Composite catalyst as well as preparation method and application thereof

A composite catalyst, polyferric aluminum chloride technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of less catalyst and long catalytic degradation time (generally more than 6 hours, biochemical Risks and other issues, to achieve the effect of high degradation efficiency, good catalytic degradation activity, and short degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a composite catalyst, including biochar, polyferric aluminum chloride and green rust. The preparation method of this composite catalyst comprises the following steps:

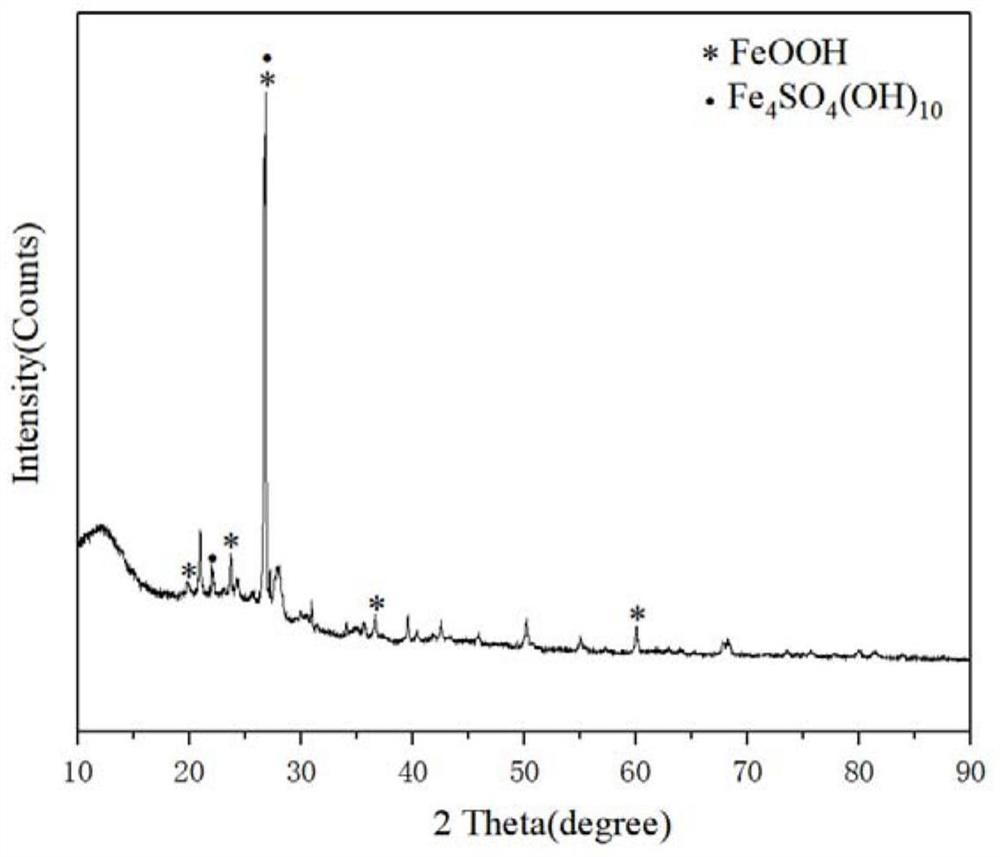

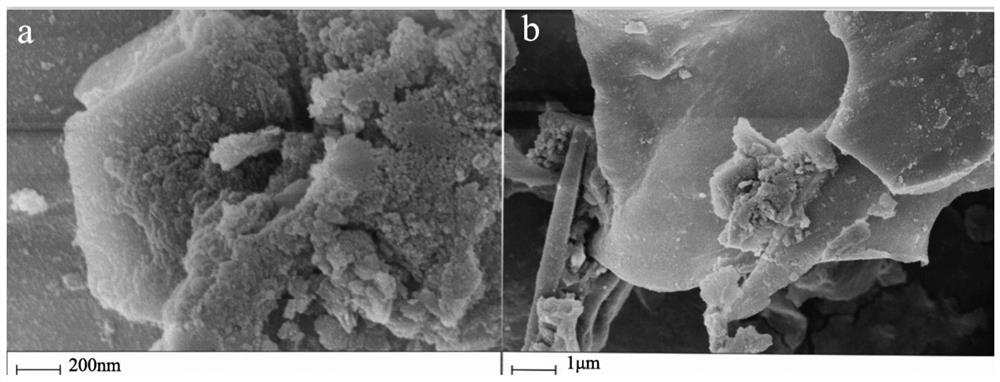

[0048] (1) Preparation of green rust

[0049] Prepare 0.05mol / LFe respectively 2 (SO 4 ) 3 solution, 0.2mol / L FeSO 4 ·7H 2 O solution and 1mol / L NaOH solution. FeSO was first added to the three-neck flask 4 ·H 2 O, Fe was added to the constant pressure burette respectively 2 (SO 4 ) 3 solution and NaOH solution. Under a nitrogen environment and magnetic stirring, open two constant pressure titration funnels, control the pH value to 7, stir the reaction at room temperature, heat up to 40°C, and age for 24 hours. After aging, centrifuge and dry to obtain the green rust product.

[0050] (2) Preparation of composite catalyst

[0051]Mix 25g of the green rust prepared in step (1), 40g of polyferric aluminum chloride and 100g of biochar, and stir magnetically at 90°C for...

Embodiment 2

[0062] This embodiment provides a composite catalyst, including biochar, polyferric aluminum chloride and green rust. The preparation method of this composite catalyst comprises the following steps:

[0063] (1) Preparation of green rust

[0064] Prepare 0.05mol / L Fe 2 (SO 4 ) 3 solution, 0.25mol / L FeSO 4 ·7H 2 O solution and 1mol / L NaOH solution. FeSO was first added to the three-neck flask 4 ·7H 2 O, Fe was added to the constant pressure burette respectively 2 (SO 4 ) 3 solution and NaOH solution. Under a nitrogen environment and magnetic stirring, two constant pressure titration funnels were opened, the pH value was controlled to be 7, the reaction was stirred at room temperature, and the mixture was heated and aged for 24 hours. After aging, centrifuge and dry to obtain green rust.

[0065] (2) Preparation of composite catalyst

[0066] Mix 20 g of the green rust prepared in step (1), 45 g of polyferric aluminum chloride and 100 g of biochar, and stir magneti...

Embodiment 3

[0070] This embodiment provides a composite catalyst, including biochar, polyferric aluminum chloride and green rust. The preparation method of this composite catalyst comprises the following steps:

[0071] (1) Preparation of green rust

[0072] Prepare 0.05mol / L Fe 2 (SO 4 ) 3 solution, 0.25mol / L FeSO 4 ·7H 2 O solution and 1mol / L NaOH solution. FeSO was first added to the three-neck flask 4 ·7H 2 O, Fe was added to the constant pressure burette respectively 2 (SO 4 ) 3 solution and NaOH solution. Under a nitrogen environment and magnetic stirring, two constant pressure titration funnels were opened, the pH value was controlled to be 7, the reaction was stirred at room temperature, and the mixture was heated and aged for 24 hours. After aging, centrifuge and dry to obtain green rust.

[0073] (2) Preparation of composite catalyst

[0074] Mix 15g of the green rust prepared in step (1), 45g of polyferric aluminum chloride and 100g of biochar, and stir magnetical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com