Patents

Literature

145 results about "Demagnetizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

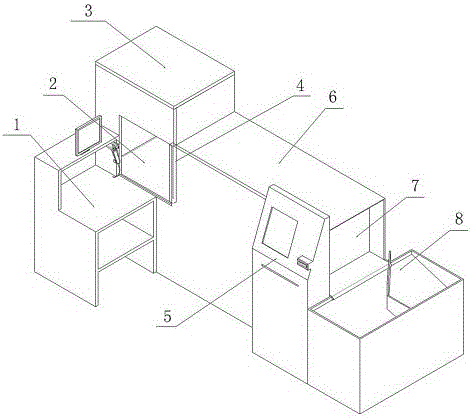

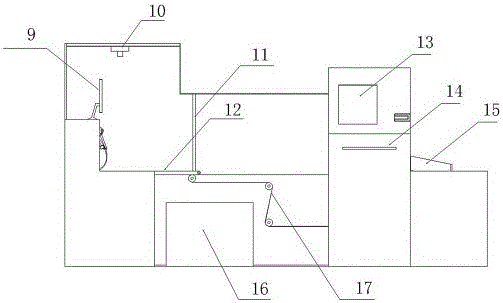

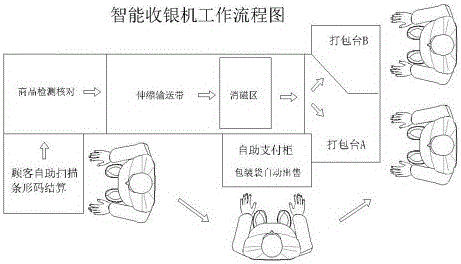

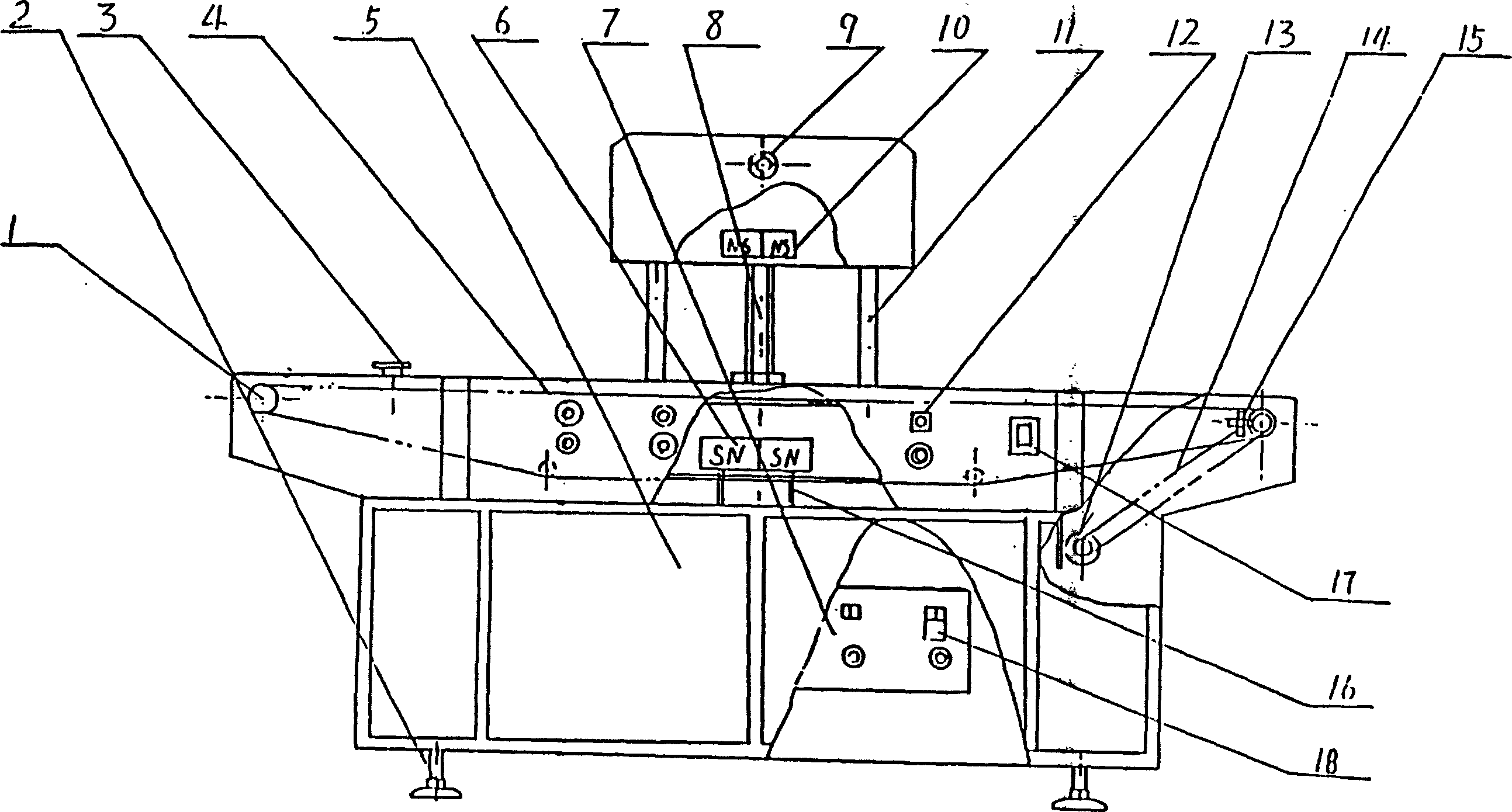

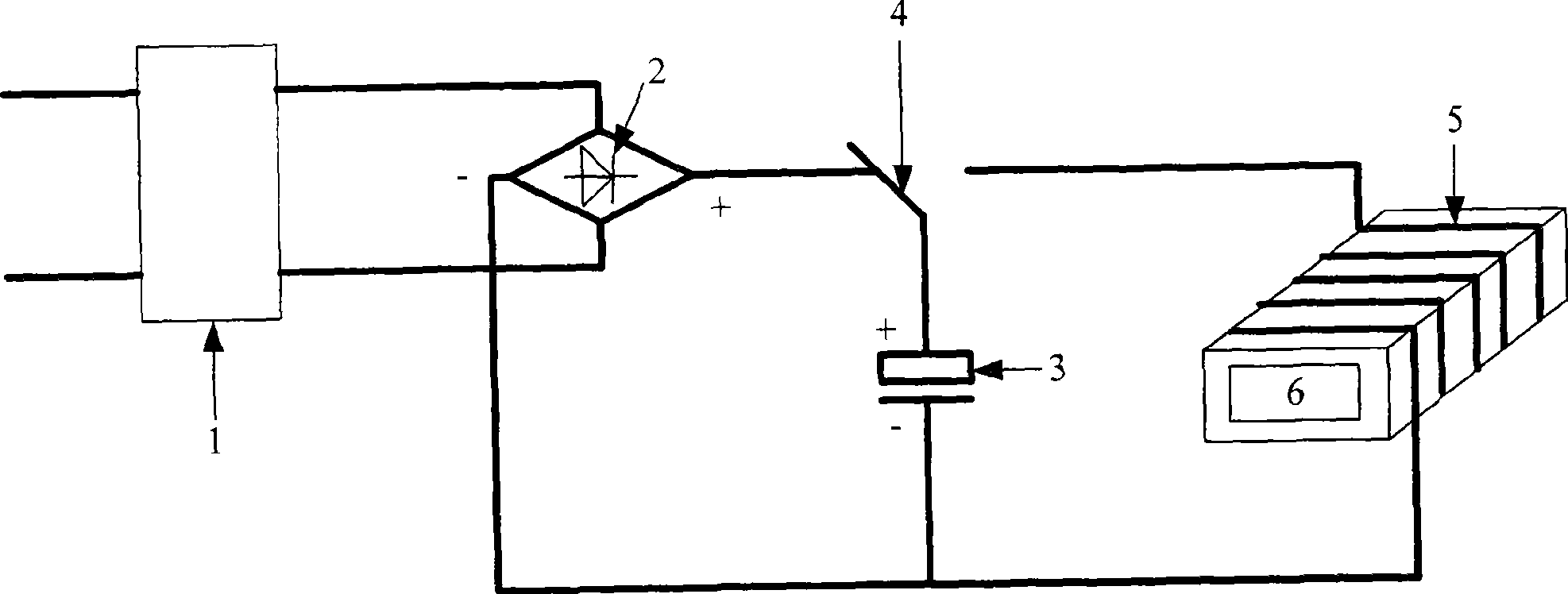

Intelligent cash register

InactiveCN106530529AEfficiency in the shopping settlement and payment processCutting costsCash registersPaymentSelf-service

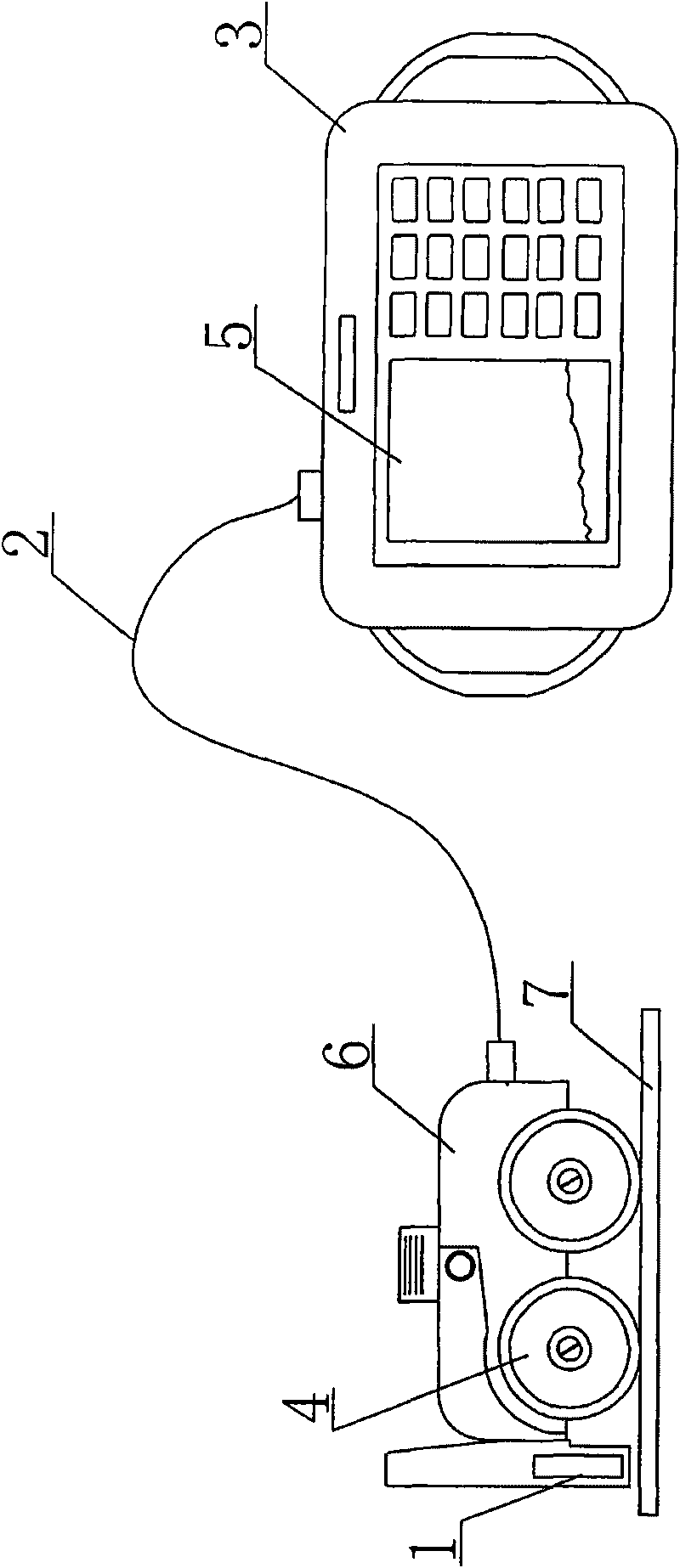

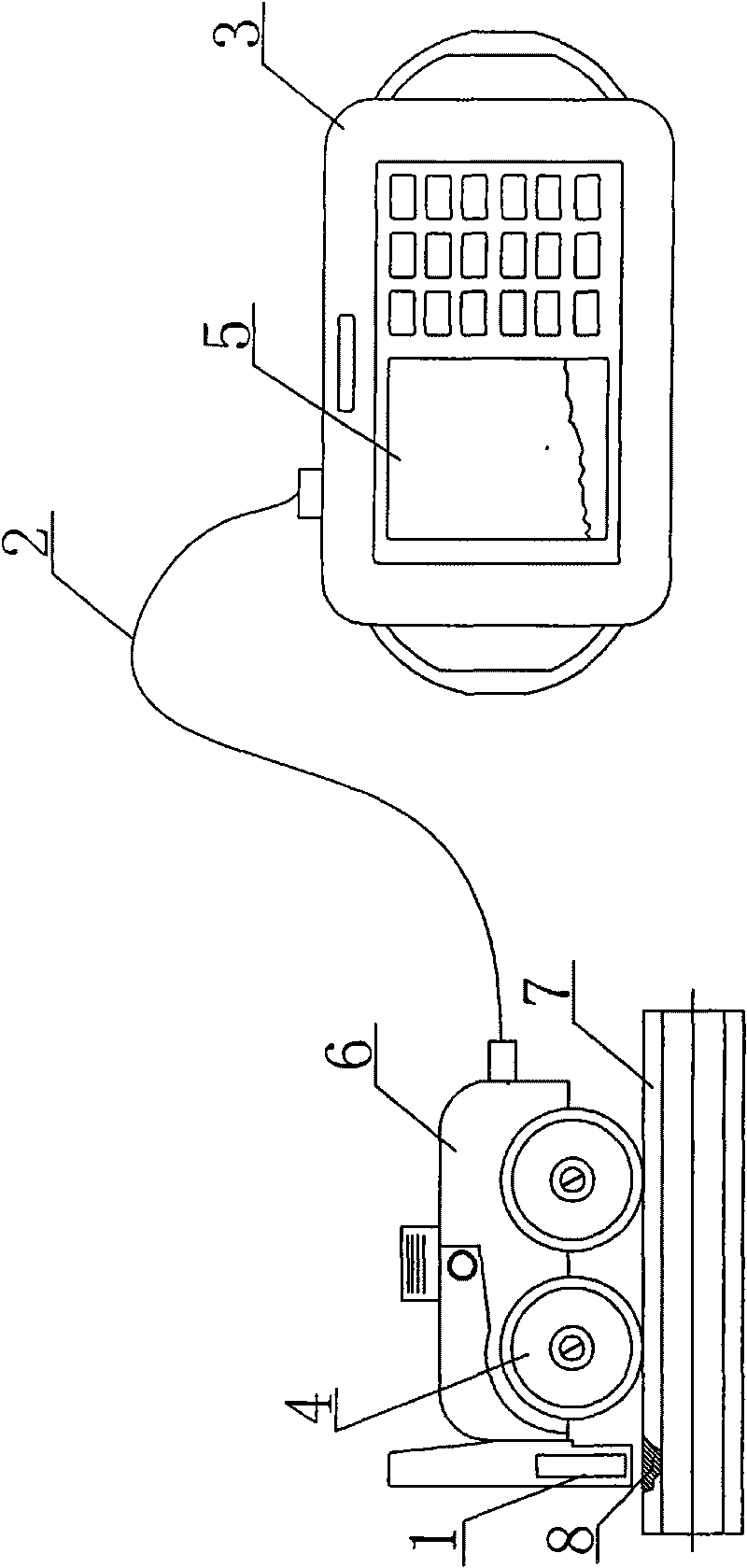

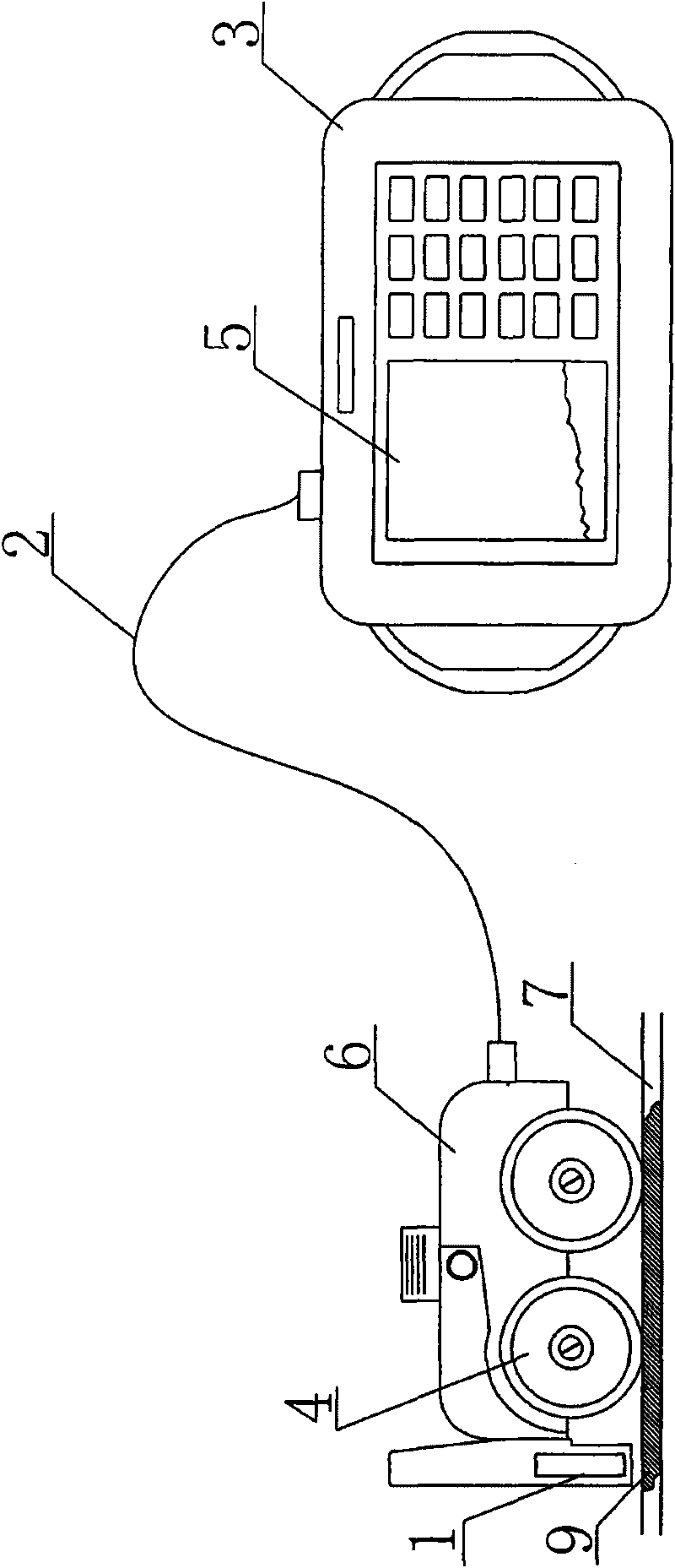

The invention relates to an intelligent cash register. A customer scans bar codes of selected commodities one by one on a self-service bar code scanning settlement platform to make settlement, and then places the scanned commodities on a detecting and checking device one by one, each commodity is identified, detected and checked automatically by the commodity detecting and checking device till the customer confirms that settlement is completed, a display screen of the settlement platform provides a sum of settlement, text and voice prompts are provided to ask the customer to make self-service payment in a payment cabinet, the commodity detecting and checking device sends commodities settled by the customer to a conveyer belt to prepare for demagnetization, after payment success of the customer, a payment cabinet system prints a shopping bill automatically, the system opens a shield door in an outlet of a packaging platform to convey the commodities to a demagnetizer for demagnetization, the commodities are sent to the packing platform, the customer is prompted to go to the packing platform to pack the commodities in a self-service manner, and if a customer selects a shopping bag, a shopping bag vending machine under the payment cabinet sends out the shopping bag selected by the customer automatically.

Owner:贤石金

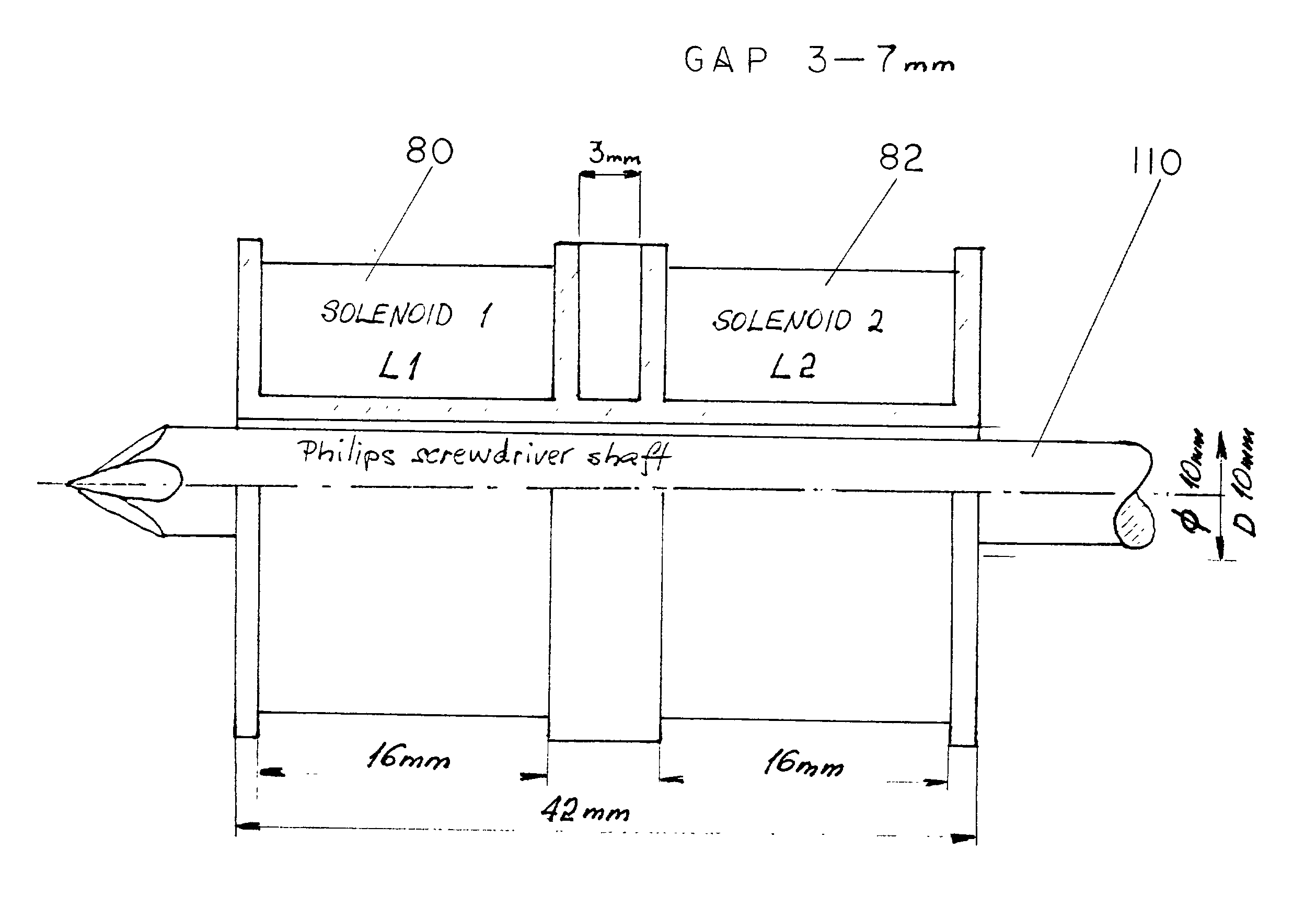

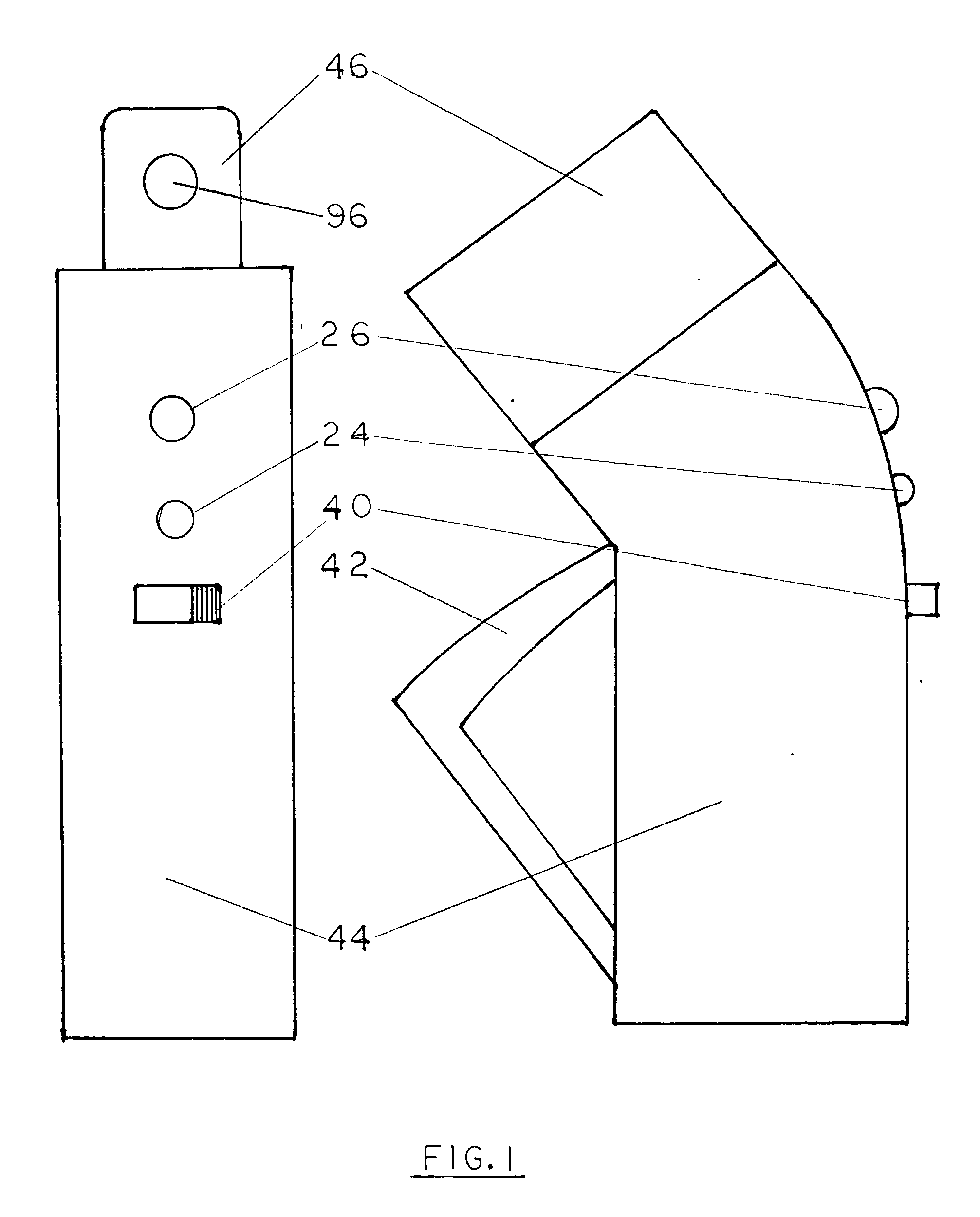

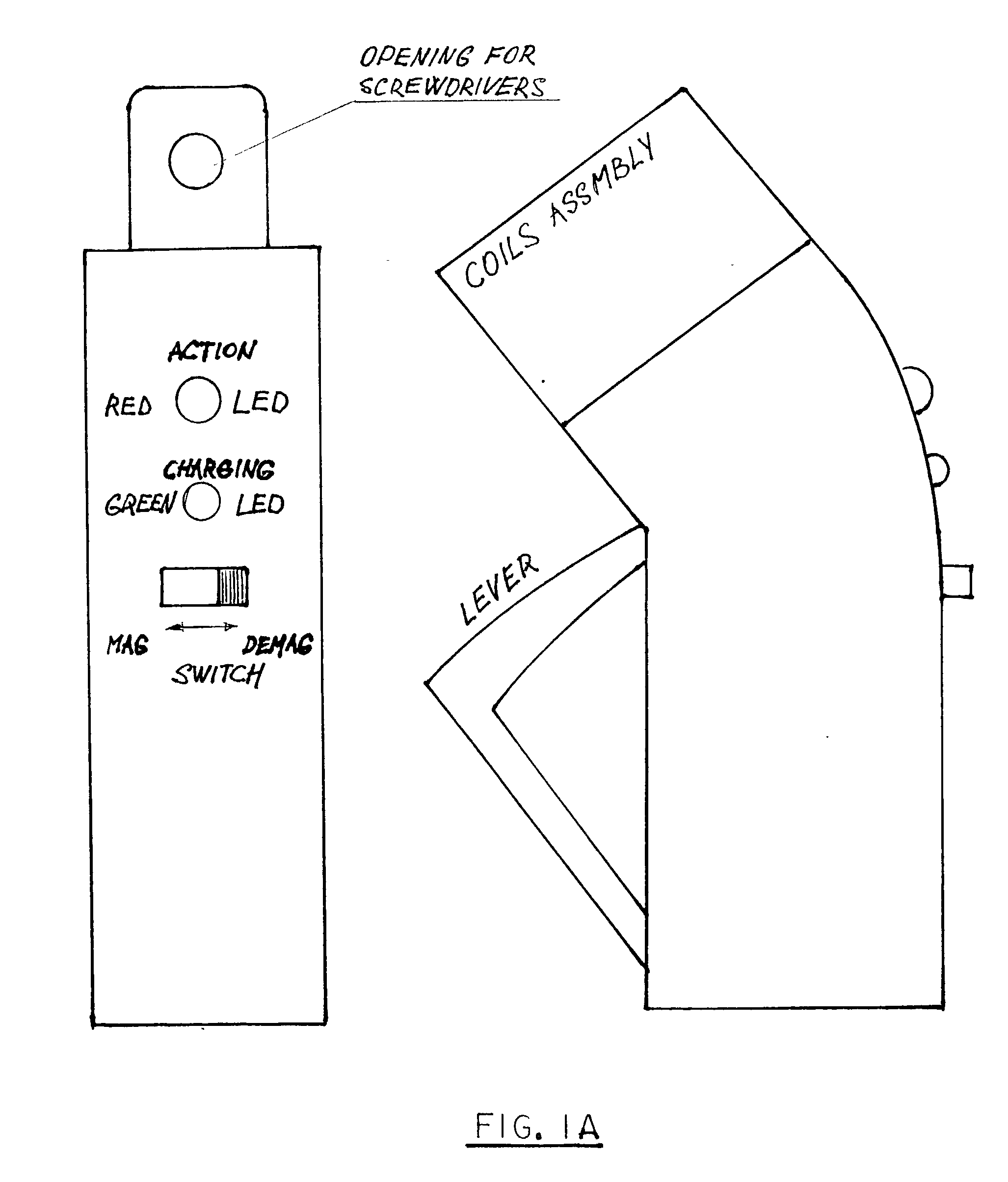

Method and apparatus for electromagnetically magnetizing and demagnetizing metallic tool shafts

A compact electric device for magnetizing and demagnetizing metal shafts, screwdrivers, or metallic tools using stored electrical energy. Handheld portable versions are illustrated (see FIGS. 1, 1A, 2, and 2A). The end of a metal shaft, or screwdriver shaft, or other said instrument is placed in (see FIGS. 3 and 6) a receiving cavity or socket (96) which is the hollow center within two coils L1 (80) and L2 (82). The operator of the device chooses either demagnetization or magnetization via a switch (86), presses an action switch (88), and electric current flows through the coils and the rest of the device in a precise way to produce the desired effect of either magnetization or demagnetization. The inserted metal shaft or other said instrument may then be removed from the receiving cavity and is now either magnetized or demagnetized. Electric power is provided by one of three methods: hand-powered push lever AC power generator, DC batteries, or AC / DC converter connected to an external power connector (94). The application range of the hand-held electric magnetizer / demagnetizer is wider.

