Patents

Literature

163results about How to "Remove comprehensively" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intravascular optical coherence tomography intravascular wall contour automatic identification method

ActiveCN110717888AOvercoming identificationOvercome the problem of extractionImage enhancementImage analysisRadiologyNuclear medicine

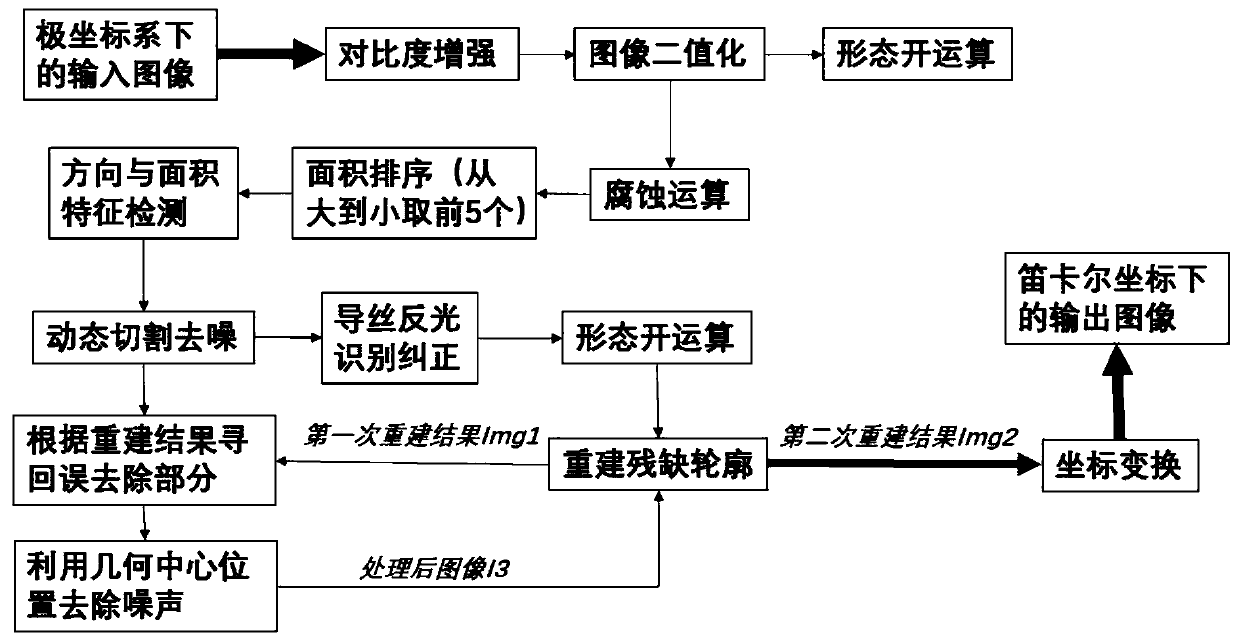

The invention relates to an intravascular optical coherence tomography intravascular wall contour automatic identification method. The method comprises the following steps: (1) preprocessing an original image Ori; (2) identifying the inner contour of the blood vessel wall, wherein the method comprises the following steps: step 1, carrying out corrosion operation; 2, sorting the areas; 3, carryingout morphological direction and area detection; 4, judging whether a guide wire exists or not; 5, identifying and correcting the guide wire; and 6, reconstructing an incomplete contour.

Owner:TIANJIN UNIV

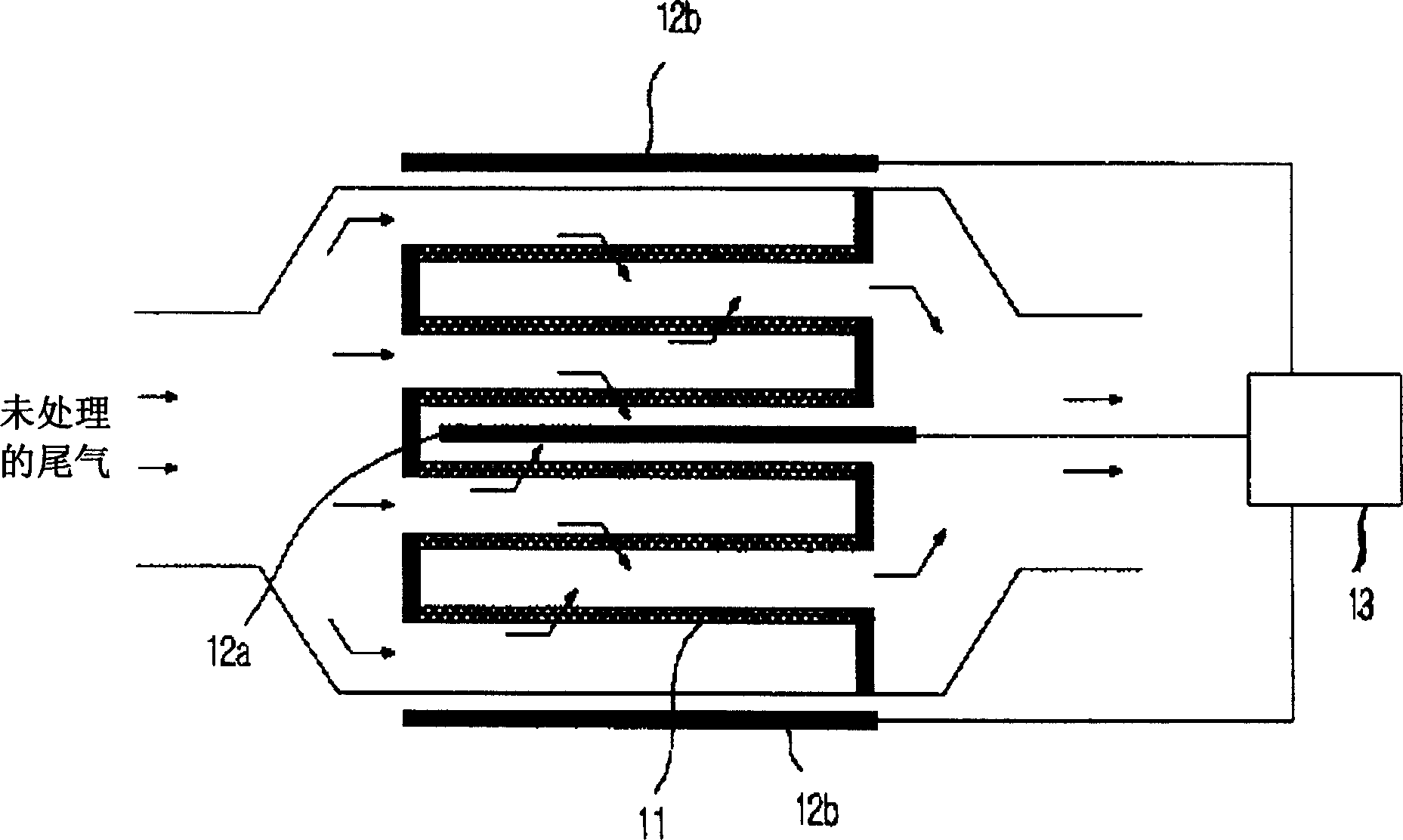

Apparatus for removing soot and NOx in exhaust gas from diesel engines

InactiveCN1420959ARemove comprehensivelyHuman health protectionDispersed particle filtrationHoneycombNitrogen oxide

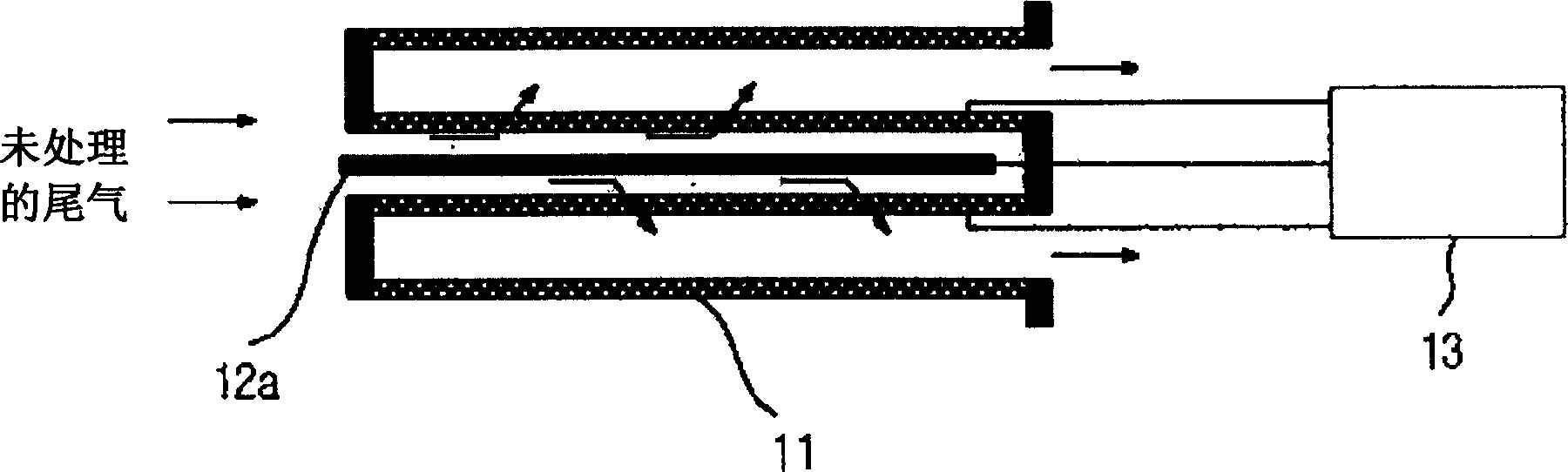

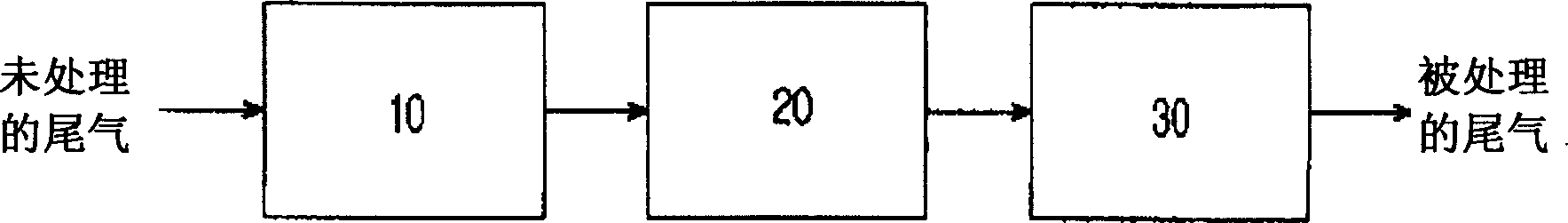

A plasma system is provided for removing soot and nitrogen oxide (NOx) in the exhaust gas of diesel engines. The system is comprised of a diesel particulate filter for adopting a honeycomb type porous element and at least one pair of electrodes; a plasma reactor for generating a predetermined amount of plasma, mounted downward or upward the diesel particulate filter; a catalytic reactor filled with a catalyst selected from 1B metal group, mounted downward the plasma reactor or the diesel particulate filter; and a means for supplying hydrocarbon to the exhaust gas, connected to a proper position upward the plasma reactor. Therefore, the soot and NOx in the exhaust gas, which are not only harmful to humans, but also which pollute the environment could be effectively removed under a normal pressure.

Owner:BLUE PLANET

Efficient flocculating agent for rapidly removing heavy metals in water

ActiveCN104261536AReduce moisture contentImproved separation propertiesWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionDissolutionCadmium Cation

The invention relates to an efficient flocculating agent for rapidly removing heavy metals in water. The efficient flocculating agent comprises a mixture A and a mixture B, wherein the mixture A comprises the following components in parts by mass: 100 parts of No.2 Hangjin soil, 5-10 parts of soil bacteria and 15-25 parts of activated carbon; and the mixture B comprises the following components in parts by mass: 10-20 parts of iron oxide, 10-20 parts of iron chloride, 20-50 parts of poly-aluminum chloride, 2.5-5 parts of an organic flocculating agent, 25-50 parts of cement and 16-32 parts of sodium thiosulfate. The efficient flocculating agent disclosed by the invention can be used for rapidly and effectively removing a variety of heavy metals such as mercury, lead, chromium, cadmium, arsenic and copper in the water, is short in reaction time, cannot cause secondary pollution, can be directly fed without early dissolution, is simple in use method, and can be widely applied to removal of the heavy metals in various industrial wastewater, polluted underground water, lakes, rivers and reservoirs.

Owner:佑景天(北京)国际水环境研究中心有限公司

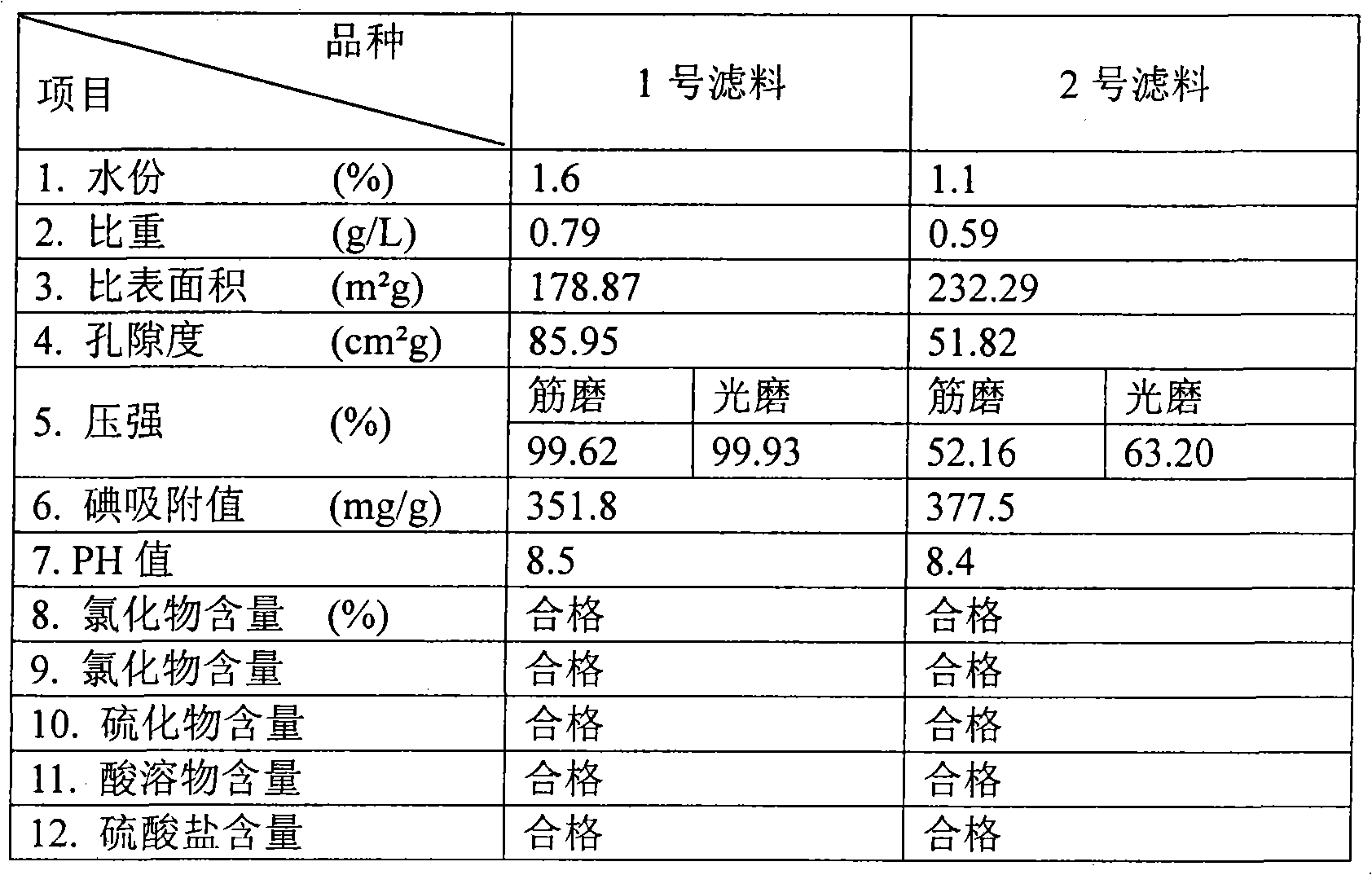

Composite filtering material for activating and regenerating coal ash and production method thereof

InactiveCN101274172ALow costReduce processingOther chemical processesFiltration separationFiltrationGranularity

The invention discloses a fly ash activation regeneration composite filtration material and a manufacture method of the filtration material, belonging to the field of water treatment technique. The fly ash activation regeneration composite filtration material consists of 80 to 90 portions of fly ashes or furnace ashes (by weight) with the grain diameter not less than 80 meshes and 10 to 20 portions of porous aluminosilicate mixed powders (by weight); the fly ash or the furnace ash are bonded as grain shape with the granularity less than 8mm; the porous aluminosilicate mixed powders are enwrapped on the surface of the fly ashes or the furnace ashes and burned so as to form a ceramic layer which is provided with an adsorption micro-hole which is communicated with an internal core. The fly ash activation regeneration composite filtration material is fabricated and formed by the steps of raw material mixing, primary granulation, secondary granulation, drying, roasting, etc., and has the advantages of low cost and good purification effect.

Owner:江苏正本净化节水科技实业有限公司

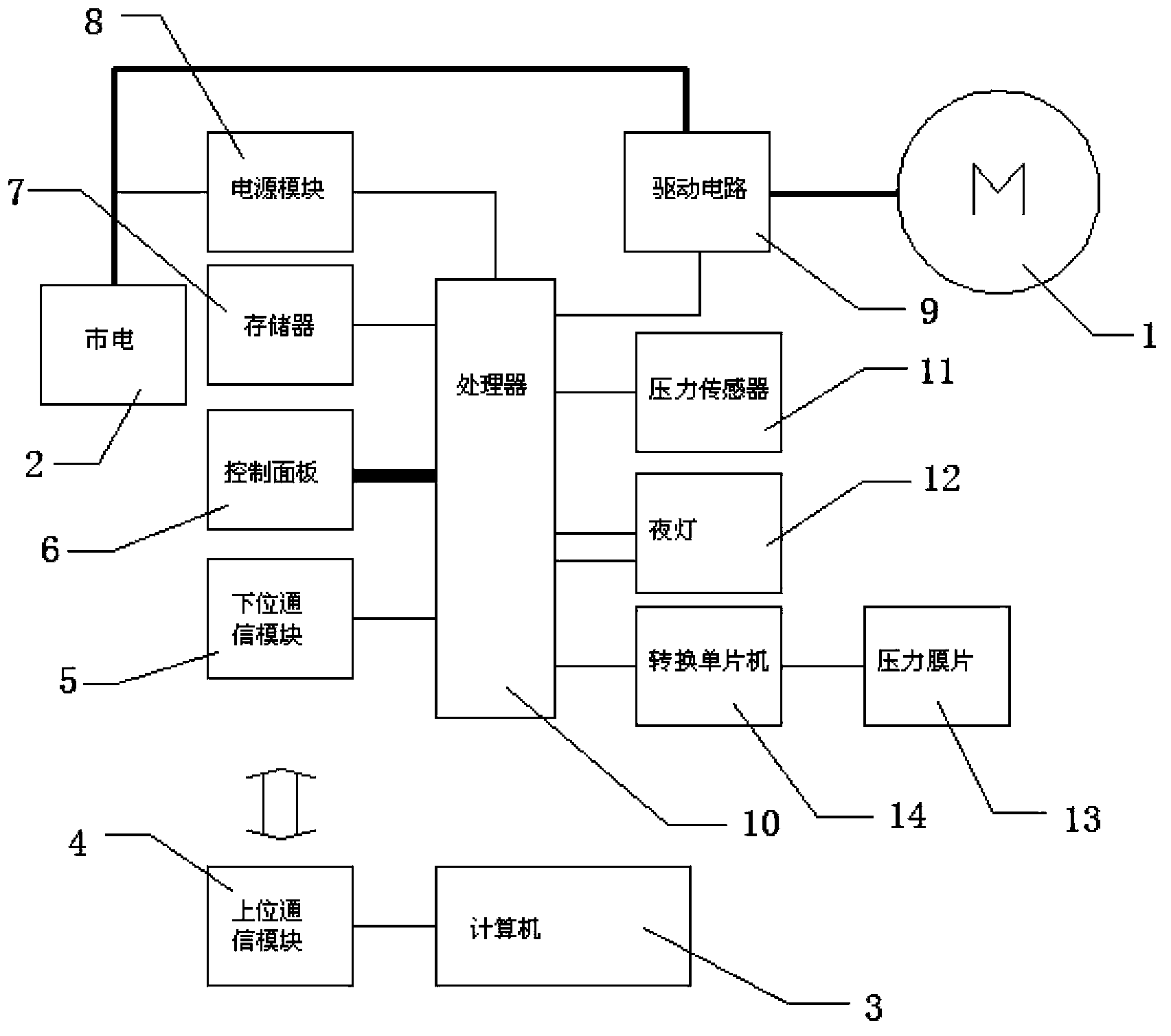

High-precision dynamic weighing sickbed system and automatic control method thereof

The invention relates to a high-precision dynamic weighing sickbed system and an automatic control method thereof and aims to solve the problems that weight detection of patients is not dynamic and in real time in the prior art, and errors cannot be removed completely. The key points of the technical scheme are as follows: the high-precision dynamic weighing sickbed system adopts commercial power for power supply and comprises a bed board, a bedstead, a control motor and support props and further comprises a control device and pressure sensors, wherein the bedstead is movably connected with the bed board and the control motor; the support props are provided with lifting cylinders; the bed board comprises an upper bed board and a lower bed board which are hinged to each other; the lower surfaces of the upper bed board and the lower bed board are both fixedly connected with the support props; the lifting cylinders are all driven by the control motor; the control motor is electrically connected with the control device; each support prop is provided with a pressure sensor; the pressure sensors are electrically connected with the control device.

