treatment, and discloses a composite catalyst as well as a preparation method and application thereof. The composite catalyst comprises polyferric aluminum chloride and green rust, the molecular formula of the green rust is [Fe<2+><1-x>Fe<3+><x>(OH)<2>]<x+>[(x / 2)(SO<4><2->)]<x->, and x is equal to 0.4-0.5. The composite catalyst provided by the invention comprises the polyferric aluminum chloride and the green rust which have a synergistic effect, so that the composite catalyst has good catalytic degradation activity on carbohydrates, fat, proteins and the like in the kitchen wastes, can effectively treat the kitchen wastes in various complex forms, and is high in degradation efficiency and short in degradation time; and no secondary pollution is generated before and after treatment, and the treatment process is simple and easy to operate. The preparation method of the composite catalyst is simple, raw materials are easy to obtain, and the cost is low.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com