Owner:SAJAN PAUL

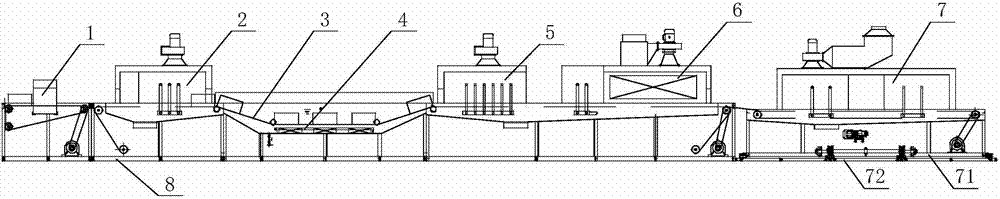

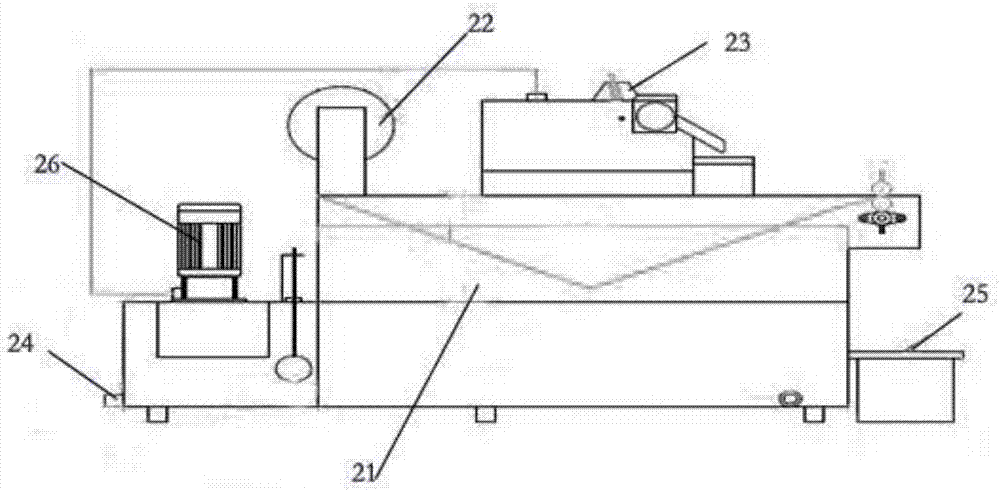

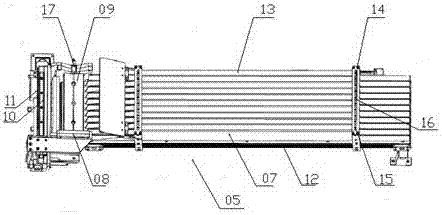

Pass-type ultrasonic cleaning machine

ActiveCN103480605ASimple structureEasy to implementLiquid surface applicatorsSpraying apparatusMegasonic cleaningEngineering

The invention discloses a pass-type ultrasonic cleaning machine which comprises a rack. A conveying belt is arranged on the rack, a demagnetizer, cleaning equipment, an ultrasonic cleaning machine body, rinsing equipment, a drying oven and oiling equipment are sequentially arranged on the rack from the left side to the right side, the ultrasonic cleaning machine body comprises a cleaning tank, an ultrasonic generator and an ultrasonic transducer, the ultrasonic generator is electrically connected with a power source, and the ultrasonic transducer is mounted at the bottom of the cleaning tank and electrically connected with the ultrasonic generator. The pass-type ultrasonic cleaning machine is simple in structure and easy to realize, adopts ultrasonic cleaning, thereby being good in cleaning effect and high in cleaning efficiency; after demagnetizing through the demagnetizer, a workpiece is enabled to be demagnetized, thereby being easy to clean up; after cleaning and drying, the workpiece is oiled by the oiling equipment, so that service life of the workpiece can be prolonged and surface effect of the workpiece can be improved.

Owner:WUXI BAOHE MACHINERY EQUIP

Magnetic memory method and device for diagnosing ferromagnetic component damage

InactiveCN101718748ARapid diagnosis of riskQuickly Diagnose DefectsMaterial magnetic variablesMagnetic memoryDisplay device

The invention discloses a magnetic memory method and device for diagnosing ferromagnetic component damage, and relates to the technical field of nondestructive inspection. The method is realized in the following way: carrying out array scanning on the component surface by using a magnetic induction sensor, testing the stray magnetic field on the component surface, converting the tested magnetic signal into an electric signal, and carrying out filter amplification on the electric signal, inputting the electric signal after being processed in an A / D conversion mode to a processor; and processing the processed electrical signal with the processor to obtain the test signal information of the component surface, thereby obtaining information on whether a certain region of the component is on the verge of the damage state or not in the damage state, and finally displaying the information on a display screen. The invention can detect the established defect, and can effectively evaluate earlier damage to metal components, such as microcracks and the like, and especially unshaped hidden discontinuous changes. The invention does not require lots of preparations before the detection; and in the detection process, the invention does not require that the equipment must be in the working condition of rated load, or require additional magnetizers and demagnetizers, thereby being very convenient for on-line detection.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Write head demagnetizer

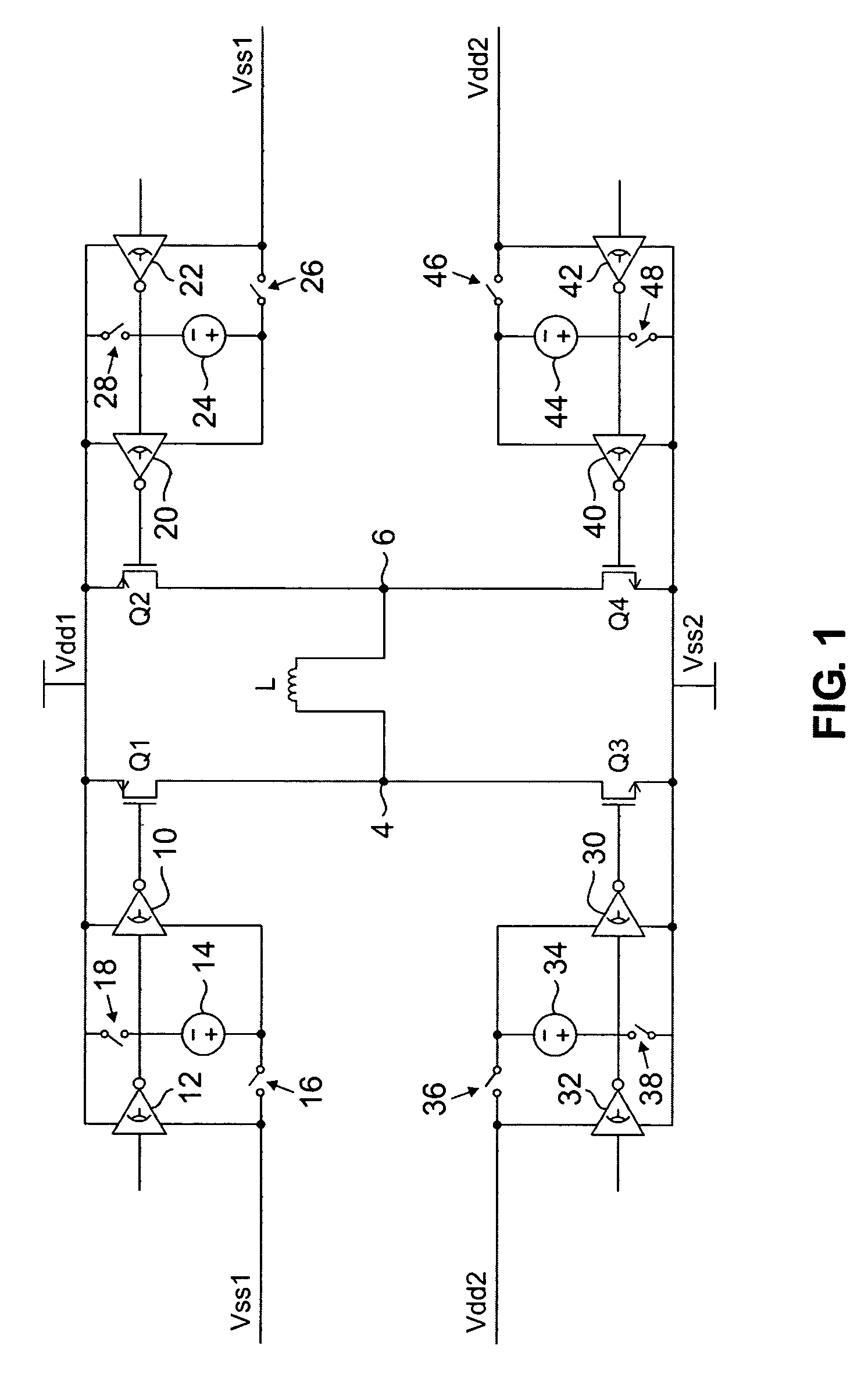

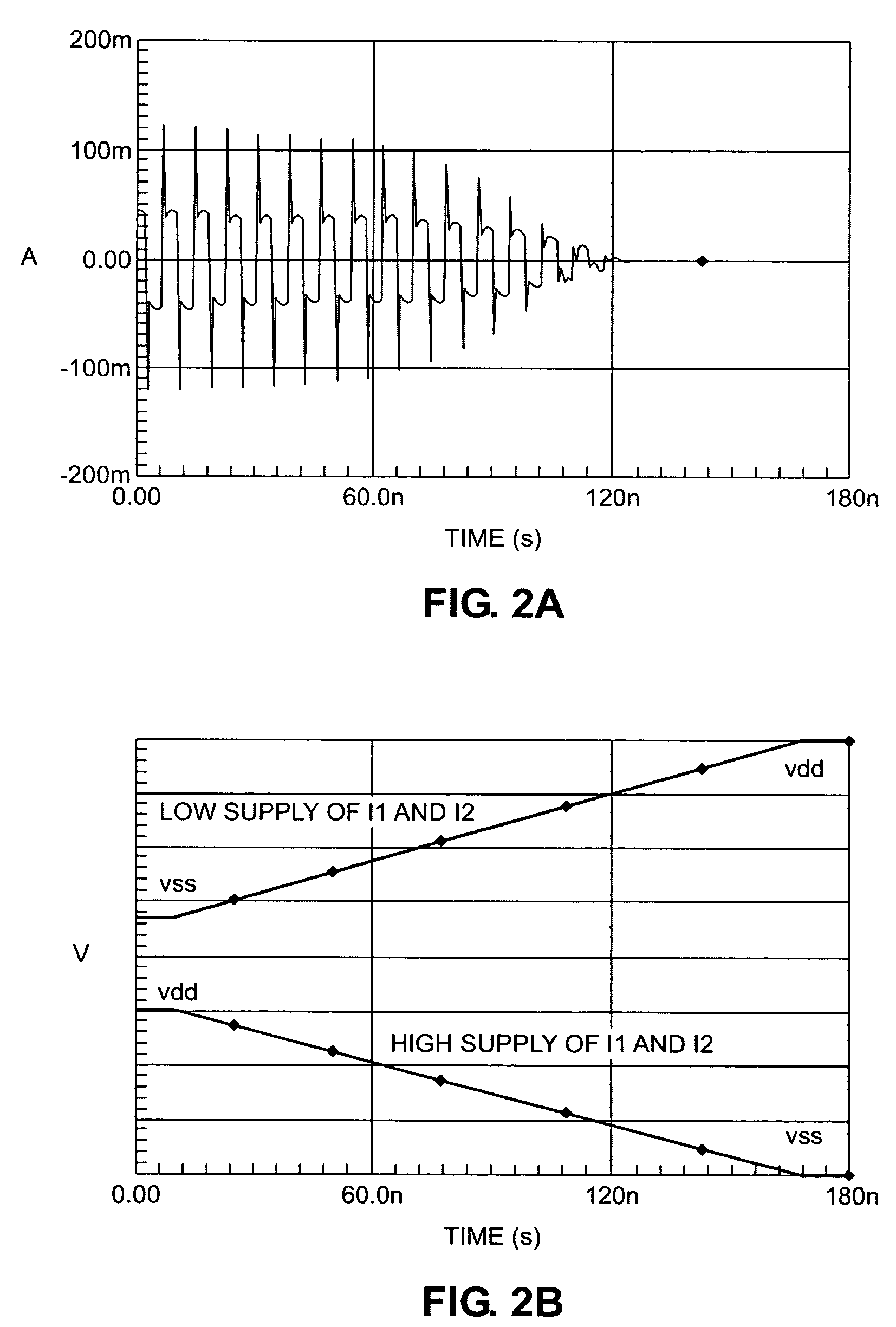

ActiveUS7106536B2Simple and inexpensiveConstruction of head windingsFilamentary/web carriers operation controlDriver circuitHemt circuits

A demagnetizer for an inductive load having a driver circuit including at least one transistor and a ramp-down voltage source switchably connected to the driver circuit, so that when the ramp-down voltage source is connected to the transistor, it drives the voltage of the transistor below its threshold voltage.

Owner:AVAGO TECH INT SALES PTE LTD

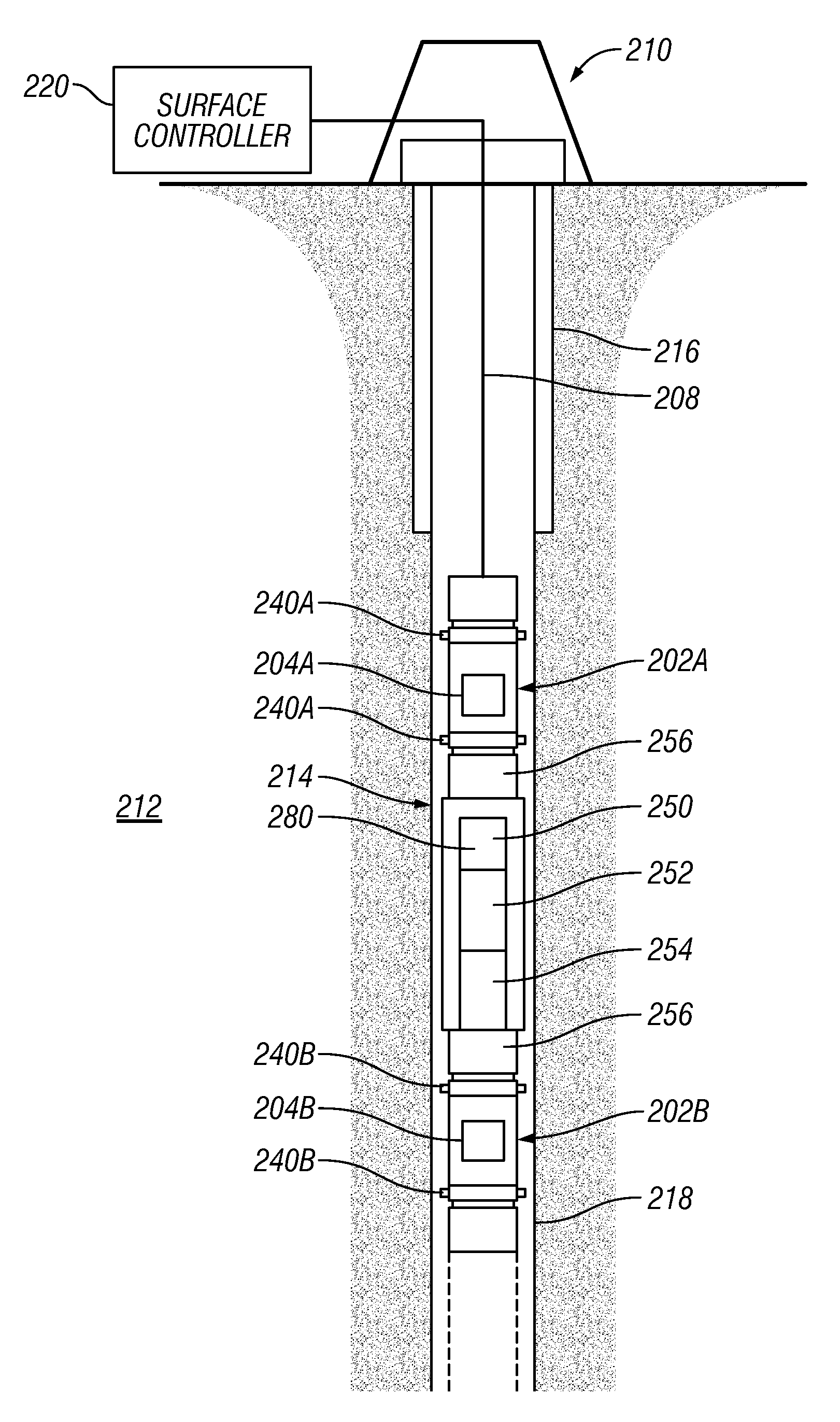

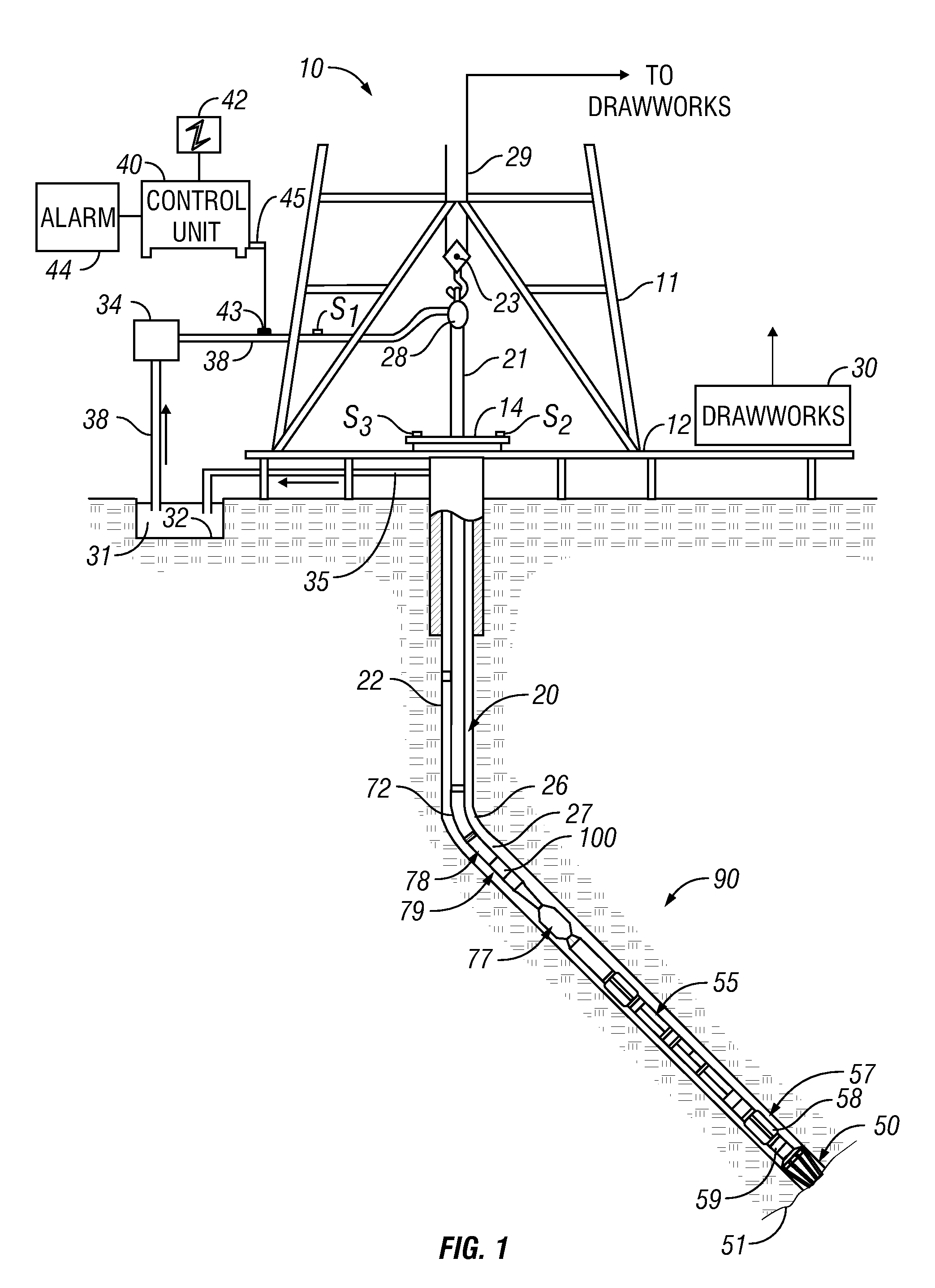

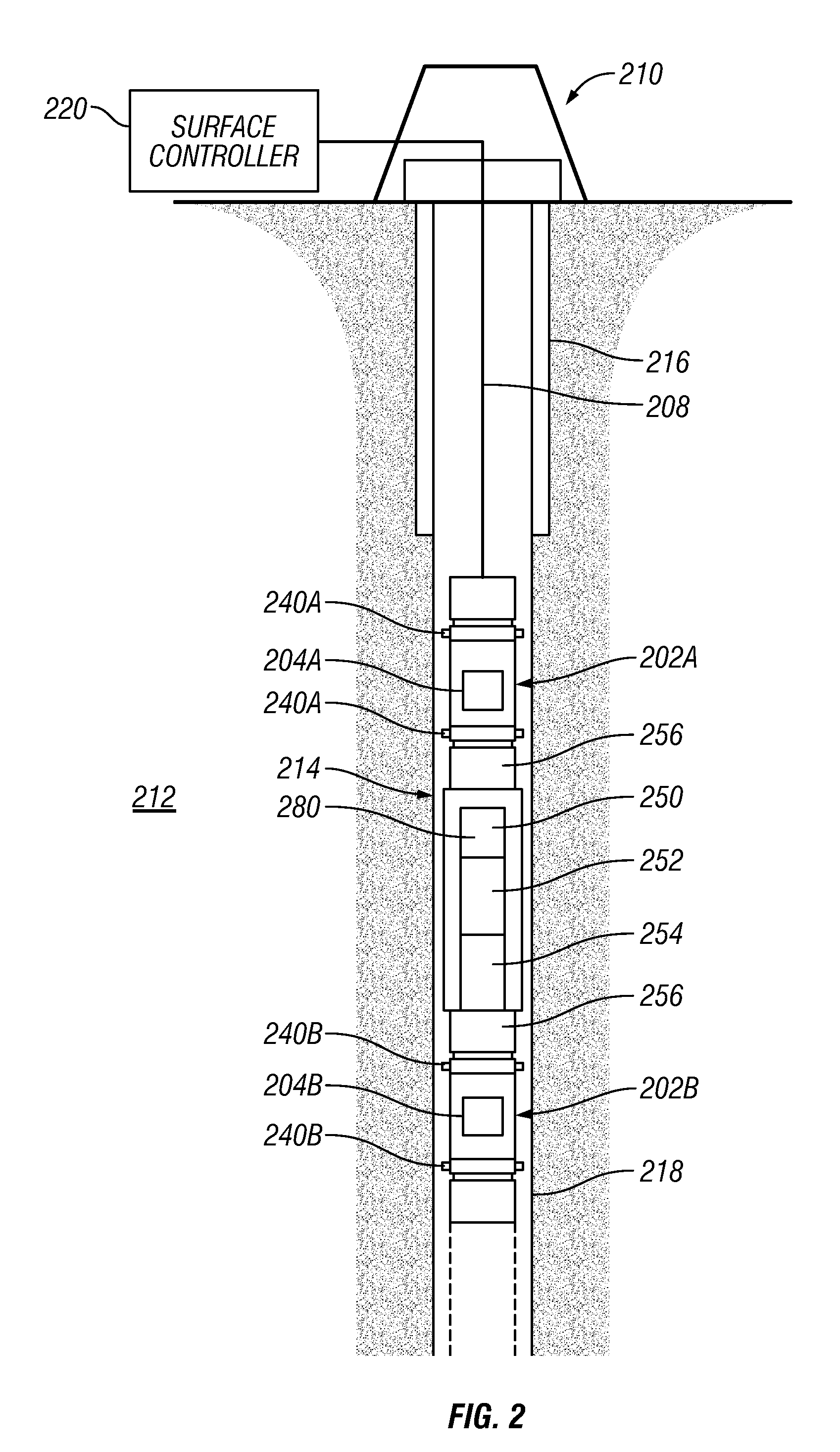

Demagnetizer to Eliminate Residual Magnetization Produced by Nuclear Magnetic Resonance Logs

InactiveUS20090015254A1Eliminate the effects ofReduce removalElectric/magnetic detection for well-loggingSurveyDemagnetizing deviceNMR - Nuclear magnetic resonance

An apparatus and method is disclosed for measuring a parameter of an earth formation surrounding a wellbore. A Nuclear Magnetic Resonance (NMR) tool and at least one second tool are conveyed in the wellbore on a wireline, the NMR tool having a magnetic influence on a region of the wellbore. The magnetic influence of the NMR tool is removed from the region of the wellbore using a demagnetizing device. The parameter of the earth formation is measured using the at least one second tool. A second demagnetizing device may be used to remove the magnetic influence of the at least one second tool from the region of the wellbore.

Owner:BAKER HUGHES INC

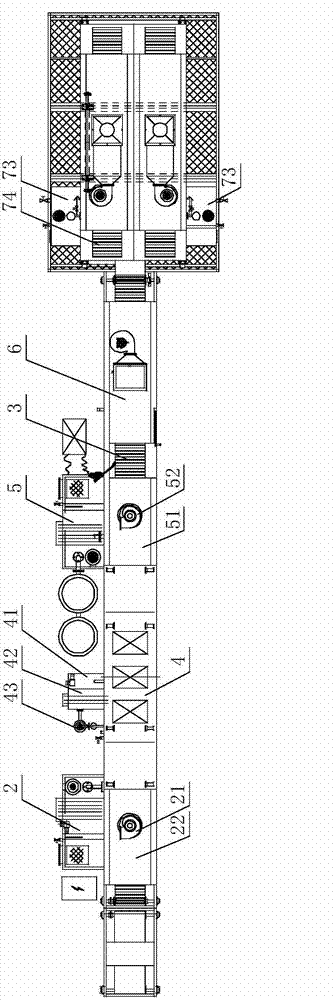

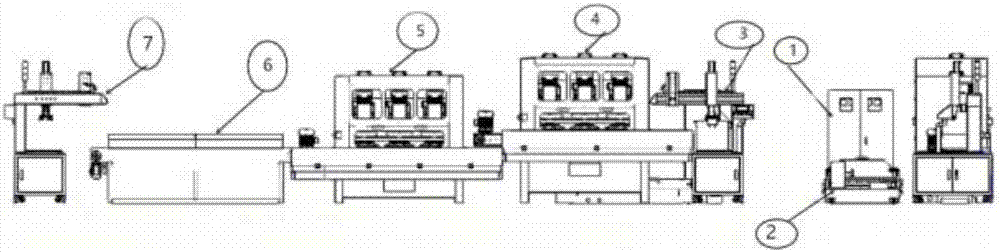

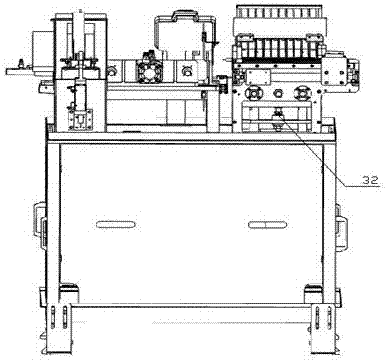

Automatic double-sided deburring and cleaning-drying production line

PendingCN107414642AImprove machining accuracyImprove processing efficiencyEdge grinding machinesDrying gas arrangementsProduction lineFiltration

The invention discloses an automatic double-sided deburring and cleaning-drying production line. The automatic double-sided deburring and cleaning-drying production line comprises an electric appliance cabinet controlling a whole system to run, a loading manipulator, a first deburring machine, a second deburring machine, a cleaning-drying all-in-one machine and an unloading manipulator, wherein the loading manipulator is arranged just above an input end of the first deburring machine, and conveys a workpiece onto an advancing rail of the first deburring machine through a magnetic attraction disc of the loading manipulator; the workpiece enters an input port of the second deburring machine through a magnetic turnover roller of the first deburring machine; the first deburring machine and the second deburring machine are connected with a paper bag-type water circulation and filtration system separately and form a circulation system; a hidden demagnetizer is arranged on an output part of the second deburring machine; the hidden demagnetizer demagnetizes the workpiece, and the workpiece enters an input end of the cleaning-drying all-in-one machine; the unloading manipulator is arranged in the vertical direction of an output end of the cleaning-drying all-in-one machine; and whole equipment is operated through a PLC programming controlled push-to-start machine. The automatic double-sided deburring and cleaning-drying production line is energy-saving and environment-friendly due to the complete water filtration and circulation system; and the production line is safe and stable, high in machining accuracy, high in machining efficiency, intelligent and high in efficiency due to totally-enclosed running and a transparent observation window.