Owner:HOUFU MEDICAL EQUIP

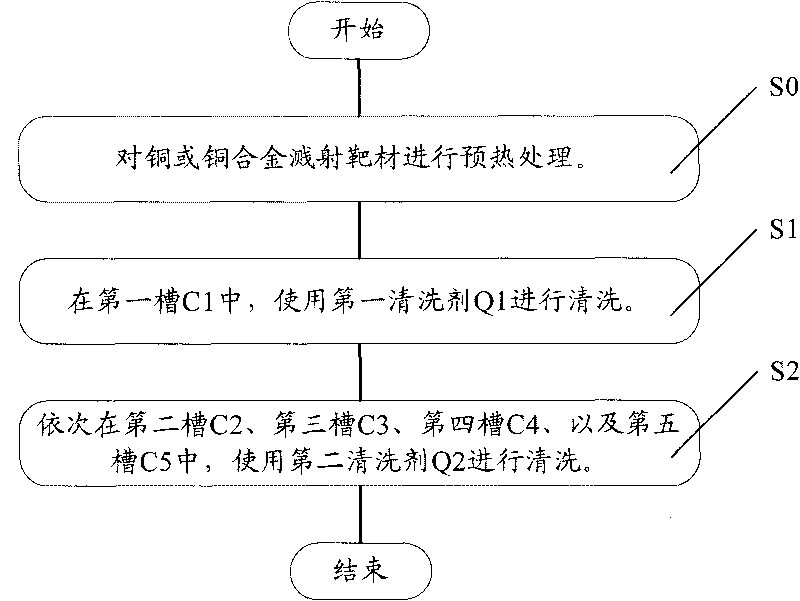

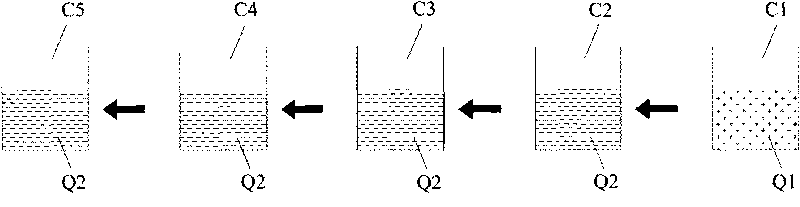

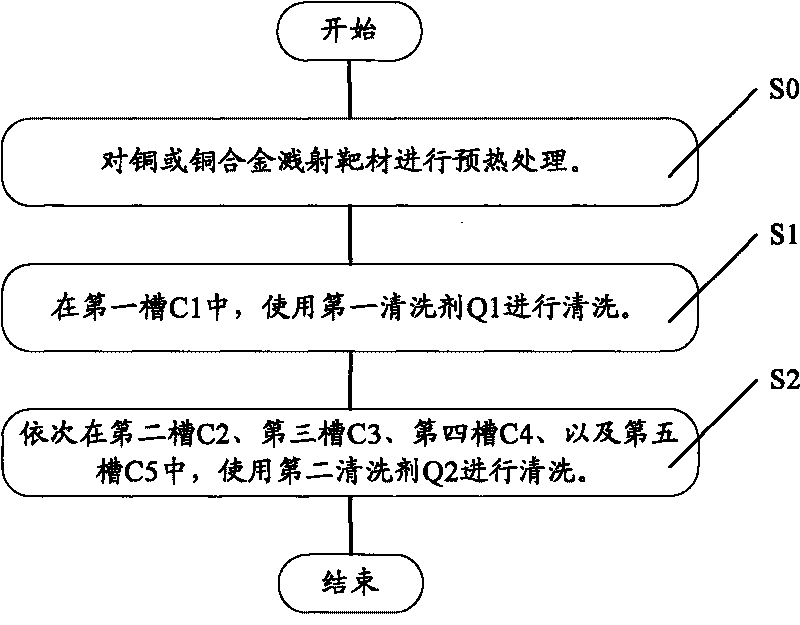

Method for cleaning copper or copper alloy sputtering target material

ActiveCN101724818ALow costRemove comprehensivelyVacuum evaporation coatingSputtering coatingSputteringOrganic solvent

The invention provides a method for cleaning a copper or copper alloy sputtering target material, which has at least two cleaning phases. In the first cleaning phase, a copper or copper alloy sputtering target material is cleaned at least once with a first cleaning agent solution; and in the second cleaning phase, the copper or copper alloy sputtering target material is cleaned at least once with a second cleaning agent solution. The first cleaning agent and the second cleaning agent are different and are independent water, organic solvents and any one of mixtures of a plurality of solvents respectively. In addition, the cleaning method can also comprises a preheating procedure before the first cleaning phase and a steam cleaning phase after the second cleaning phase. The invention can comprehensively remove oil contamination, dust, impurities, and the like fully, reduce the cleaning cost and obtain more favorable cleaning effect.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

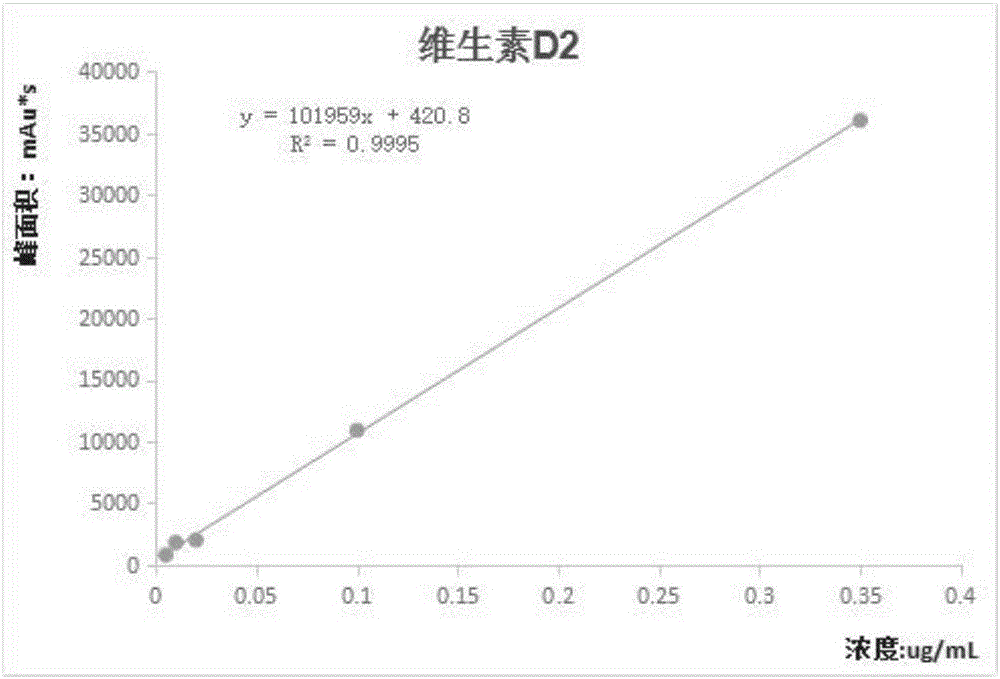

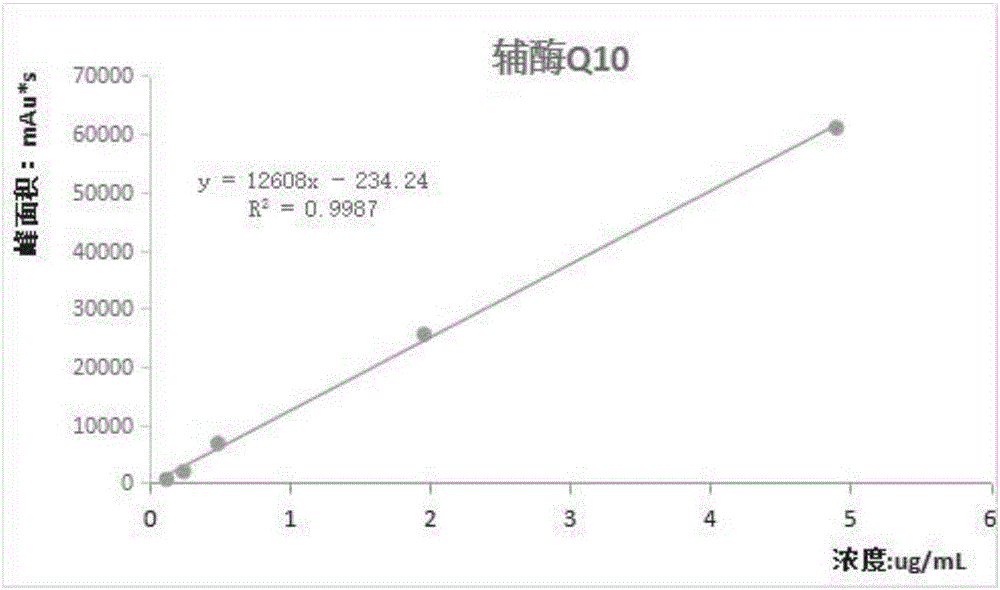

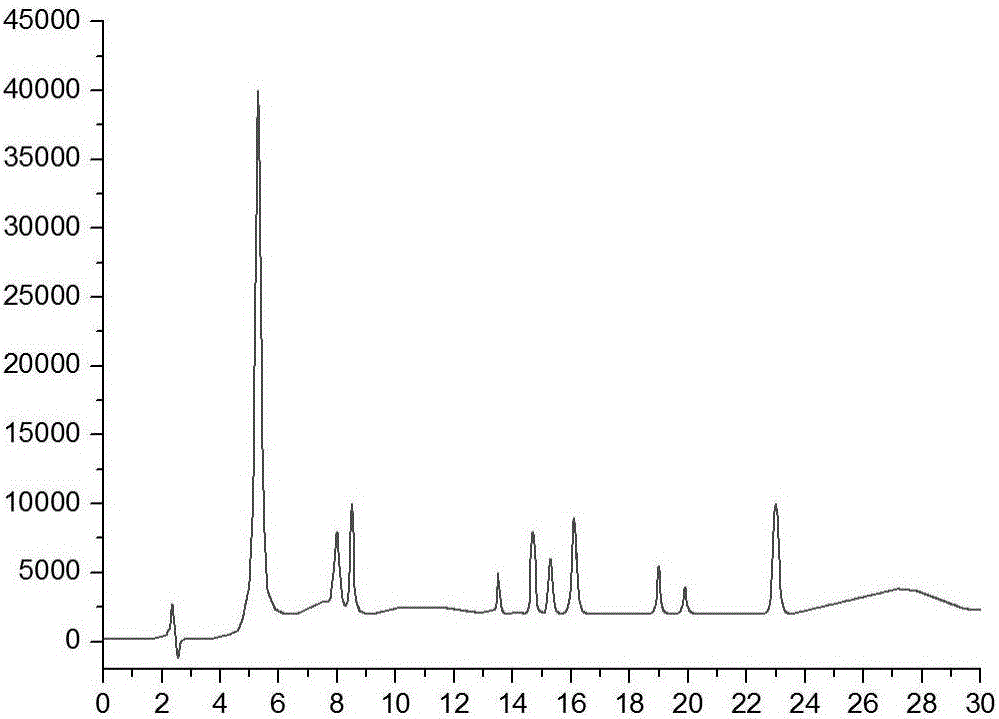

Method for determination of fat-soluble vitamins by using semi-automatic sample treatment liquid chromatographic technology

ActiveCN106404947ASimple sample handlingHigh throughputComponent separationChemistryFat-Soluble Vitamin

The invention discloses a method for simultaneous determination of various fat-soluble vitamins in serum by using a semi-automatic sample treatment liquid chromatographic technology; the HPLC method is adopted, and the chromatographic conditions comprise that a mobile phase A is a 0.05% trifluoroacetic acid aqueous solution, a mobile phase B is a 0.02% trifluoroacetic acid methanol-ethanol mixed solution, and gradient elution is adopted; the various fat-soluble vitamins are selected from vitamin A, vitamin D2, vitamin D3, alpha-tocopherol, beta-tocopherol, gamma-tocopherol, delta-tocopherol, K1, K2 or Q10. Through optimization of a sample pretreatment method and high performance liquid chromatographic conditions, the method for simultaneous determination of the various fat-soluble vitamins in the serum is established, can carry out precise qualitative and quantitative analysis, is a detection method having the advantages of simple and fast sample processing, high flux, reliable result and low cost, has the advantages of strong specificity, high sensitivity, simple operation, low cost and the like, has easily analyzed and objective results, and is especially suitable for clinical popularization and application.

Owner:济南国益生物科技有限公司

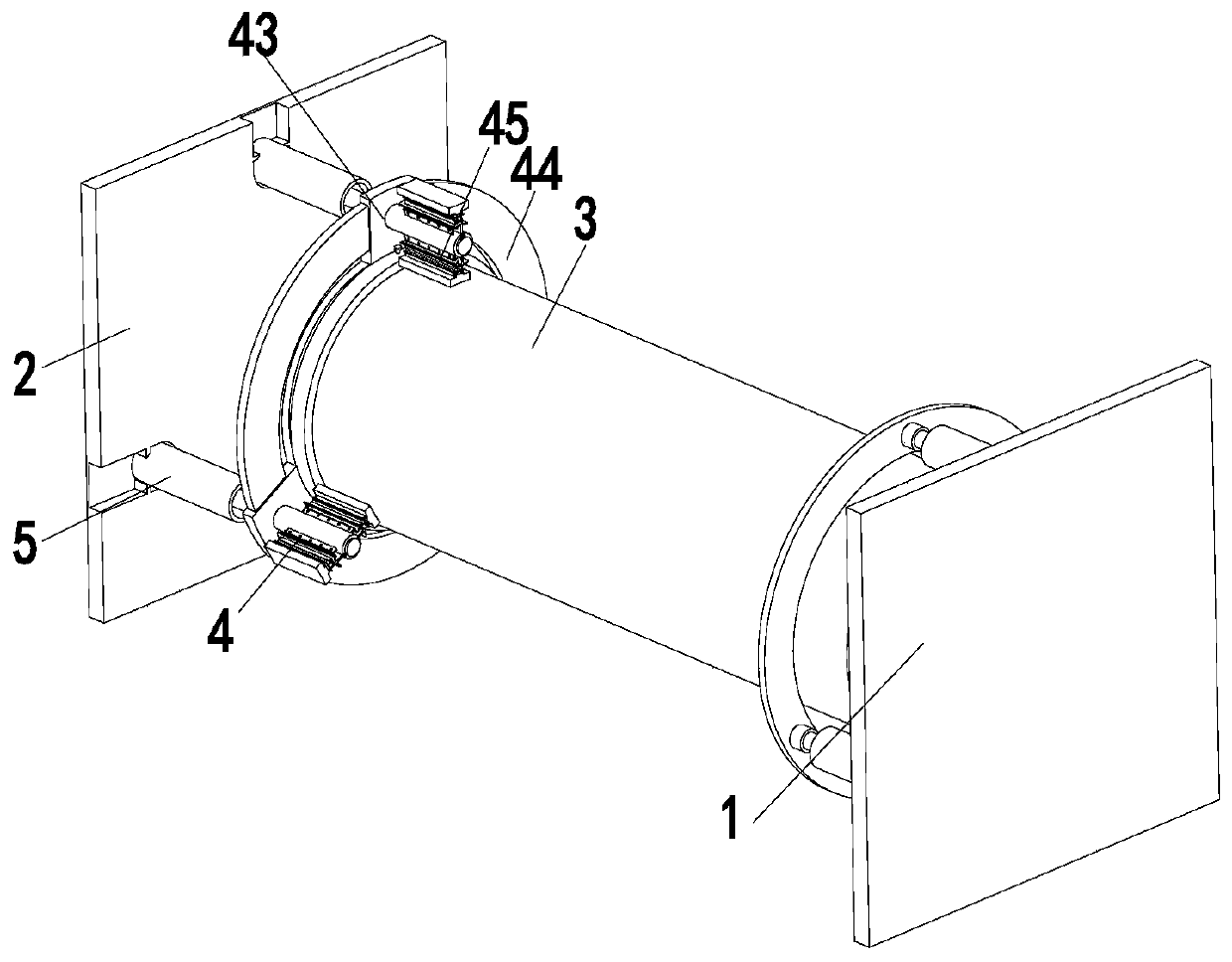

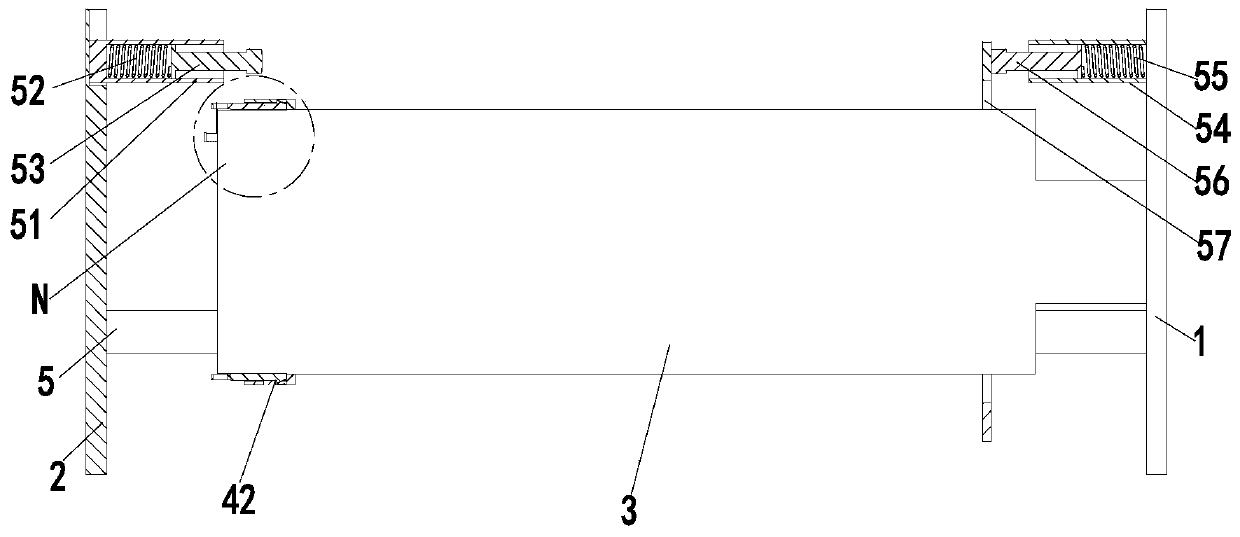

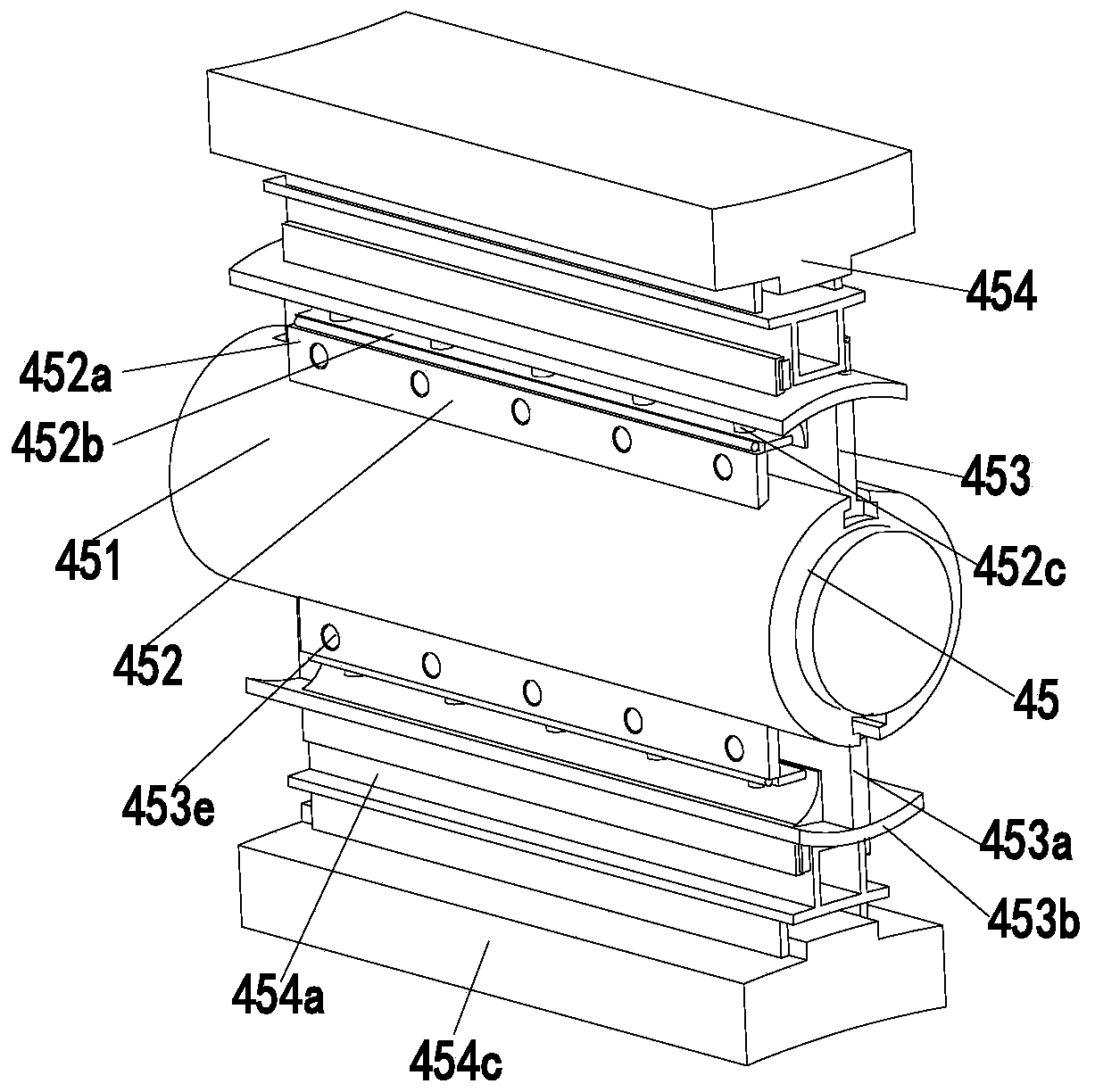

Printing cylinder of self-cleaning type printer

ActiveCN110077094ADisassembly does not need to be frequentExtended service lifeRotary pressesPrinting press partsEngineeringPrinting press

The invention relates to a printing cylinder of a self-cleaning type printer. The printing cylinder of the self-cleaning type printer comprises a first installing plate, a second installing plate, a printing cylinder body, a cleaning mechanism and an ejection mechanism; the printing cylinder body is installed on the side wall of the first installing plate through a bearing, the cleaning mechanismis installed on the printing cylinder body, the ejection mechanism is arranged at the left end of the cleaning mechanism, and the ejection mechanism is installed on the second installing plate; the cleaning mechanism comprises a linear bearing, an installing branch chain, rotating blocks, an electric rotating disc and cleaning branch chains; and the ejection mechanism comprises installing cylinders, ejection springs, ejection rods, fixing cylinders, reciprocating springs, reciprocating rods and collision rings. According to the printing cylinder of the self-cleaning type printer, the printingcylinder body is detachably installed, the occupation size is small, the printing cylinder does not need to be frequently disassembled, and therefore the service life of the printing cylinder is prolonged; and stains at any positions of the outer wall of the printing cylinder can be removed instead of a manual mode, cleaning brushes can not waggle in the cleaning process, and the cleaning effect is good.

Owner:苏州科士达印务有限公司

Preparation method of photocatalyst formaldehyde-removal blanket

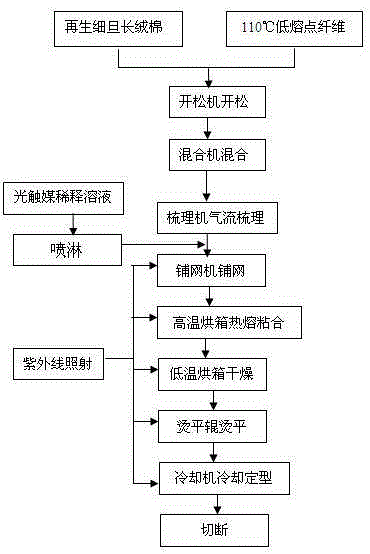

ActiveCN105420919AFast full loadRemove comprehensivelyDispersed particle separationTextile treatment by spraying/projectingFiberEngineering

The invention discloses a preparation method of a photocatalyst formaldehyde-removal blanket. Regenerated fine-denier long-stapled cotton and low-melting-point fiber with the temperature of 110 DEG C are selected as the raw materials, and meanwhile a photocatalyst dilute solution is prepared; regenerated fine-denier long-stapled cotton and low-melting-point fiber with the temperature of 110 DEG C are put into an opener to be opened and enter a carding machine to be carded after being mixed by a mixer, and a web is output; a high-pressure spraying gun is started to continuously and evenly spray the photocatalyst dilute solution to the upper surface of the web when the web is output by the carding machine to enter a web laying machine; when the web loaded with the photocatalyst dilute solution sequentially enters the web laying machine, a high-temperature oven, a low-temperature oven, an ironing roller and a cooling machine, an ultraviolet lamp is always turned on to irradiate nanometer titanium dioxide. A felt is rapidly and sufficiently loaded with the photocatalyst dilute solution through a spraying process, and the photocatalyst dilute solution has an efficient catalytic effect on removing formaldehyde through the ultraviolet lamp.

