Liquid ejecting apparatus

A technology of liquid and ejection part, applied in printing devices, printing, typewriters, etc., can solve problems such as recording control failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

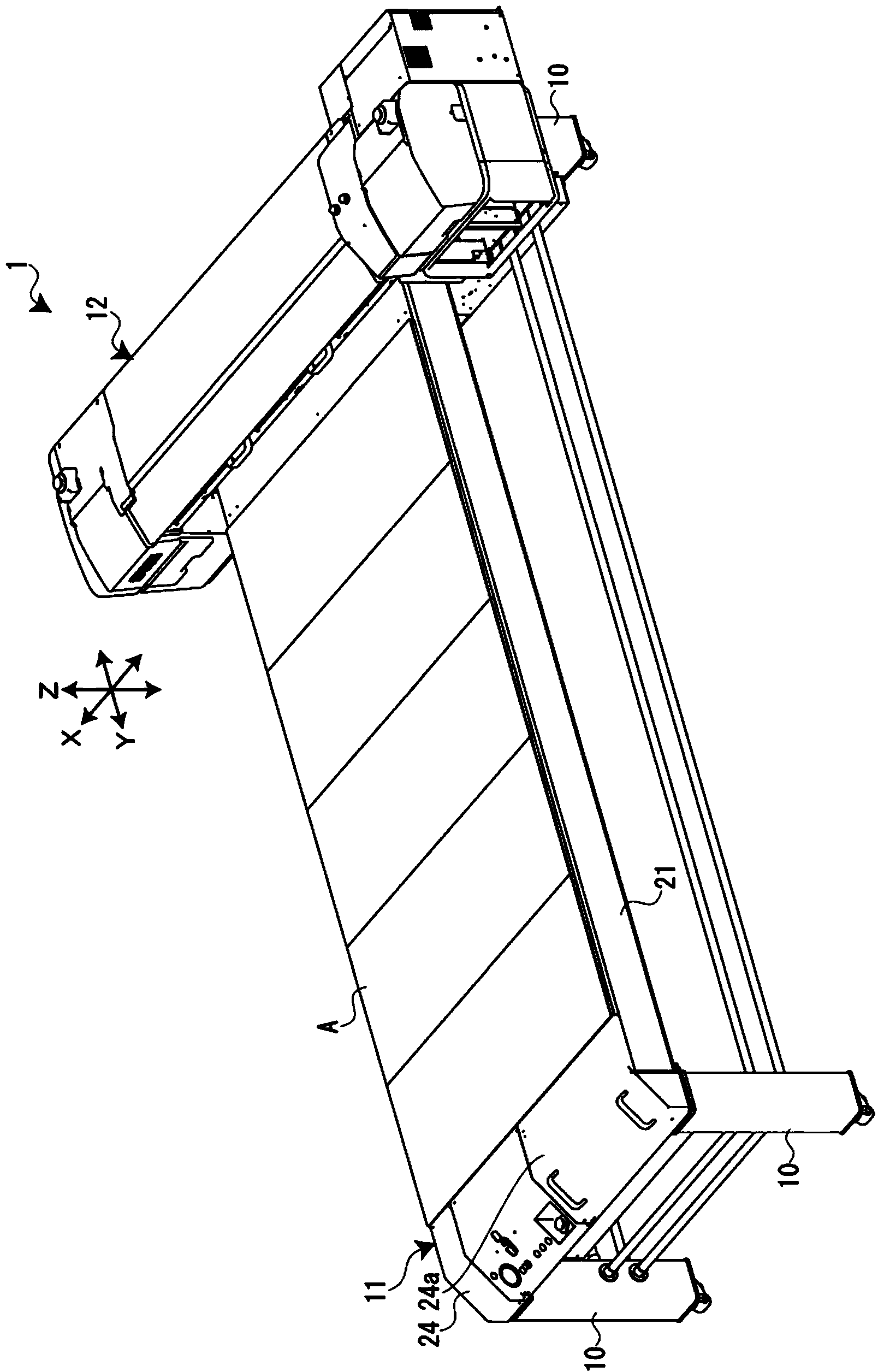

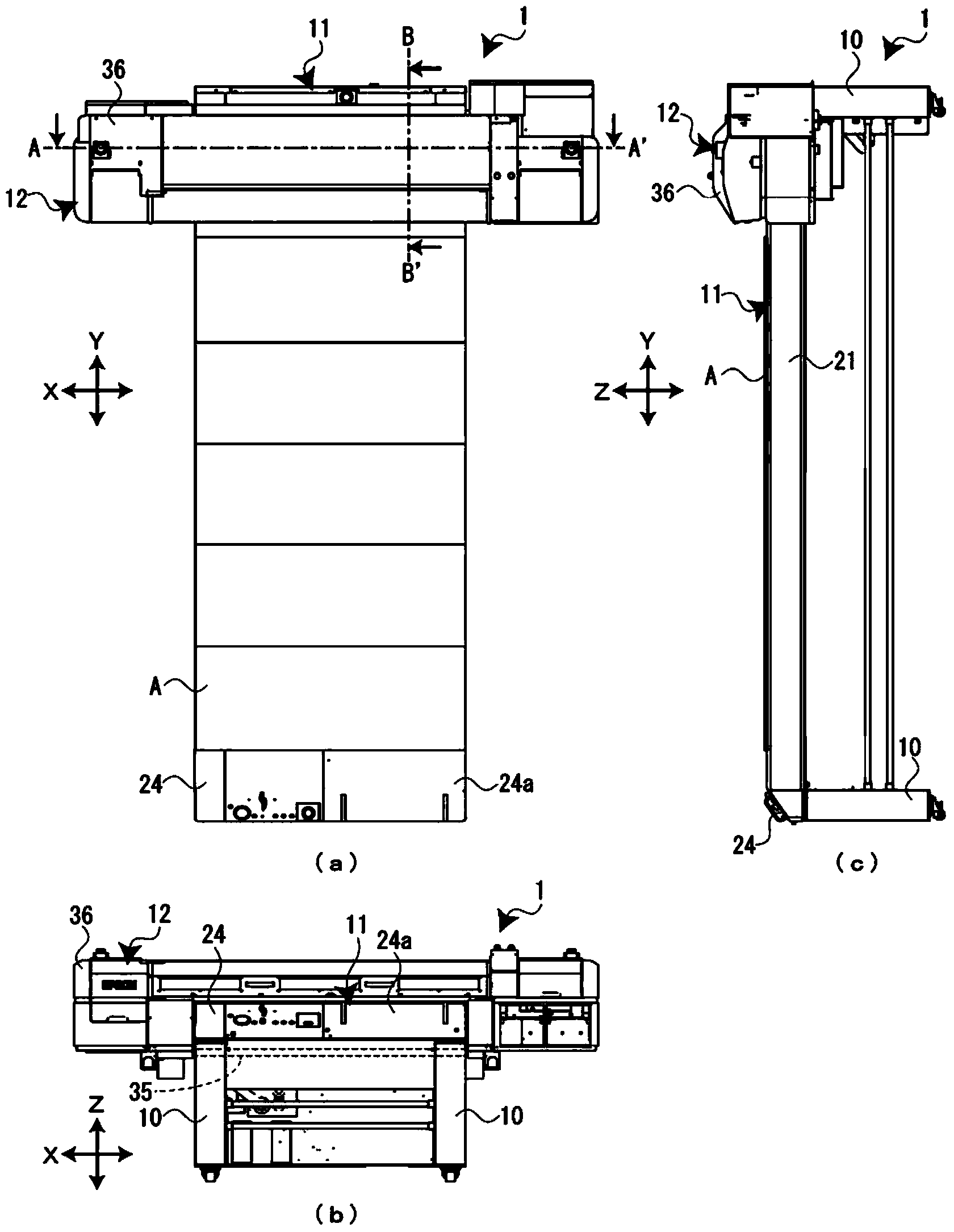

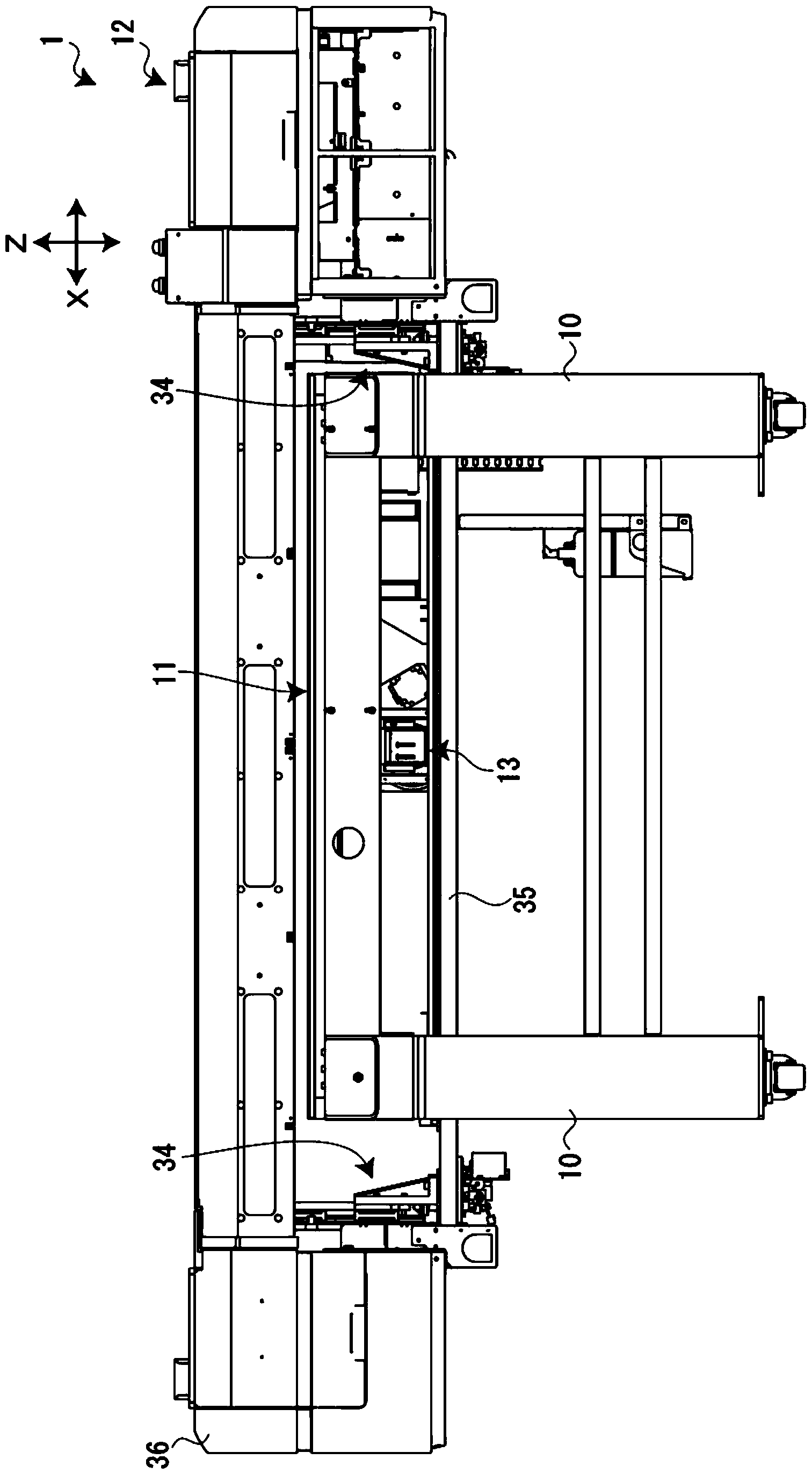

[0031] Hereinafter, a liquid ejection device according to an embodiment of the present invention will be described with reference to the drawings. This liquid ejection device is a liquid ejection device that records a desired image on a recording medium (medium) by ejecting ultraviolet curable ink (active energy ray curable ink) by an inkjet method. In addition, the present liquid ejection device is a so-called flatbed type liquid ejection device that performs recording by moving the liquid ejection head with respect to the recording medium supported on the support stage. As the recording medium, for example, recording media having different thicknesses such as thick paper, wood, ceramic tiles, plastic boards, styrene boards, and corrugated paper are assumed. In addition, the X-axis (left-right direction), the Y-axis (front-rear) direction, and the Z-axis (up-down) direction are defined as shown in each figure, and will be described later. Additionally, the figure 1 The nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com