Owner:万创(苏州)智能装备有限公司

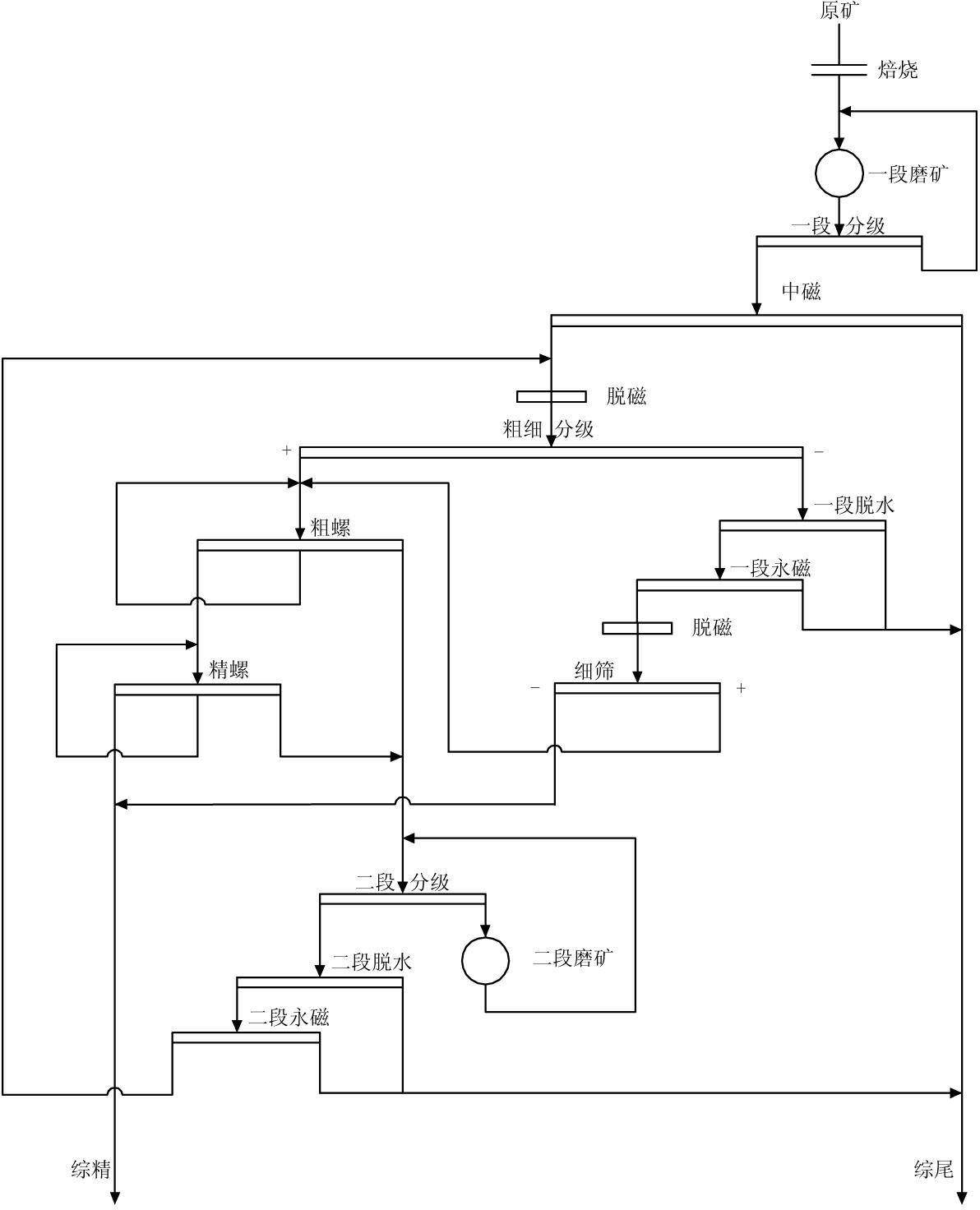

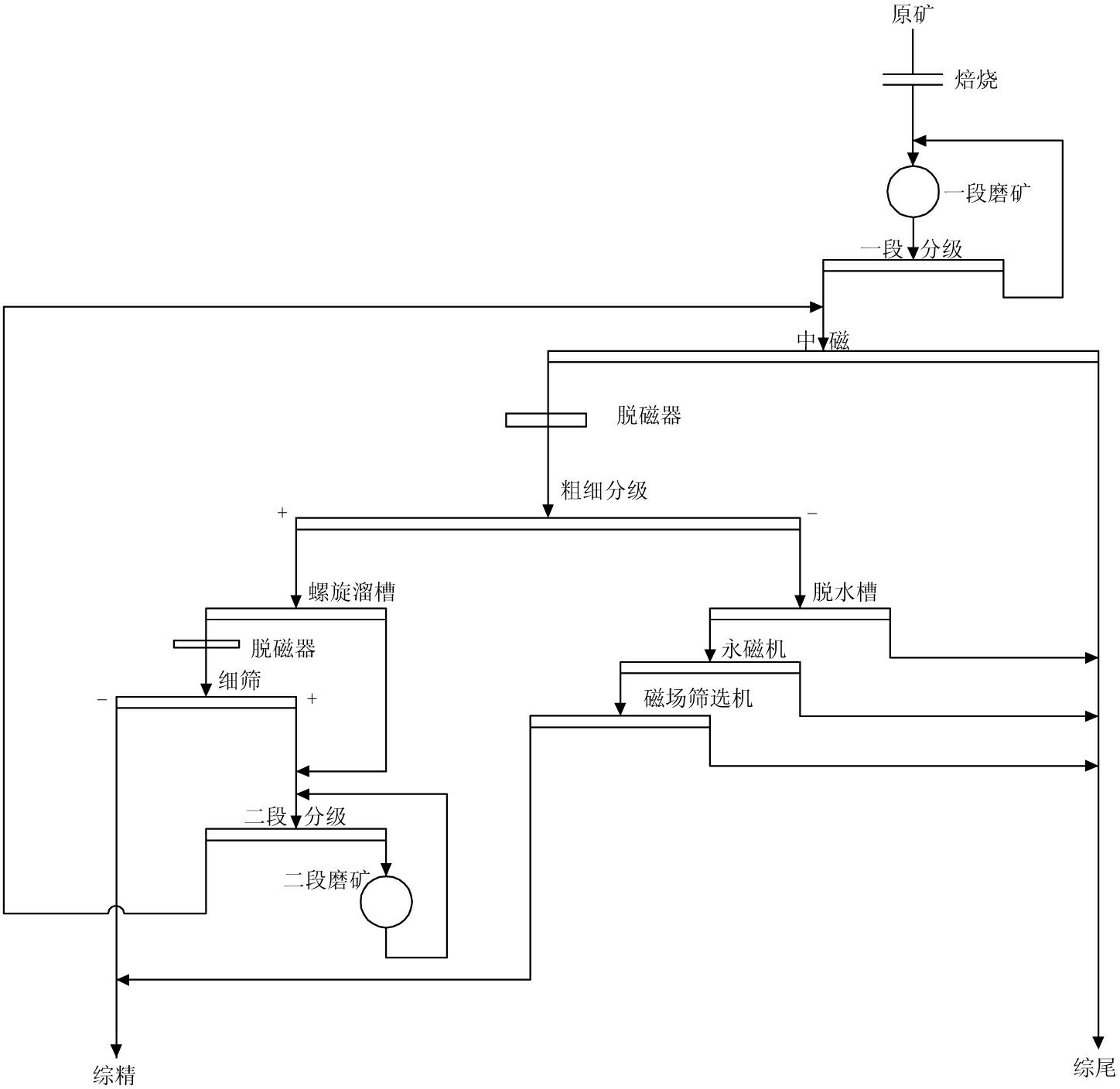

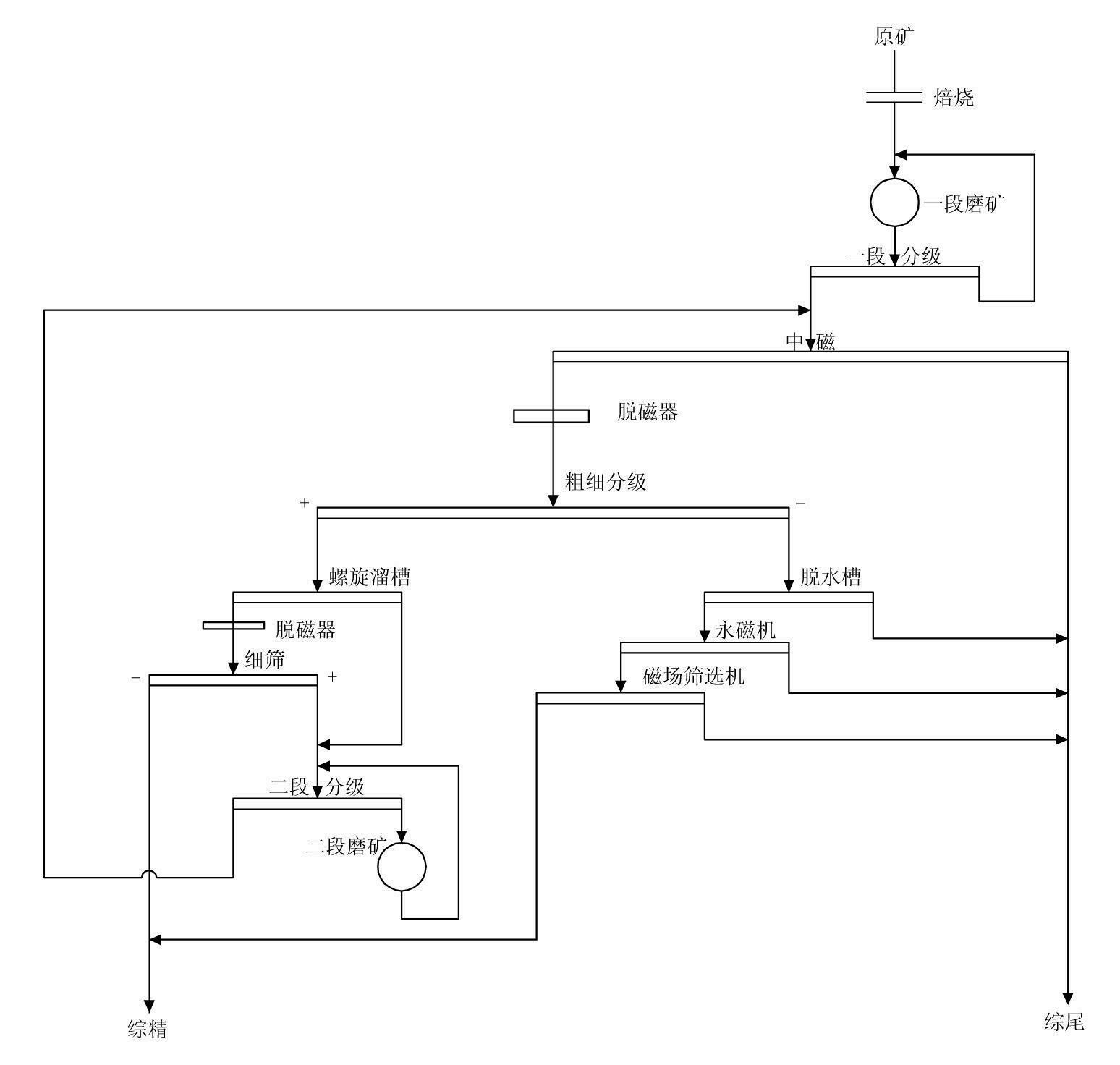

Hematite roasting, stage grinding, intermediate magnetic separation, fineness classifying, gravity concentration-magnetic separation technique

ActiveCN102631984AImprove sorting efficiencyImproved technical indicatorsWet separationScreening proceduresClosed loop

The invention belongs to the technical field of iron ore grading and especially relates to a hematite roasting, stage grinding, intermediate magnetic separation, fineness classifying, gravity concentration-magnetic separation technique, comprising raw ore roasting, first segment of closed loop grinding, primary grading, intermediate magnetic separation, fineness classifying and gravity concentration-magnetic separation. The technique is characterized by feeding the intermediate magnetic separation concentrate in a demagnetizer, grading the concentrate through fineness classifying, grading the material into rough granule level product and fine granule level product, feeding the rough granule level product in the fineness classifying procedure in a helical chute, demagnetizing the concentrate in the helical chute and performing screening procedure on the concentrate, serving the tailings in the helical chute and the oversize product in the screening procedure as middlings, performing secondary grading and second segment of closed loop grinding procedures on the middlings, and feeding the fine granule parts in the fineness classifying procedure in a dehydration tank, a permanent magnetic machine and a magnetic field screening machine to perform magnetic separation procedure. The comprehensive concentrate is composed of screening concentrate and magnetic field screening machine concentrate, and the compressive tailings are composed of intermediate magnetic separation tailings, dehydration tank tailings, permanent magnetic machine tailings and magnetic field screening machine tailings. The technique has the advantages that the sorting efficiency of the whole procedure is improved, the screening concentrate in rough granule procedure and the magnetic field screening machine concentrate in fine granule procedure can reach 65-67%, the level of the comprehensive concentrate is higher than 65-67%, and the level of the compressive tailings is reduced to 8-10%.

Owner:ANSTEEL GRP MINING CO LTD

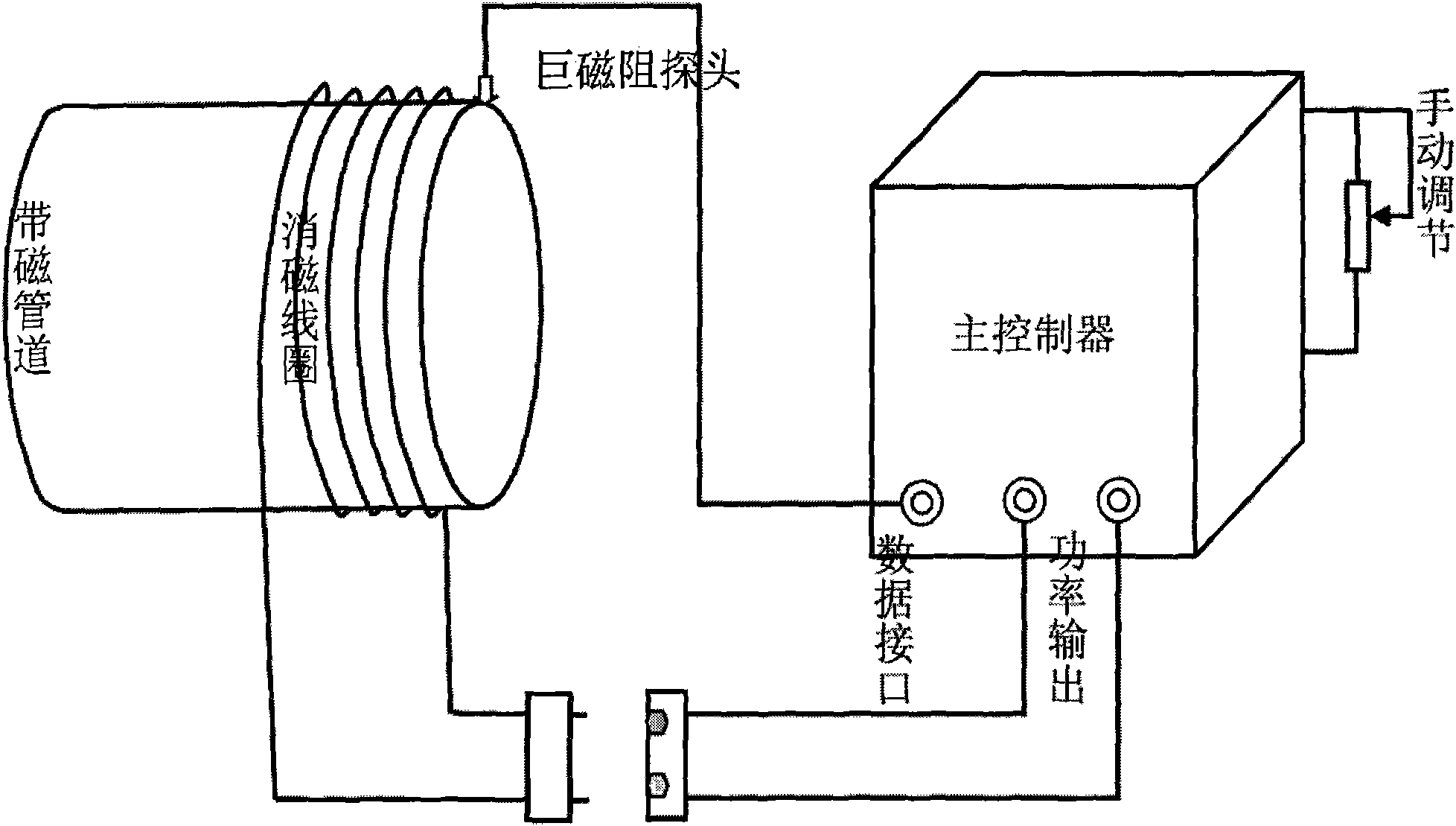

Pipeline port hysteresis buffer demagnetization method and demagnetizer

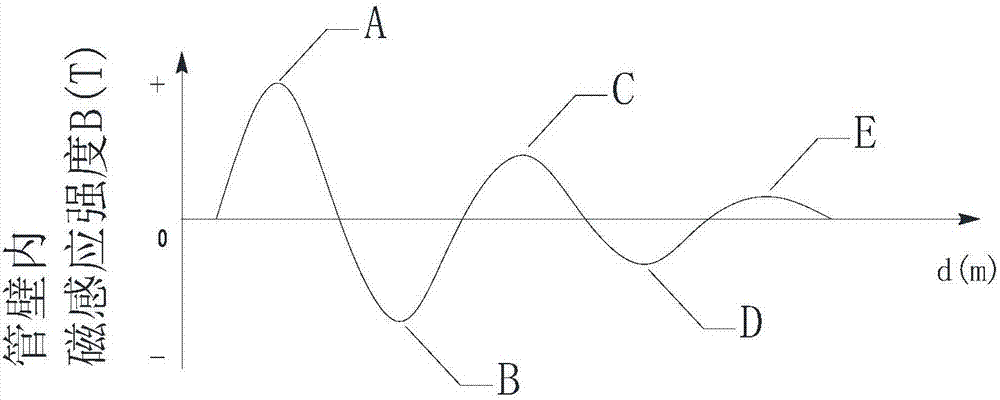

ActiveCN102403083AOvercoming coercive forceLow magnetic blow effectMagnetic bodiesHysteresisEngineering

The invention discloses a pipeline port hysteresis buffer demagnetization method and a demagnetizer and relates to the technical field of pipeline systems. Demagnetization coils are wound at a port of a pipeline to be demagnetized; a giant magneto-resistance probe is fixed at an outer edge of the port of the pipeline; the giant magneto-resistance probe is connected with a data interface of a maincontroller of the demagnetizer; and the demagnetization coils are connected with a power output end of the main controller. The method comprises the following steps that: the main controller picks upa signal of the giant magneto-resistance probe and measures the size and direction of the remanence of the pipeline; according to the size and direction of the remanence of the pipeline and differences of materials, the main controller automatically calculates output parameters and controls a circuit part to convert a power frequency alternating current of 50 Hz into a high frequency alternating current of 20 to 45 kHz; and the main controller performs voltage reduction and rectification and controls a power supply to generate the size and direction of a required current so as to obtain a magnetic field of which the size is equal to that of the remanence of the pipeline and the direction is opposite to that of the remanence of the pipeline. Compared with the conventional demagnetization product, the demagnetizer has the advantages of light weight, low energy consumption, advanced control mode, reliability in operation, high demagnetization speed, good demagnetization effect and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

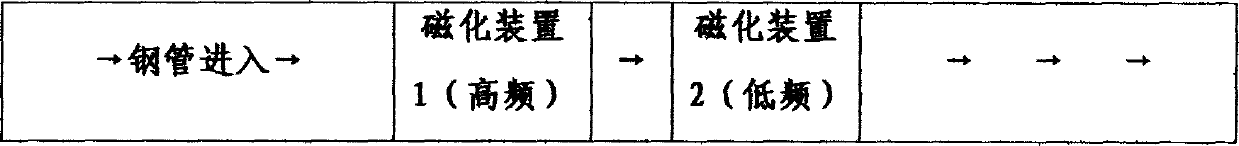

Eddy current high/low-frequency compound detection equipment for seamless steel tubes

InactiveCN103105431AEasy to detectImprove work efficiencyMaterial magnetic variablesEngineeringEddy current

The invention discloses eddy current high / low-frequency compound detection equipment for seamless steel tubes. The equipment comprises an electric control system, front and rear roller paths, a positioning pressure wheel device, a three-roller centering device, a lifting device, magnetizing devices, a flaw detection instrument, a demagnetizer, a stand and a blanking frame. The steel tubes to be detected stably enter into the pressure wheel device, the three-roller centering device and the two magnetizing devices through the transmission roller paths controlled by the electric control system for finishing full coverage detection of the steel tubes; the flaw detection instrument is used for displaying detection results; and the steel tubes enter into the demagnetizer and the stand for demagnetizing the steel tubes, finally enter into the blanking frame and are automatically separated and stored in qualified and unqualified product storage tanks. The equipment has the beneficial effects that each magnetizing device is equipped with a high-frequency probe and a low-frequency probe for on-line detection, so that the detection effect and the working efficiency are improved and the missing detection risk is lowered.

Owner:沈玉琴

Fast-cleaning electromagnetic iron removing machine

InactiveCN104258989AQuick washEasy to cleanHigh gradient magnetic separatorsSlagElectromagnetic shielding

A fast-cleaning electromagnetic iron removing machine comprises a rack, an inner cylinder, a feeding port, a discharging port, electromagnetic coils, a heat dissipation tank, a demagnetizer and a power supply, wherein the inner cylinder is mounted on the rack; the outer side of the inner cylinder is wound with the electromagnetic coils; the feeding port is formed in the lower end of the inner cylinder; the discharging port is formed in the upper end of the inner cylinder; soft magnetic nets are arranged in the inner cylinder and mounted on a vibration pole; a vibration motor is connected onto the vibration pole; an elastic connector is arranged between the vibration motor and the inner cylinder; a water inlet is formed in the top end of the inner cylinder; and a slag removing port is formed in the bottom of the inner cylinder. Besides, the demagnetizer is used for eliminating magnetism of the soft magnetic nets and ferromagnetic slag absorbed on the soft magnetic nets during soft magnetic net cleaning, the electromagnetic coils are sealed in the heat dissipation tank, and a liquid is injected into the heat dissipation tank for cooling the electromagnetic coils. The fast-cleaning electromagnetic iron removing machine is equipped with the demagnetizer, water spray devices are arranged at the top end of the inner cylinder, and the vibration device is connected onto the soft magnetic nets, so that the cleaning is convenient and fast.

Owner:YUEYANG SHENGANG ELEVATORING ELECTROMAGNET

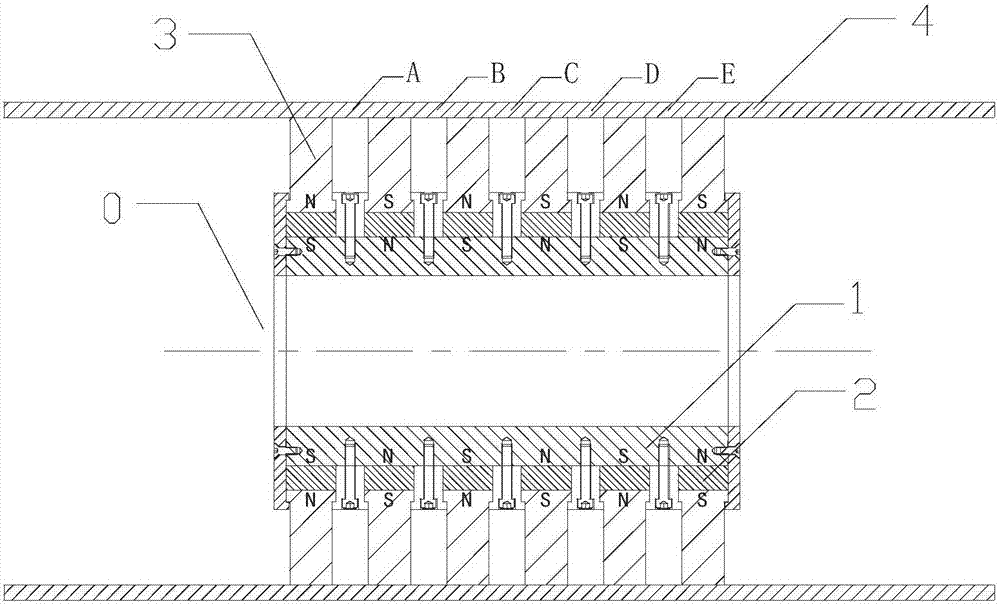

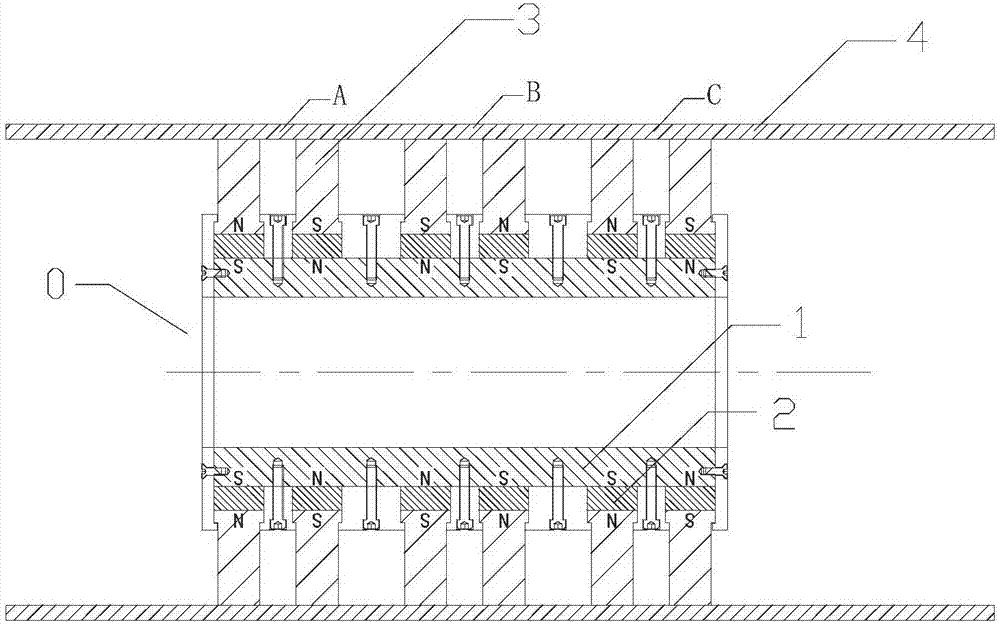

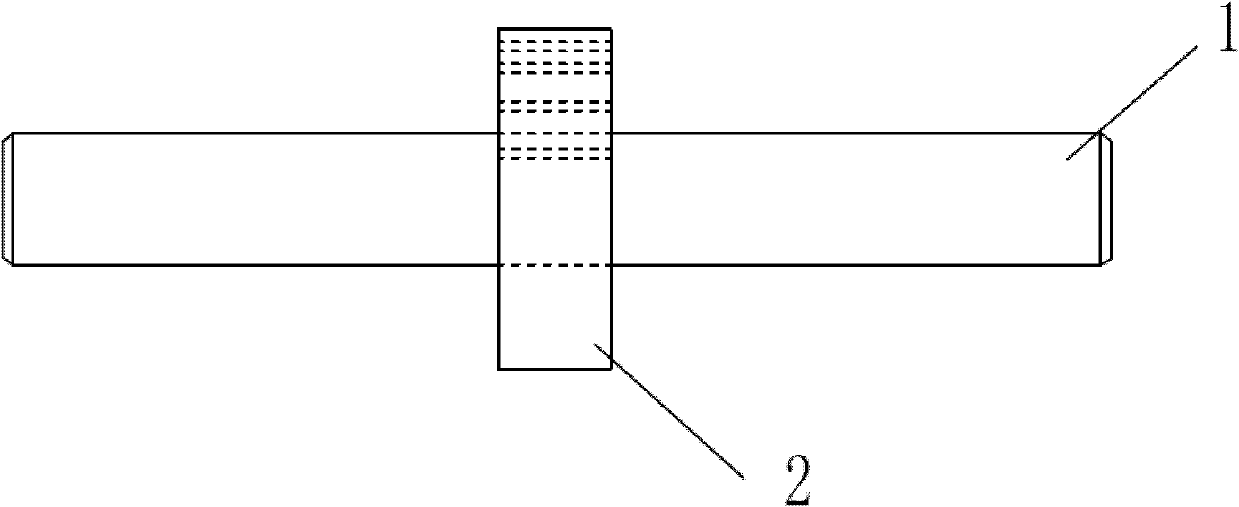

Pipeline demagnetizer based on permanent magnet structure and application of pipeline demagnetizer

ActiveCN107424721AEasy to achieve the purpose of demagnetizationPermanent magnetsEngineeringDemagnetizer

The invention relates to a pipeline demagnetizer based on a permanent magnet structure and application of the pipeline demagnetizer. The pipeline demagnetizer comprises a center piece and permanent magnets distributed on the center piece, wherein magnetic fields with alternatively varied directions are formed in the wall of the pipeline in the axial direction from front to back; the intensity of the magnetic field is decreased gradually; the demagnetizer can adopt a built-in structure or a built-out structure and is applied for pipeline demagnetization. Compared with the prior art, the pipeline demagnetizer has the advantage that a group of steady alternative attenuation magnetic fields are formed in space, and the magnetized pipeline and the group of alternative attenuation magnetic fields have relative displacement in space, so that the wall of the pipeline goes through the group of alternative attenuation magnetic fields, therefore, the purpose of demagnetization can be achieved.