Owner:INTERIOR DECORATION MATERIALS CO LTD ZHENJIANGTONGDA

Method for purifying silicon through phase separation and dealloying

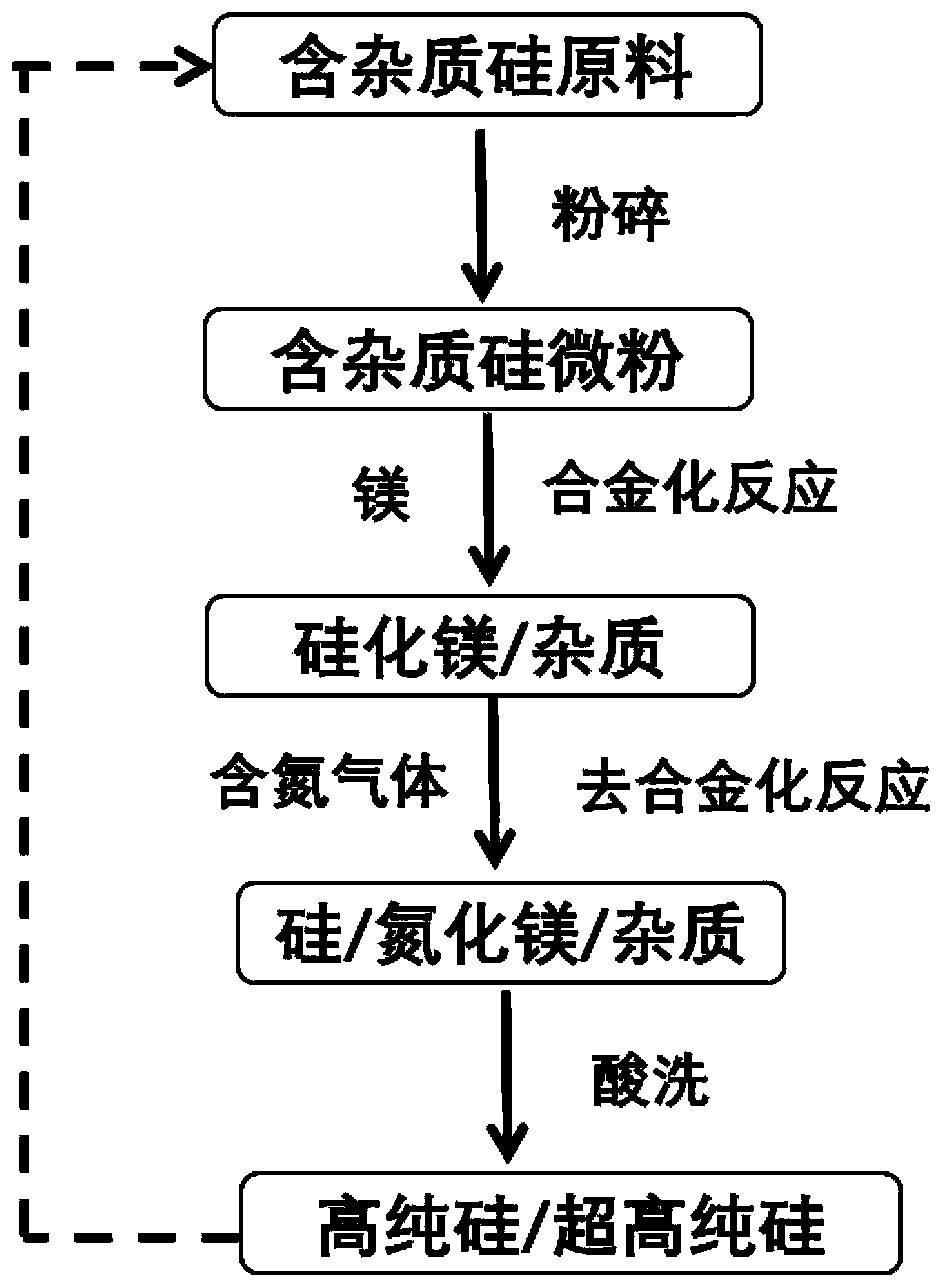

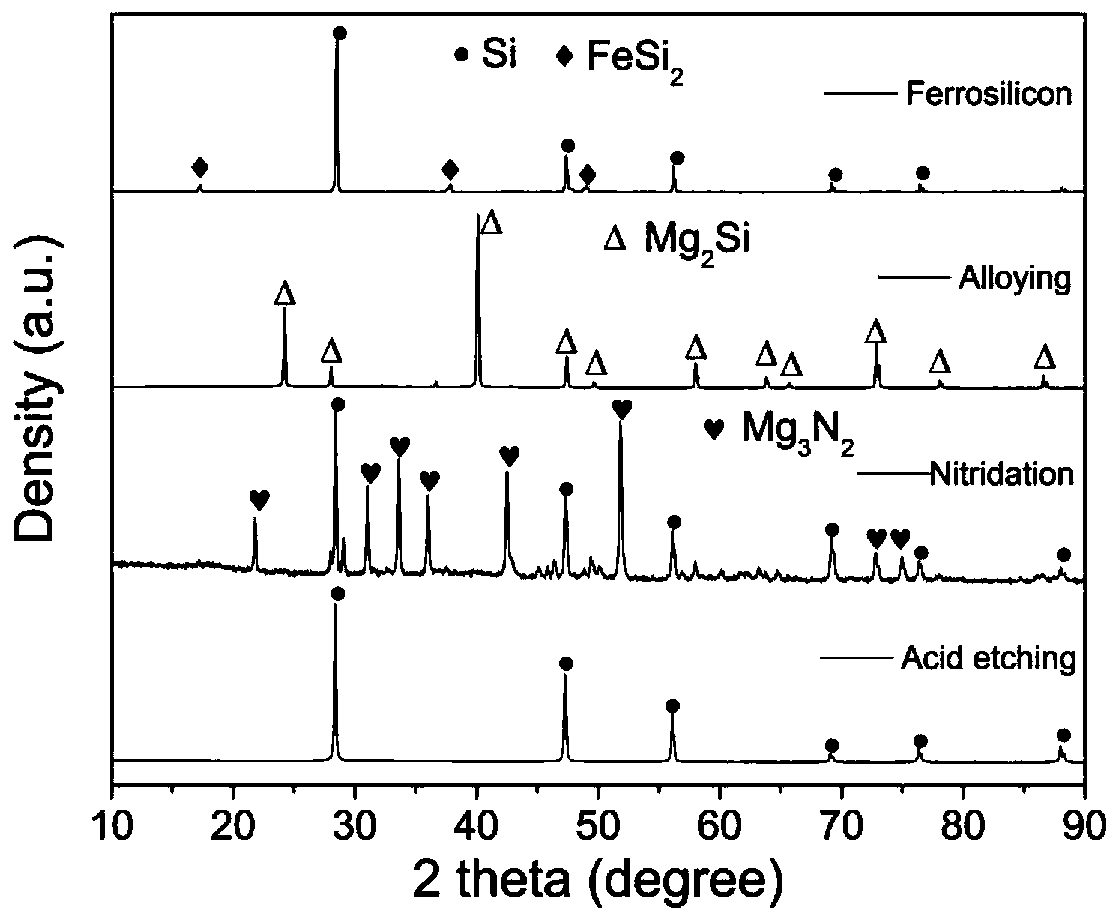

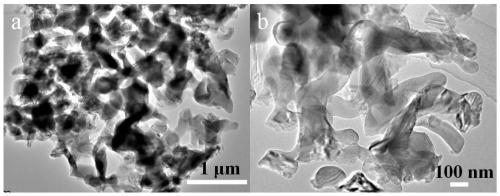

ActiveCN109941998AAchieve the first separationAchieve separationSilicon compoundsReaction temperatureMetal impurities

The invention belongs to the technical field of purification of silicon, and particularly relates to a method for purifying silicon through a phase separation and dealloying reaction method. Firstly,a silicon raw material containing metal or non-metal impurities is mixed with magnesium powder, and then a sufficient reaction is carried out under the inert atmosphere, so that silicon atoms in the silicon raw material react with magnesium to be converted into magnesium silicide, and the impurities in the silicon raw material are separated from silicon to obtain a first product; then the first product is subjected to a nitridation reaction under the nitrogenous atmosphere, the magnesium silicide in the first product is converted into liquid-phase magnesium nitride at the reaction temperature,silicon separates crystals from the liquid-phase magnesium nitride, three-dimensional porous silicon and magnesium nitride distributed in pore passages of the three-dimensional porous silicon are formed, and a second product is obtained; in the process of separating out the crystals by the silicon, the impurities are further separated and dissolved in the liquid-phase magnesium nitride; finally,the second product is treated through acid pickling, wherein the magnesium nitride and the impurities are dissolved and converted into a solution, and a solid product is high-purity porous silicon.

Owner:WUHAN UNIV OF SCI & TECH

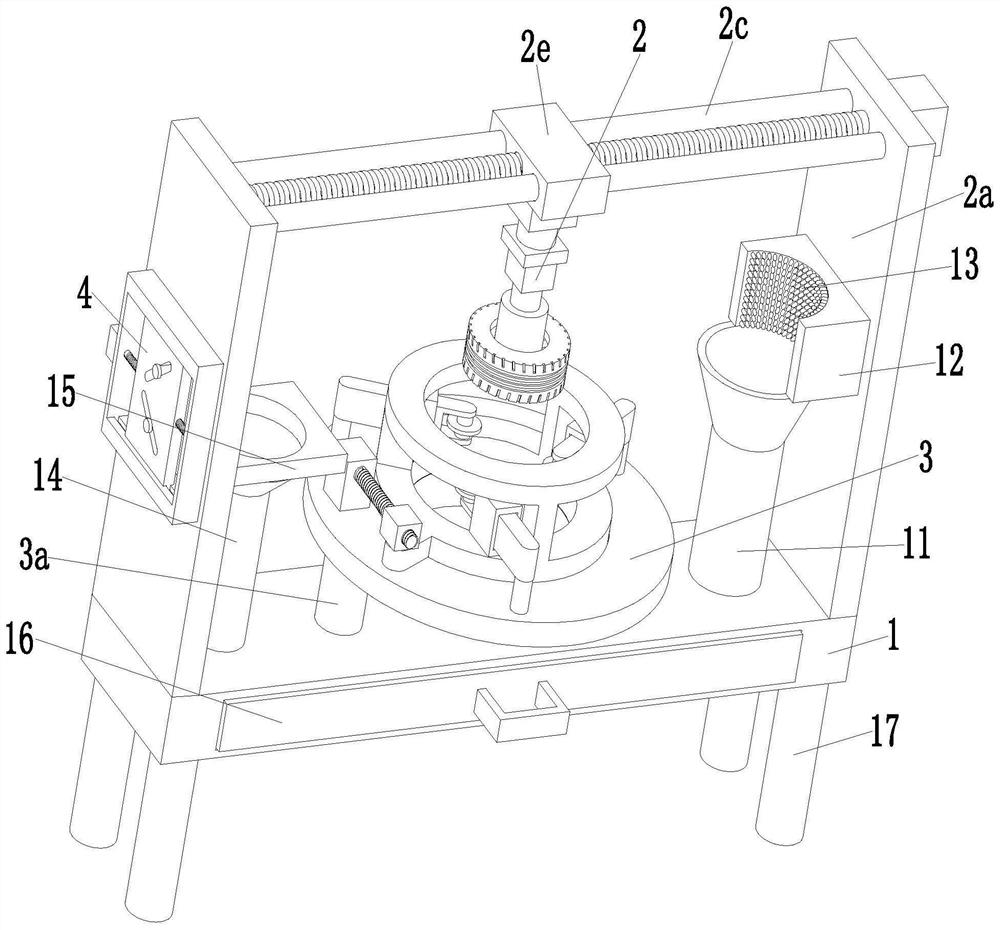

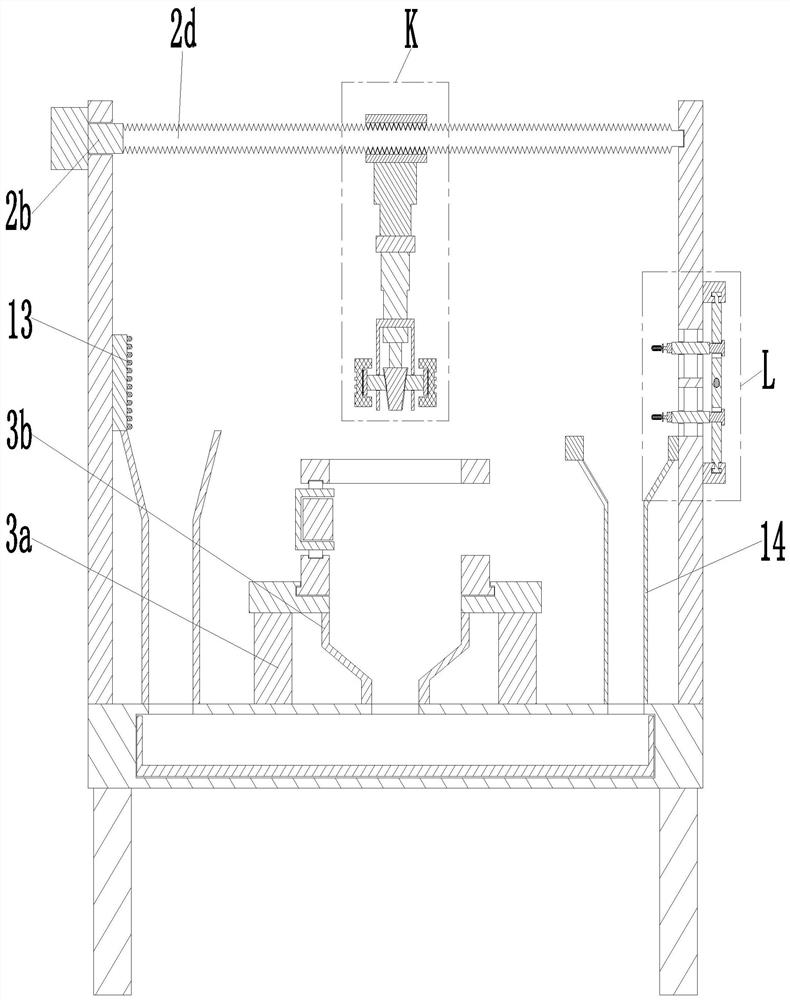

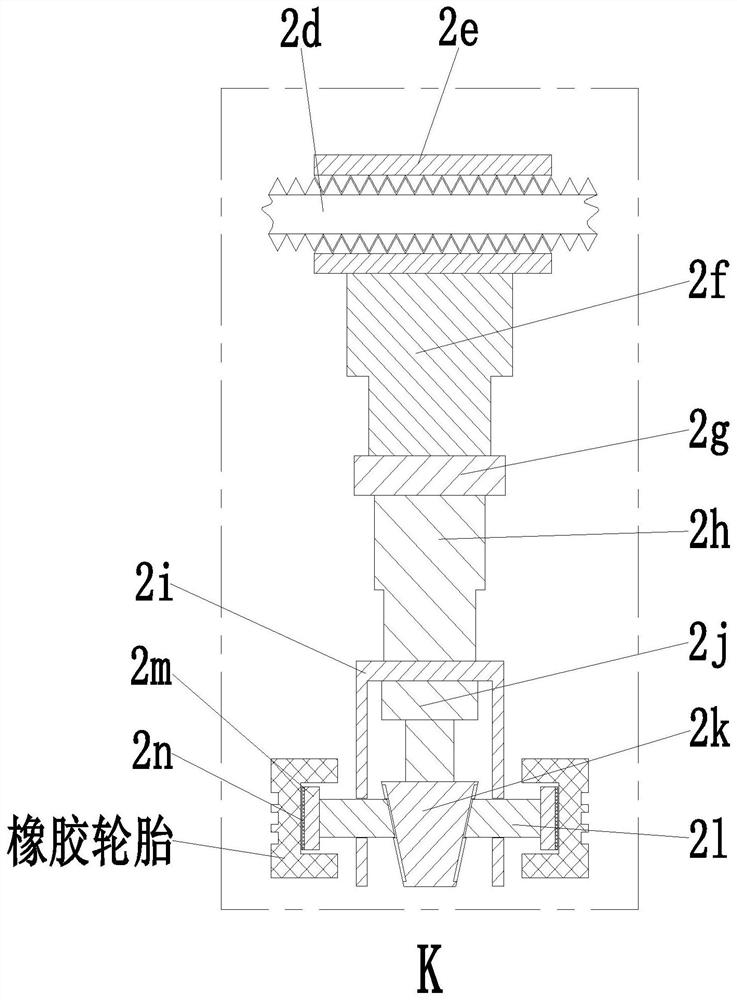

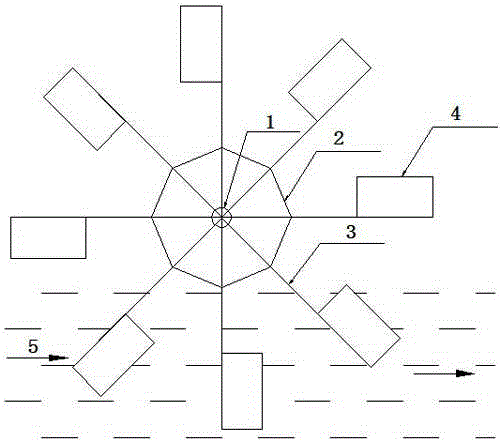

Surface treatment device used after rubber tire manufacturing and molding

ActiveCN111872785ALabor intensivePoor effectEdge grinding machinesGrinding carriagesAutomotive engineeringManufacturing engineering

The invention relates to a surface treatment device used after rubber tire manufacturing and molding. The surface treatment device comprises a bottom plate, a clamping device, a grinding device and agrinding removing device, wherein the clamping device is arranged on the bottom plate, the grinding removing device is arranged on the clamping device, and the grinding device is arranged at the middle end of the bottom plate. The surface treatment device can solve the following problems, existing in a rubber tire burr removing process at present, that 1, in the traditional rubber tire burr removing process, generally, a curved blade is manually held to conduct cutting, in the rubber burr removing process, the standing position of a user needs to be continuously adjusted, after rubber burrs onone side are removed, a tire needs to be turned over to conduct rubber burr removing operation on the other side, and the labor intensity of manual rubber tire burr removing is high; and 2, when burrs are removed through an existing rubber tire burr removing device, incomplete burr removing often occurs, the burrs after removal cannot be collected, the environmental sanitation is affected, and the rubber tire burr removing efficiency and effect can be affected.

Owner:江门腾晖橡胶有限公司

Aeration waterwheel

InactiveCN105174507AIncrease dissolved oxygen contentPromote degradationTreatment using aerobic processesWater aerationOxygen contaminationWater wheel

The invention belongs to the field of water pollution treatment and control, and relates to an aeration waterwheel for water body especially city rivers. The aeration waterwheel is characterized in that the aeration waterwheel comprises a waterwheel rotation shaft, a waterwheel blade and a container, the waterwheel blades is fixedly disposed on the waterwheel rotation shaft, and the tail end of the waterwheel blade is provided with the container. The aeration waterwheel rotates under the driven effect of flowing water body, the container is taken to a position under the liquid level and releases air, and then is taken to a position above the liquid level and holds air, and thus the aeration process of the waterwheel is finished. The aeration waterwheel is capable of increasing dissolved oxygen content in water body and reducing oxygen-consumed pollutants in water body, is pushed by means of water body, automatically runs, consumes zero or a little of electricity, and is low in running cost.

