Device and method for synchronously demagnetizing steel wire lining conveyor belt

A degaussing device and conveyor belt technology, applied in the direction of conveyors, transportation and packaging, magnetic objects, etc., can solve the problems of increasing energy consumption, shortening the life of the metal object removal system, affecting the normal identification of metal detectors, etc., to ensure normal operation , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

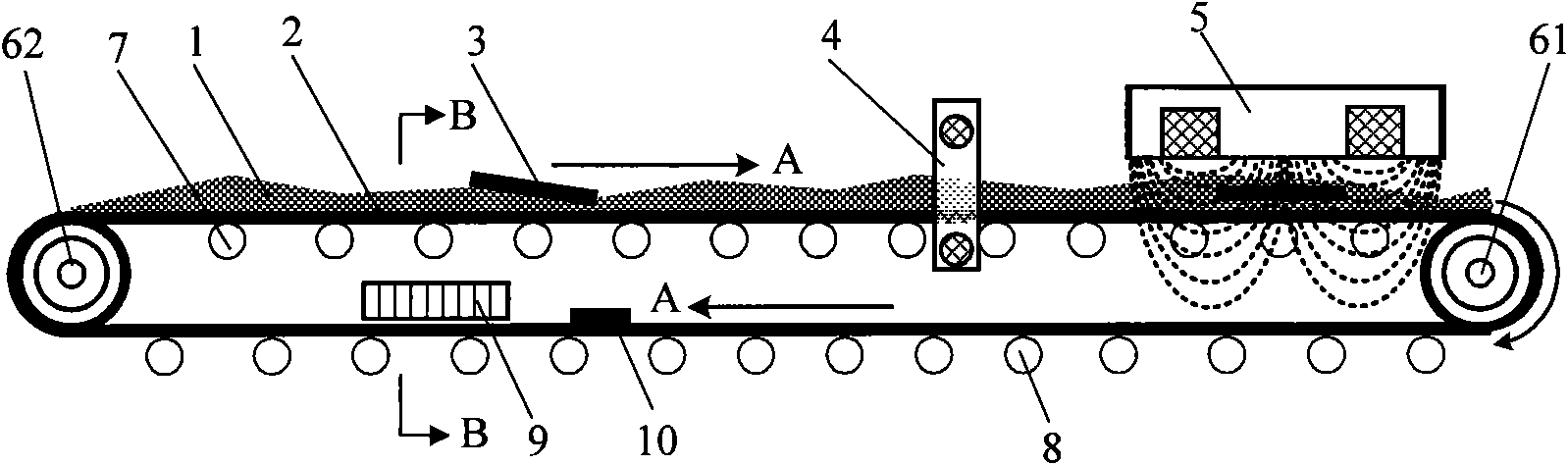

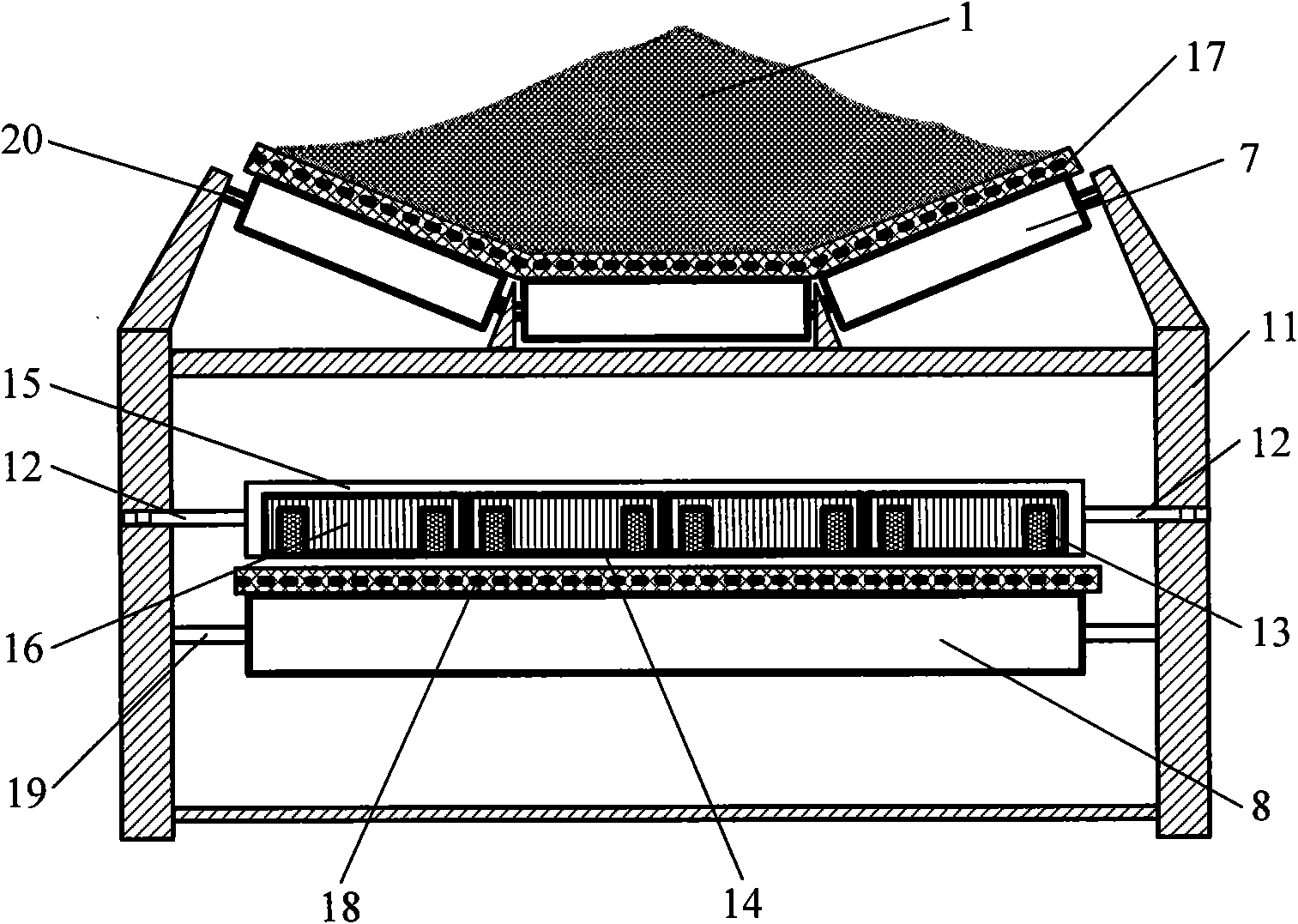

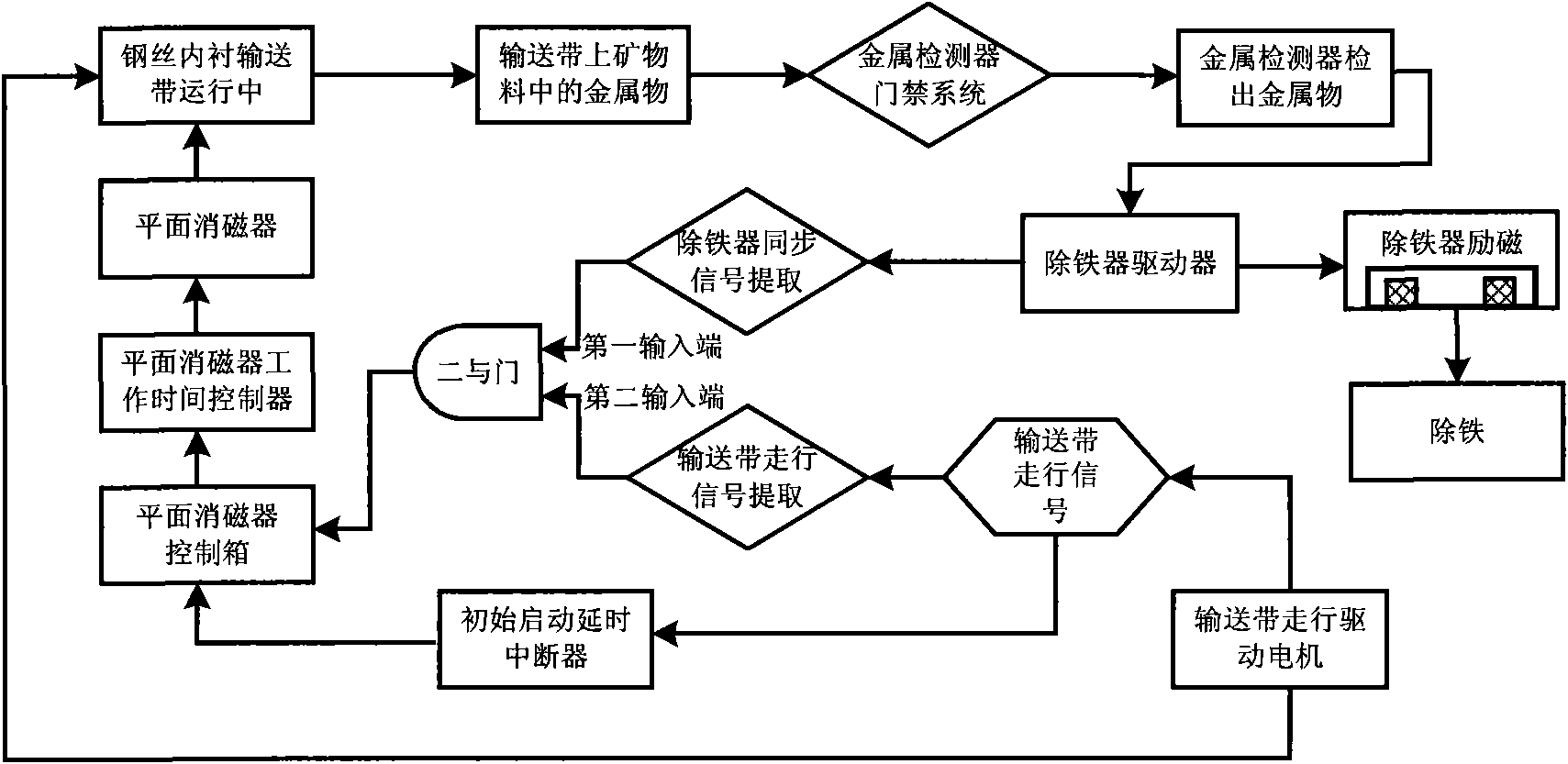

[0024] see figure 1 , figure 2 , a synchronous degaussing device for a steel wire-lined conveyor belt, the upper idler 7 and the lower idler 8 are fixedly installed on the bracket 11 through roller shafts 20, 19 respectively, and the upper surface 17 of the steel wire-lined conveyor belt 2 is arranged on the upper idler 7, the upward surface 17 is a concave surface, and the mineral material 1 containing the metal object 3 is carried on the upward surface 17; the downward surface 18 of the steel wire lined conveyor belt 2 is arranged on the downward idler 8, and the downward surface 18 is a plane. Front and rear drive rollers 61 and rear drive rollers 62 are respectively provided at the front and rear ends of the steel wire-lined conveyor belt 2. Driven by the front and rear drive rollers 61 and 62, the steel wire-lined conveyor belt 2 runs al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com