Owner:SHANGHAI JIELING MAGNETIC MATERIAL & DEVICES

Battery cathode material mixing device with demagnetizer

InactiveCN106732141ADegaussing fastThe first effect is thoroughTransportation and packagingMixersElectrical batteryEngineering

The invention discloses a battery cathode material mixing device with a demagnetizer. The battery cathode material mixing device comprises a damping base, a mixing chamber is arranged at the top of the damping base, a discharge pipe and a second additive inlet pipe are arranged on the right side of the mixing chamber, a first additive inlet pipe is arranged on the left side of the mixing chamber, and the top of the mixing chamber is provided with a motor cover and a feed port. The battery cathode material mixing device is simple in structure, reasonable in design and convenient to use, materials enter the device through a feed pipe, crushed qualified materials are filtered by a filter plate after being crushed by a first crushing shaft and a second crushing shaft, and the materials are demagnetized in a demagnetizing pipe for the first time and uniformly scattered under the action of a scattering device to contact with the left inner wall and the right inner wall of the demagnetizing pipe, so that the materials are more thoroughly demagnetized. The materials fall onto the demagnetizer and are secondarily demagnetize, so that the materials are more rapidly demagnetized, demagnetizing effects are better, and the materials are conveyed into the mixing chamber through the feed port and stirred and mixed with additives.

Owner:SHENZHEN JUOCAN TECH CO LTD

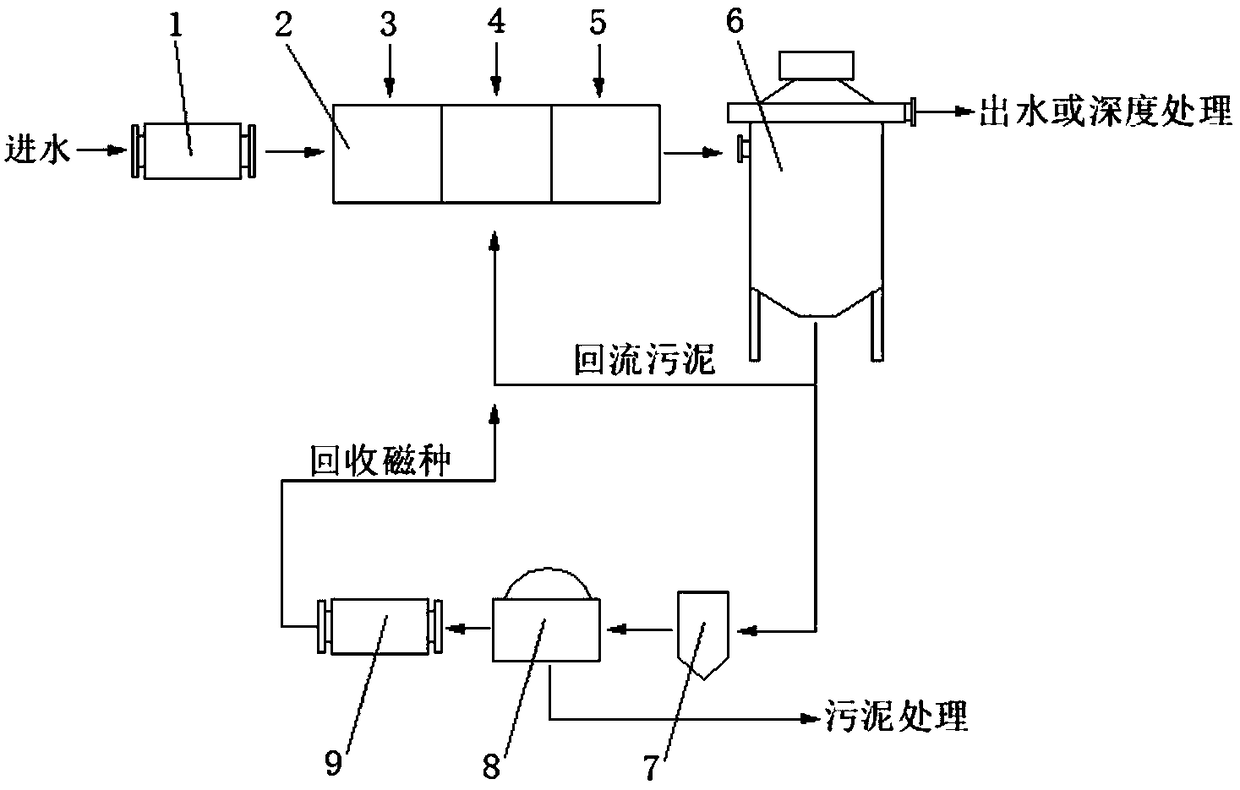

Urban sewage disposal system and method based on magnetic enhancement and coagulation separation

PendingCN108298759AImprove processing efficiencyEfficient reuseMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludgeMagnetization

The invention discloses an urban sewage disposal system and method based on magnetic enhancement and coagulation separation. The system includes a pipe-type pre-magnetizer, a coagulating pond, a magnetic sedimentation accelerating equipment, a high-speed shearing machine, a magnetic separator special for magnetic seed recovery and a pipe-type demagnetizer which are connected with one another in sequence. The disposal method mainly includes the steps of pre-magnetization of sewage, loading of magnetic seeds for coagulation of sludge, sedimentation acceleration of flocculating sludge constituents through a spiral magnetic field, high-speed shearing separation of the magnetic seeds from the sludge, efficient recovery of the magnetic seeds through a multipole alternating magnetic field, magnetic oscillation for demagnetization of the magnetic seeds, and reloading of the magnetic seeds for recycling. Through full-process coverage of a magnetic technology, fast sedimentation of micro-fine granular suspended solids and efficient reuse of the magnetic seeds are achieved, the hydraulic sedimentation standing time is greatly shortened, the sewage disposal efficiency is improved, and the quality of discharged water is stabilized; all-weather efficient reduction of total phosphorus and other pollutants is achieved, loads of a secondary disposal process are alleviated, the planned floor area is obviously reduced, and the operation cost is decreased.

Owner:BGRIMM MACHINERY & AUTOMATION TECH CO LTD +1

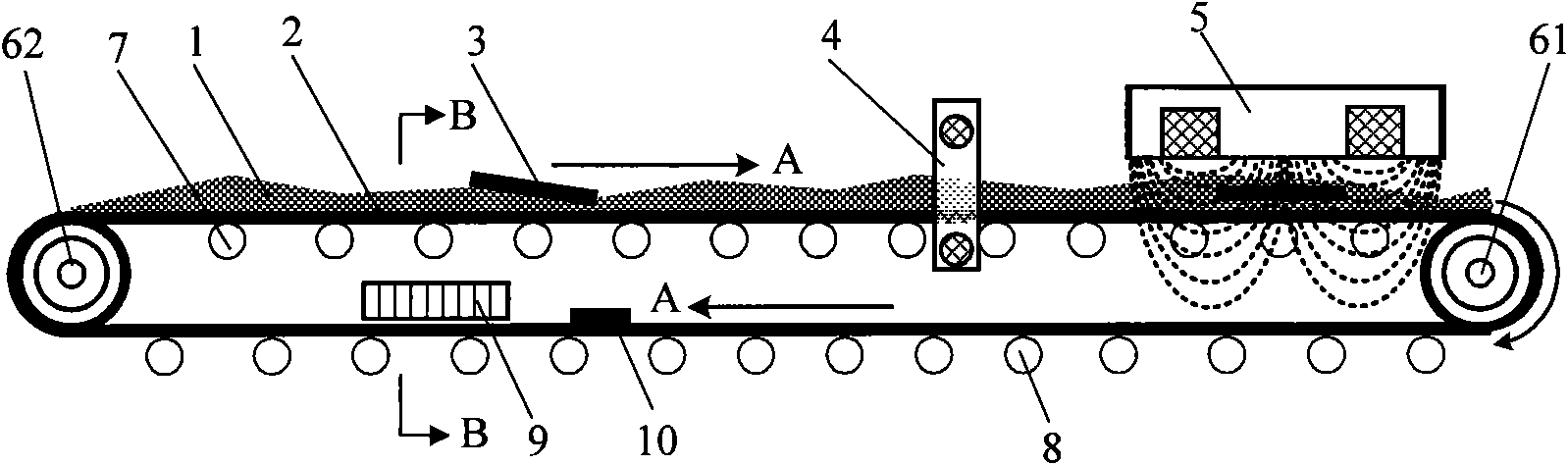

Device and method for synchronously demagnetizing steel wire lining conveyor belt

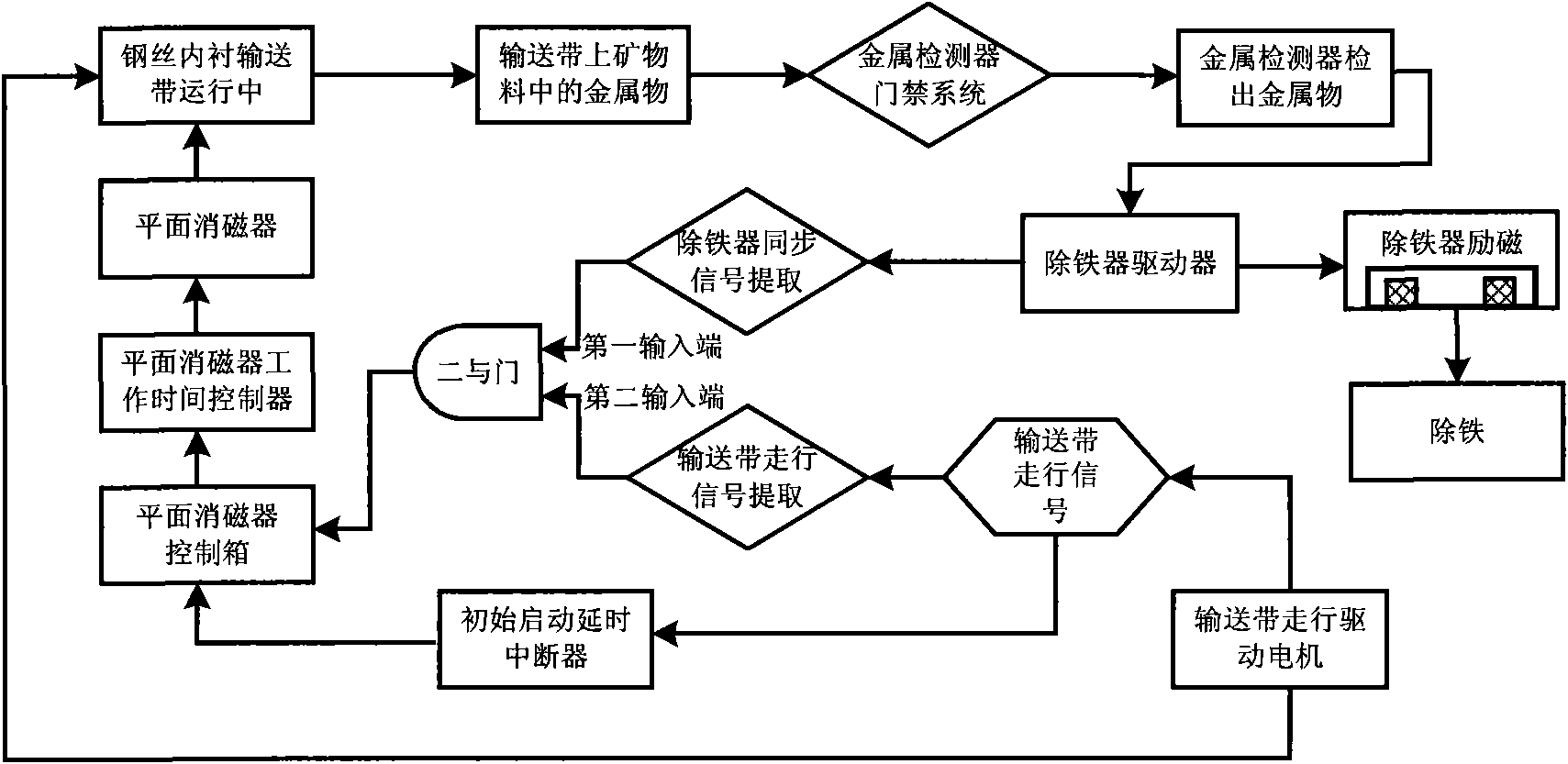

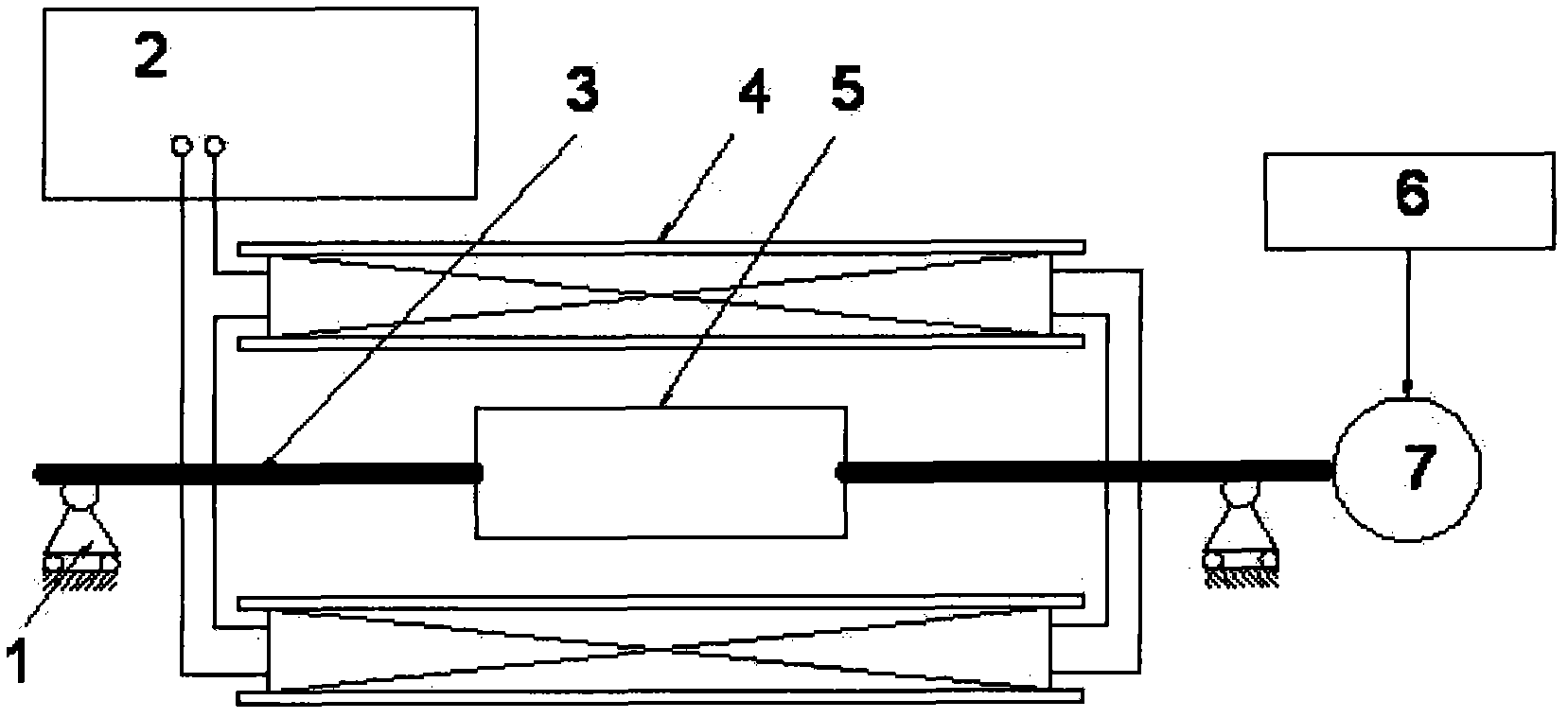

InactiveCN101552083AGuaranteed uptimeAvoid influenceConveyorsMagnetic bodiesDemagnetizing deviceStart time

The invention discloses a device and a method for synchronously demagnetizing steel wire lining conveyor belt, wherein the demagnetizing device comprises a planar demagnetizer, a planar demagnetizer controlling box and a support frame; a magnetizer is arranged in a magnet exciting coil which is positioned on a magnet exciting board and connected with the planar demagnetizer controlling box; a magnet exciting board shell is arranged on the magnet exciting board to form a cavity body; two ends of the support frame are respectively and fixedly connected with a bracket and the magnet exciting board shell, and the planar demagnetizer is fixed above a descending plane of the conveyor belt. The method comprises the following steps: an iron remover is started after metals in mineral materials are detected by a metal detector, and a signal is input into the first input end of an and gate circuit; a conveyor belt walking signal is transmitted into the second input end of the and gate circuit; the planar demagnetizer controlling box is started by an and gate circuit transmission signal; and the planar demagnetizer is controlled to demagnetize the conveyor belt after the planar demagnetizer controlling box receives a signal emitted from an initial start time-delay interrupter. The invention can entirely demagnetize the steel wire lining conveyor belt and ensures the normal operation of the metal detector.

Owner:BAOSHAN IRON & STEEL CO LTD

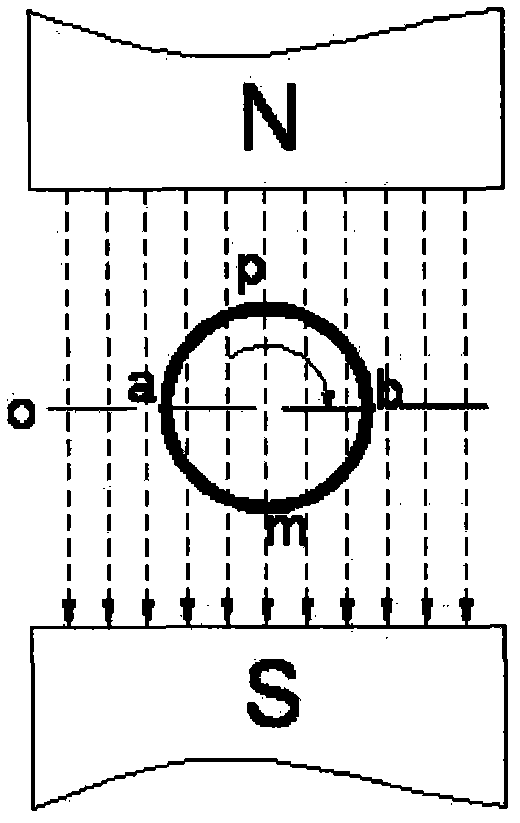

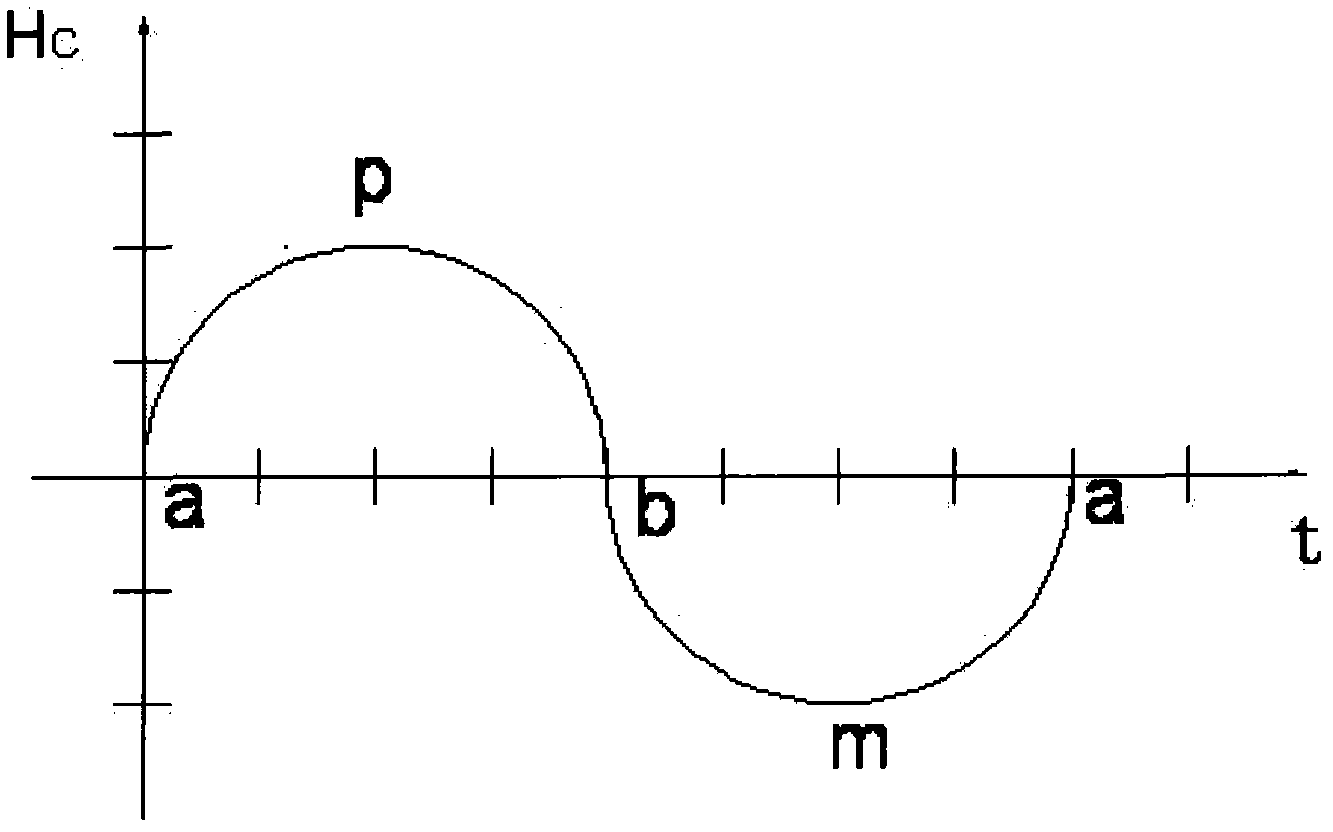

Demagnetizer and demagnetization method thereof

The invention relates to a demagnetizer and a demagnetization method thereof. The demagnetizer comprises a coil or a coil assembly which can work together with a magnetizing power supply to generate a demagnetizing field attenuating gradually, and a material box which can rotate at an adjustable speed is arranged in the coil or coil assembly in a penetrating way. In the prior art, a natural attenuation pulse mode is used for demagnetization; since a generated alternating magnetic field rapidly attenuates and the residual magnetic induction intensity on the surface of the magnetic material subjected to the action of the alternating magnetic field is not less than 30Gs, the technical defect of unsatisfied demagnetization effect can be caused. By the adoption of the demagnetization method provided by the invention, the technical defect can be overcome. The demagnetizer provided by the invention can achieve ideal demagnetization effect by utilizing high electric energy wave once, and more than 95% of electric energy can be saved.