Owner:邱光稳

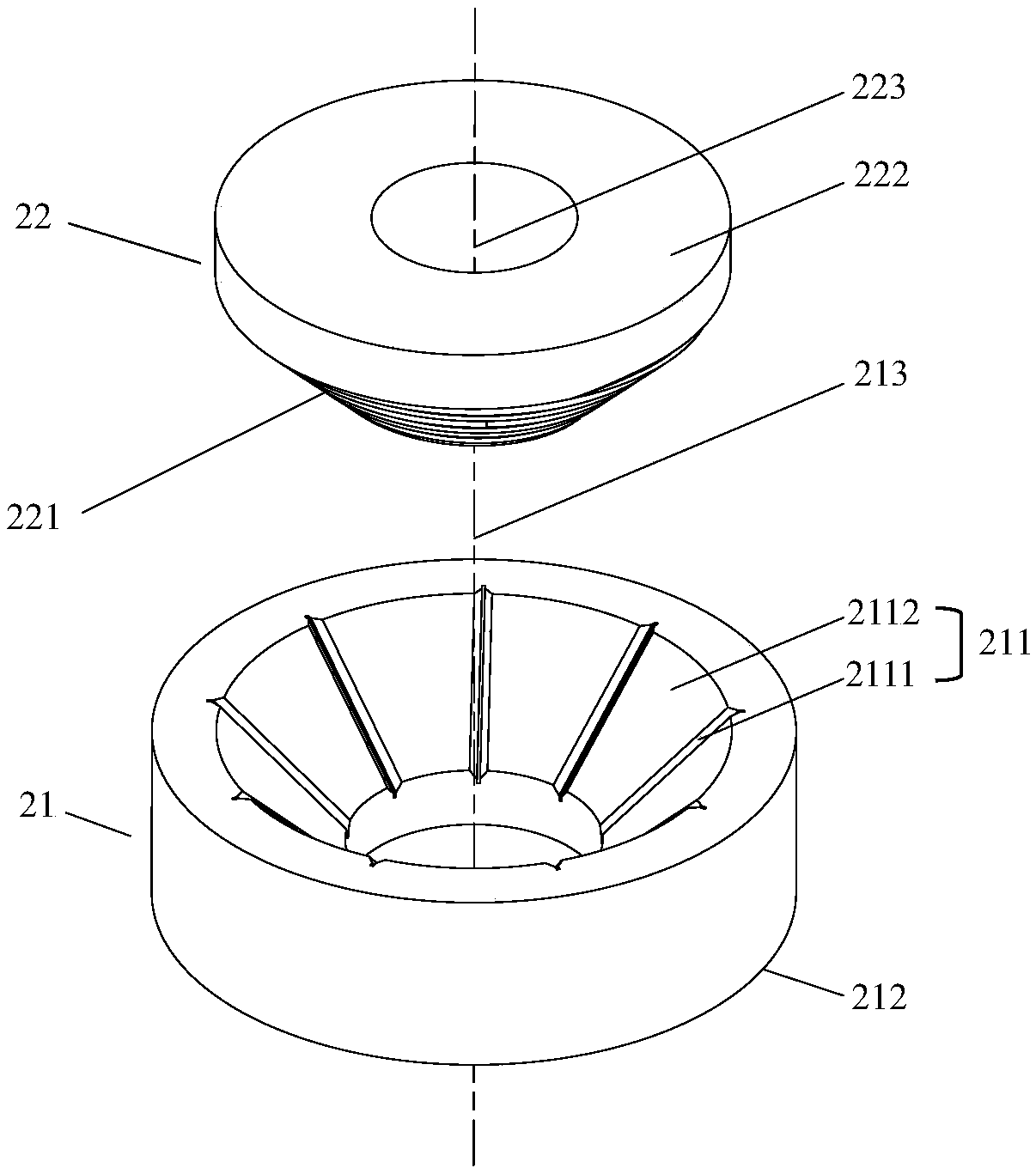

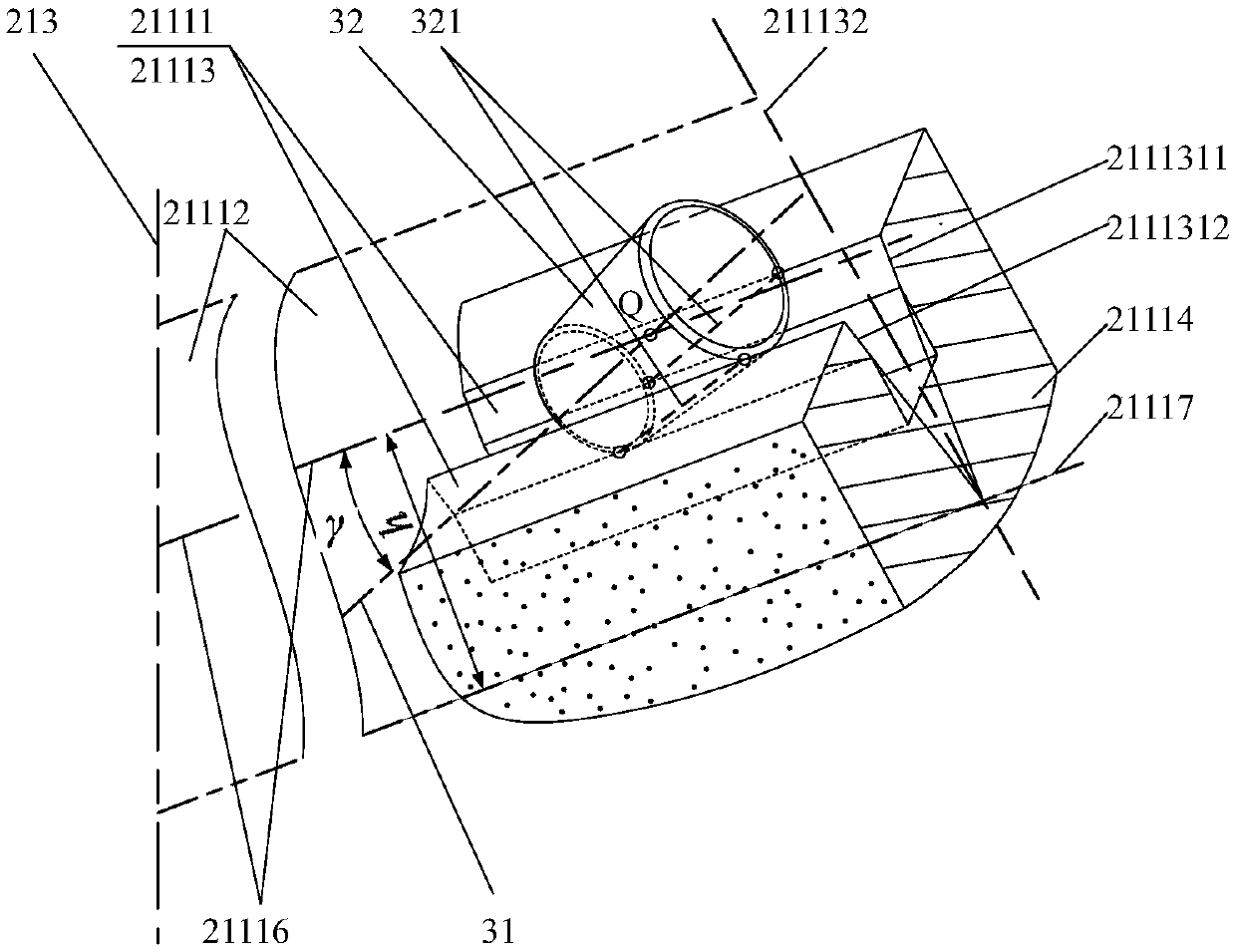

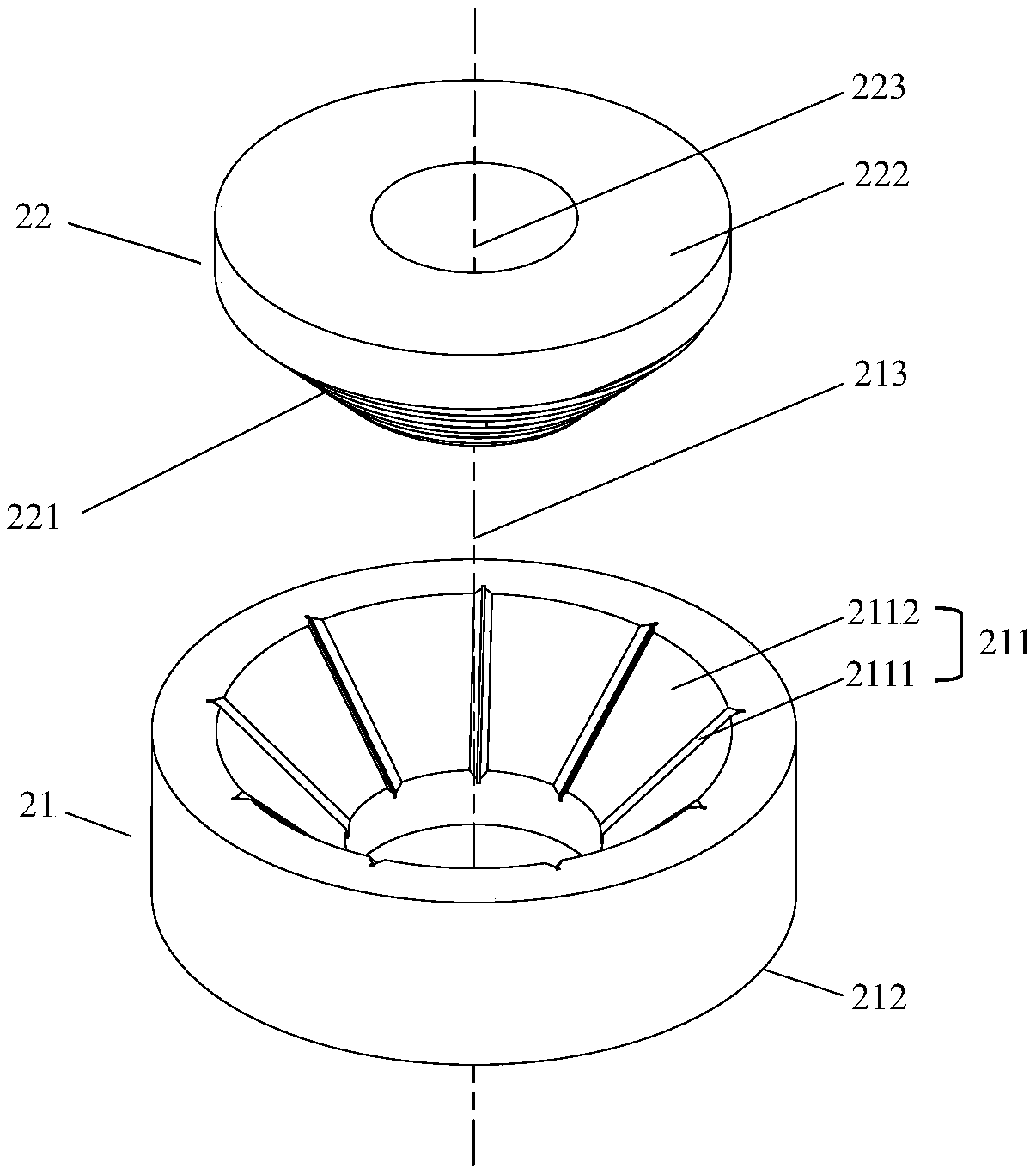

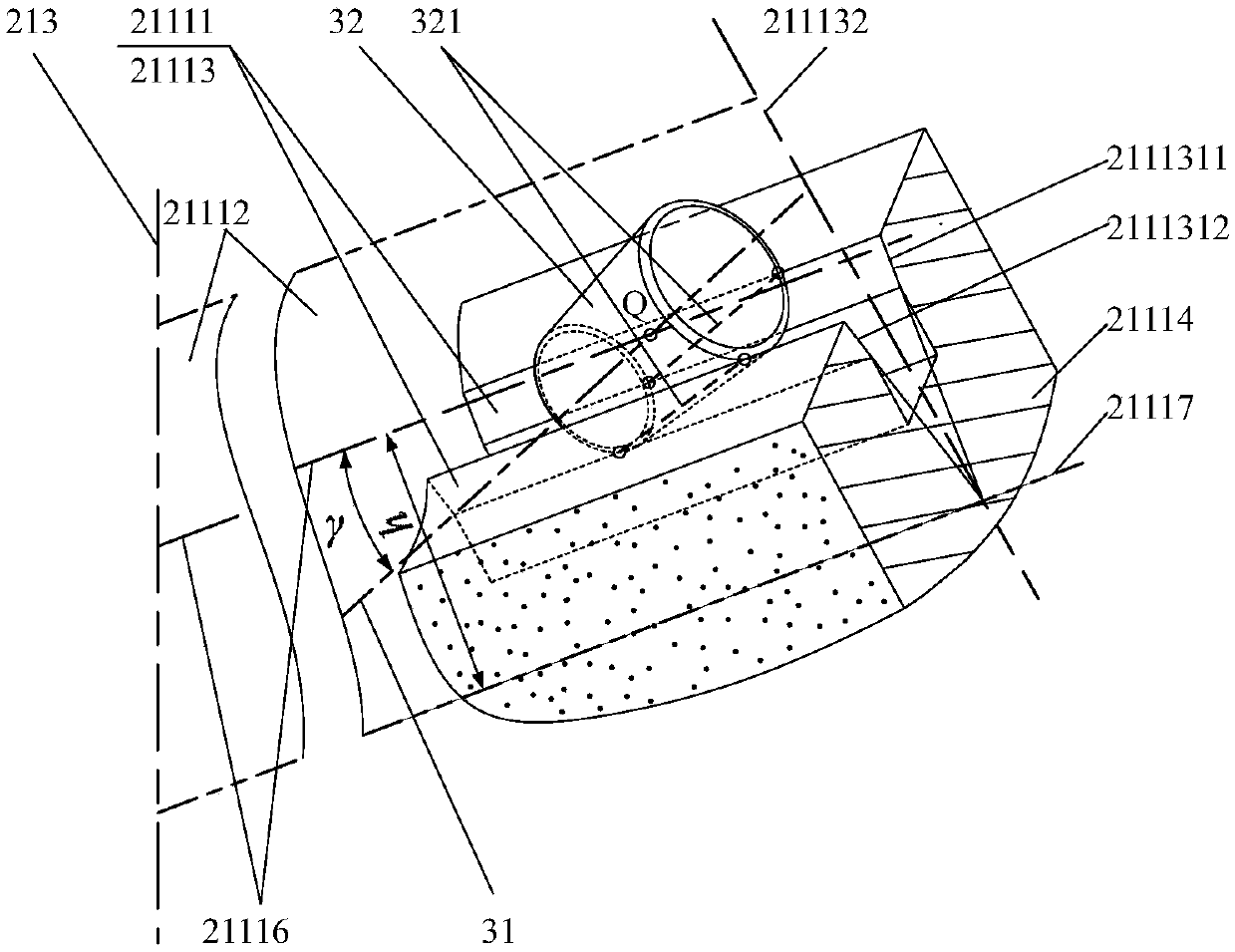

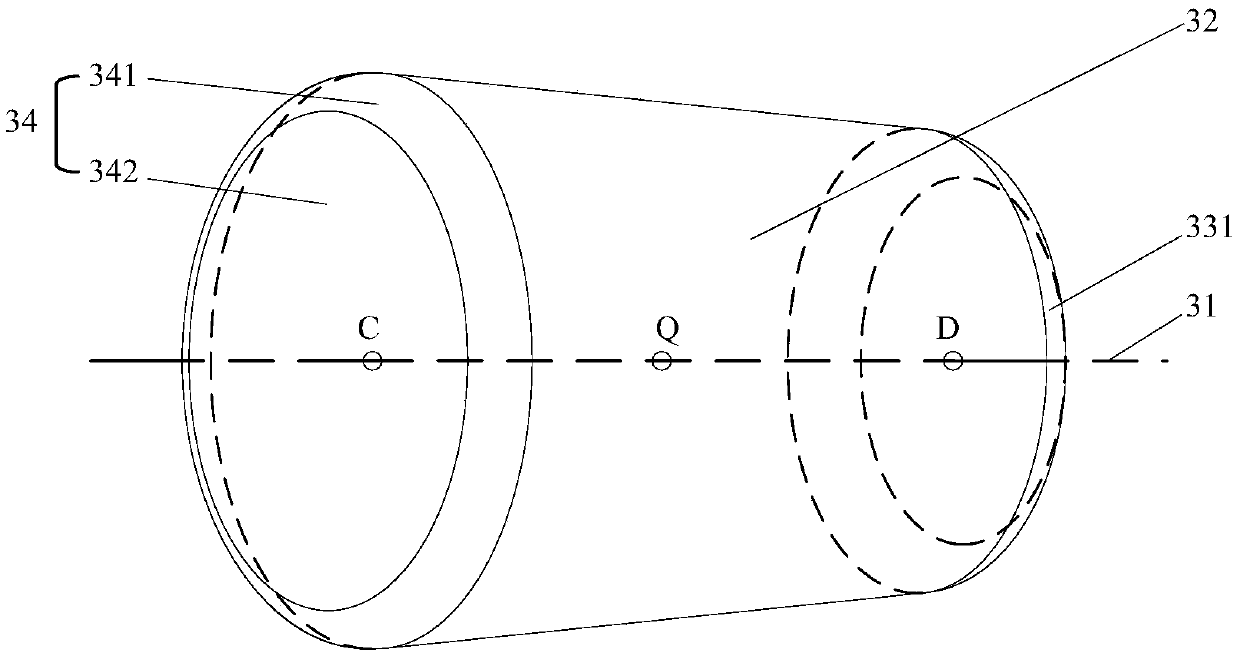

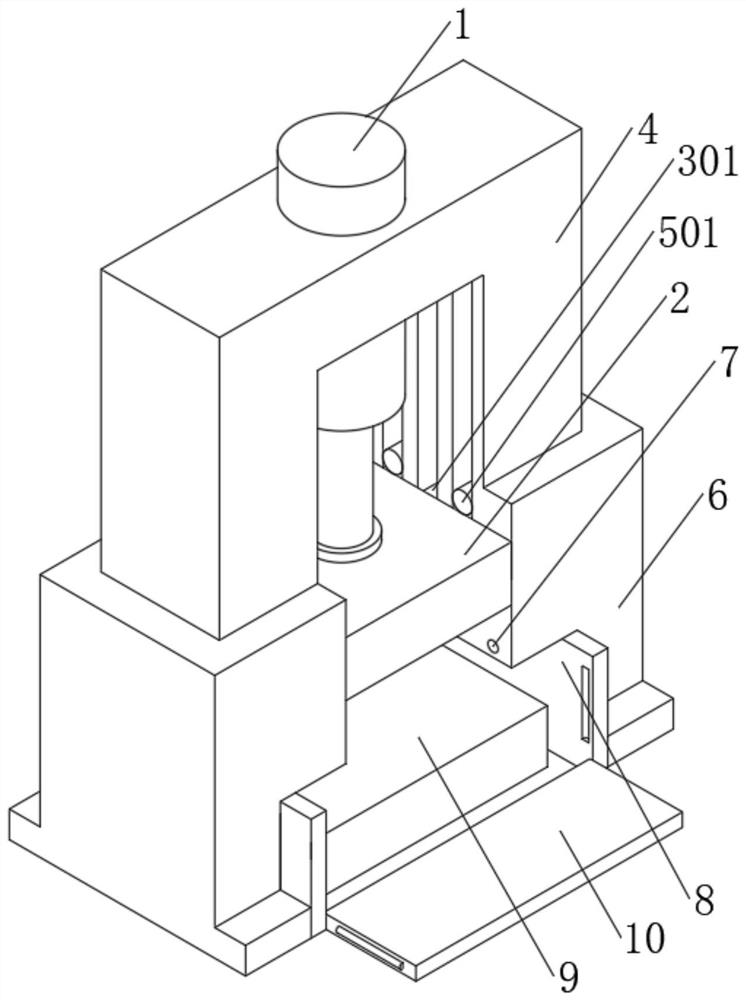

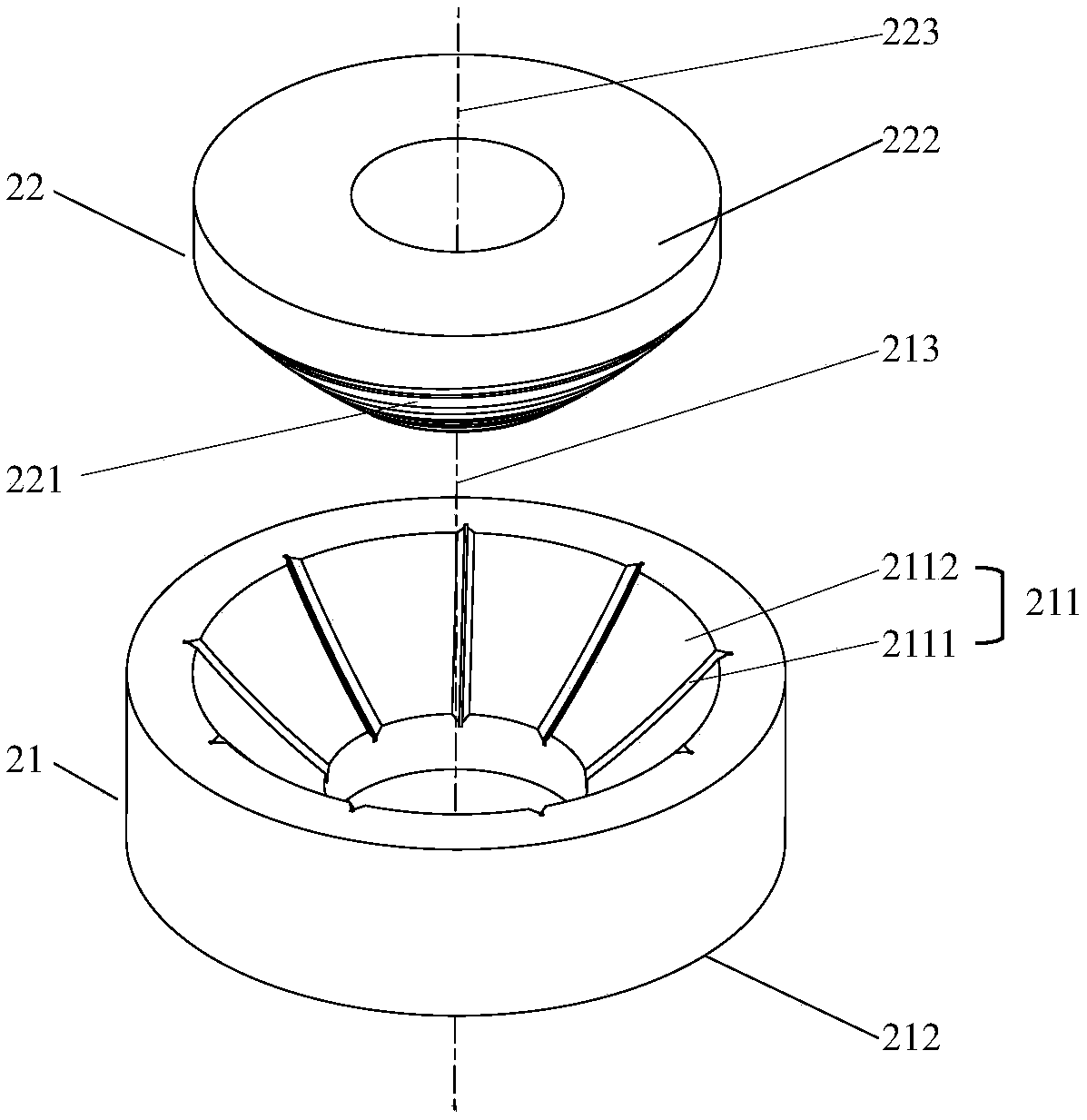

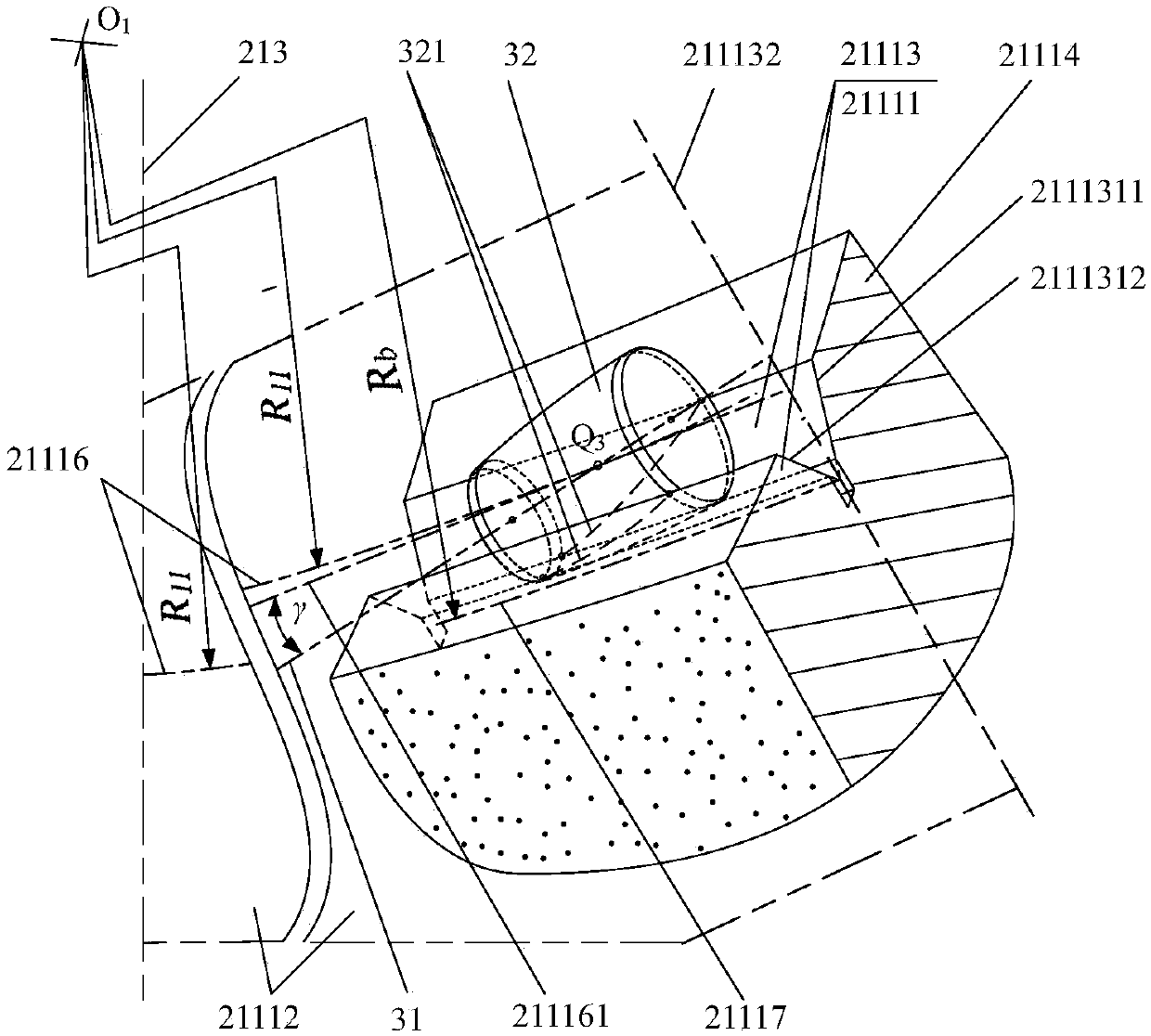

Grinding disc used for precise processing of rolling surface of tapered roller and equipment method

PendingCN108723979AReduce removalRemove comprehensivelyLapping machinesLapping toolsCircular discEngineering

The invention discloses grinding equipment used for precise processing of the rolling surface of a tapered roller and a grinding disc sleeving piece. The grinding equipment comprises main equipment, the grinding disc sleeving piece and a roller circular disc external system, the main equipment comprises a base, an upright column, a beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device, and the roller circular disc external system comprises a roller collecting device, a roller transporting system, a roller arrangement system and a roller feed-in mechanism; the grinding disc sleeving piece comprises a pair of coaxially arranged first and second grinding discs of which the front surfaces are opposite to each other, the front surface of the first grinding disc comprises a set of linear grooves distributed on the base surface (right circular conical surface) of the first grinding disc in a radial form, the front surface of the second grinding disc comprises one or more spiral grooves distributed on the base surface (right circular conical surface) of the second grinding disc, and the sum of the cone apex angles of the base surfaces of the first and second grinding discs is 360 degrees. The grinding equipment has the precise processing capacity to process the rolling surfaces of mass tapered rollers.

