Novel enhanced coagulation wastewater treatment method

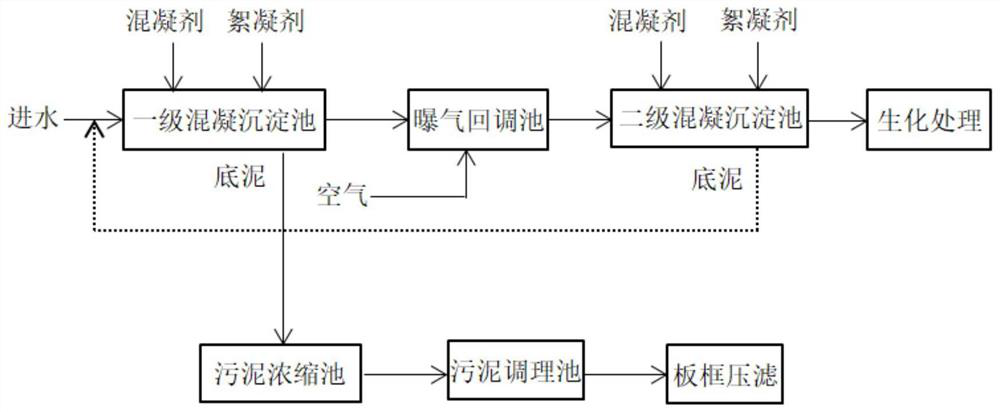

A technology for treating wastewater and coagulation, which is used in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. and other problems to achieve the effect of reducing costs and optimizing the removal of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

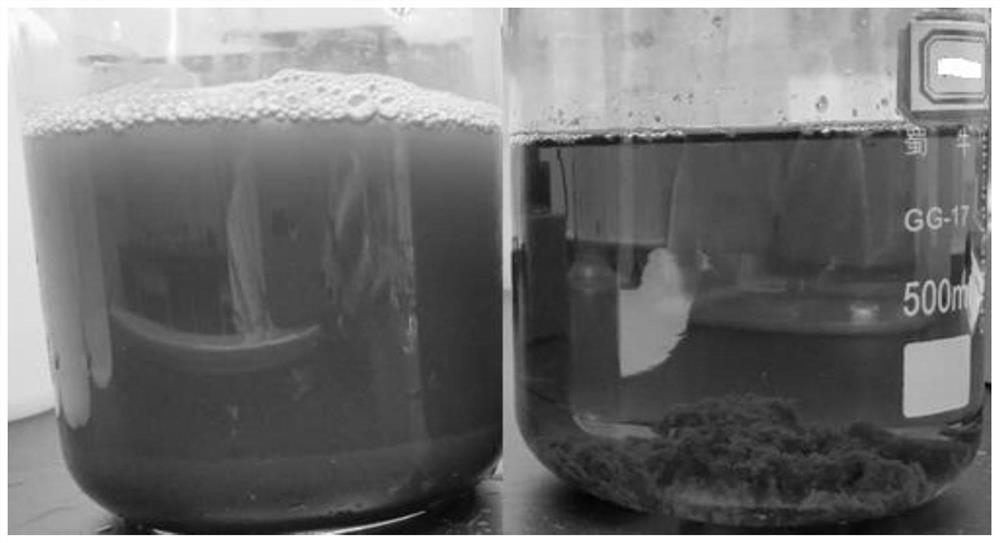

[0078] A sludge THP (thermal hydrolysis) anaerobic fermentation biogas slurry has high COD, high nitrogen, phosphorus and SS, and complex pollution components. The water quality is shown in Table 1. The biogas slurry from sludge fermentation has a certain biological inhibition effect. Without effective pretreatment, the biochemical system cannot operate effectively. The conventional primary coagulation and sedimentation treatment was previously adopted, adding 450mg / L (measured as Fe) ferric chloride, coagulation reaction for 2 hours, PAM dosage was 0.5mg / L, flocculation and sedimentation for 2 hours, and primary coagulation and sedimentation The water was still cloudy ( figure 2 Left), the water quality of the effluent is not very ideal (Table 1). Use the method of the present invention to process instead, and the first-stage coagulation and sedimentation process is: ferric chloride dosage is 400mg / L (measured in Fe), coagulation reaction 2h, PAM dosage is 0.5mg / L, floccula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com