Owner:SHANGHAI RUISUI MAGNETIC

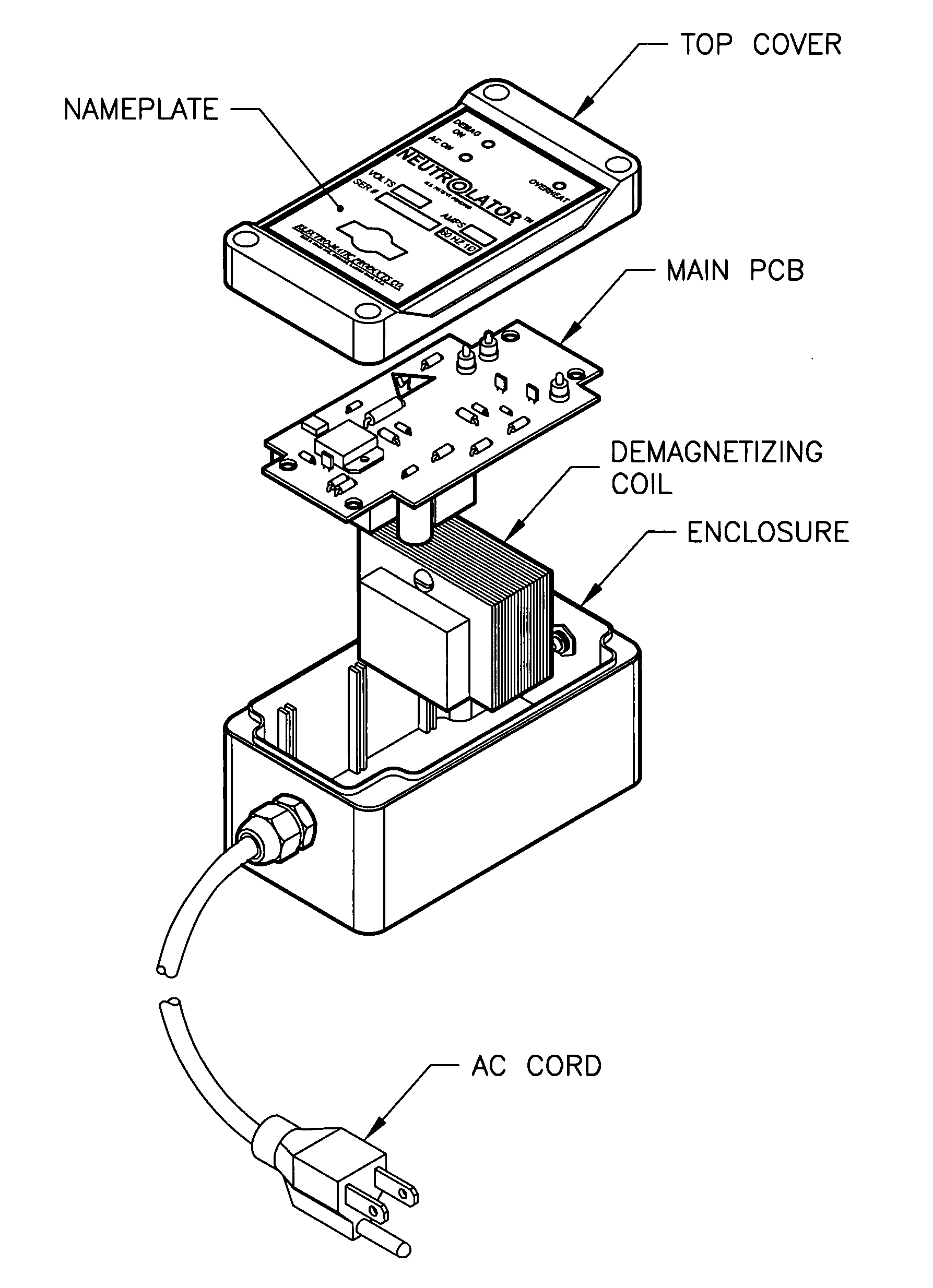

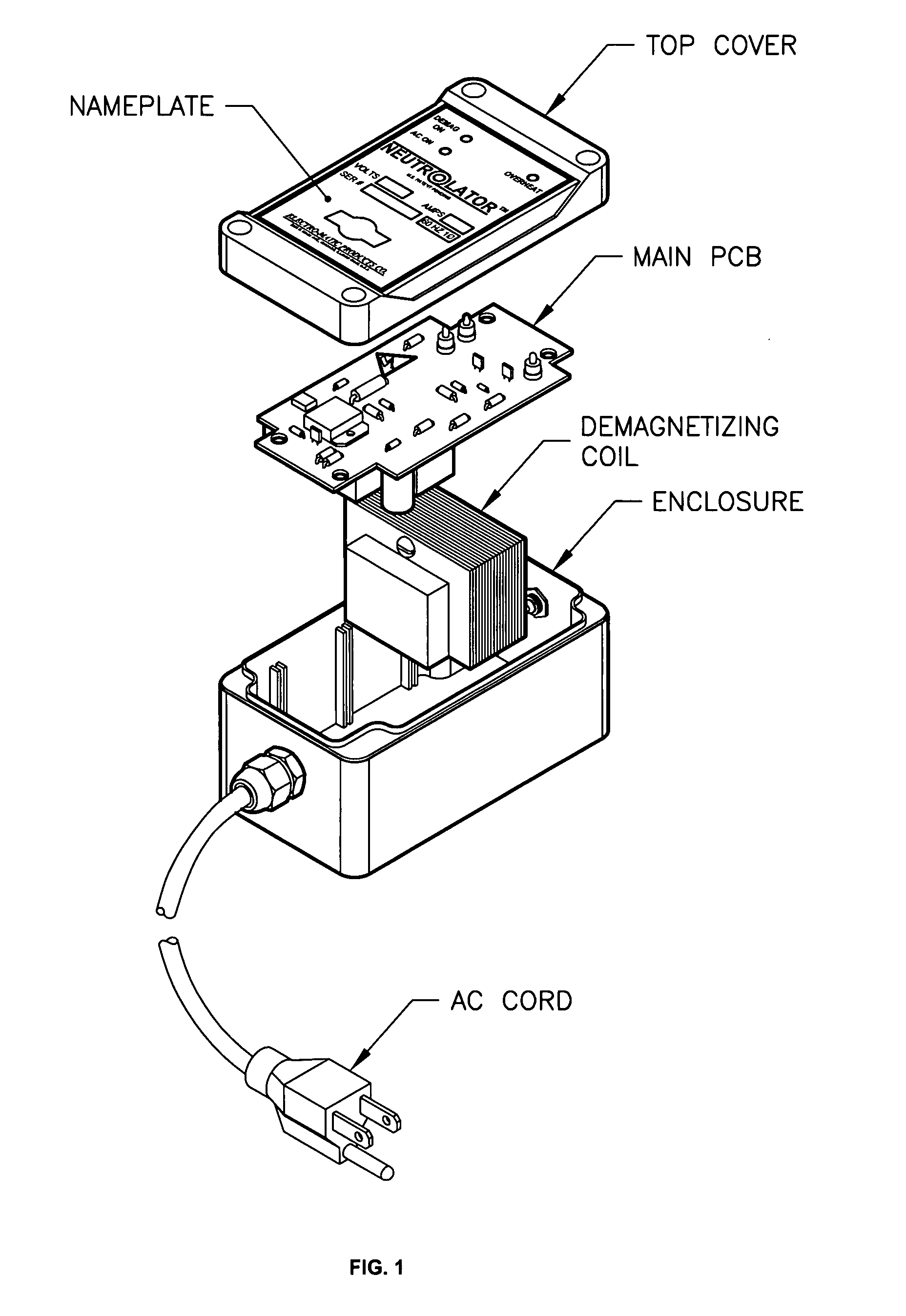

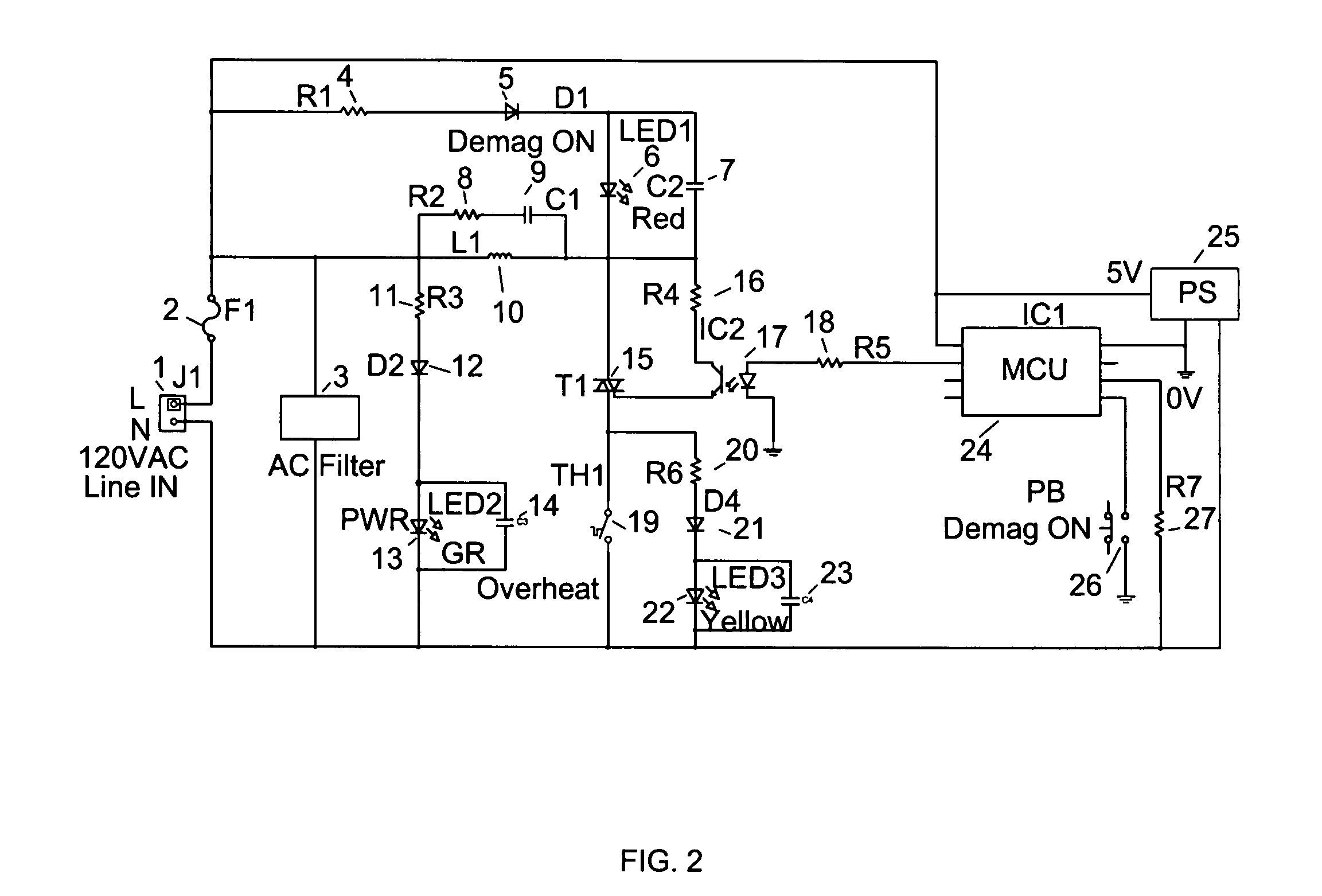

Thyristor controlled alternating current demagnetizer

This unit is intermittent duty, small, and light weight. Use of a thyristor(s) control reduces the unit's energy consumption through reduced AC input voltage while still producing sufficient demagnetizing power and effective demagnetizing results.This principle may be applied to ANY and ALL sizes of demagnetizing coils.With the burst control we can achieve same demagnetizing power and reduce overall power consumption of the demagnetizing coil(s) reducing size and weight of the coil(s). For this intermittent duty coil(s) the power consumption is reduced by over 40% and heating rate reduced which allows approx. 40% longer continuous running time.

Owner:ELECTRO MATIC PRODS

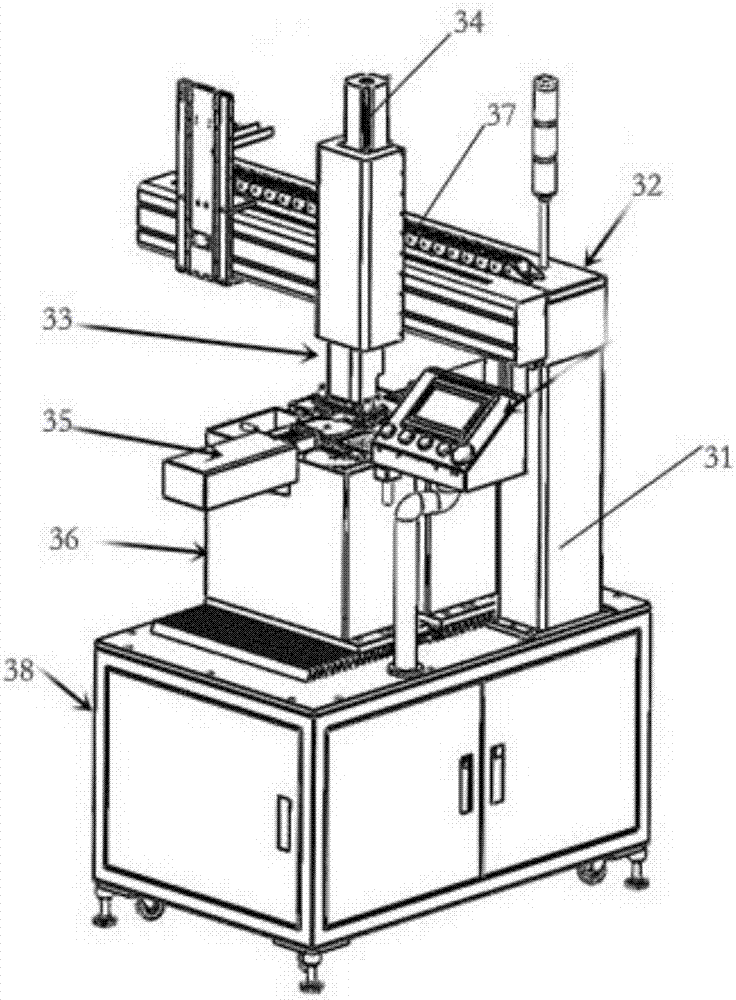

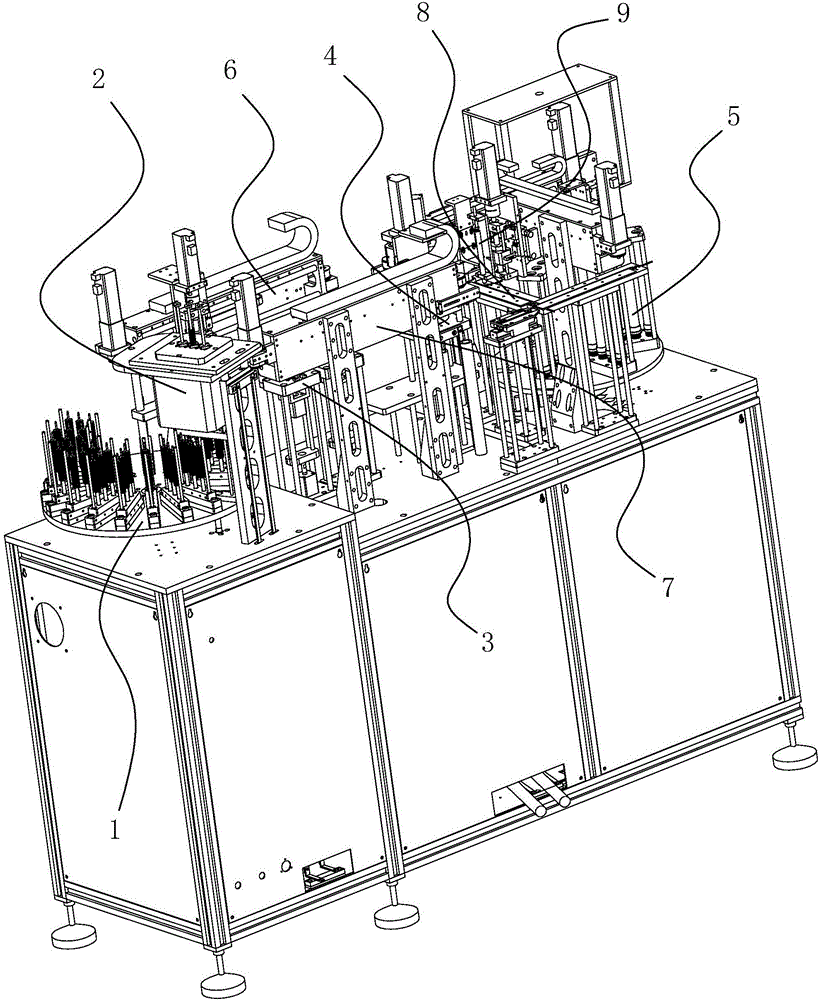

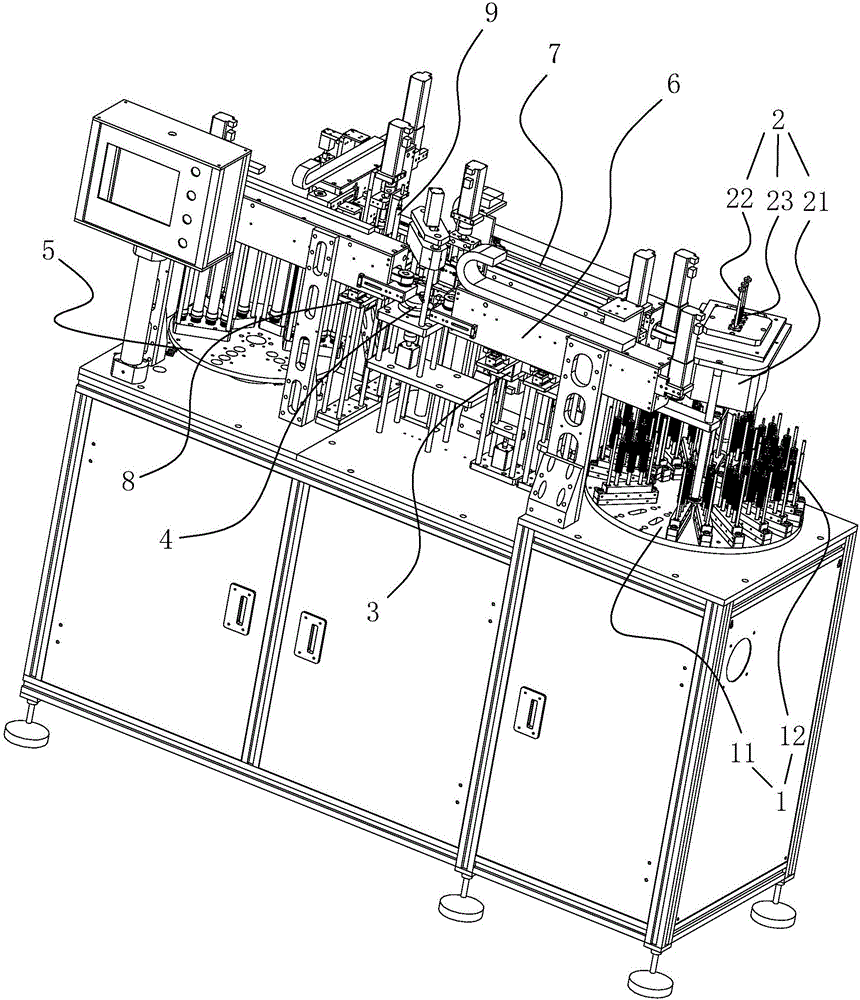

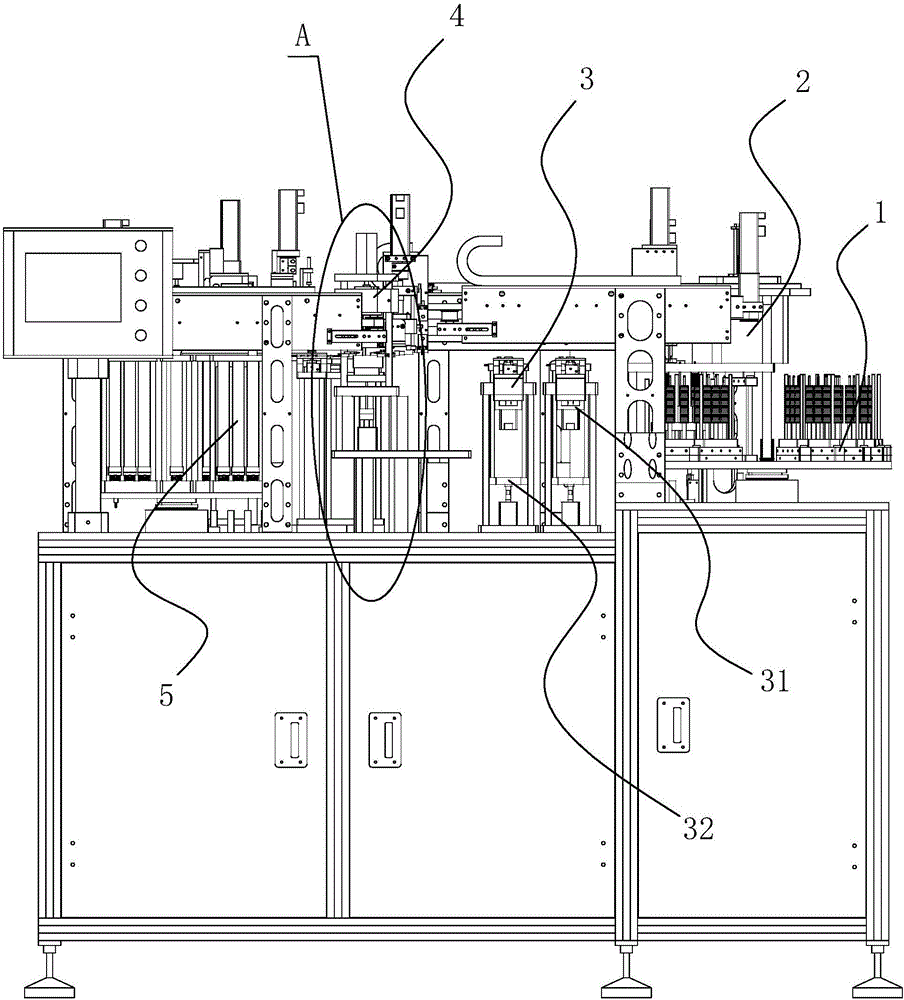

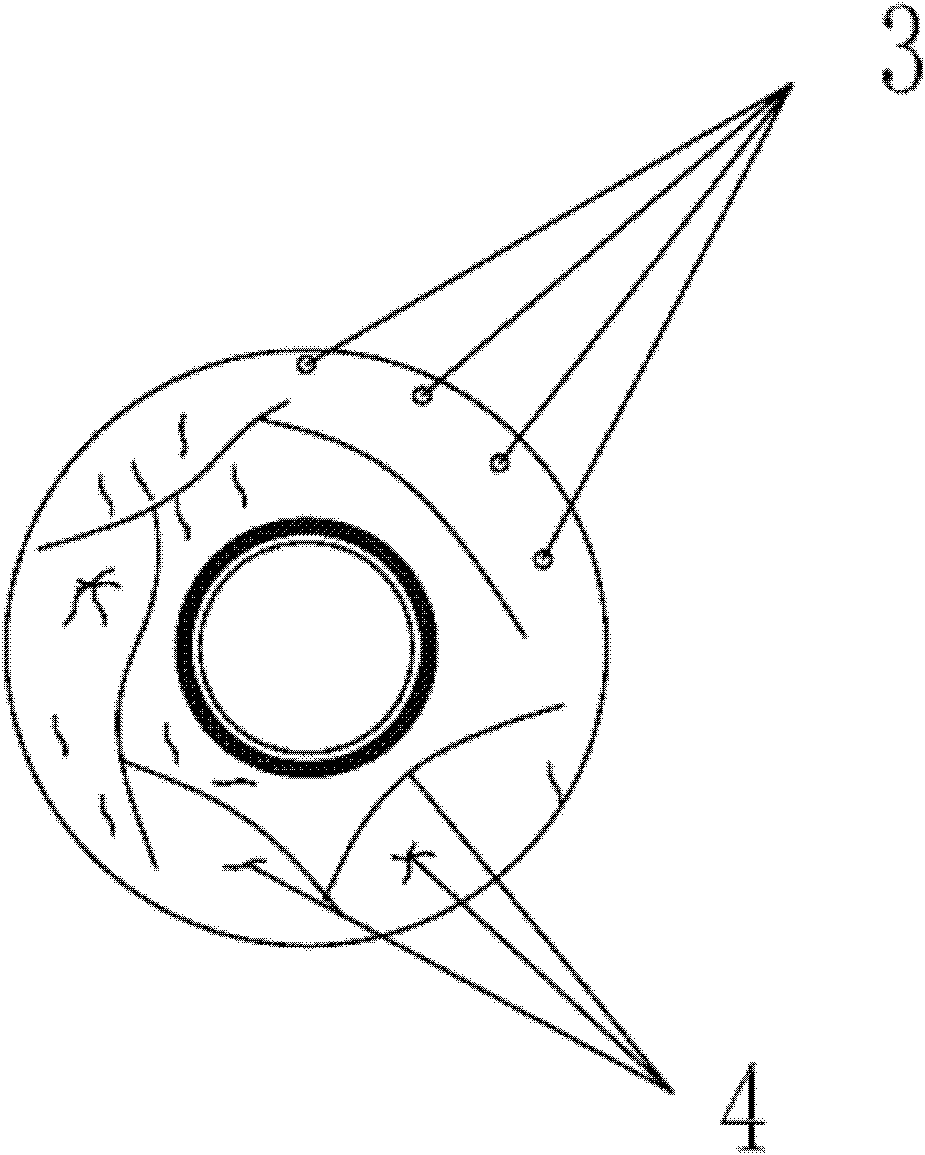

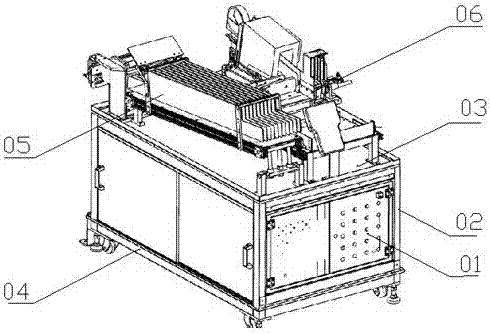

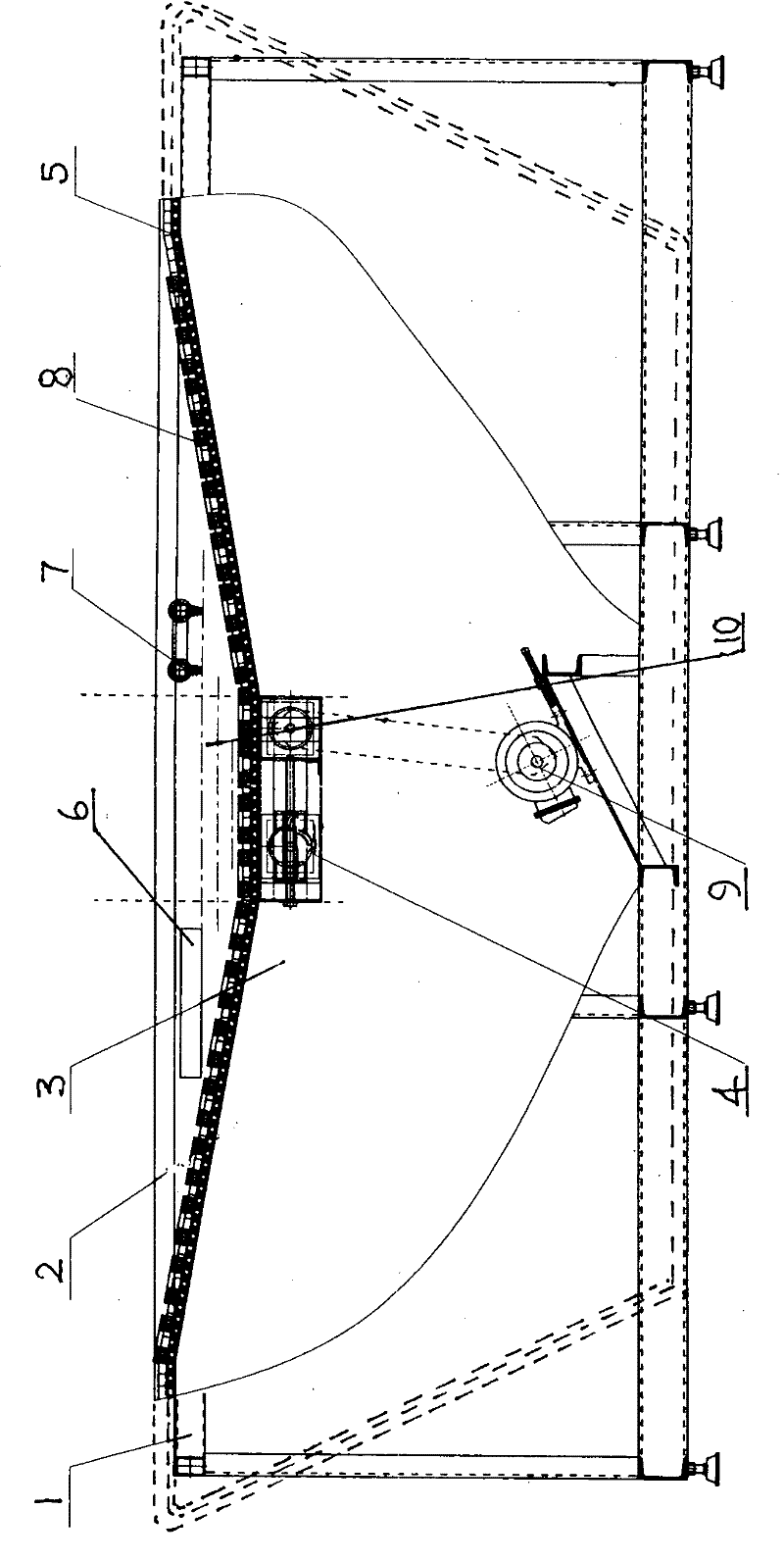

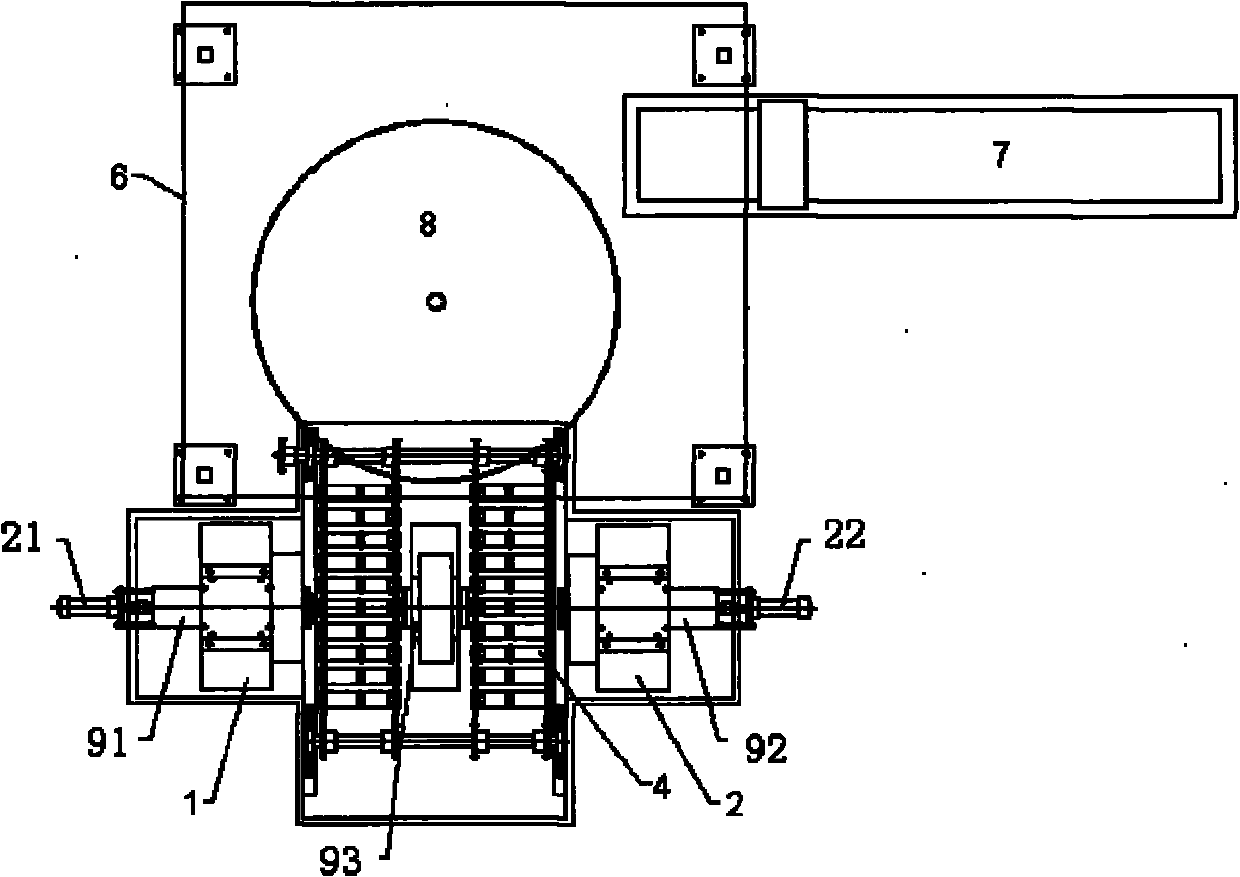

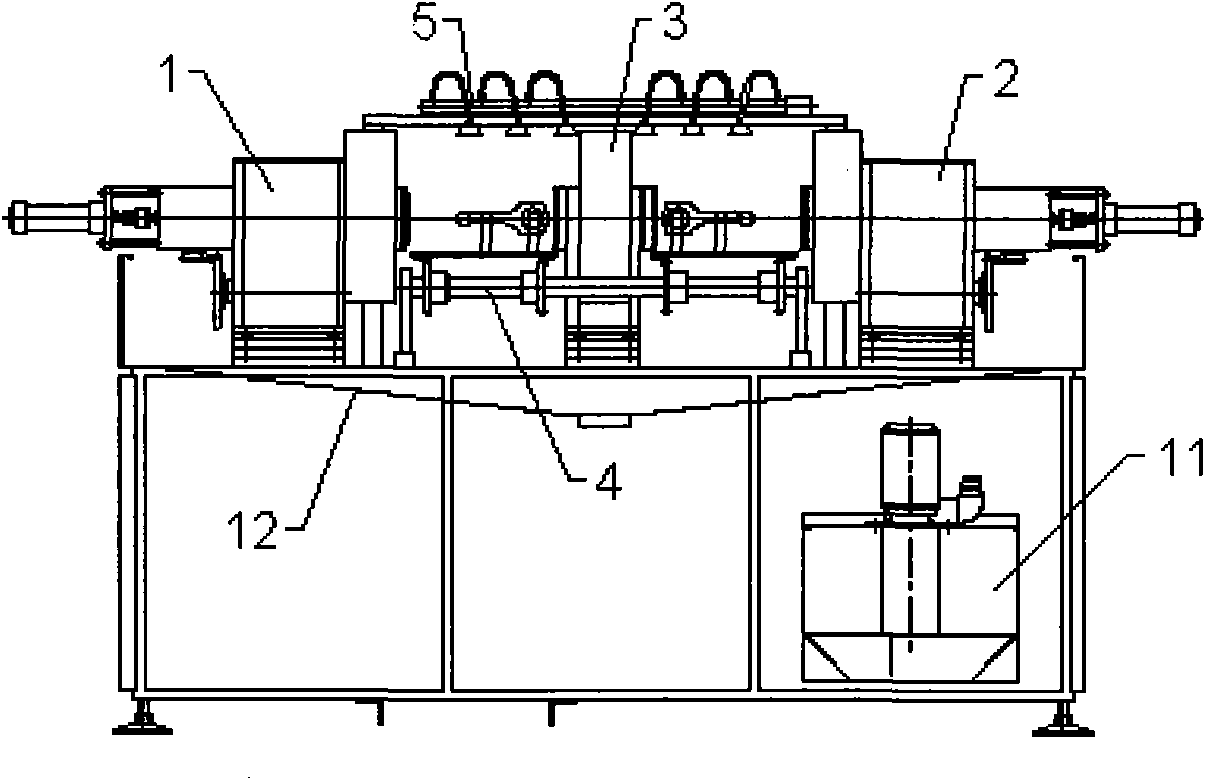

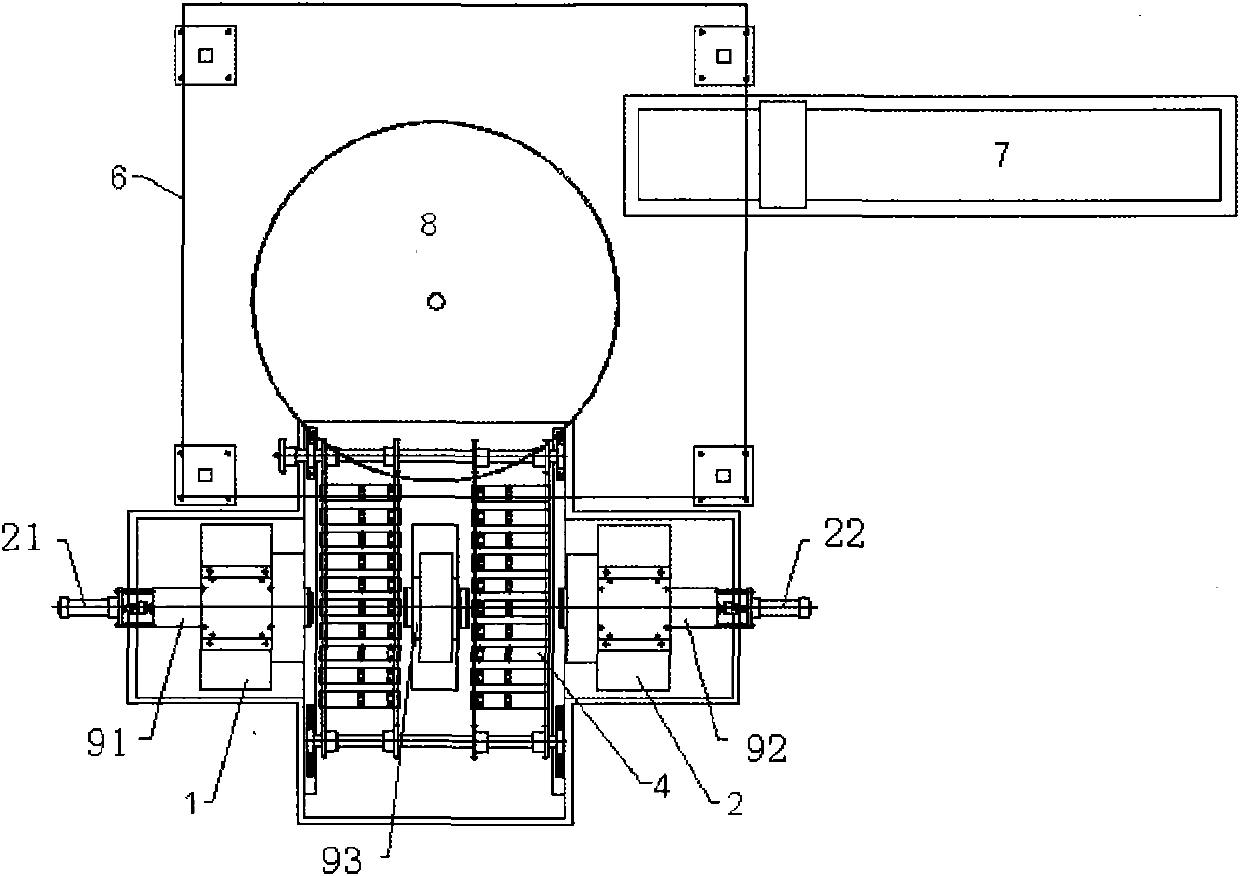

Full-automatic magnetization and demagnetization equipment for rotary inductive locating of magnetic rings