Owner:TIANJIN UNIV

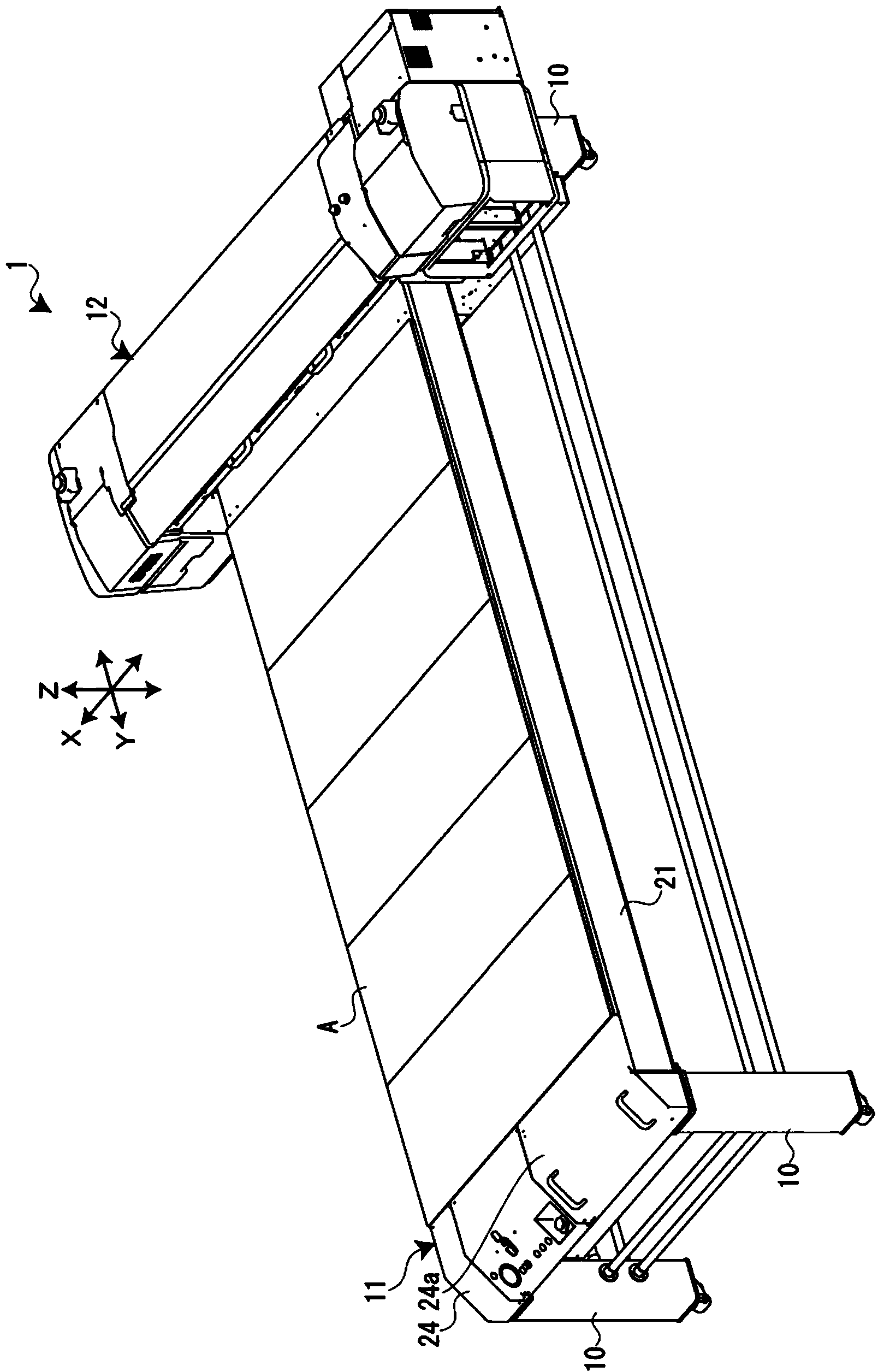

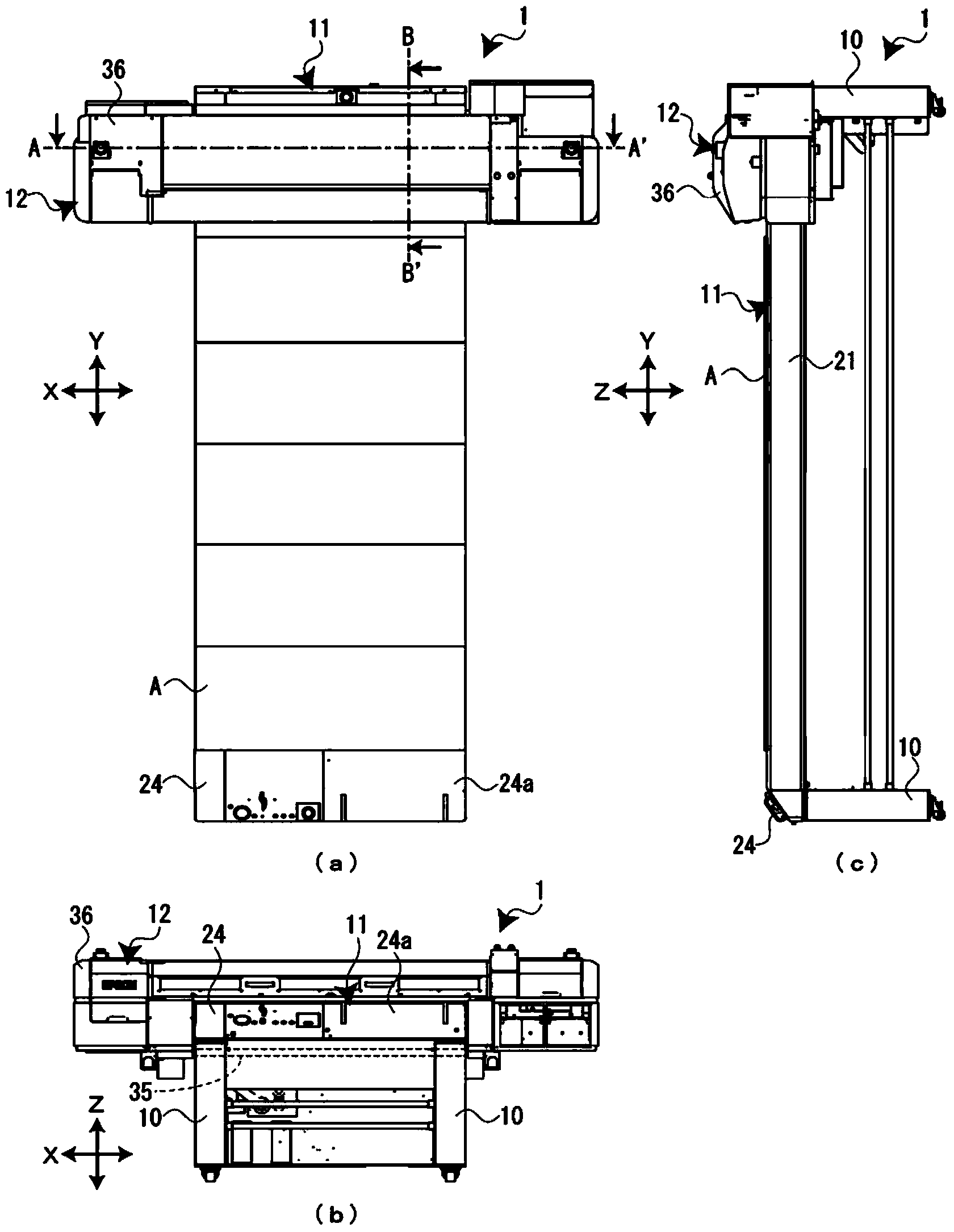

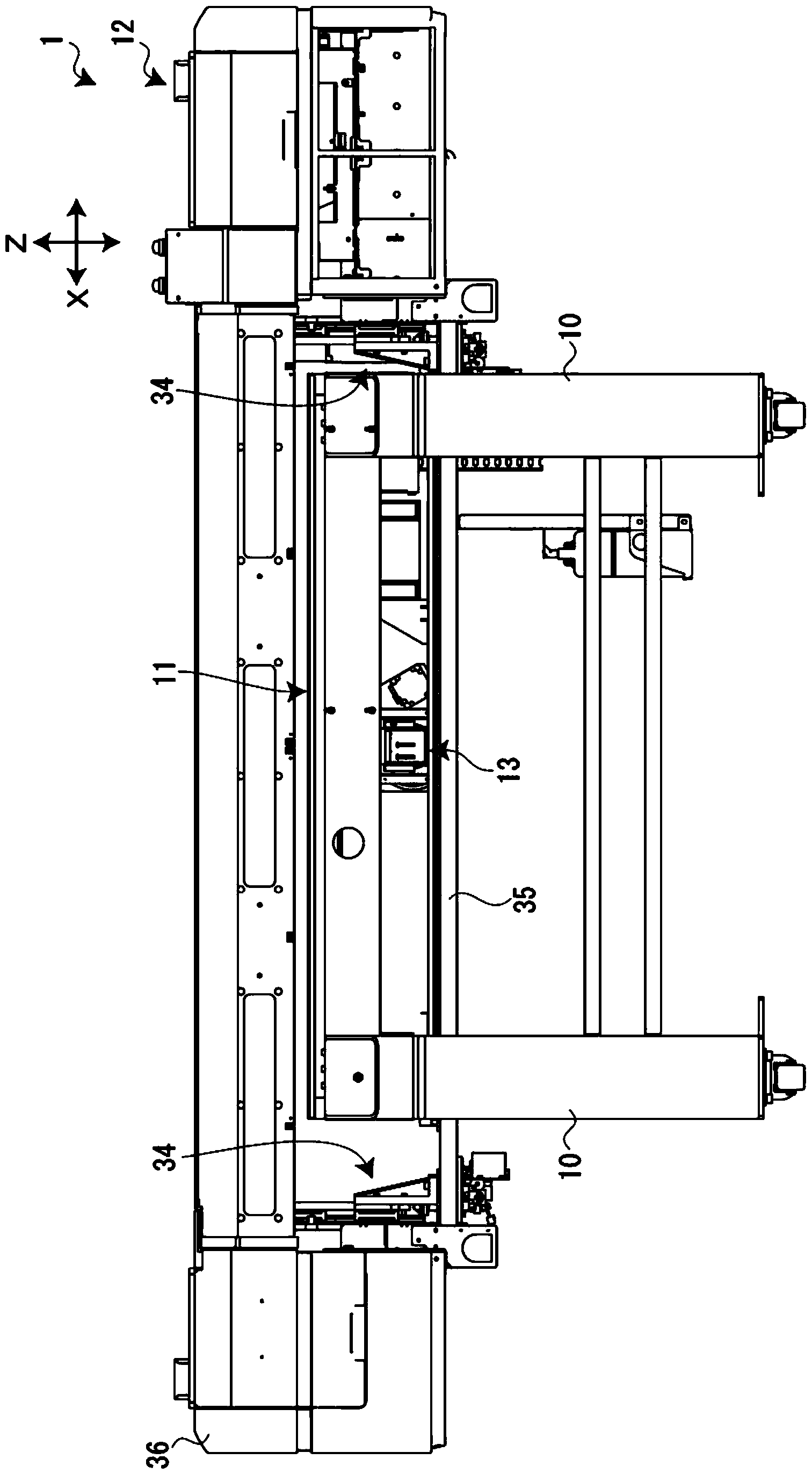

Liquid ejecting apparatus

ActiveCN104070798ARemove comprehensivelyTypewritersOther printing apparatusUltraviolet irradiationSupport surface

A liquid ejecting apparatus includes a support stage; a liquid ejecting unit that ejects an ink; an ultraviolet irradiation unit that has an intake port, an exhaust port and a filter; a guide axis that supports the liquid ejecting unit and the ultraviolet irradiation unit; an X-axis driving mechanism that moves the liquid ejecting unit and the ultraviolet irradiation unit; a liquid ejecting portion that has the guide axis and the X-axis driving mechanism; and a ventilation fan that causes a gas to flow between the liquid ejecting portion and the support surface. The ultraviolet irradiation unit is supported by the X-axis driving mechanism on a rear side. The exhaust port is arranged on a front side, and the intake port is arranged thereabove.

Owner:SEIKO EPSON CORP

Compound enzyme detergent powder

InactiveCN105462695AImprove decontamination abilityHave synergistic effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAmylaseCarboxymethyl cellulose

The invention provides compound enzyme detergent powder. The compound enzyme detergent powder comprises the following components in percentage by mass: 0.5-3% of compound enzyme, 10-20% of alkyl benzene sulfonic acid, 10-20% of sodium carbonate, 10-25% of sodium silicate, 30-60% of anhydrous sodium sulfate, 1-10% of carboxymethyl cellulose (CMC), 0.1-1% of a fluorescent brightening agent, 5-15% of speckles, and 0.5-3% of a perfume. The compound enzyme is compounded from two or more of alkaline protease, amylase, lipase and cellulase. The compound enzyme is added in the compound enzyme detergent powder provided by the invention, so that the dirt-removing power of the detergent powder is improved.

Owner:天津市天亨洗涤剂有限公司

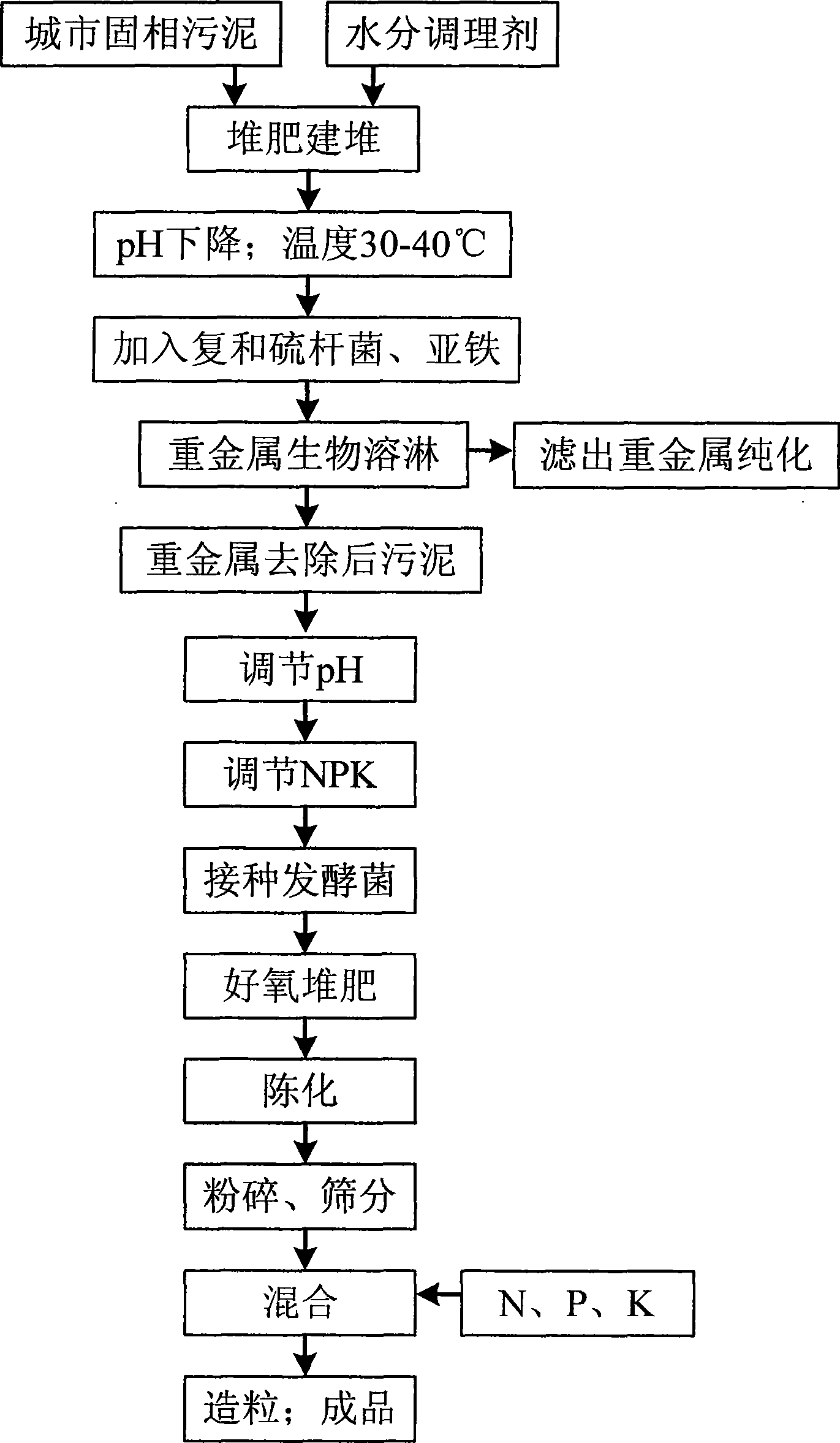

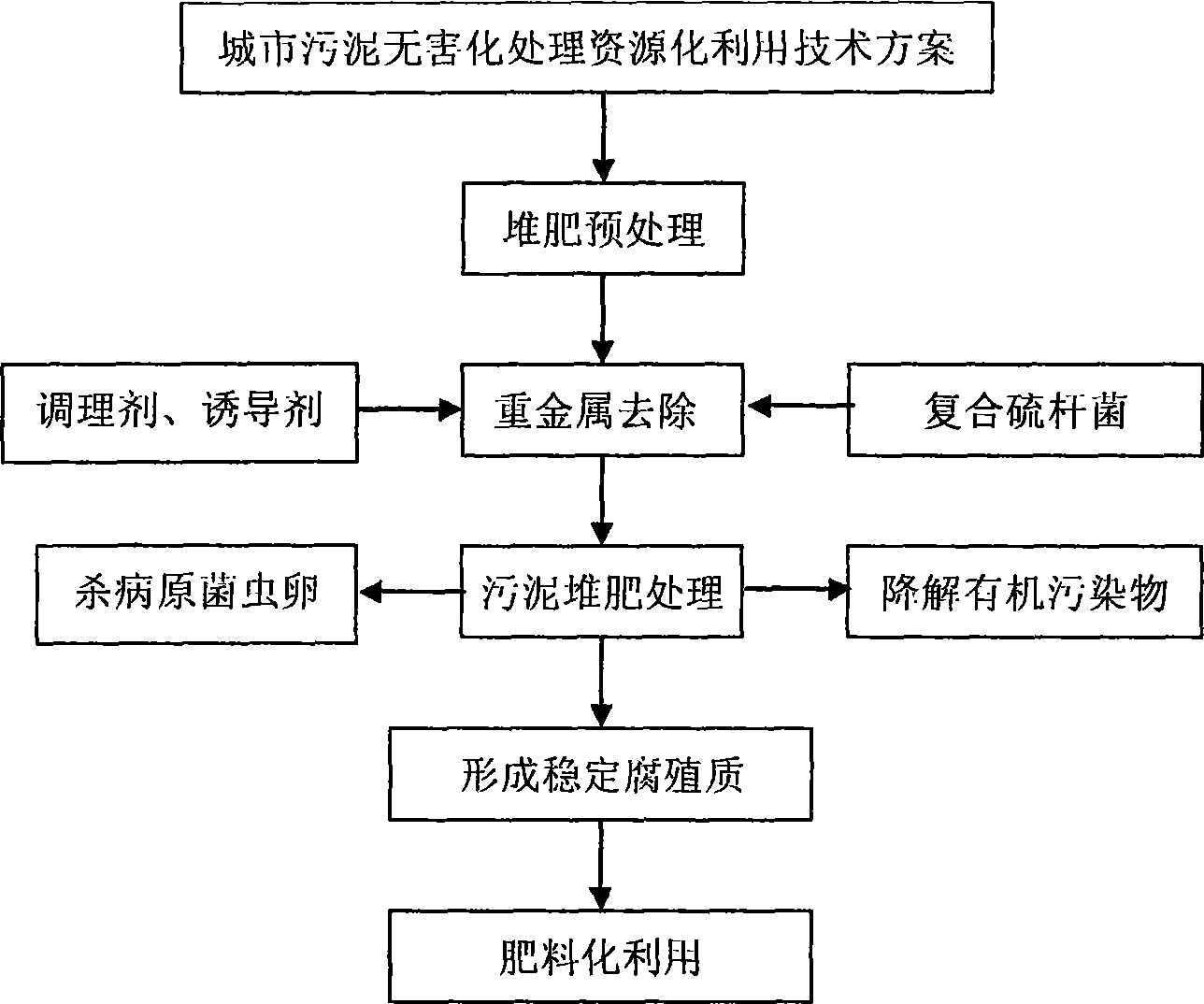

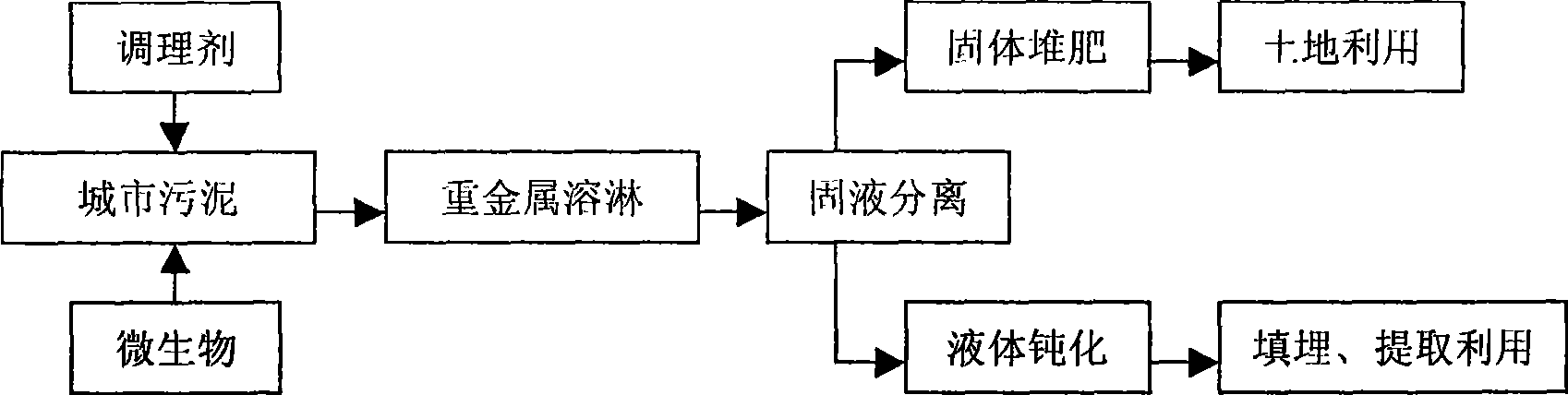

Solid phase sludge joint treatment method and use

InactiveCN101475411AHigh activityIncrease profitBio-organic fraction processingSludge processingSludgeInorganic compound

The invention discloses a method for innocent treatment of sludge by combining composting technology and biological leaching technology and application thereof. The invention provides the sludge combined treatment method aiming at the defects of high investment and large land occupation in the prior sludge innocent treatment method. The treatment method integrates the biological leaching and heavy metal removal technology and the composting technology, and simultaneously removes heavy metals, pathogenic bacteria, insect eggs, organic pollutant and the like in the sludge through combined treatment. Moreover, the treatment method makes the two types of technology mutually create favorable reaction conditions during application, saves the treatment cost, and greatly improves the innocent quality. The treated sludge has small toxic compositions and high retention rate of nutritive elements, can be continuously processed into biological organic and inorganic compound fertilizers which accord with the national standards, and is suitable to be used in green agricultural production. The method has the characteristics of simple technological process, strong practicality, low use cost and easy realization of industrialization, and is particularly suitable for the national conditions.

Owner:成都禾力宝生物肥料有限责任公司

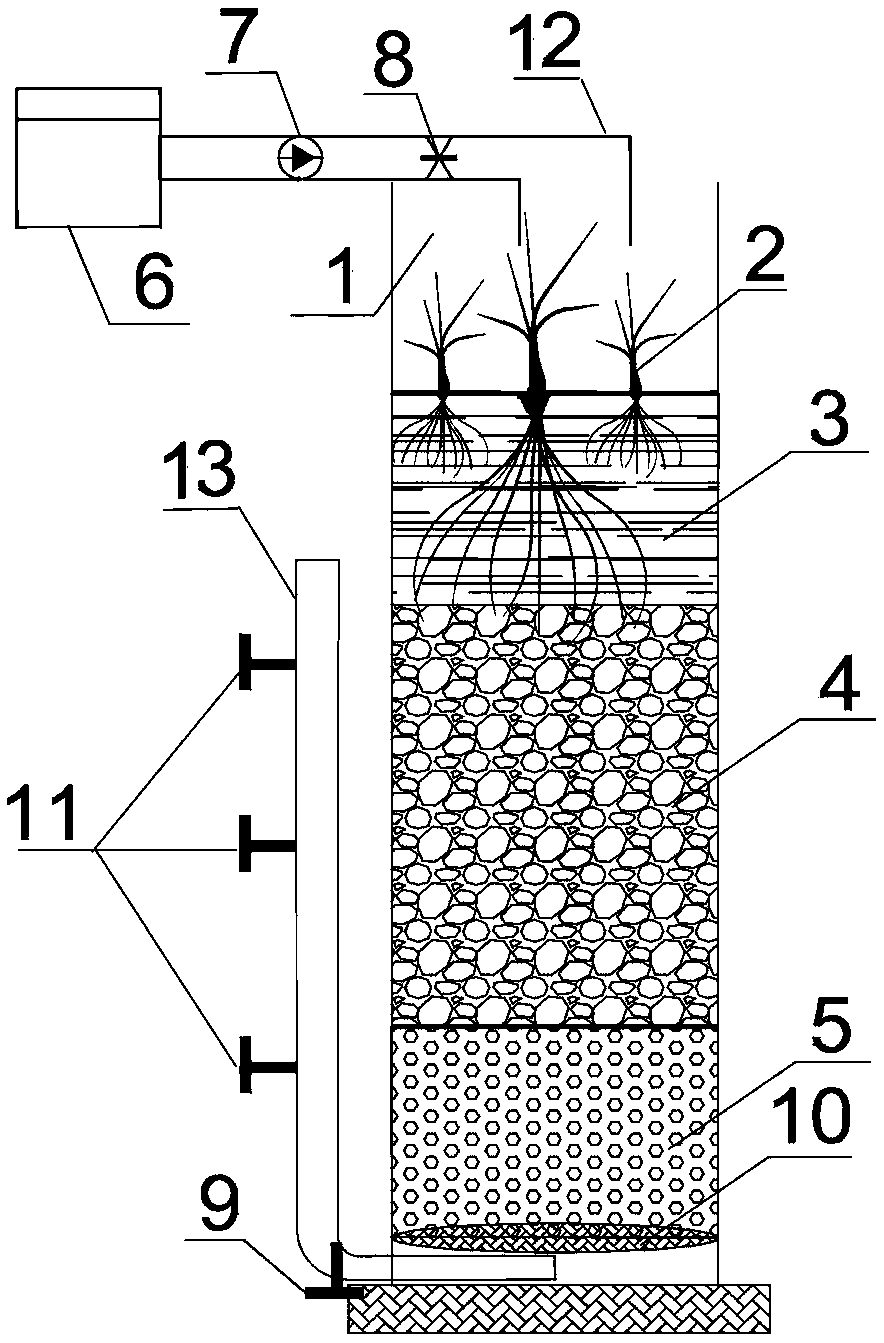

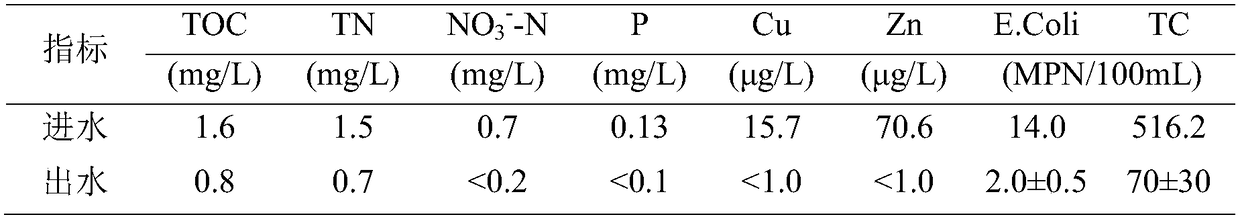

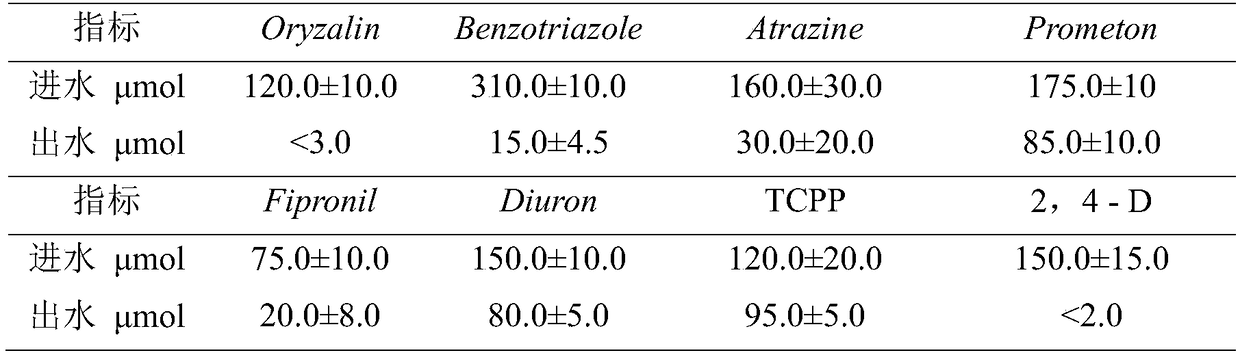

Rainfall runoff purification device and method

ActiveCN109095728AReduce volumeRemove comprehensivelyWater treatment compoundsSpecific water treatment objectivesRainfall runoffSewage

The invention discloses a rainfall runoff purification device and method and belongs to the field of sewage treatment. Water collection, water inlet, purification and drain systems are integrated; a purification filter in the device is provided with four filter areas including a plant area, a compost interception area, a biochar filler area and a drain area from top to bottom, four different treatment processes and methods are compounded and connected in one system in series, and organic compost particles have higher aromaticity, can be utilized with organic substrates as carbon sources and can produce unique microbial florae to degrade pollutants, so that better and more stable rainfall runoff purification tretament effects are realized. The used filler is low in cost, and the investmentis greatly reduced while the sewage tretament effect is guaranteed. The device has the advantages of being small in size, flexible and wide in application, simple in structure, reasonable in design and easy to manufacture.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Magnetic grinding disc, equipment and method for tapered roller rolling surface finishing

PendingCN108723982AReduce removalRemove comprehensivelyLapping machinesLapping toolsDemagnetizing deviceSurface finish

The invention discloses grinding equipment and a magnetic grinding disc kit for tapered roller rolling surface finishing of ferromagnetic materials. The grinding equipment comprises a main body, the magnetic grinding disc kit and a roller circulation disc outer system. The main body includes a base, a column, a beam, a slide table, an upper tray, a lower tray, an axial loading device and a spindledevice. The roller circulation disc outer system includes a roller collecting device, a roller demagnetizing device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism. The magnetic grinding disc kit includes a pair of coaxial first and second grinding discs of which the front surfaces are disposed opposite to each other. The front surface of the first grindingdisc includes a set of linear grooves radially distributed on a base surface (positive conical surface) of the first grinding disc, the front surface of the second grinding disc includes one or morespiral grooves distributed in the base surface (positive conical surface) of the second grinding disc, and a ring-shaped magnetic structure is embedded inside a base body. The grinding equipment has the finishing ability of multitudinous ferromagnetic material tapered roller rolling surfaces.

Owner:TIANJIN UNIV

Descaling hydraulic device for forging

InactiveCN113245489ARemove comprehensivelyLoss of extraction forceDirt cleaningForging press detailsStructural engineeringMechanics

The invention discloses a descaling hydraulic device for forging, and relates to the field of forging. The descaling hydraulic device comprises a hydraulic device body, a forging plate is fixed to the bottom end of the hydraulic device body, a collecting device is installed on one side of the forging plate, a bearing frame is connected to the outer wall of the hydraulic device body, a descaling device is arranged in the bearing frame, a base is fixed to the bottom end of the bearing frame, a touch switch is installed on one side of the base, and an isolation box is fixed to the bottom end of the base. The hydraulic device body, the forging plate, the collecting device, a forging table, the descaling device and the isolation box are arranged, a rotating plate and a discharging pipe are connected with a rotating shaft through a spring clamp, and a spring is arranged at the bottom end of the rotating plate, so that when gas in a piston pipe is discharged, after the gas pushes away the rotating plate, oxide skin on the rotating plate enters the collecting box through the discharging pipe, and a user can conveniently collect the oxide skin removed by the descaling device through the collecting device, and meanwhile, dust generated during forging is sucked.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

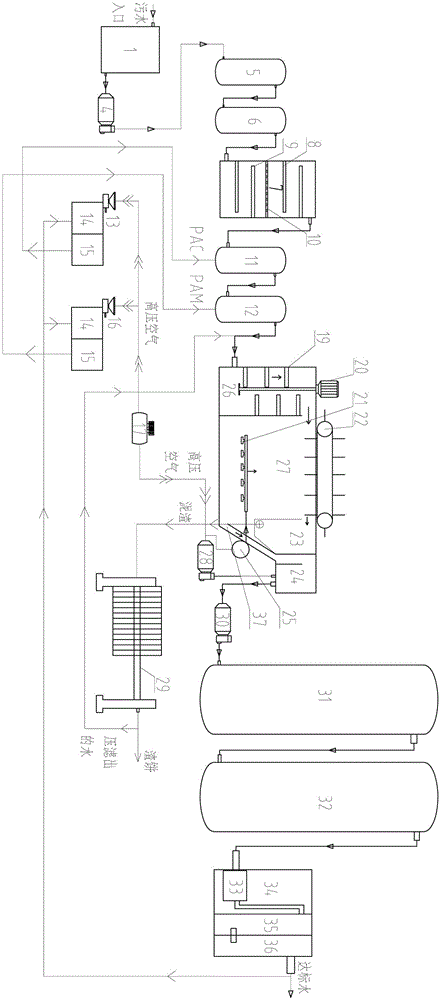

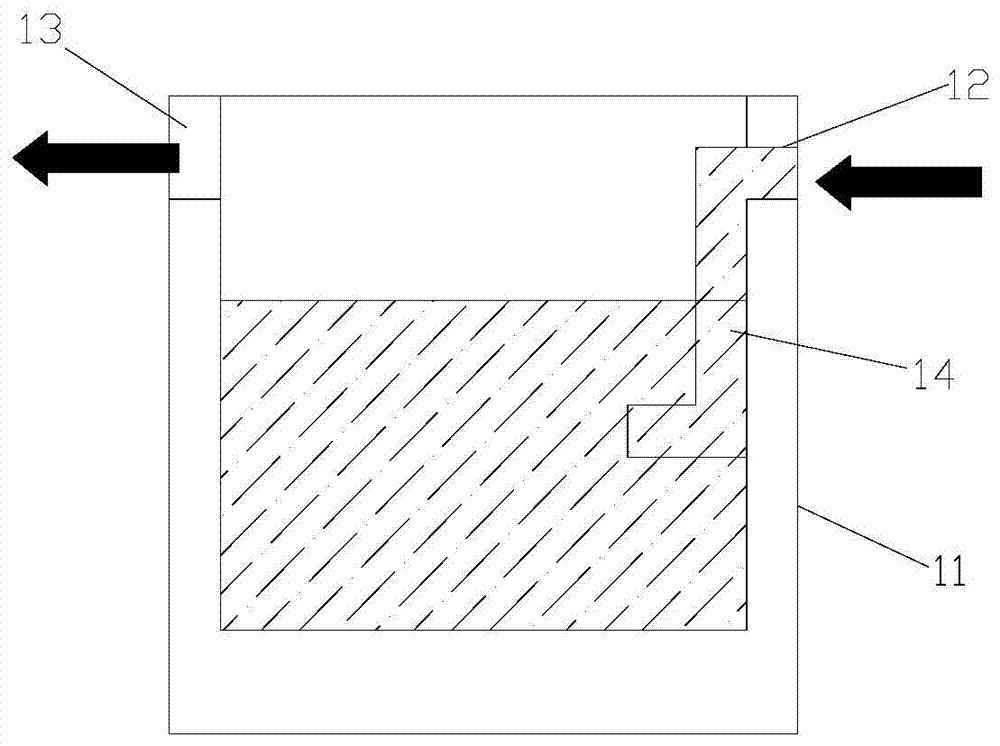

EPN (Ethyl P Nitrophenyl Phenylphosphonothioate) livestock breeding sewage disposal system

InactiveCN104150659AAchieve reuseAchieve emission standardsMultistage water/sewage treatmentSludgeWater quality

The invention relates to an EPN (Ethyl P Nitrophenyl Phenylphosphonothioate) livestock breeding sewage disposal system. The EPN livestock breeding sewage disposal system comprises a centrifugal extrusion solid-liquid separating system, a water feeding system, an EPN electrochemical generator, a dosing system, a floatation system, a sludge drying system, an EPN acousto-optical chemical water quality super oxidization system and a post-treatment water quality stabilization system. A method for implementing the system comprises the following steps: removing large suspended solids (SS) through solid-liquid separation, reducing COD (Chemical Oxygen Demand) and SS in a water body, and scraping flocculates in the water body on the surface to remove the SS in the water; removing heavy metals and antibiotics in sewage and reducing the COD, BOD (Biochemical Oxygen Demand) and ammonia nitrogen through an EPN electrochemical generator, and combining impurities into flocculates in a collision way; effectively grabbing and floating small SS in water through the floatation system, and removing the flocculates formed in the EPN electrochemical generator; and filtering sand carbon through post-treatment, and stabilizing the water quality through the EPN acousto-optical chemical water quality super oxidization system in order to discharge the sewage up to a certain standard and recycle the sewage.

Owner:毛斌全

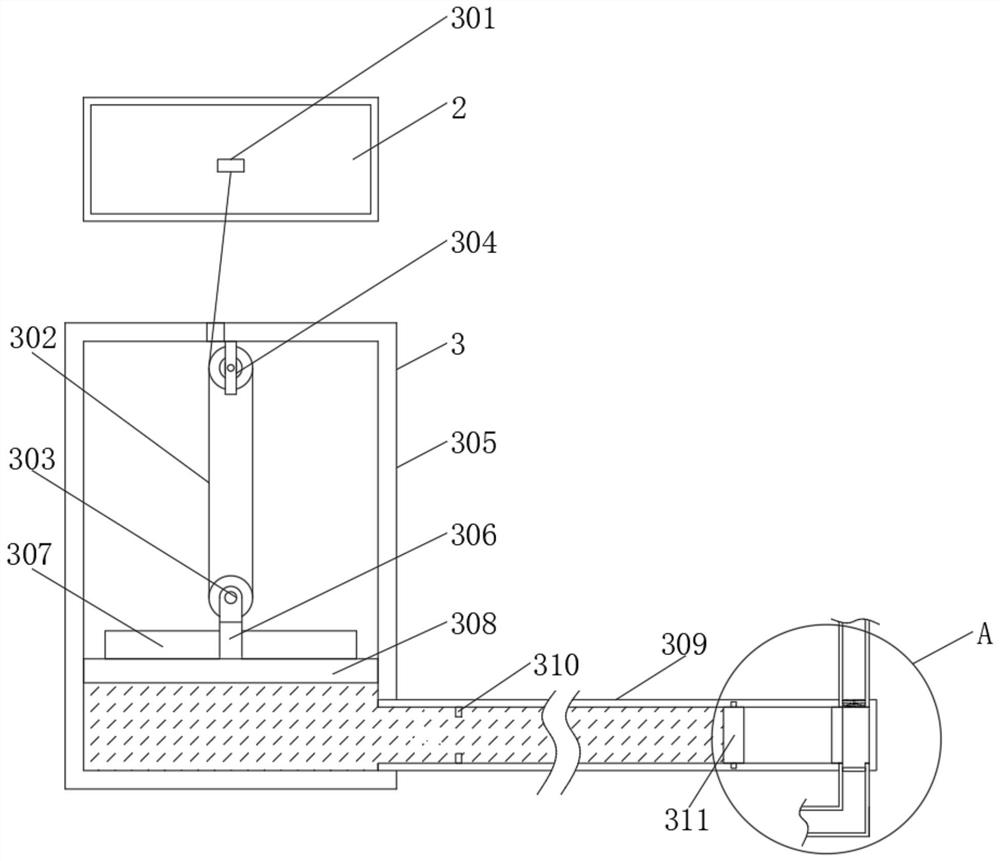

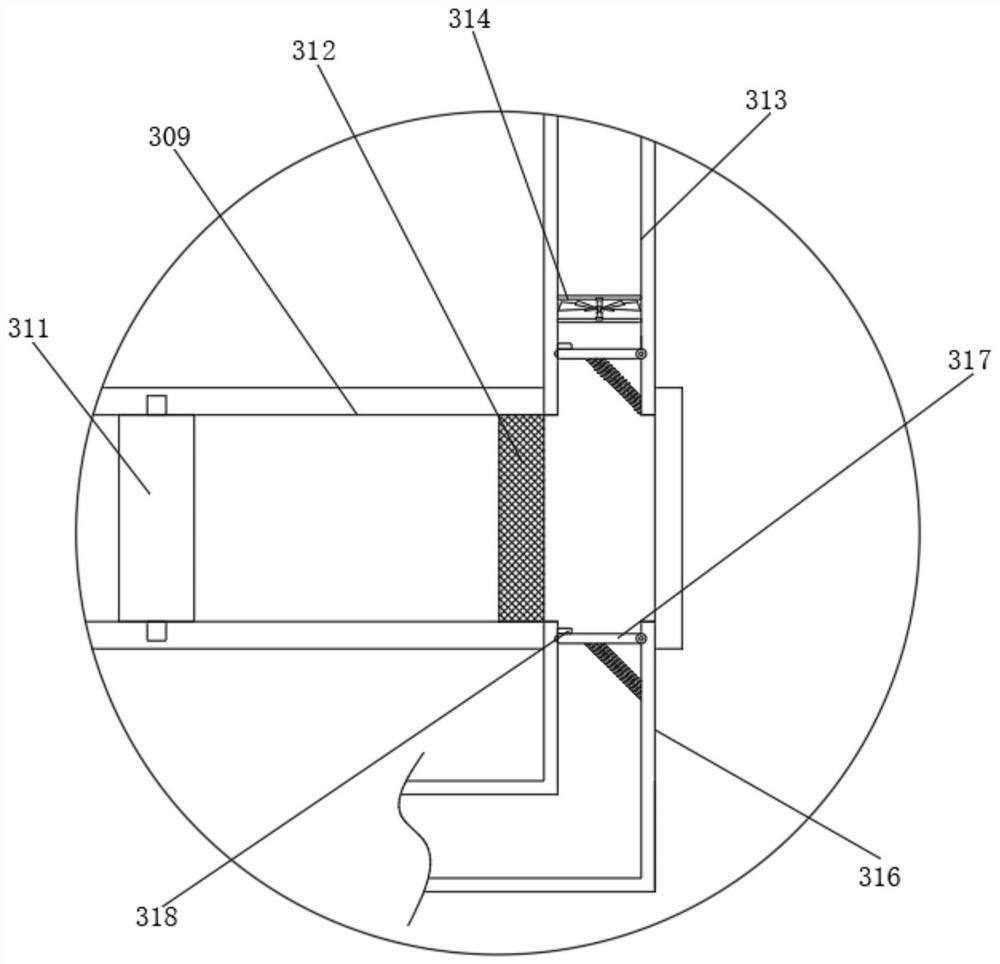

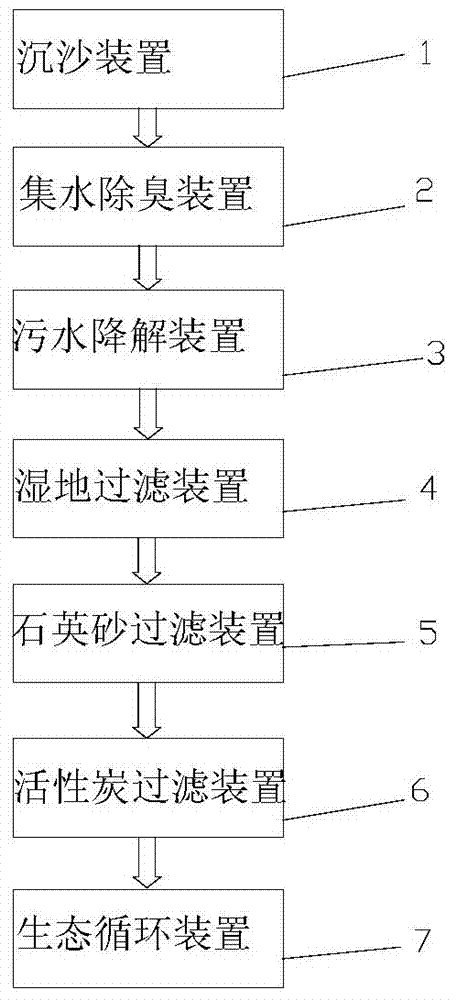

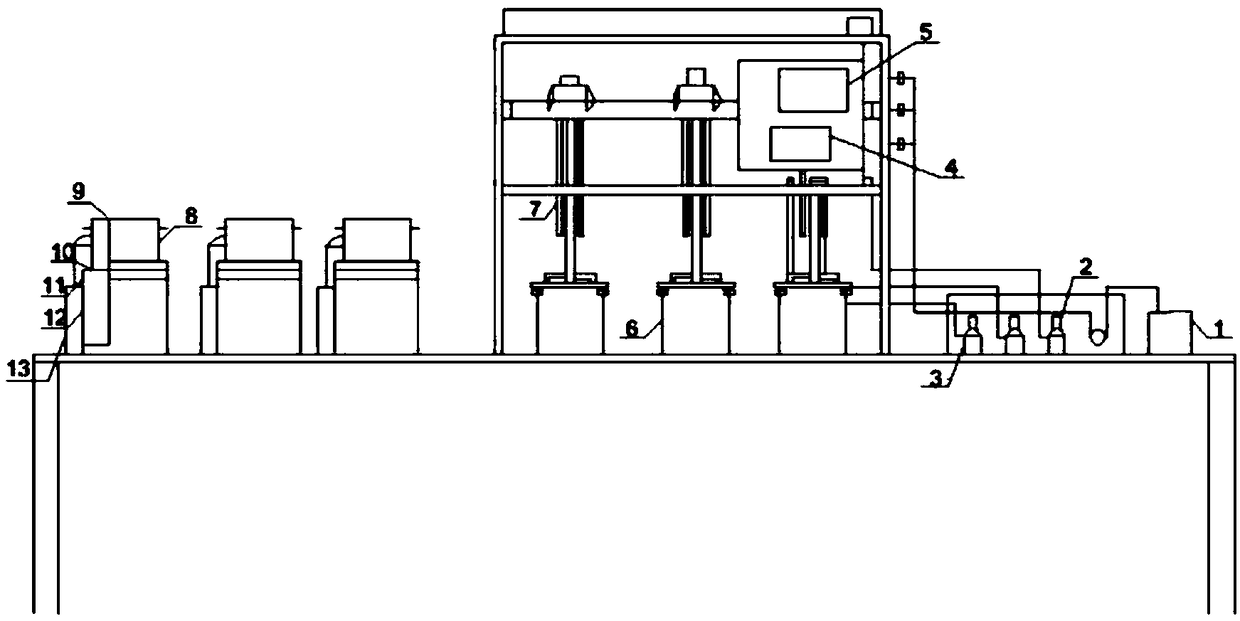

Multistage sewage treatment system and method

ActiveCN103936236ASimple structureRemove comprehensivelyMultistage water/sewage treatmentEnergy based wastewater treatmentHeavy metalsSewage treatment

The invention provides a multistage sewage treatment system which sequentially comprises a sand setting device for removing sands in sewage, a water collecting and deodorizing device for blowing sewage and eliminating smell of sewage, a sewage degrading device for degrading and stabilizing organic matters in sewage, a wetland filter device for removing nitrogen compounds, phosphorus compounds and degradation-resistant organic matters in water, a quartz sand filter device for blocking suspended matters in sewage, an activated carbon filter device for absorbing peculiar smell and absorbing harmful substances and an ecological circulating device for improving the water quality. The multistage sewage treatment system provided by the invention can remove impurities such as solid impurities, colloid matters, nitrogen compounds, phosphorus compounds, heavy metals, degradation-resistant organic matters, bacteria and viruses in sewage to obtain ideal water quality.