ActiveCN106531398ARealize fully automatic degaussingAchieve magnetizationMagnetic bodiesRotary conveyorsMagnetic polesMagnetization

The invention discloses full-automatic magnetization and demagnetization equipment for rotary inductive locating of magnetic rings. The full-automatic magnetization and demagnetization equipment comprises a rotary material table, a demagnetization assembly, a corner correcting assembly, a magnetization assembly, a collection assembly, a first displacement assembly, a second displacement assembly and a third displacement assembly, wherein the demagnetization assembly comprises a demagnetizer arranged above the rotary material table and a clamping elevator assembly capable of enabling the magnetic rings to pass in and out of the demagnetizer. Through the demagnetization assembly arranged above the rotary material table, demagnetization of the magnetic rings can be completed in the transport process; and the magnetic rings before being magnetized all are located according to consistent corner positions through the corner correcting assembly, so that the magnetized magnetic rings are consistent in magnetic poles and the quality of a product is improved. The machining processes of full-automatic magnetization and demagnetization of the magnetic rings are achieved through coordination of the rotary material table, the demagnetization assembly, the corner correcting assembly, the magnetization assembly, the collection assembly, the first displacement assembly, the second displacement assembly and the third displacement assembly, and the efficiency is very high.

Owner:江门协立磁业高科技有限公司

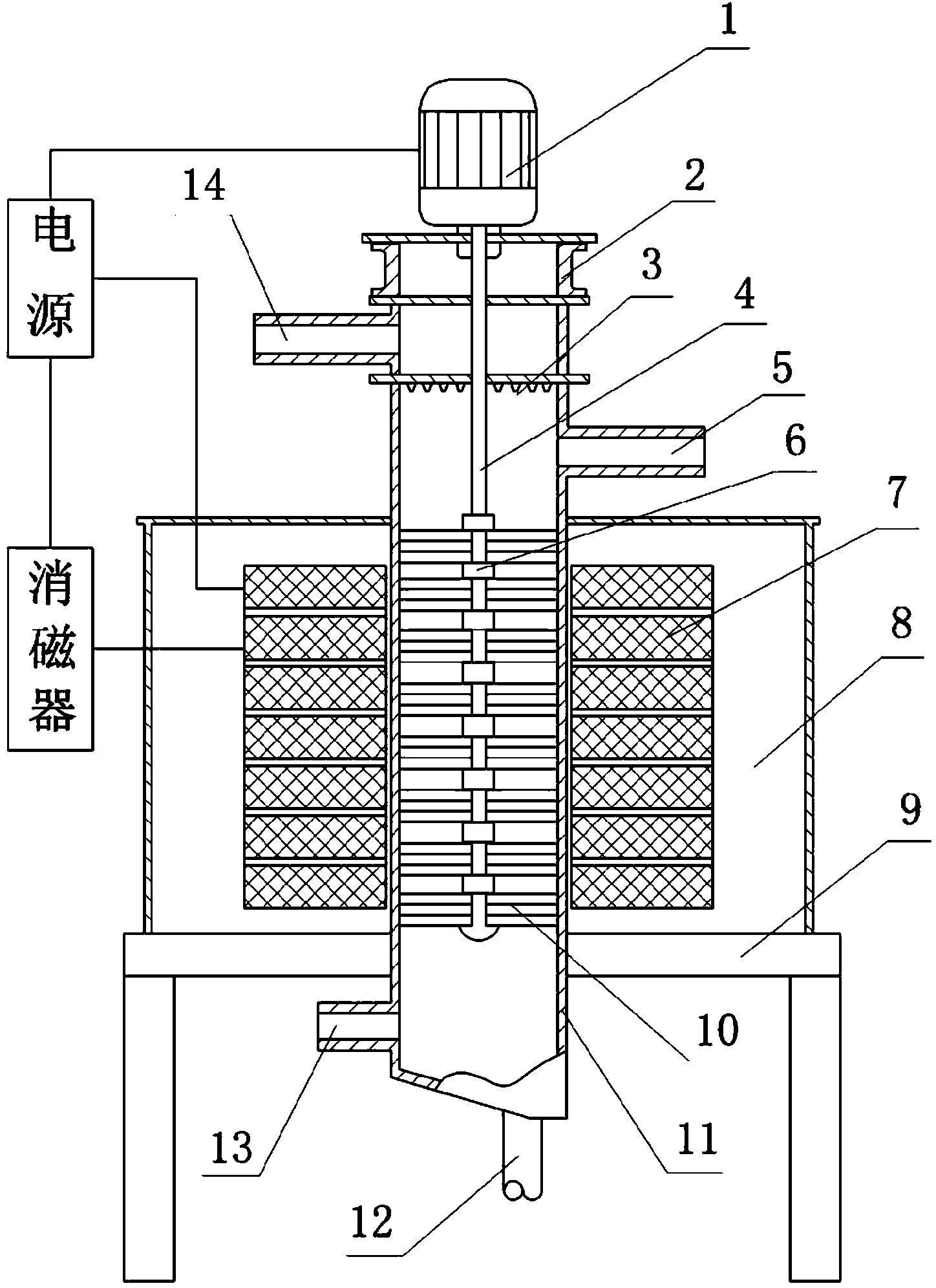

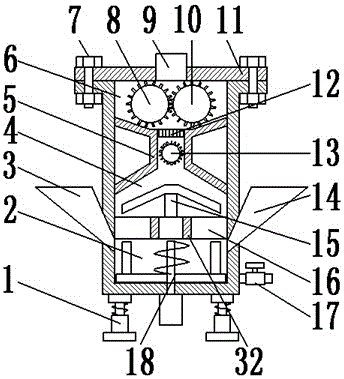

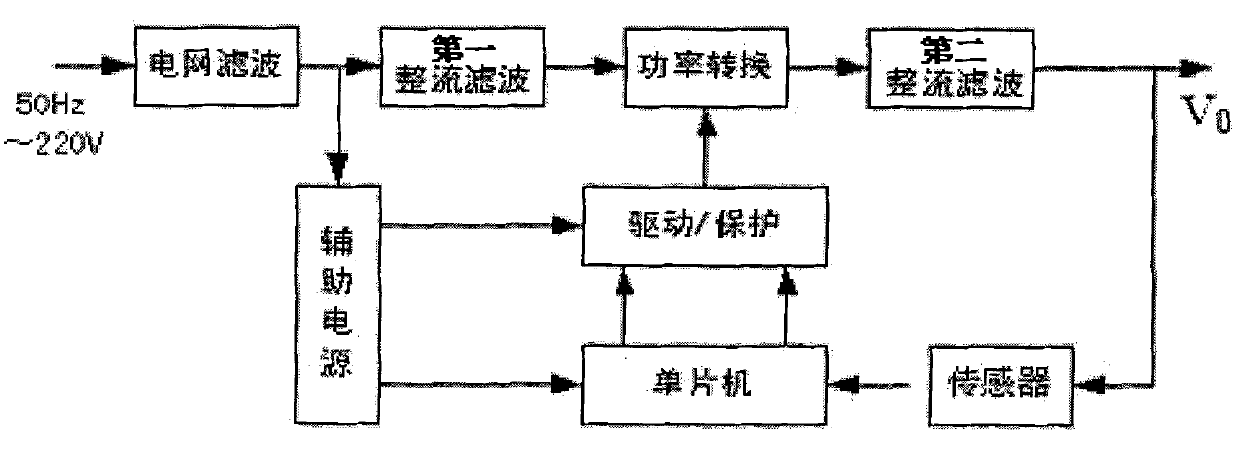

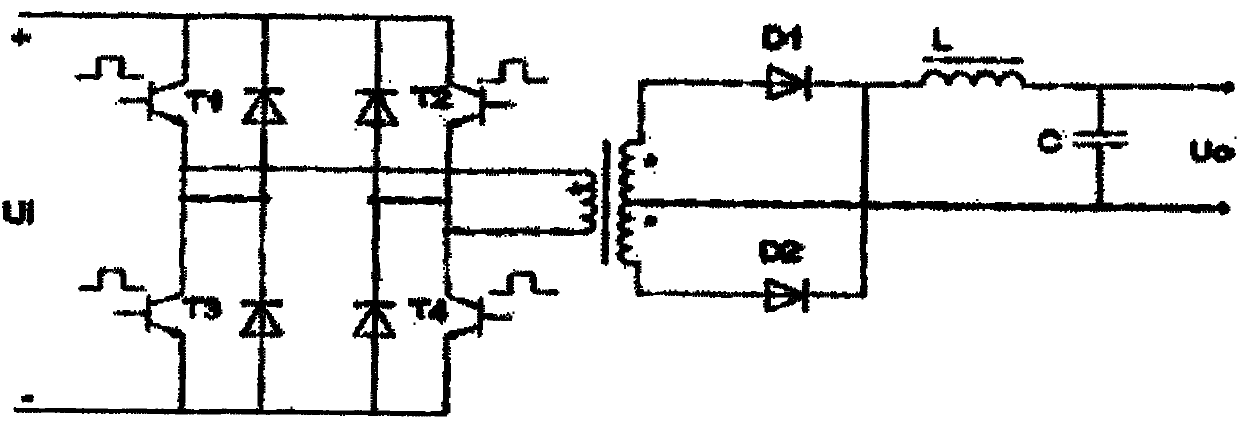

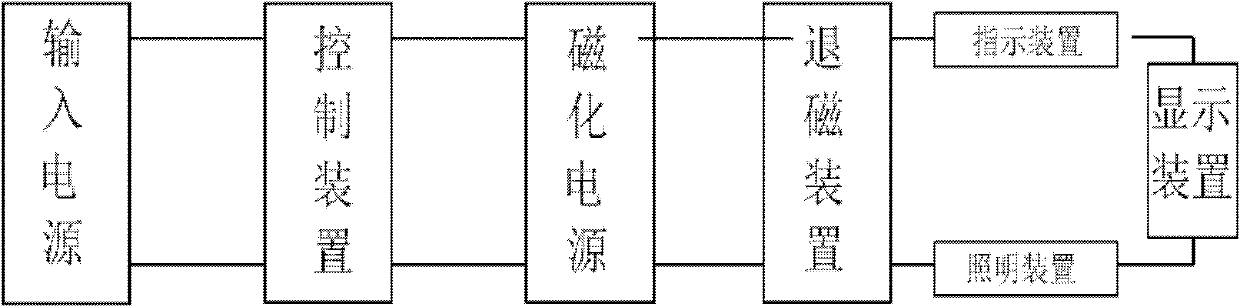

Conjugated pipeline demagnetizer

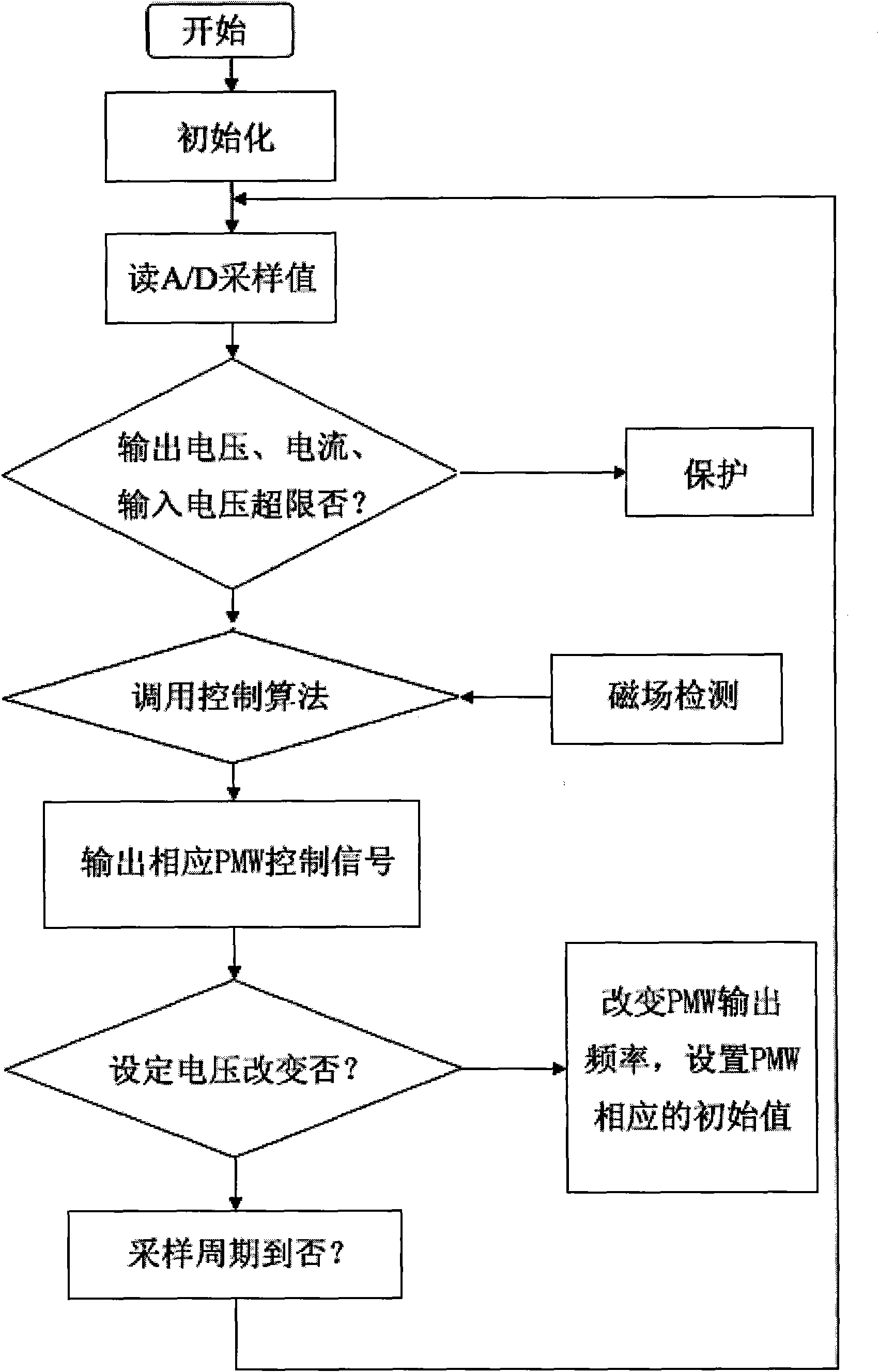

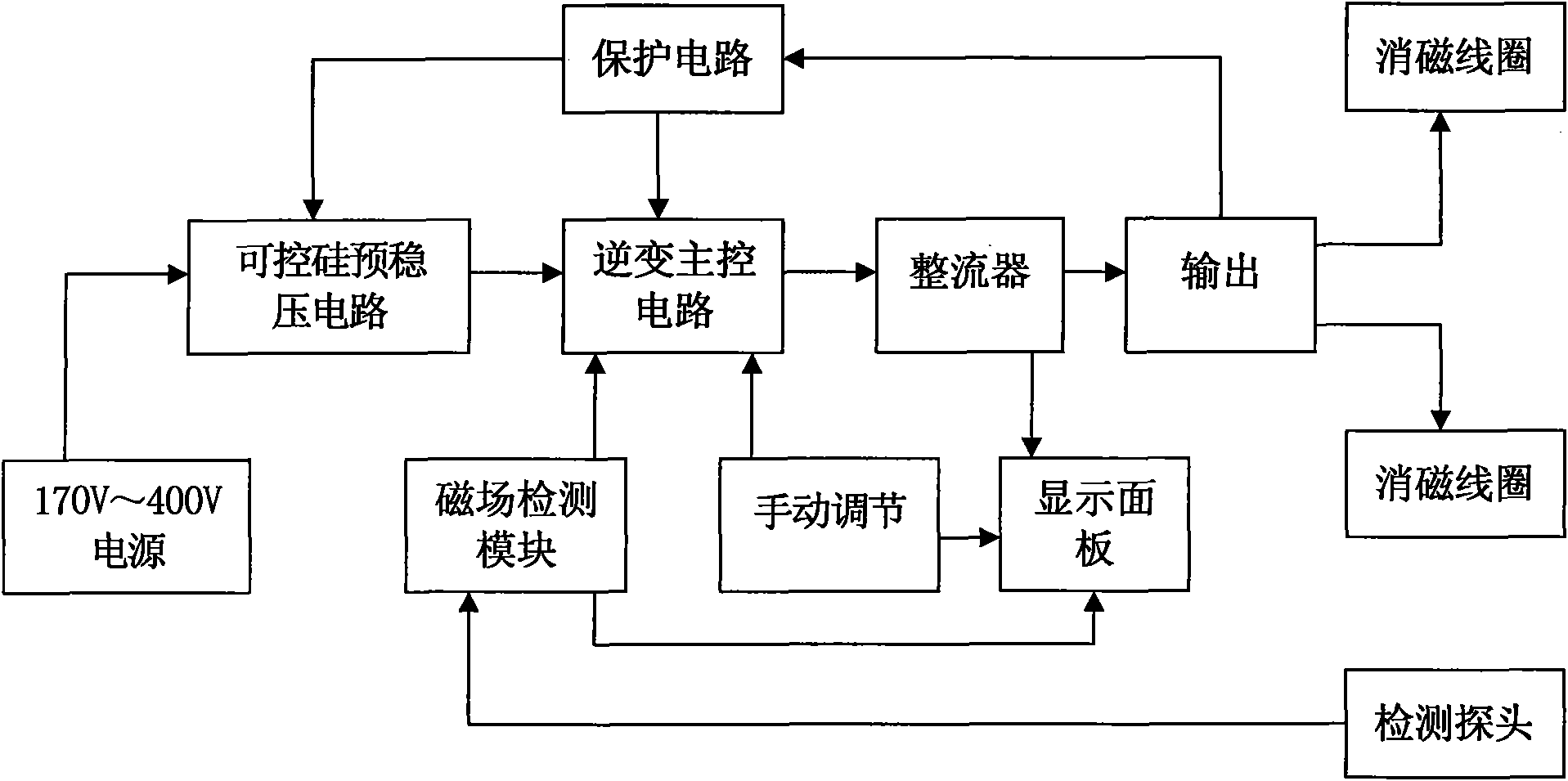

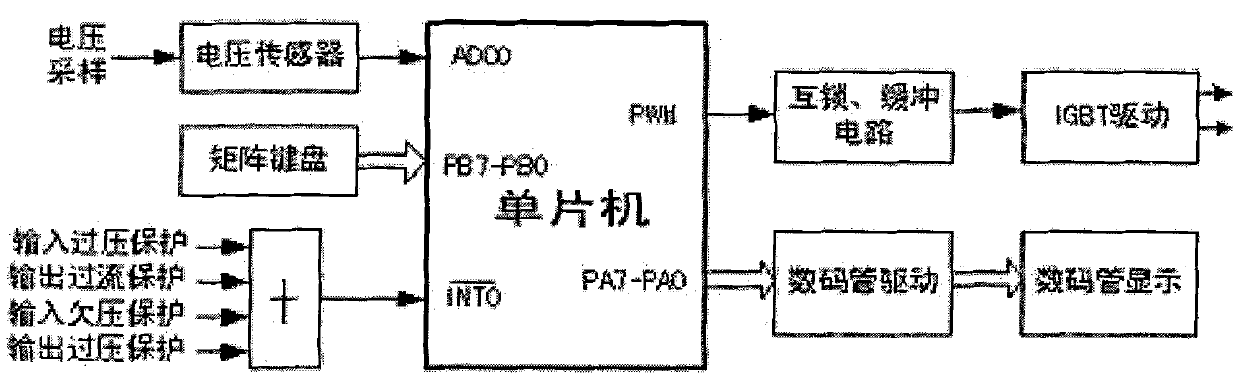

ActiveCN102024547AReduce magnetic field strengthGood degaussing effectMagnetic bodiesMicrocontrollerPower switching

The invention discloses a conjugated pipeline demagnetizer. The conjugated pipeline demagnetizer comprises a switching circuit, a control circuit, a drive circuit and a demagnetizing coil. The switching circuit provides direct current for pipeline demagnetization for the demagnetizing coil. A singlechip is arranged in the control circuit. The drive circuit drives a power switching device in the switching circuit. The switching circuit is formed by sequentially connecting a power grid filter circuit, a first rectification filter circuit, a power conversion circuit, and a second rectification filter circuit. The demagnetizing coil is made from flexible wire and an explosion-proof aviation plug is adopted for connection. The conjugated pipeline demagnetizer has the advantages of high demagnetization and self-shielded characteristic, good adaptability of terminal, and energy conversation and security.

Owner:国家管网集团北京管道有限公司

Display capability tester of magnetic powder or magnetic suspension

ActiveCN102788839AShow abilityImprove readabilityMaterial magnetic variablesElectrical conductorCurrent sheet

The present invention provides a display capability tester of magnetic powder or a magnetic suspension. The tester comprises: a display apparatus, wherein the display apparatus comprises a display test block, a center conductor for providing a magnetic field for the display test block, and a connection electrode for electrifying the center conductor, and the display test block is provided with an artificial defect; a magnetization power supply, wherein the magnetization power supply is connected to the connection electrode, and provides an adjustable magnetization current for the connection electrode; a demagnetization apparatus, wherein the demagnetization apparatus comprises a demagnetizer connected to the connection electrode, and is provided for demagnetizing the display test block; a control apparatus, wherein the control apparatus is provided for electrically connecting the magnetization power supply and the demagnetization apparatus, and comprises a magnetization switch for opening the magnetization power supply, a demagnetization switch for opening the demagnetization apparatus, and a current adjustment mechanism for adjusting a magnetization current of the magnetization power supply; and an indication apparatus, wherein the indication apparatus comprises an ammeter for indicating a magnetization current value of the magnetization power supply. The display capability tester of the present invention mainly has the following advantages that: by providing the standard display test block and the adjustable magnetization current, a test platform with characteristics of convenience, accuracy and capability of reference comparison is provided for display capability of the magnetic powder or the magnetic suspension.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Acoustic-magnetic label demagnetizer and demagnetization method

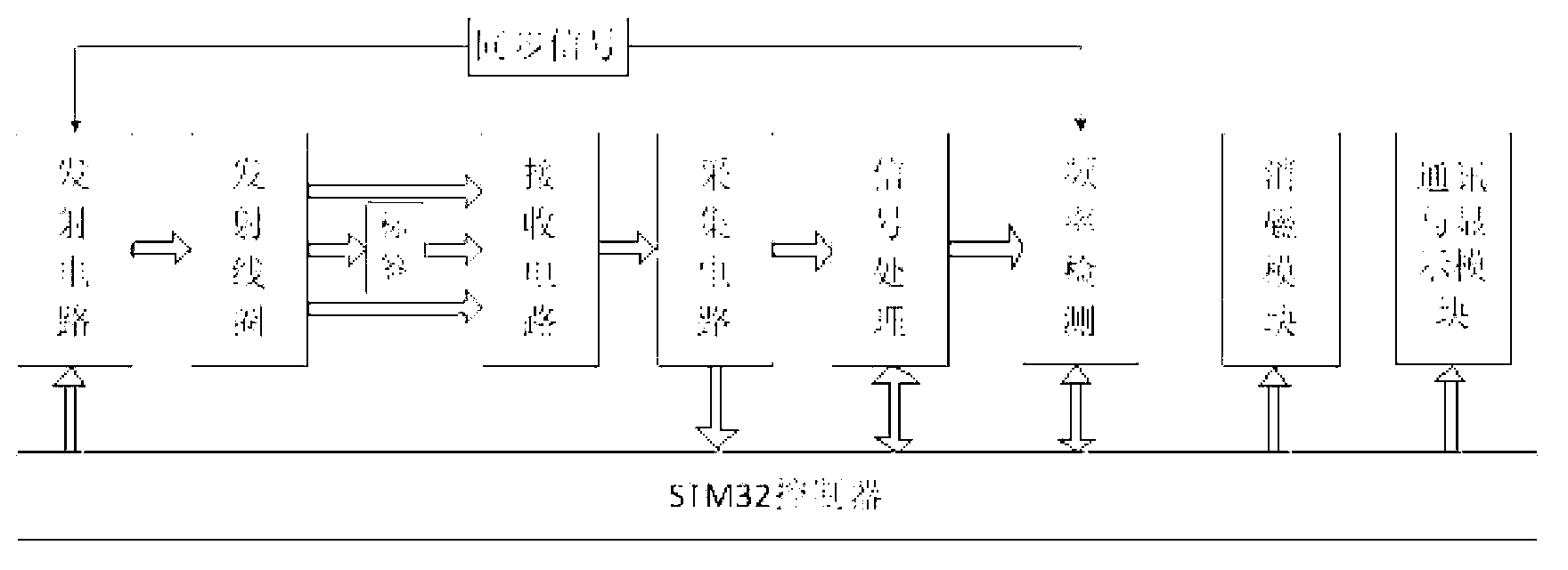

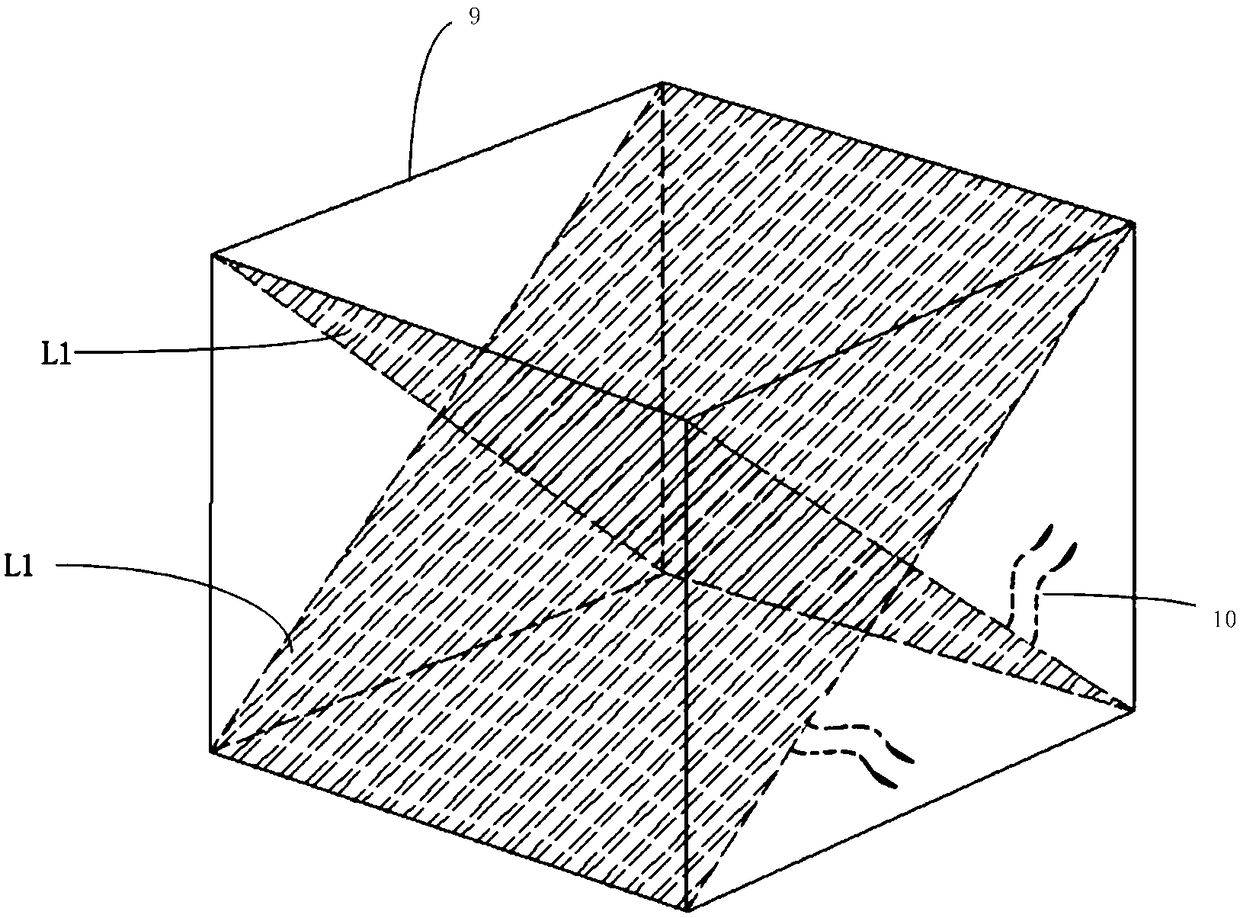

InactiveCN103021624AIncreased degaussing distanceEnhanced degaussing energyMagnetic bodiesTelecommunicationsFrequency detection

The invention discloses an acoustic-magnetic label demagnetizer and a demagnetization method. The acoustic-magnetic label demagnetizer comprises a synchronous signal circuit, a transmitting circuit, a receiving circuit, an acquisition circuit, a signal processing module, a frequency detection module, a demagnetization module, a communication and display module and a main-control module, wherein the output end of the synchronous signal circuit is respectively connected with the input ends of the transmitting circuit and the frequency detection module; the output end of the transmitting circuit is connected with the input end of the receiving circuit; the output end of the receiving circuit is connected with the input end of the acquisition circuit; the output end of the acquisition circuit is respectively connected with the signal processing module and the main-control module; the output end of the signal processing module is connected with the input end of the frequency detection module; the output end of the main-control module is respectively connected with the transmitting circuit, the demagnetization module and the communication and display module; and the signal processing module and the frequency detection module are respectively in both-way communication with the main-control module. The equipment increases the demagnetization distance, strengthens the demagnetization energy, and reduces the design cost.