Owner:GUANGZHOU DI ER CONSTR & ENG CO LTD +1

Remediation device for contaminated soil

PendingCN109433811ARapid solid-liquid separationAvoid secondary pollutionContaminated soil reclamationLiquid wastePollution soil

The invention relates to a remediation device for contaminated soil. The remediation device comprises oxidation treatment equipment. The oxidation treatment equipment comprises a water tank, a quantitative dosing pump, oxidant tanks, stirring equipment and a vacuum separator. A water outlet of the water tank is connected with the quantitative dosing pump. The output ends of the oxidant tanks are connected with the input end of the quantitative dosing pump. The output end of the quantitative dosing pump is connected with the input end of the stirring equipment. The vacuum separator comprises afirst space for containing materials in the stirring equipment and a second space which is in vacuum and is used for containing waste liquid. According to the remediation device for the contaminated soil, by arranging the quantitative dosing pump, the water in the water tank and an oxidant in the oxidant tanks can be quantitatively added to the stirring equipment, and the water quantity and the drug quantity can be flexibly adjusted according to actual requirements; the oxidant and pollutants are fully stirred in the stirring equipment so as to realize a complete oxidizing reaction; and afterthe reaction, the materials in the stirring equipment are moved to the vacuum separator for solid-liquid separation, so that secondary pollution caused by waste liquid is avoided, and soil remediationis realized.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS +2

Method for implementing back polishing in crystalline silicon solar battery production

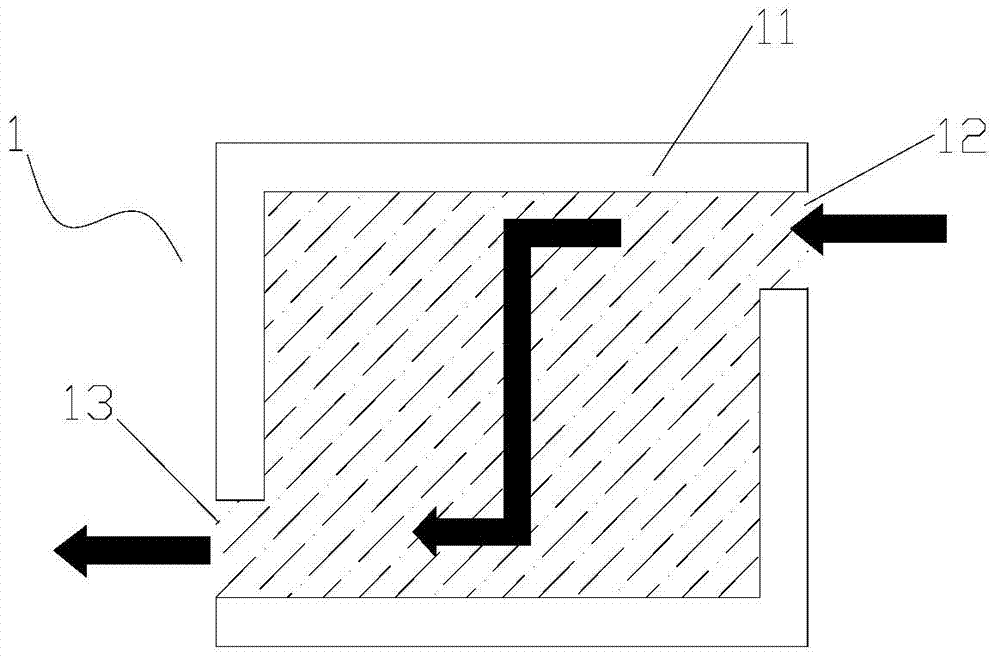

ActiveCN103361739ATemperature controlControl concentrationAfter-treatment detailsFinal product manufactureEngineeringSilicon solar cell

The invention discloses a method for implementing back polishing in the crystalline silicon solar battery production. The method is characterized in that a new wet etched alkali tank structure is adopted and divided into two independent parts which are respectively a soaking zone and a spraying zone, wherein the two zones are provided with independent tank bodies and have independent control functions, and the control functions comprise the control on the concentration and the temperature of alkali liquor, water replenishing and liquid medicine addition; and a 'floating on water' manner is adopted in the soaking region of the alkaline tank for completing the back polishing through the corrosion of alkali liquor, and a spraying manner is adopted in the spraying zone of the alkaline tank for spraying the front surface and the back surface of a silicon wafer so as to remove porous silicon on the surface of the silicon wafer. The method can be used for realizing the goal of back polishing in the solar battery production under the condition that the front surface of the silicon wafer is not influenced, is simple to operate and has excellent effects.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

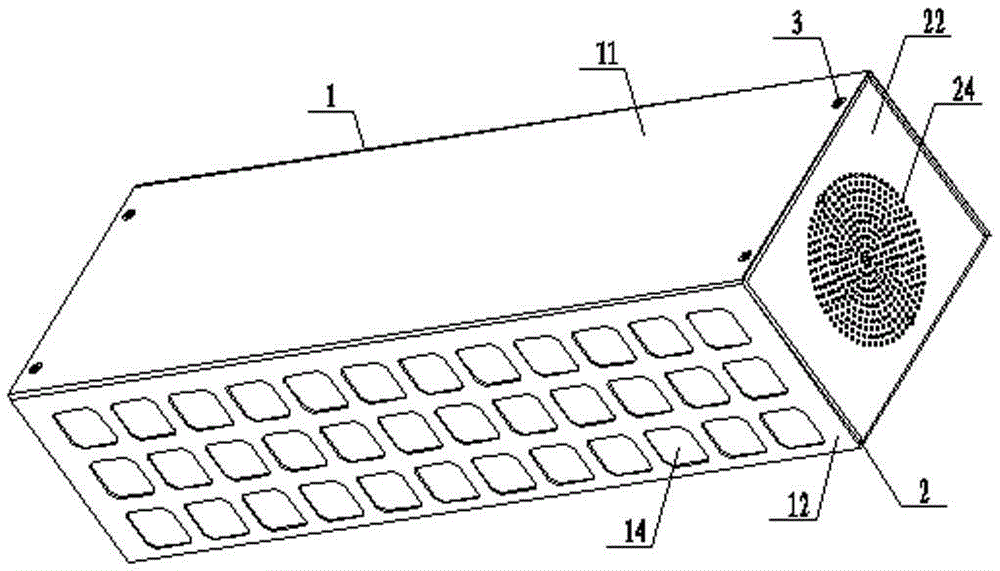

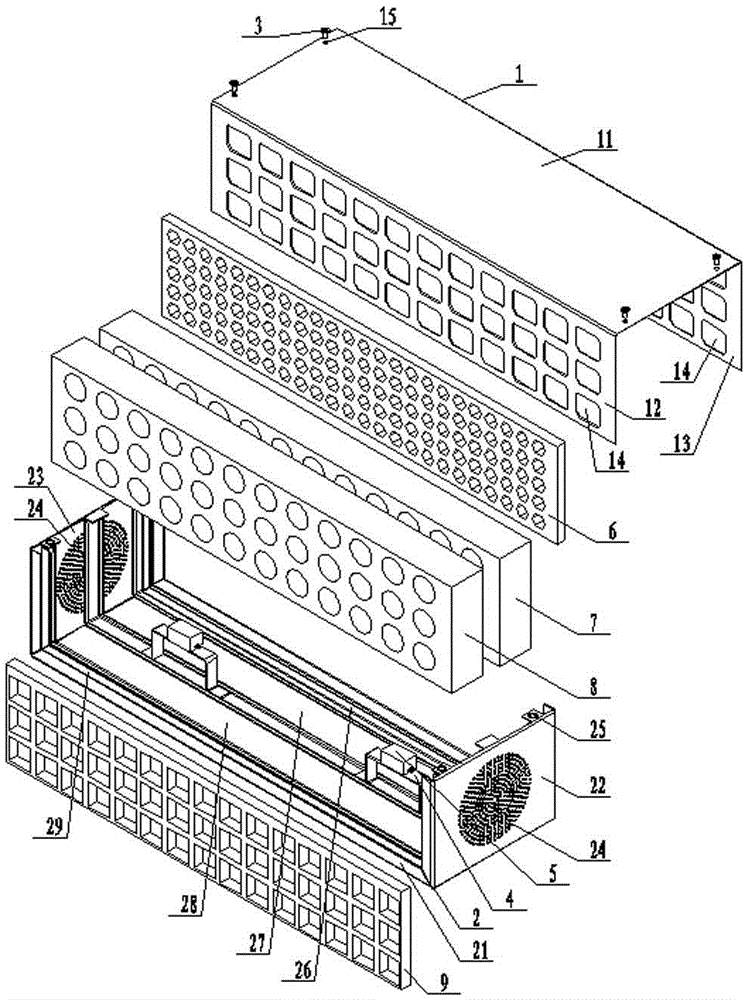

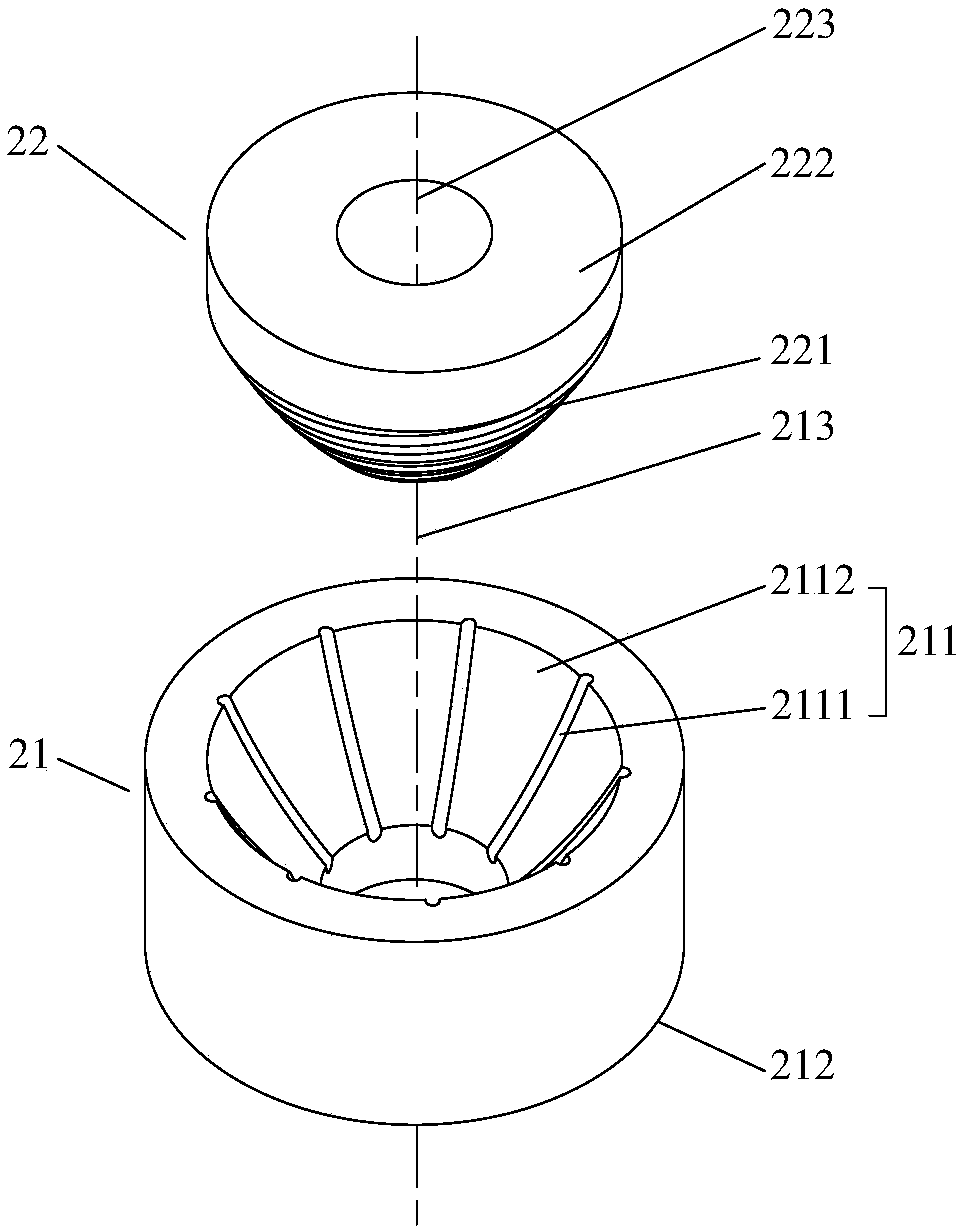

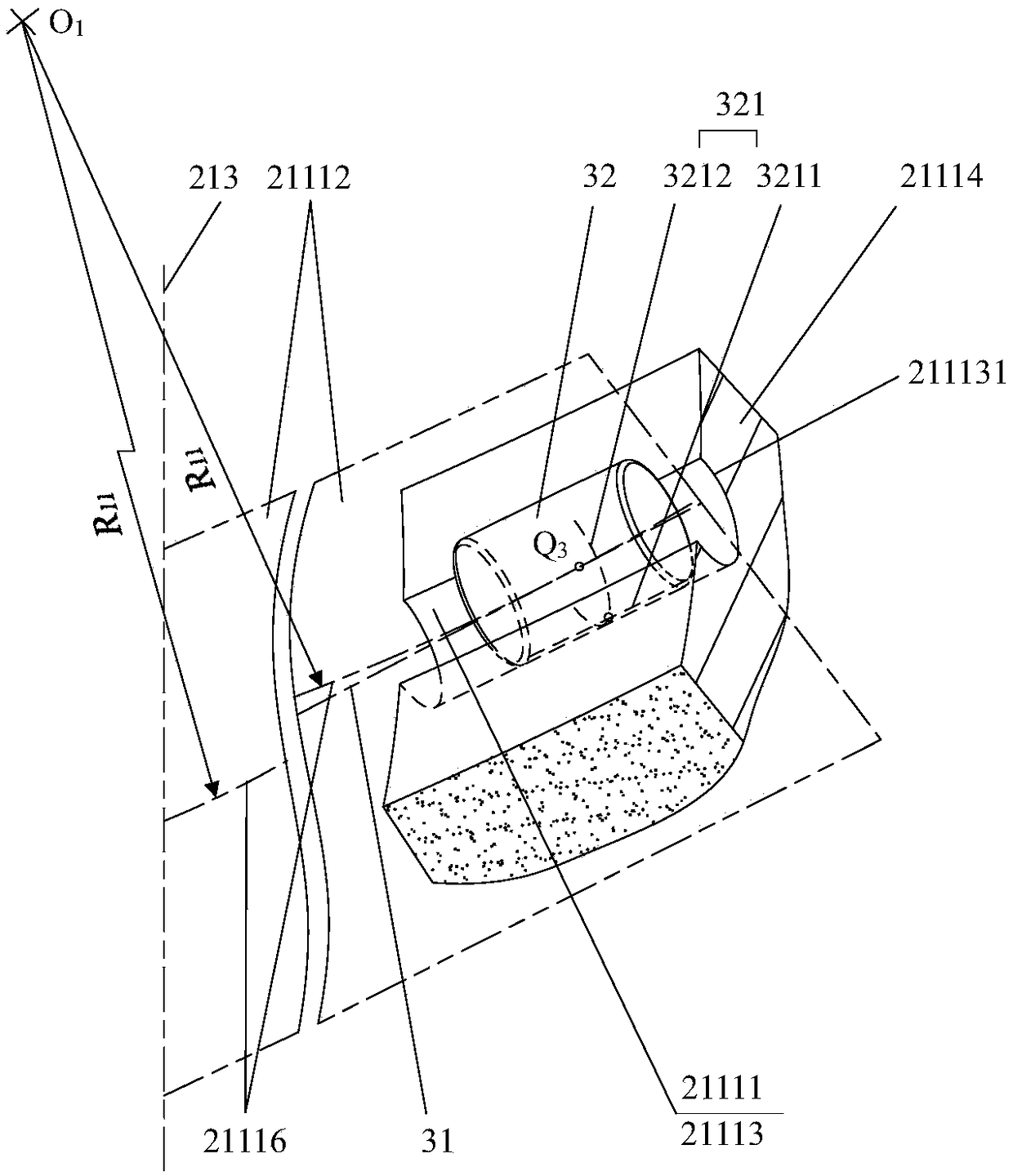

Air purifier special for train

ActiveCN105172818AComprehensive adsorptionRemove comprehensivelyRailway heating/coolingActivated carbon filtrationAir purifiers

The invention discloses an air purifier which is good in air purification effect and special for a train. The air purifier special for the train comprises an upper box body and a lower box body matched with the upper box body. The upper box body structurally comprises an upper covering plate, a front side plate and a rear side plate, wherein the front side plate and the rear side plate are arranged on two sides of the upper covering plate and are each evenly provided with a plurality of side plate breathable holes, and upper bolt holes are formed in four corners of the upper covering plate. The lower box body structurally comprises a bottom plate, a left side plate and a right side plate, wherein the left side plate and the right side plate are arranged on two sides of the bottom plate, each evenly provided with a plurality of side surface breathable holes, and provided with lower bolt holes matched with the upper bolt holes. The upper box body and the lower box body are mutually fixed through bolts, the upper bolt holes and the lower bolt holes. A cold catalyst filtering screen installation cavity, a first electrostatic generator installation cavity, a second electrostatic generator installation cavity and an activated carbon filtering screen installation cavity are arranged in the lower box body sequentially from front to back.