Owner:郭明新

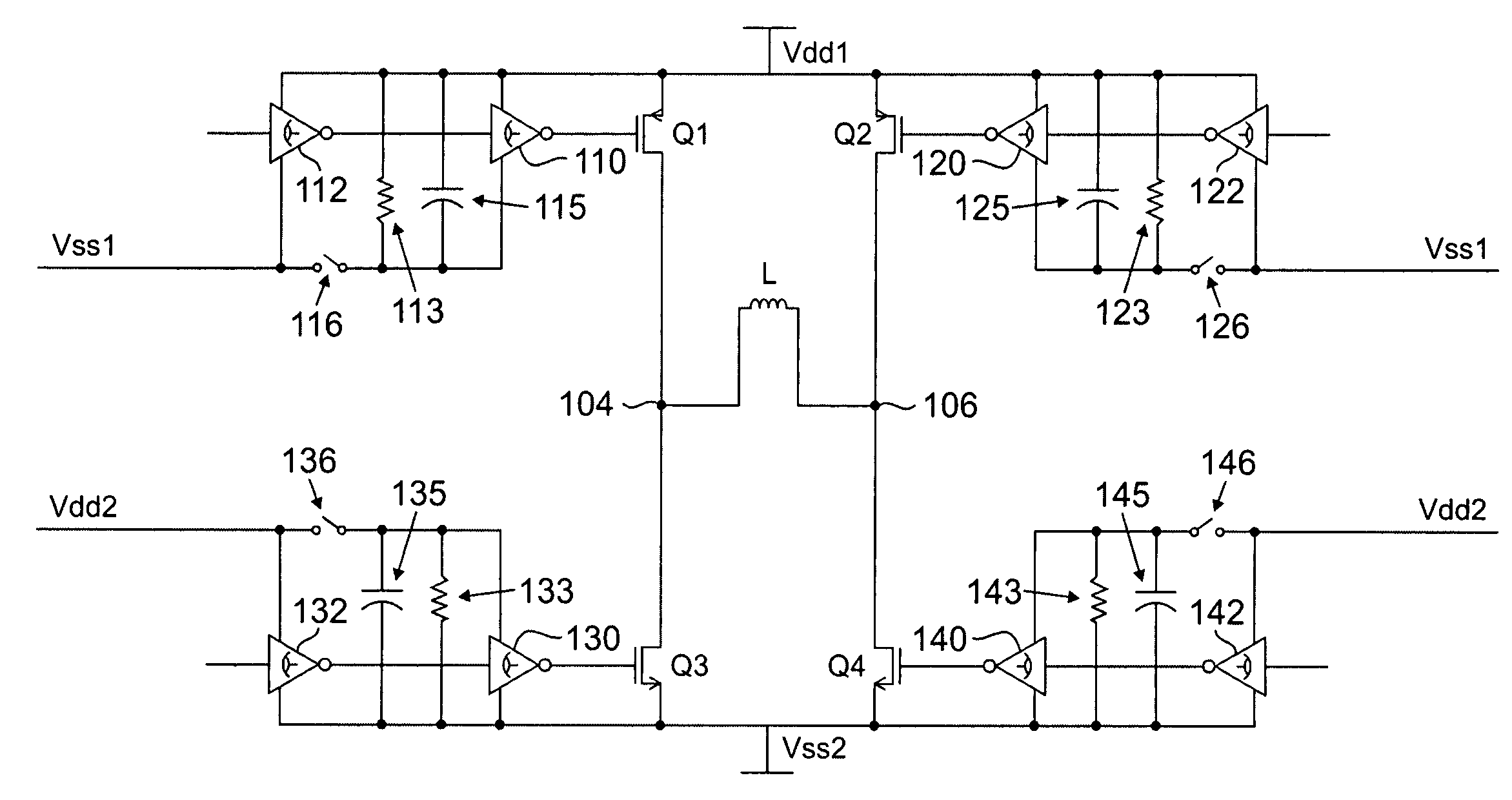

Demagnetization circuit, demagnetizer, and control method for demagnetization circuit

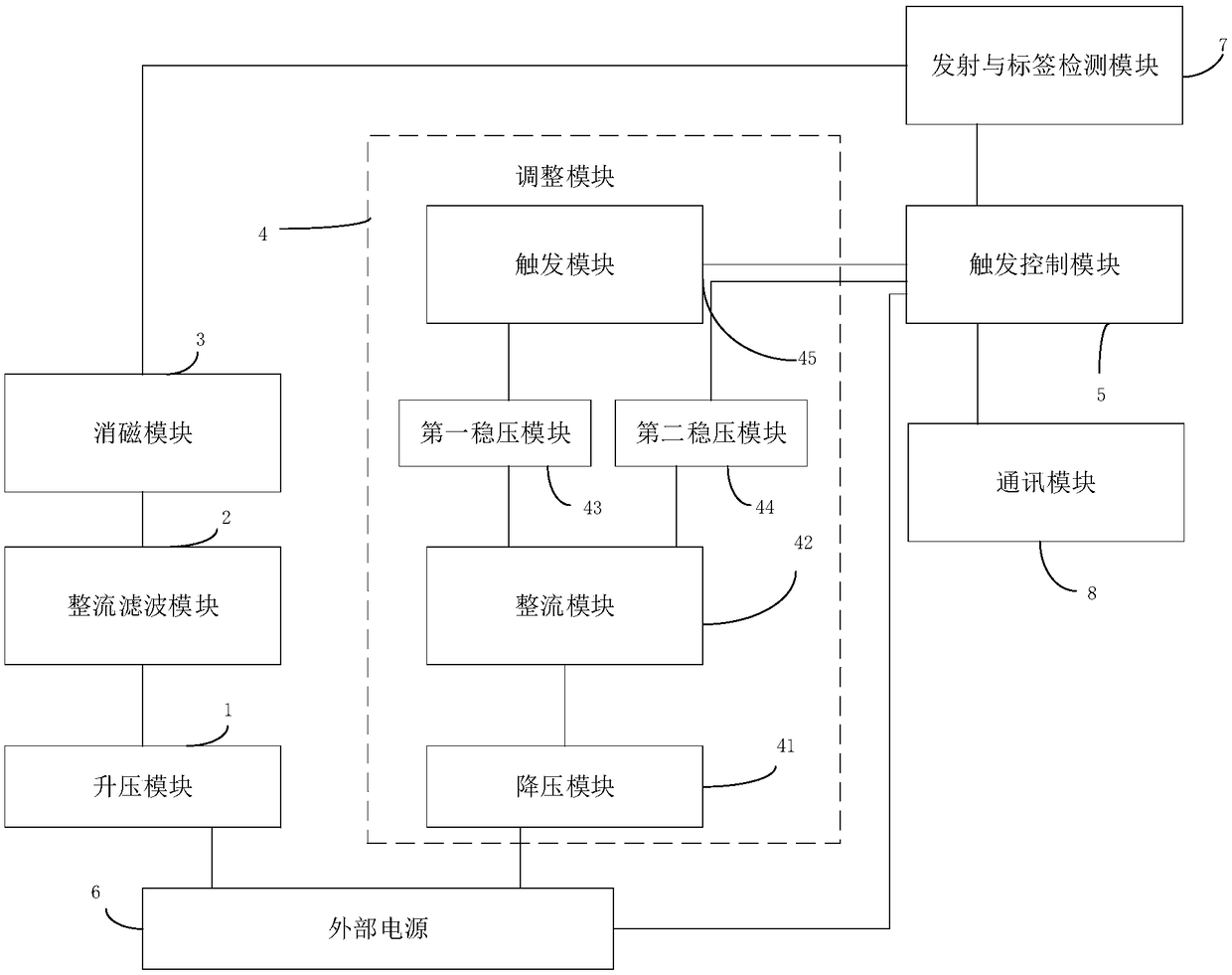

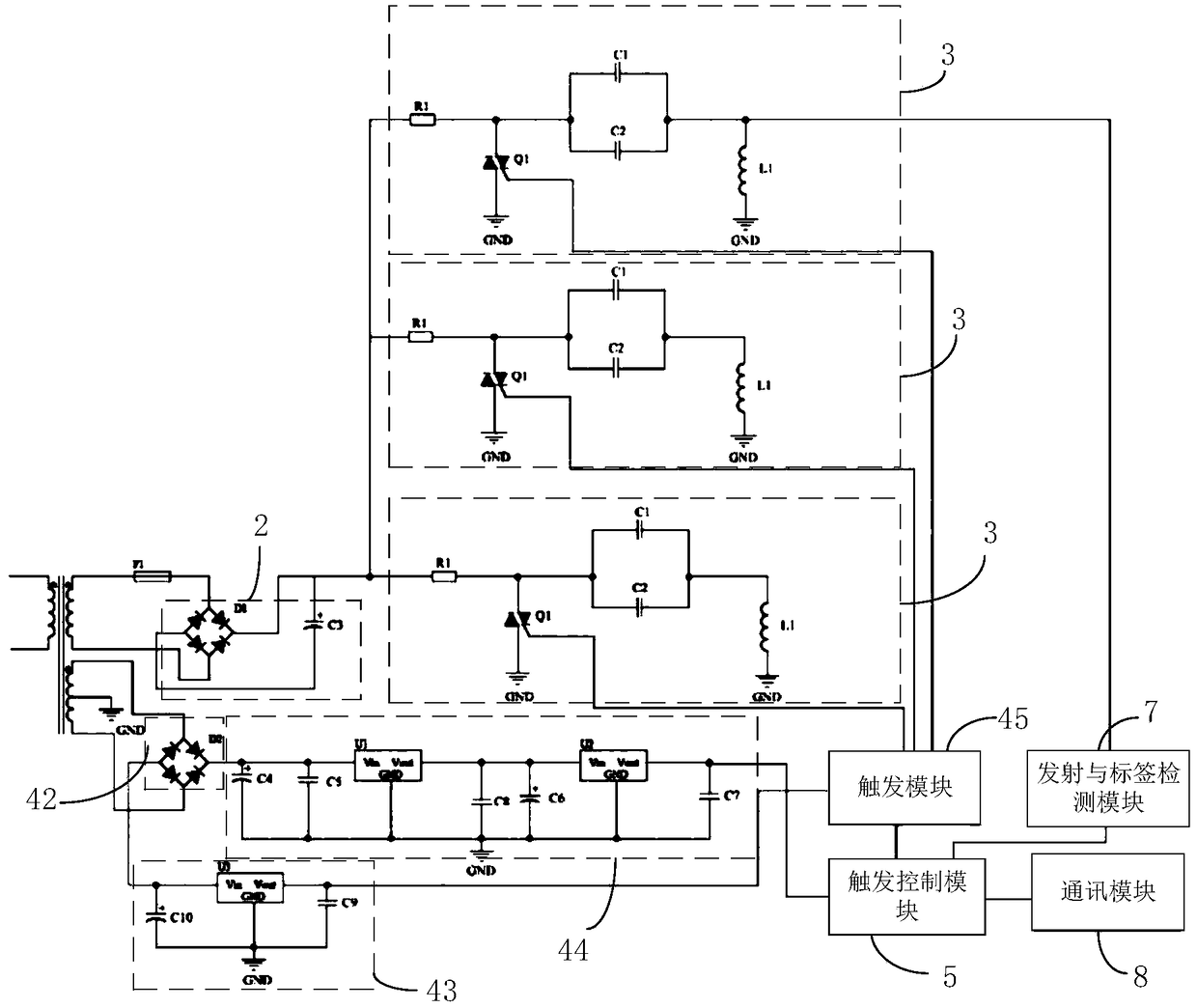

ActiveCN108933015AGood for simultaneous degaussingImprove energy utilizationMagnetic bodiesEngineeringAlternating current

The invention discloses a demagnetization circuit, a demagnetizer, and a control method for the demagnetization circuit. A circuit part comprises a trigger control module, an adjusting module, a boostmodule, a rectification filtering module, and at least a demagnetization module. The demagnetization module is connected with the boost module through the rectification filtering module. The boost module makes input voltage of an external power supply boost. The rectification filtering module converts current of the boost module to direct current from alternating current, and filters. The triggercontrol module is connected with the demagnetization module through the adjusting module. The trigger control module controls a trigger timing sequence of the demagnetization module through the adjusting module. The demagnetizer solves technical problems that a conventional demagnetizer has small demagnetization range, has large demagnetization capability difference on orientations of antitheft labels, and cannot effectively demagnetize the antitheft labels which are on different positions and direction at the same time.

Owner:SHENZHEN PROMATIC SECURITY SYST

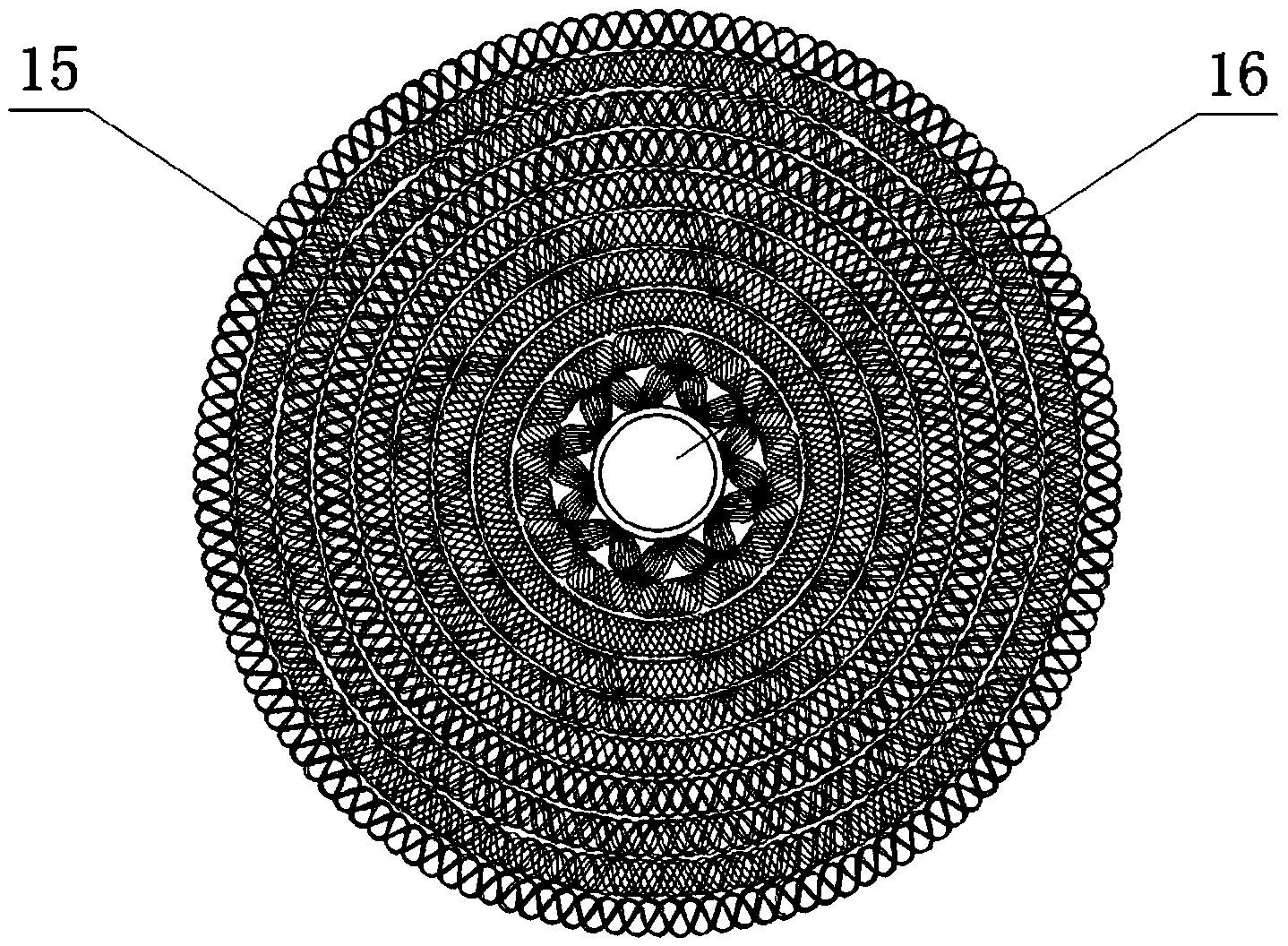

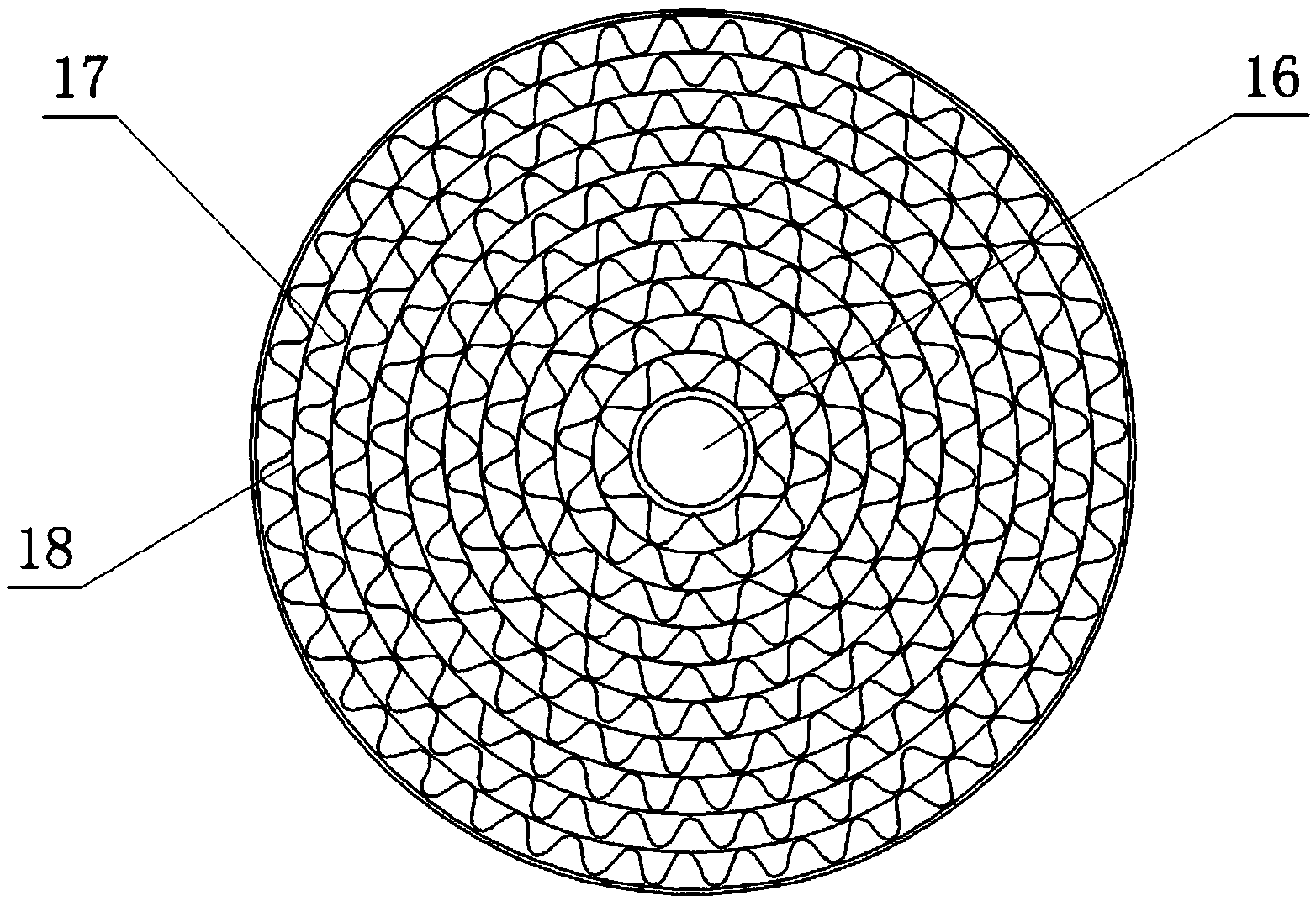

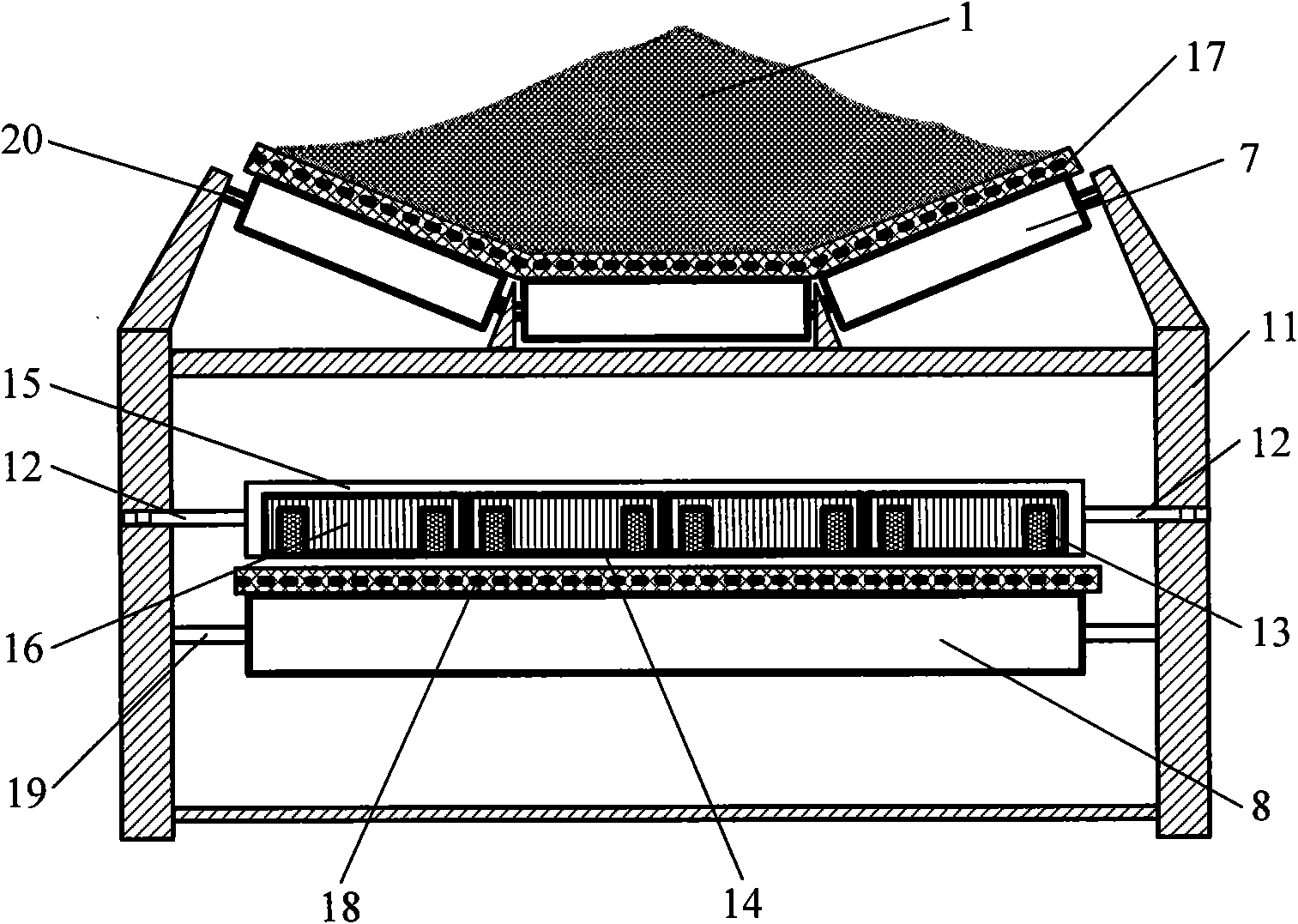

Bearing parts, finished products demagnetizer and usage thereof

Demagnetization machine includes housing, conveyer system, electrical control system and demagnetization system. The demagnetization system is composed four groups of upper demagnetization coil and lower demagnetization coil arranged in alternation. Adjustable ungula is in base of the housing. Screw rod and control hand wheel is setup on upper demagnetization coil for adjusting its height; and screw is setup on lower demagnetization coil for adjusting its height. Universal steering controller and frequency converter on housing is for adjusting power of demagnetization coil and conveying velocity of belt. Workpieces to be demagnetized on conveyer belt pass through upper demagnetization coil and lower demagnetization coil so as to complete de-magnetizing procedure. Features are: raised demagnetization effect, and applicable to workpieces in different specifications and different heights.

Owner:迟安生 +1

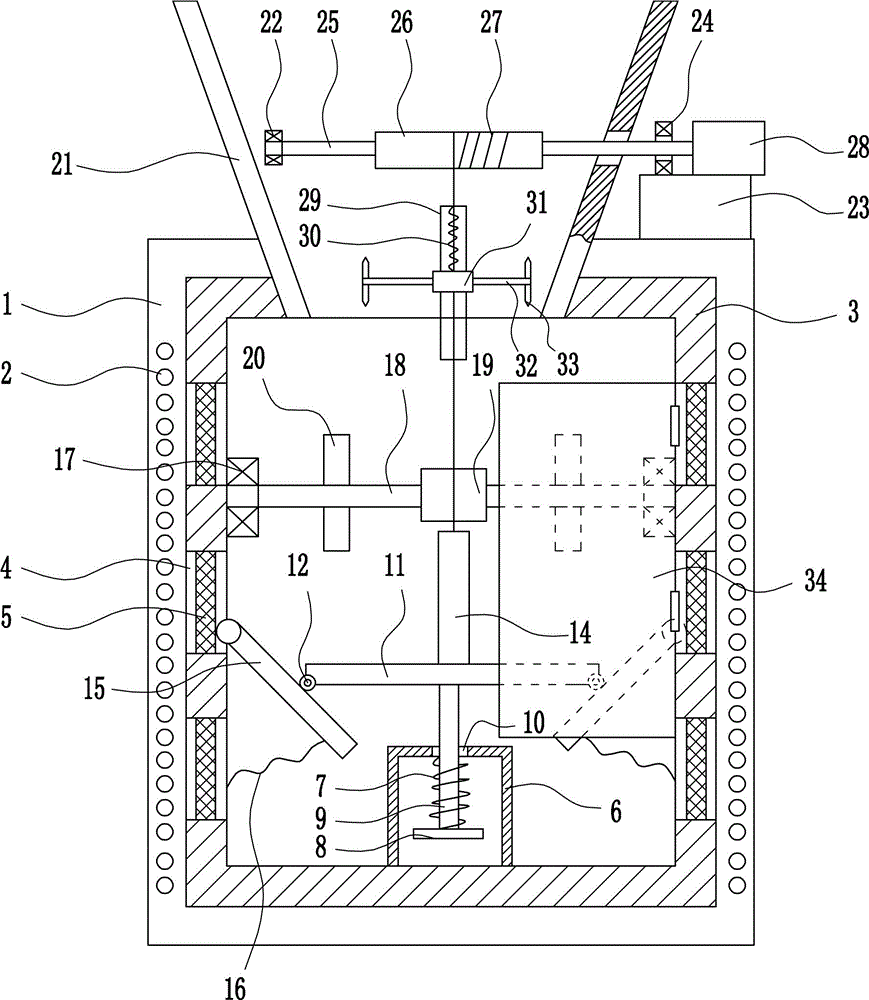

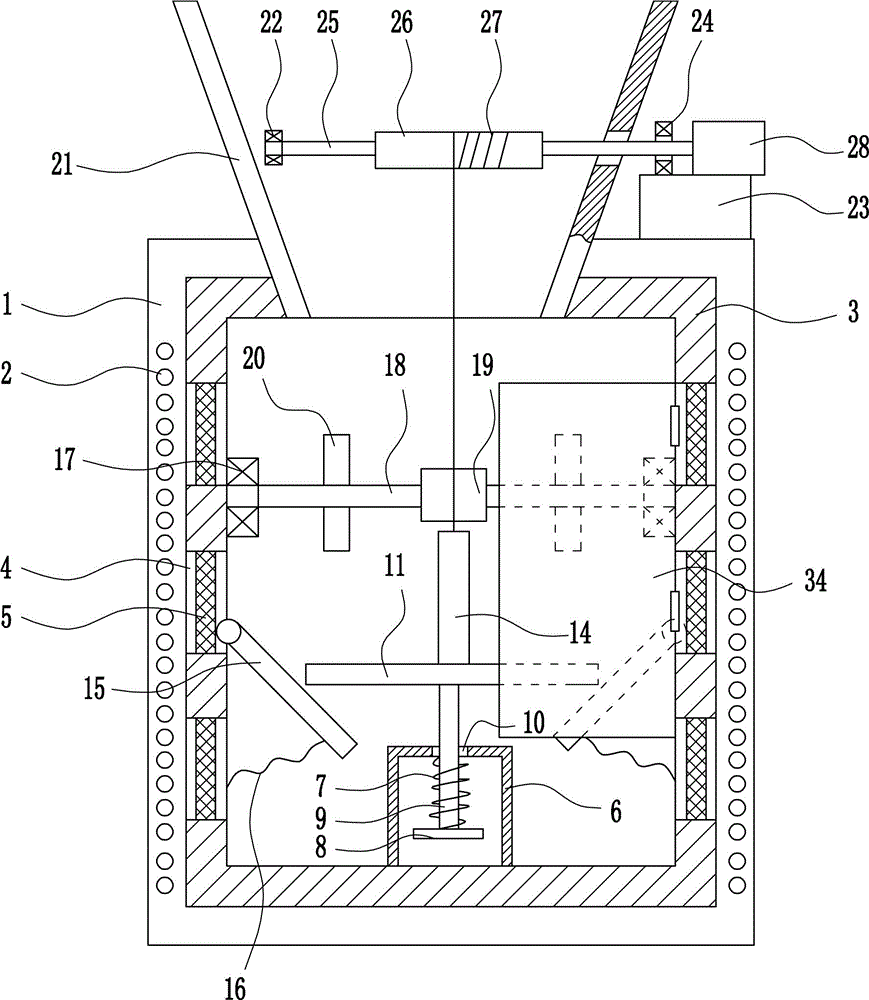

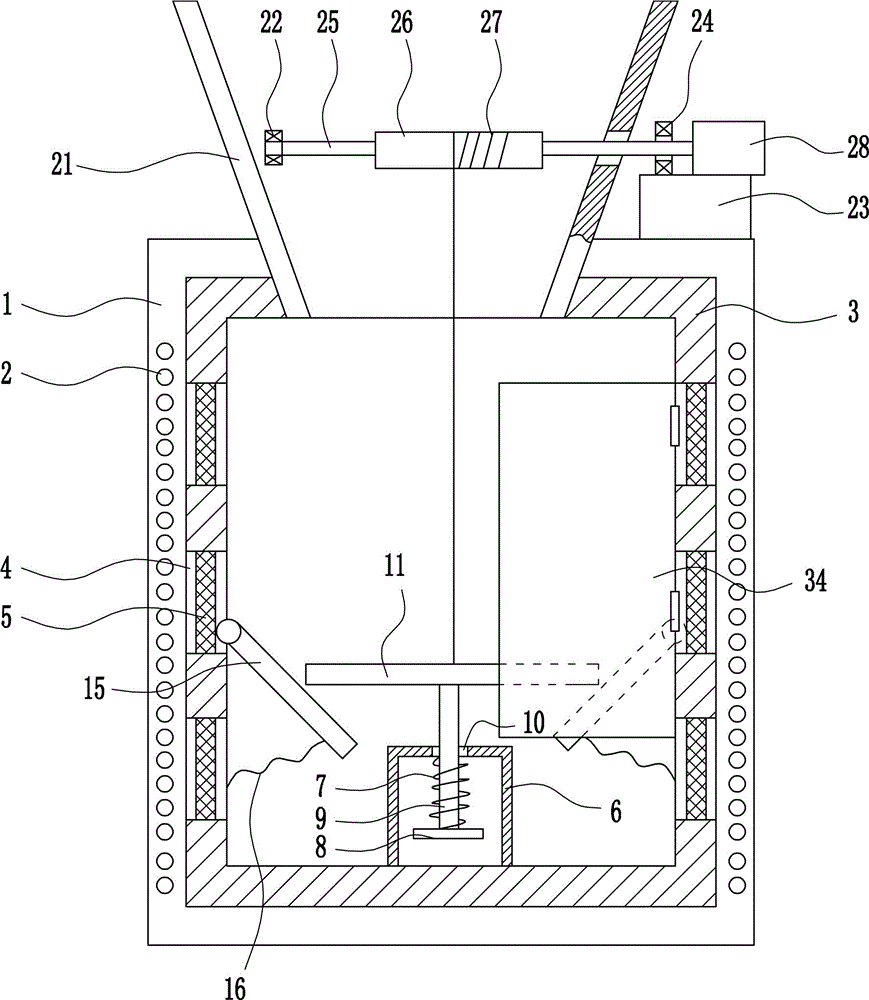

Sufficient demagnetizer for electronic information equipment

ActiveCN106782620ADegaussing completePlay a dredging roleErasing methodEngineeringElectronic information

The invention relates to a demagnetizer for electronic information equipment, in particular to an sufficient demagnetizer for electronic information equipment. The sufficient demagnetizer for the electronic information equipment is sufficient in demagnetizing and comprises an outer frame, a demagnetizing coil, an inner frame, a filter screen, a guide rod, a first spring, a pressing plate, a lifting rod, a mounting plate, a swing plate, a second spring, feeding hoppers and the like. The inner frame is welded in the outer frame, the demagnetizing coil is uniformly adhered in the outer frame, the feeding hoppers are arranged at the top centers of the outer frame and the inner frame, the front walls of the feeding hoppers are connected with third bearing blocks in a bolted connection mode, and a fixing block is welded on the right side of the top of the outer frame. The electronic information equipment is poured into the inner frame by the feeding hoppers, the electrified demagnetizing coil generates a magnetic field for the electronic information equipment in the inner frame, and further the electronic information equipment is demagnetized and destroyed.

Owner:BEIJING JINGCHUANGDA SCI & TECH

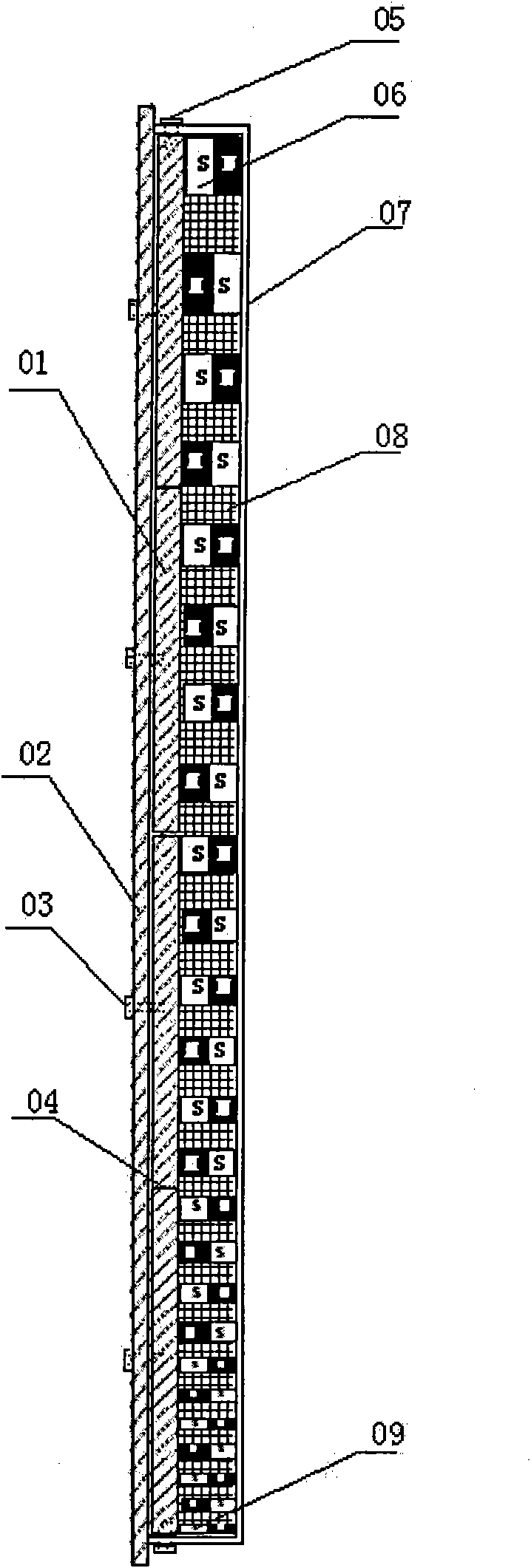

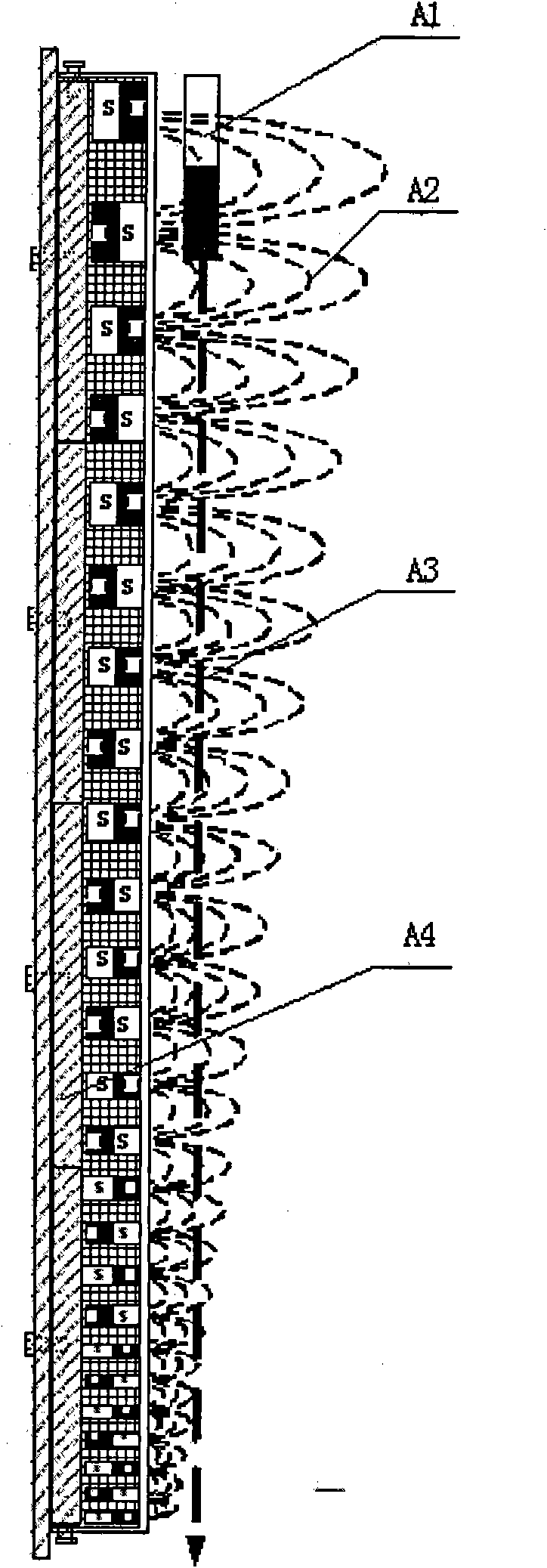

Magnetic density order descending array demagnetizing plate

ActiveCN102254666AMeet the requirements of manual degaussing without power consumptionNo energy consumptionMagnetic bodiesElectricityHigh energy

The invention discloses a magnetic density order descending array demagnetizing plate. The demagnetizing plate is structurally characterized in that: S and N staggered permanent magnet steels (06) are arranged on a magnet steel array bottom plate, and the permanent magnet steels are arranged from top to bottom and from big to small; a nonmagnetic substance (08) is embedded among the permanent magnet steels; and the magnetic intensity of the permanent magnet steels meets a descending order of 5,000 to 100gs, and is in oblique linear gradient change. The area of A4 magnet steel array bottom plate units (A4) and the number of unit combination can be freely increased and reduced according to the requirements of demagnetized characteristics, and the size and the magnetic intensity of the arraymagnet steels can be freely adjusted according to the requirements of the demagnetized characteristics; the demagnetizing plate is suitable for large-area demagnetizing operations of ships, submarines, plates, steel lining conveyer belts, vehicles and the like, and is also suitable for small magnetized bodies such as watches, screwdrivers and the like; and the demagnetizing plate breaks through the electric oscillation principle of the traditional demagnetizer with high energy consumption, is maintenance-free, and has no energy consumption, a wide application range and a high popularization value.

Owner:BAOSHAN IRON & STEEL CO LTD

Gravity-based material bin for charging and discharging of grinder truss

ActiveCN107214623AEasy loading and unloadingEasy to adjustGrinding carriagesGrinding feedersManipulatorDemagnetizer

The invention discloses a gravity-based material bin for charging and discharging of a grinder truss. The gravity-based material bin comprises an electrically-controlled box, a bin frame, a charging bin and a discharging bin, wherein the electrically-controlled box is arranged in front of the bin frame; the bin frame comprises an oil receiving plate positioned at the lower part of the bin frame, and a tabletop positioned at the upper part of the bin frame; the charging bin and the discharging bin are correspondingly arranged at two sides of the tabletop; the charging bin comprises a blank channel, a positioning baffle plate, a blank groove, a guide rail, a propping cylinder and a positioning cylinder; the discharging bin comprises a receiving cylinder, a demagnetizer, a receiving groove, a tilting preventing baffle plate, a sequencing baffle plate, a pushing moving baffle plate, a tilting preventing cylinder, a sequencing cylinder, a pushing moving cylinder and a finished product channel. The gravity-based material bin for the charging and discharging of the grinder truss has the advantages that the structures of the charging bin and the discharging bin are improved, thus people can conveniently charge and discharge materials, and as a result, the working efficiency can be greatly increased; the manipulator grabbing mode is improved, and the positioning accuracy is ensured; a manipulator is prevented from being collided and damaged; and a charging mechanism is improved, and thus the convenience of model changing and adjusting is ensured.

Owner:JIANGSU WANDA SPECIAL BEARING CO LTD

Bearing roller demagnetizer and usage thereof

InactiveCN1564274AMeet the needs of demagnetizationPractical structureMagnetic bodiesFrequency changerUngula

Demagnetization machine includes housing, conveyer system, electrical control system and demagnetization system. The demagnetization system is composed on air core coil and portal shaped coil arranged in front and behind. Universal steering controller and frequency converter for conveyer belt is installed on the housing. Adjustable ungula is in base of the housing. Fine setting device and tensioning device for conveyer belt is installed on upper part of the belt. Conveyer belt is rotated circlewise, frequency converter adjusts number of speeds, universal steering controller determines power of demagnetization coil. Work pieces to be demagnetized on conveyer belt pass through fully enclosed air core coil and portal shaped coil in uniform velocity so as to complete de-magnetizing procedure. Features are: easy of operation, good effect of demagnetization, applicable to workpieces in different specifications and different heights.

Owner:赵贵军 +1

A device for demagnetization by soaking in antirust solution

InactiveCN102262954AReduce bumpsComplete demagnetizationMagnetic bodiesLiquid stateUltimate tensile strength

The invention discloses a demagnetization device soaked in an antirust solution, which belongs to parts and components demagnetization machinery in the industrial production process. There is a frame, a tank body is arranged in the middle of the frame body, the tank body is filled with anti-rust liquid, the center of the tank body is provided with a demagnetizer matched with the demagnetization motor, and a conveyor belt is arranged at the upper end of the demagnetizer device. Because the present invention utilizes the antirust liquid, and soaks the workpiece in the antirust liquid to increase the resistance, thereby reducing the bumps between the workpieces, solving the quality problems caused by the bumps, and improving the work efficiency, reducing the labor force and labor intensity. The tank body is equipped with a spray pipe and an overflow port, and the circulation system of the demagnetizer is used to keep the liquid level in the tank balanced during work, so as to ensure that the workpiece can be completely demagnetized without being bumped in the liquid.

Owner:陈碧海 +1

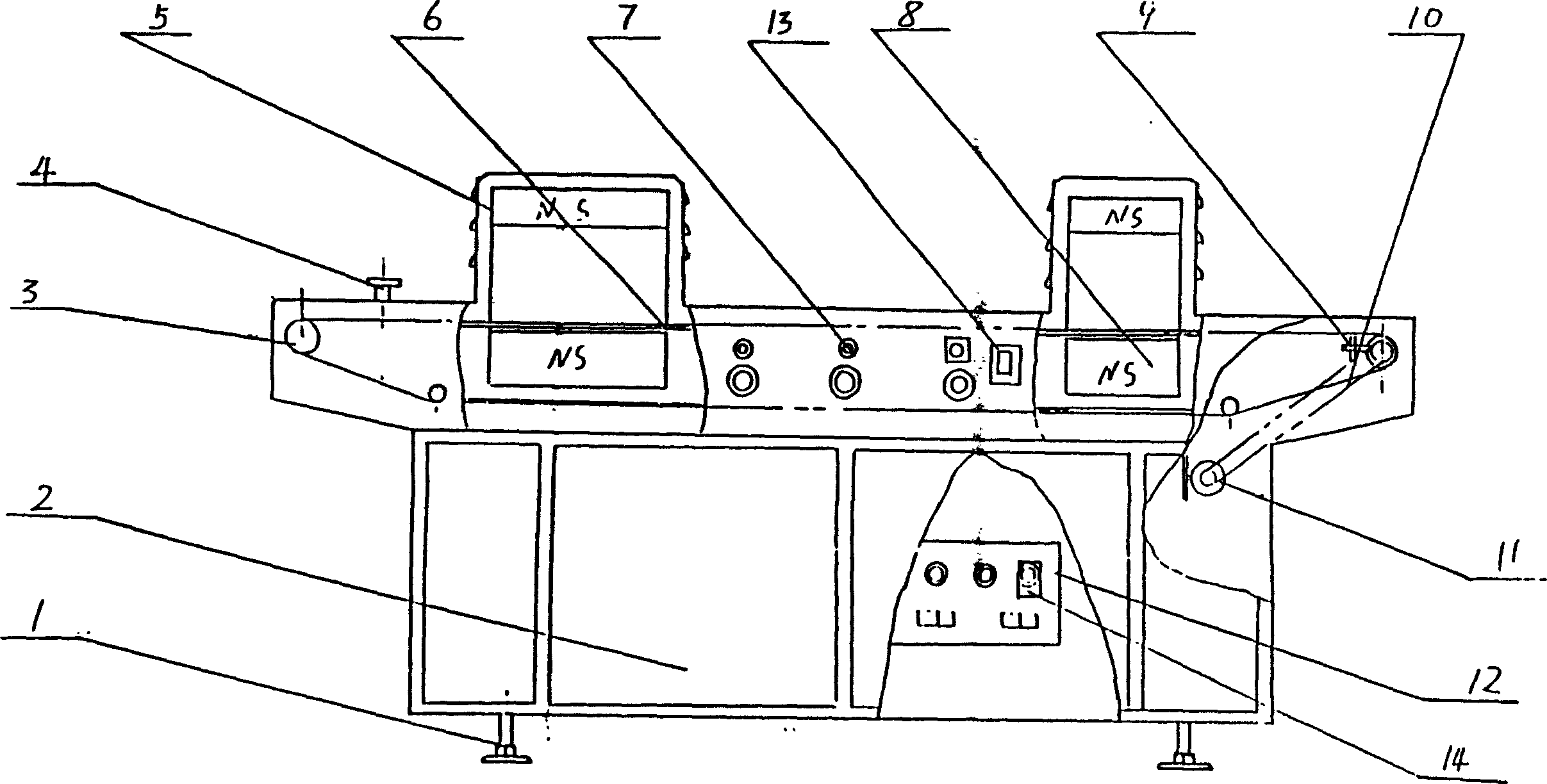

Semi-automatic AC/DC fluorescence magnetic prospecting set dedicated for connecting rod

ActiveCN101907604AGood magnetization effectArtificial defects are clearCurrent/voltage measurementMaterial magnetic variablesRotary stageSprayer

The invention relates to a semi-automatic AC / DC fluorescence magnetic prospecting set dedicated for a connecting rod, which is characterized by comprising a headstock, a tailstock and a middle frame, wherein the middle frame is arranged between the headstock and the tail stock; the headstock, tailstock and the middle frame are provided with a grip shaft respectively; the grip shaft is provided with a circumferential magnetization device and a longitudinal magnetization device; the grip shafts of the headstock and the tailstock are connected with an air cylinder; a motor-driven bull-chain device is respectively arranged between the headstock and the middle frame as well as between the tailstock and the middle frame; a magnetic suspension sprayer nozzle is arranged above the motor-driven bull-chain device; the rear end of the motor-driven bull-chain device is connected with a rotary platform; and the input ends of the rotary platform and a demagnetizer are arranged in a dark shed. The invention has the advantages of high work efficiency, good magnetization effect, convenient operation and reliable performance.

Owner:SHANGHAI CHENGYOU INDAL GROUP +2

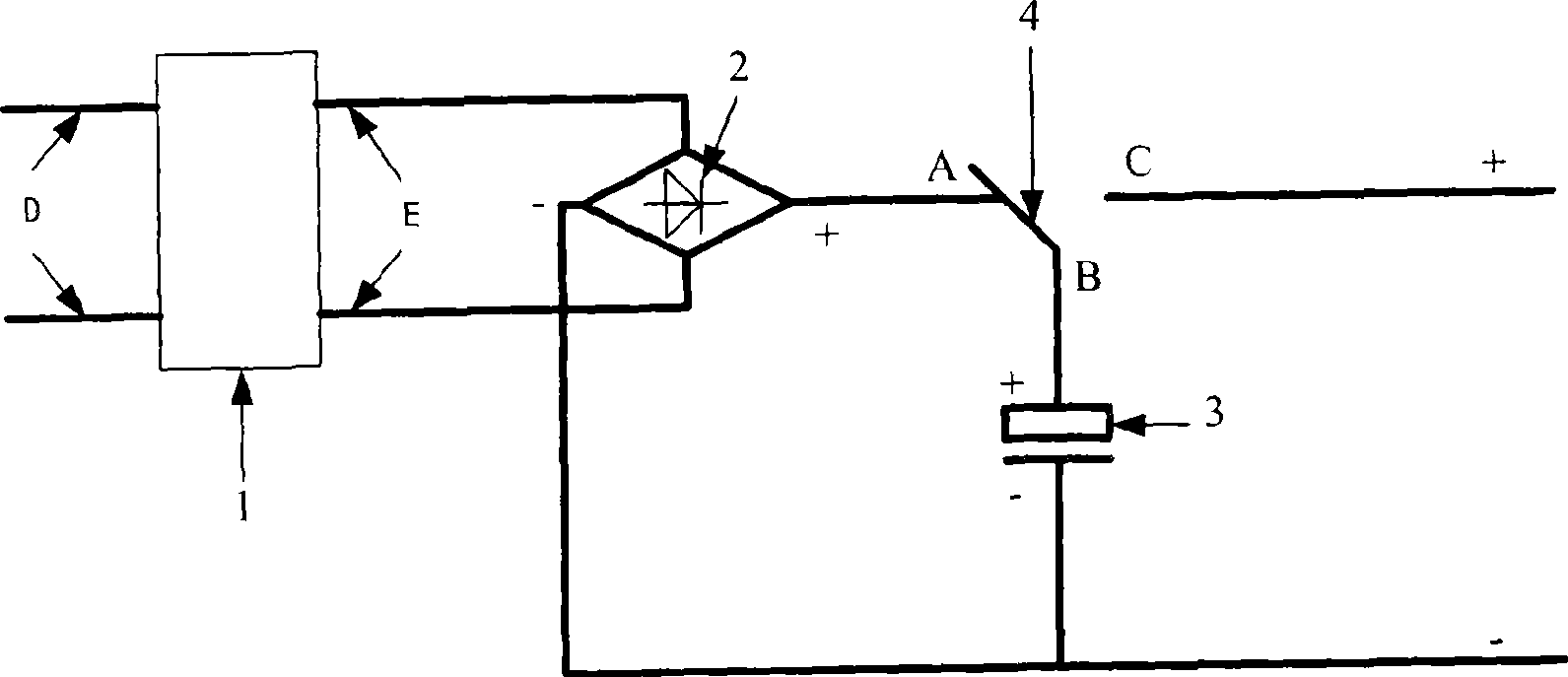

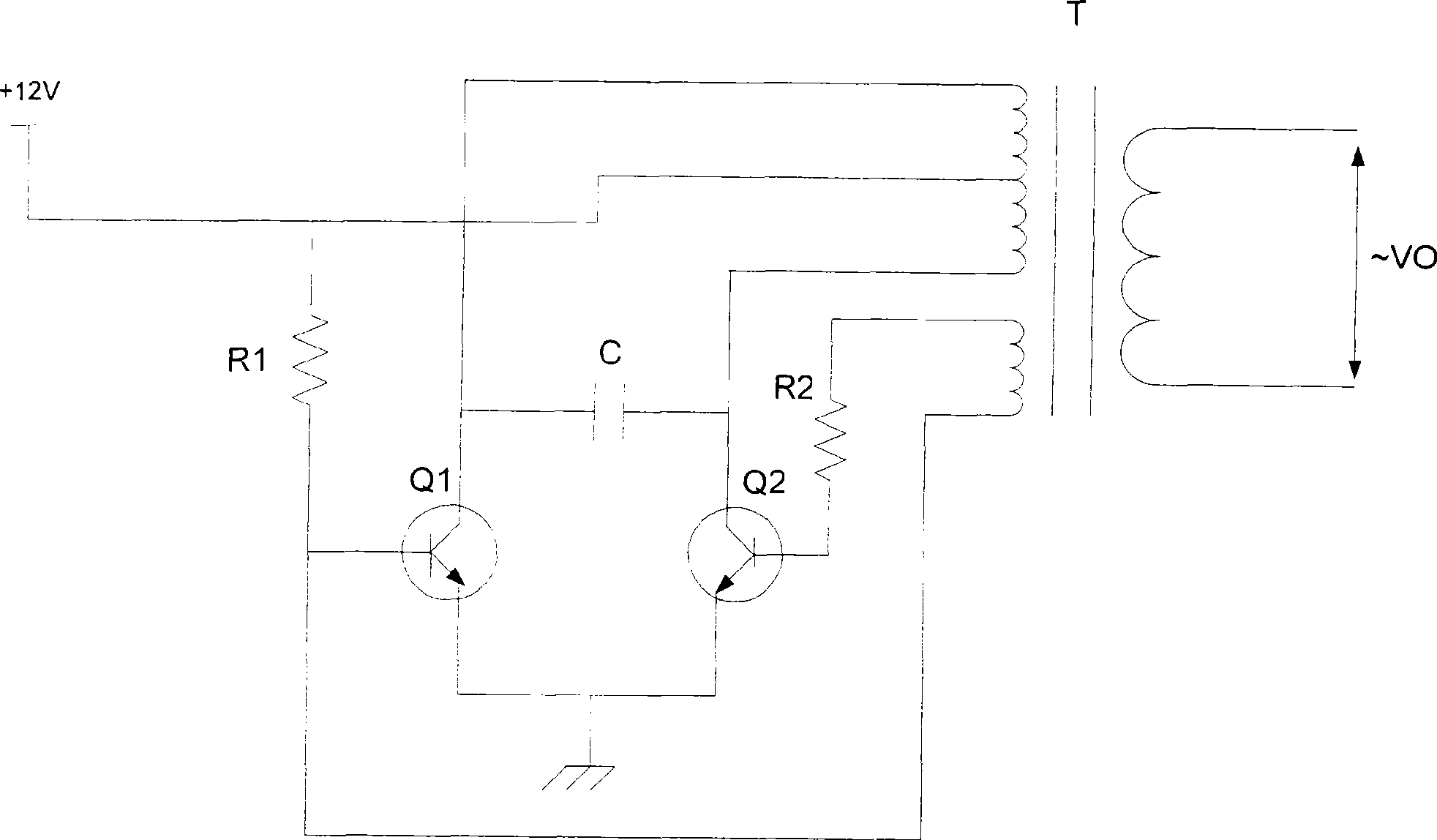

Power supply device for demagnetizer

The invention discloses a power supply device for demagnetizer, which comprises an inverter, a rectifier circuit, a capacitor and a switching circuit; the power supply input end of the inverter is connected with a low voltage dc power supply, and the high voltage ac power supply output end thereof is connected with the ac power supply input end of the rectifier circuit; the inverter is used for inverting low voltage dc into high voltage ac for demagnetization; the anode of the capacitor is connected or disconnected with the anode of a high voltage pulse dc power supply output by the rectifier circuit through the switching circuit; the cathode of the capacitor is connected with the cathode of the high voltage pulse dc power supply output by rectifier circuit; meanwhile, the anode of the capacitor is disconnected or connected with the anode output end of the power supply device through the switching circuit; the cathode of the capacitor is also connected with the cathode output end of the power supply device. As the work power supply of the invention is a low voltage dc power supply, the power supply device can invert the low voltage dc into high voltage ac for demagnetization; thereby, when the power supply device for demagnetizer is mounted on a demagnetizer, the demagnetizer is ensured to operate in any working environment.

Owner:BEIJING HESHENGDA INFORMATION SECURITY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com