Owner:JIANGSU RONGBANG MACHINERY MFG

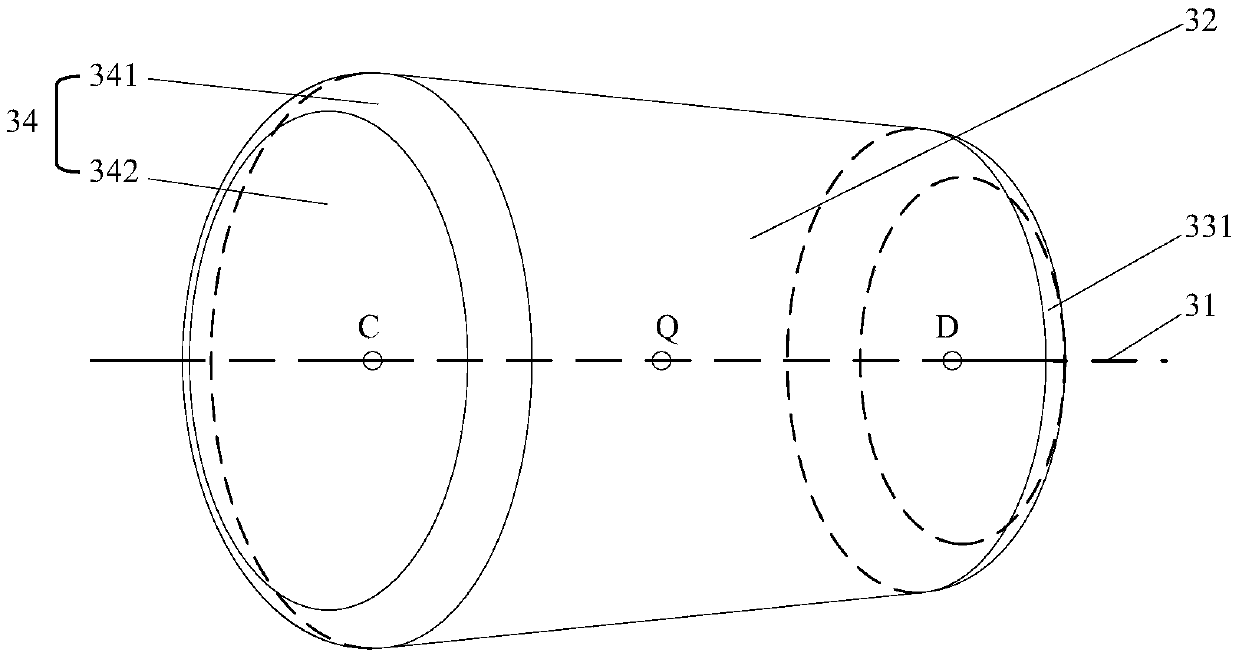

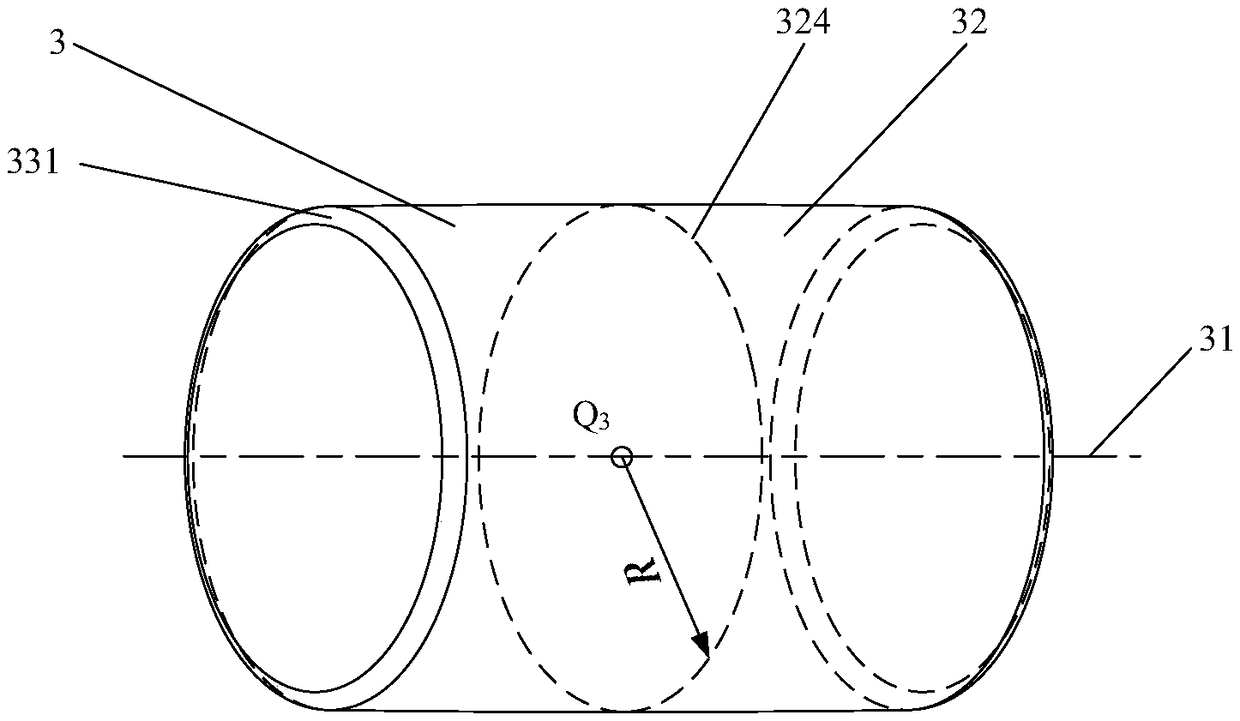

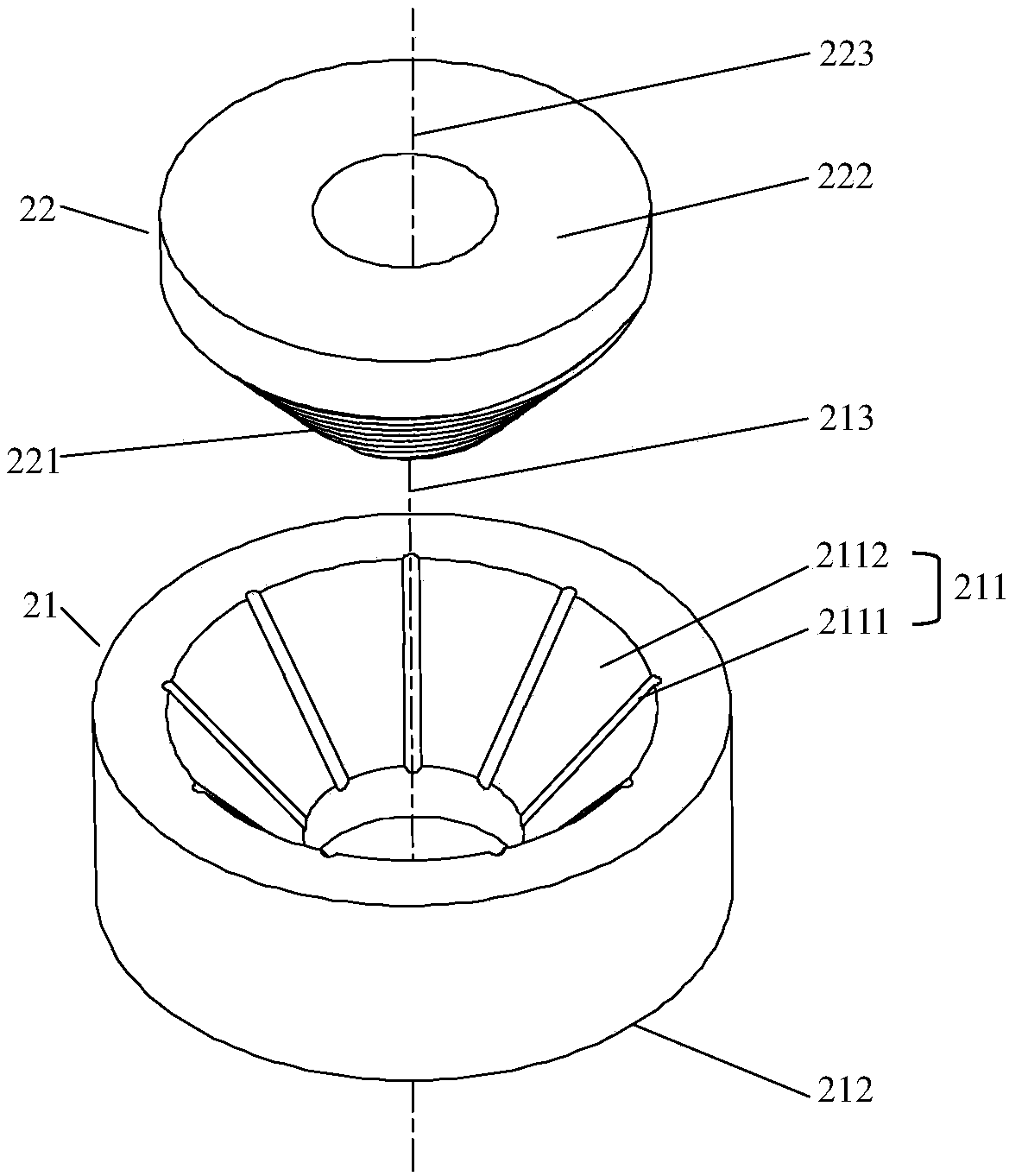

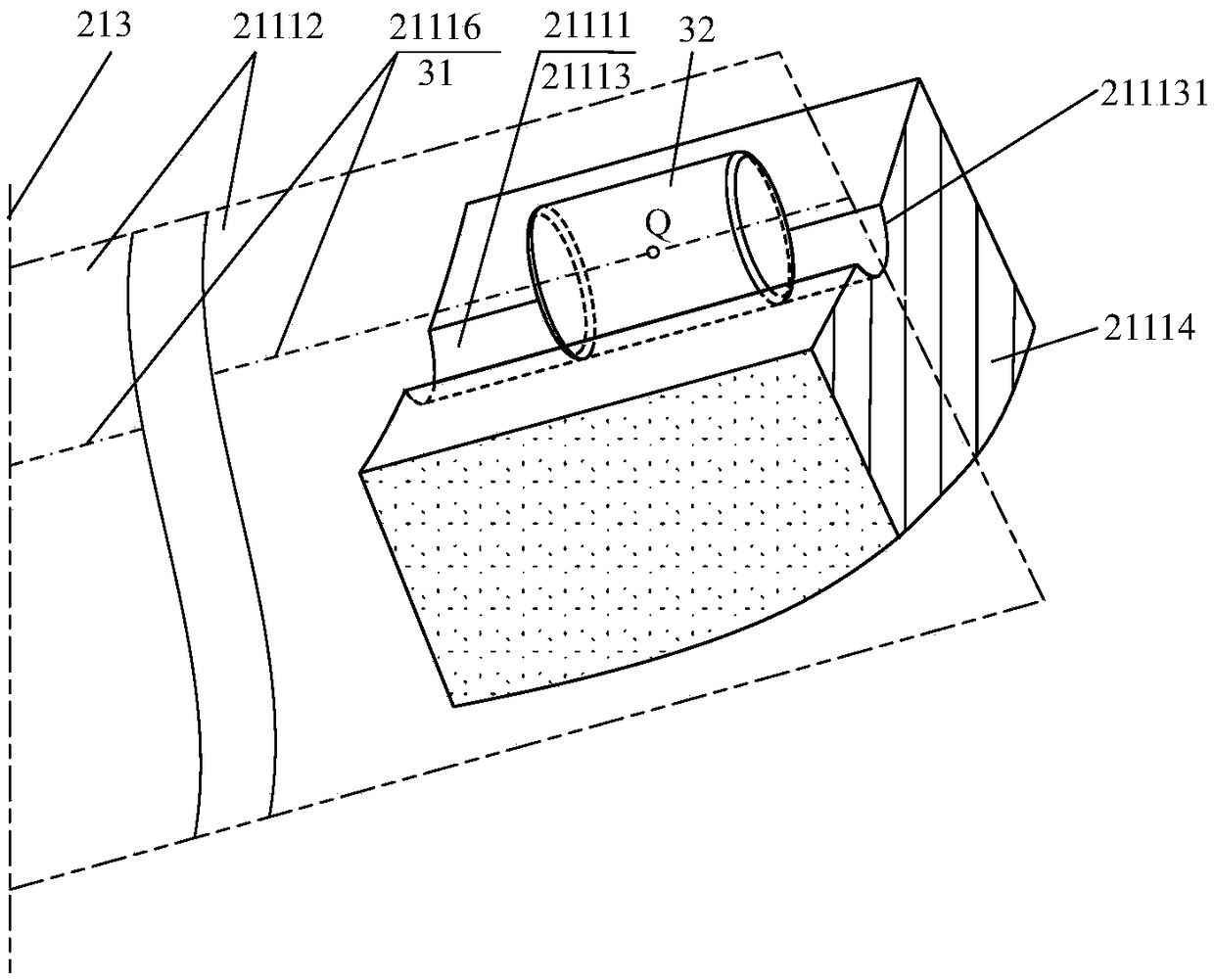

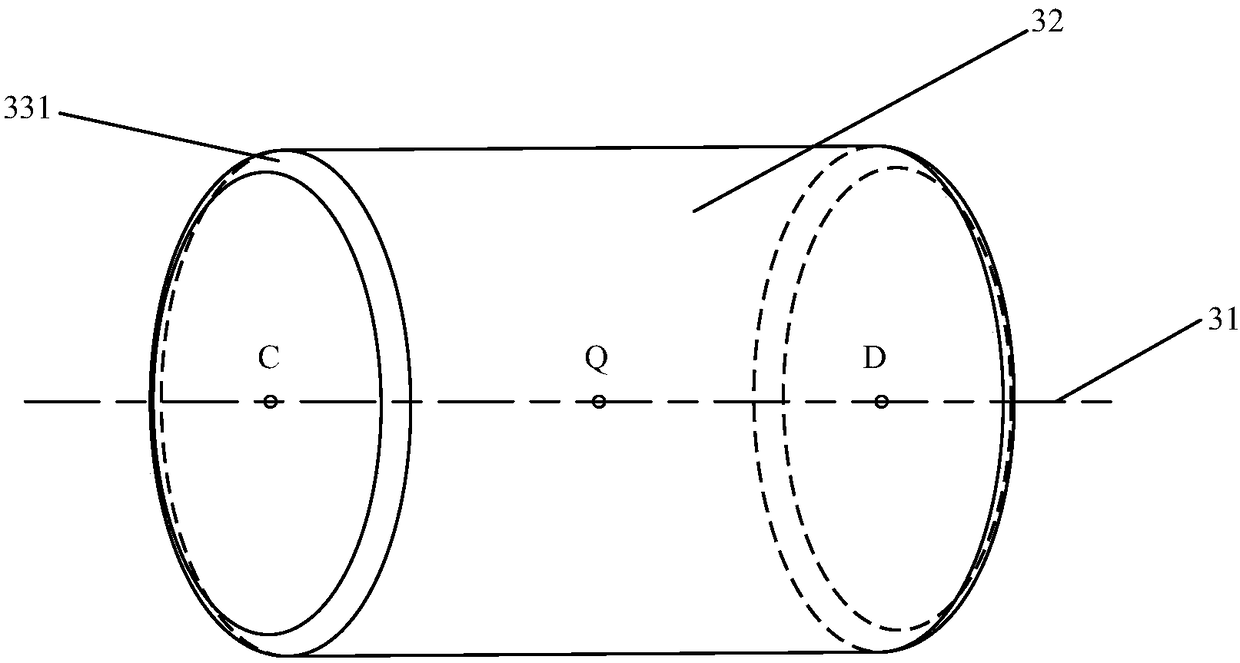

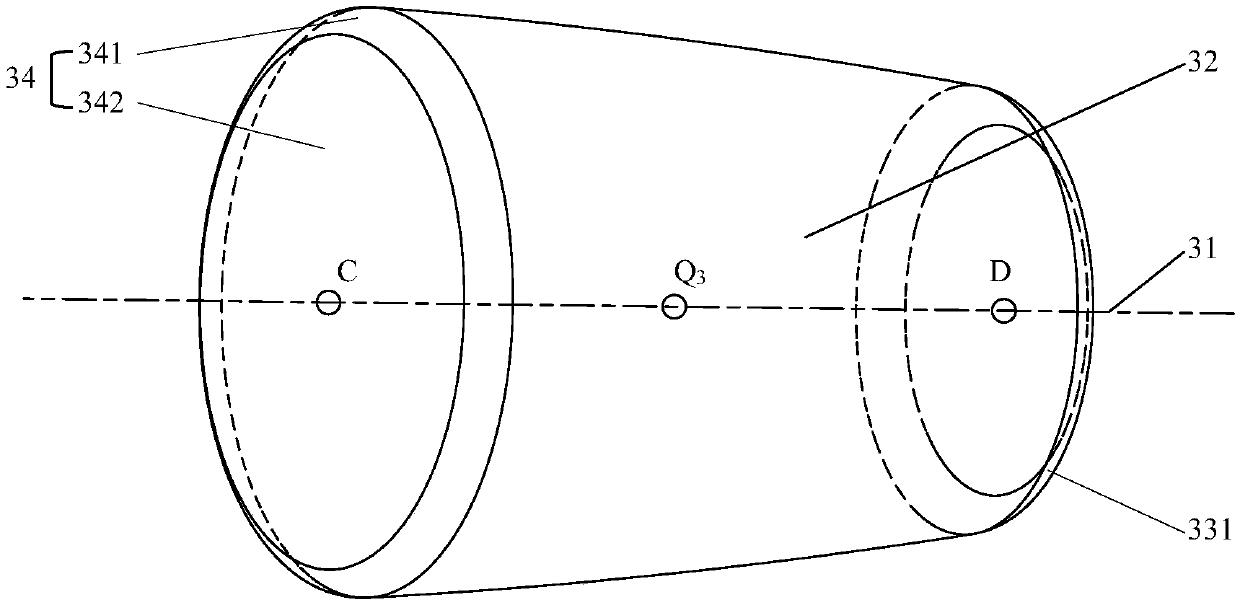

Grinding disk, apparatus and method for finishing rolling surface of convex cylindrical roller

ActiveCN108890516AAchieve removalRemove comprehensivelyLapping machinesLapping toolsMechanical engineeringEngineering

A lapping apparatus and a lapping disk kit for finis a rolling surface of a convex cylindrical roller are disclose. That lapping apparatus includes a main body, a lapping disk kit and a roller circulation disk out system. The main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device, wherein the main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device. The outer system of the roller circulating disk comprises a roller collecting device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism. The abrasive disk kit includes a pair of first and second abrasive disks coaxially and oppositely disposed facing each other. A front surface of the first abrasive disk includes a set of concave arc grooves radially distributed on a base surface of the first abrasive disk (concave circular arc rotating surface), The front surface of the second abrasive disk includes one or more spiral grooves distributed on the base surface of the second abrasive disk (convex circular arc rotating surface),and the radii of curvature of the base circle and the radii of curvature of the cross-section of the base surface of the first and second abrasive disks are equal to each other. A lapping apparatus ofthat present invention has the finis machining capability of a rolling surface of a large numb of convexity cylindrical rollers.

Owner:TIANJIN UNIV

Huanglian Shangqing Granule and preparation method thereof

InactiveCN1544030AExtract completelyRemove comprehensivelyAntipyreticAnalgesicsMedicineCurative effect

The invention relates to a goldthread root granule for heat-clearing, bowel relaxing, pain relieving, and the process for its preparation comprising boiling the raw material repeatedly, displacement for extraction. The invention realizes more complete extraction for effective composition and more complete removal of ineffective component, thus the curative effect for the product can be developed to the maximum limit.

Owner:重庆东方药业股份有限公司

Magnetic grinding plates, equipment and method for finish machining of rolling surface of cylindrical roller

The invention discloses grinding equipment and a magnetic grinding plate suite for finish machining of the rolling surface of a cylindrical roller made of a ferromagnetic material. The grinding equipment comprises a main unit, the magnetic grinding plate suite and a roller circulating plate external system, wherein the main unit comprises a base, a stand column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device; the roller circulating plate external system comprises a roller collecting device, a roller demagnetizer, a roller conveyor, a roller finishing mechanism and a roller feed-in mechanism. The magnetic grinding plate suite comprises a first grinding plate and a second grinding plate which are coaxial, and the front sides of the pair of grinding plates are opposite; a group of linear grooves radially distributed on the base surface (right circular conical surface) of the first grinding plate are arranged on the front side of the first grinding plate, one or more spiral grooves distributed on the base surface (right circular conical surface) of the second grinding plate are formed on the front side of the second grinding plate, and an annular magnetic structure is inlaid in a substrate of the second grinding plate. The grinding equipment has the finish machining capacity for the rolling surfaces of a large scale of cylindrical rollers made of the ferromagnetic material.

Owner:TIANJIN UNIV

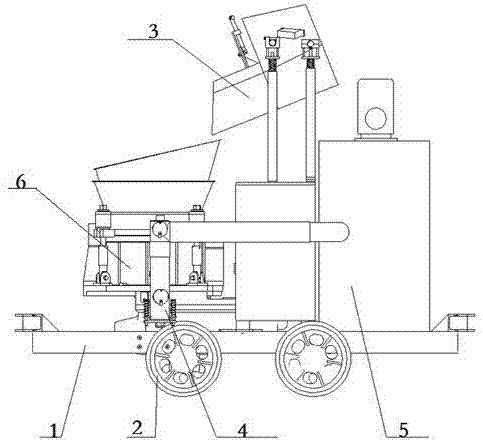

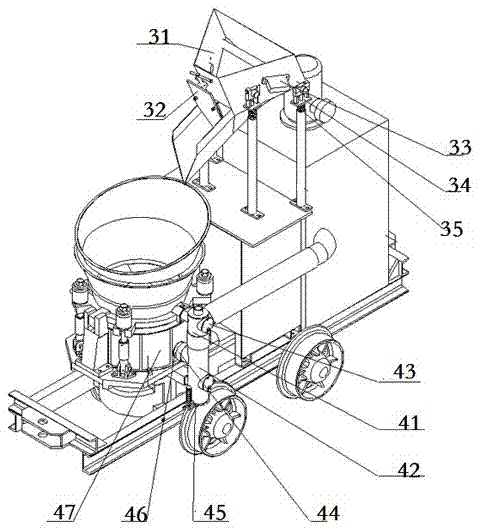

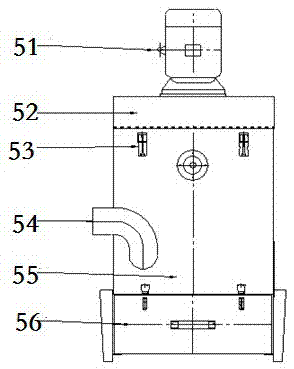

Dust removal type concrete spraying machine

ActiveCN105443142APrevent overflowAvoid pollutionUnderground chambersTunnel liningReducerPulp and paper industry

The invention belongs to the technical field of mining machinery application, and particularly relates to a dust removal type concrete spraying machine. The machine comprises a chassis, walking wheels installed on the lower portion of the chassis, a concrete spraying machine body, an automatic accelerator adding mechanism and a dust removal device. The concrete spraying machine body comprises a speed reducer and a rotor body assembly connected with an output shaft of the speed reducer. One side of the concrete spraying machine body is provided with a dust discharge mechanism. The dust discharge mechanism comprises an upper air overflowing opening, an air outlet and a lower air overflowing opening which are communicated with a vertically-arranged air exhaust pipe at the same time. The air exhaust pipe is connected with the dust removal device. By the adoption of the dust removal type concrete spraying machine, working dust produced by a dry spraying type concrete spraying machine can be removed, and environmental pollution and harm caused to the bodies of workers are avoided.

Owner:河南省煤科院科明机电设备有限公司

Grinding disc, equipment and method for finish machining of rolling surface of convex circular cone roller

PendingCN108673331AReduce removalIncrease contact stressLapping machinesLapping toolsEngineeringCircular cone

The invention discloses grinding equipment and grinding disc external member for finish machining of the rolling surface of a convexity circular cone roller. The grinding equipment comprises a main machine, the grinding disc external member and a roller circulating disc external system. The main machine comprises a base, a stand column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device. The roller circulating disc external system comprises a roller collecting device, a roller conveying system, a roller cleaning mechanism and a roller feeding mechanism. The grinding disc external member comprises a pair of first and second grinding discs, wherein the front surfaces of the first and second grinding discs are coaxially arranged are arranged in an opposite mode. The front surface of the first grinding disc comprises a group of concave arc grooves radially distributed on the first grinding disc base surface (concave arc rotating surface), the front surface of the second grinding disc comprises one or more spiral grooves distributed on the second grinding disc base surface ( convex arc rotating surface ), and the radius of curvature of the base circle and the radius of curvature of the base surface cutting line of the first and second grinding discs are equal. The grinding equipment and grinding disc external member for finishmachining of the rolling surface of the convexity circular cone roller has the finish machining capability of rolling surfaces of large-scale convexity circular cone rollers.

Owner:TIANJIN UNIV

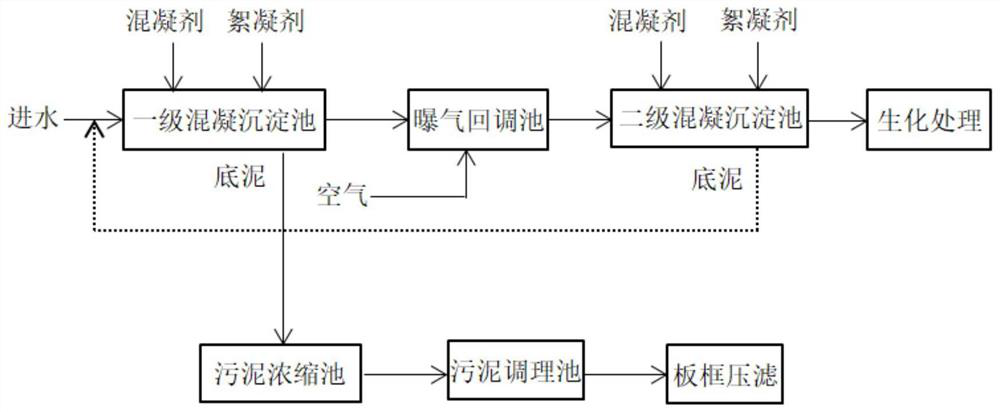

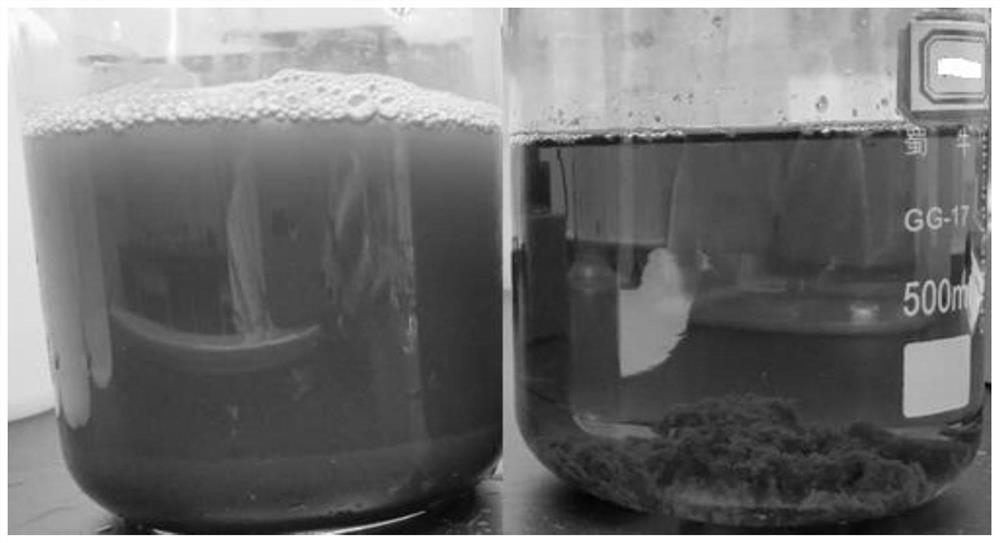

Novel enhanced coagulation wastewater treatment method

PendingCN112794555AGood removal effectEfficient removalMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludgeWastewater

The invention provides a novel enhanced coagulation wastewater treatment method. The novel enhanced coagulation wastewater treatment method comprises the following steps of: S1, primary coagulation sedimentation: wastewater is introduced into primary coagulation sedimentation equipment, and a coagulant and a flocculant are added for coagulation reaction and solid-liquid separation; S2, aeration back-regulation of the pH value: the effluent of the primary coagulation sedimentation equipment enters aeration back-regulation equipment, and the pH value is back-regulated through aeration; S3, secondary coagulation precipitation: the effluent of the aeration back-regulation equipment enters secondary coagulation precipitation equipment, and a coagulant and a flocculant are added for secondary coagulation precipitation treatment; and S4, sludge treatment: sludge generated in the primary coagulation sedimentation step enters sludge concentration equipment for subsequent treatment, and sludge generated in the secondary coagulation sedimentation step flows back to the front end of the primary coagulation sedimentation equipment or is directly conveyed into the sludge concentration equipment for subsequent treatment. According to the method provided by the invention, different reaction conditions are respectively optimized in two-stage coagulation sedimentation, so that different types of substances can be efficiently removed, and the cost of an alkaline substance agent for regulating the pH value of the wastewater is saved or reduced by utilizing a method for back-regulating the pH by aeration in the pH back-regulation stage of two-stage coagulation.

Owner:联合环境技术(天津)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com