Patents

Literature

31results about How to "Improved technical indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

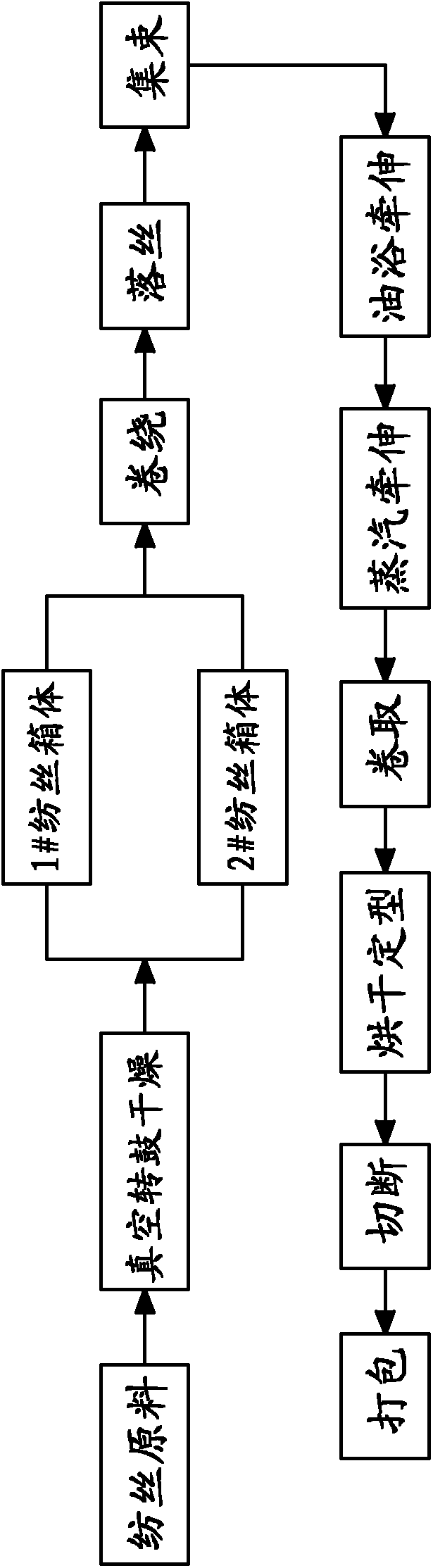

Method for preparing mixed regenerated polyester fibers special for non-woven material

ActiveCN102505177AStable ratioWell mixedArtificial filament heat treatmentMonocomponent polyesters artificial filamentPolyesterState of art

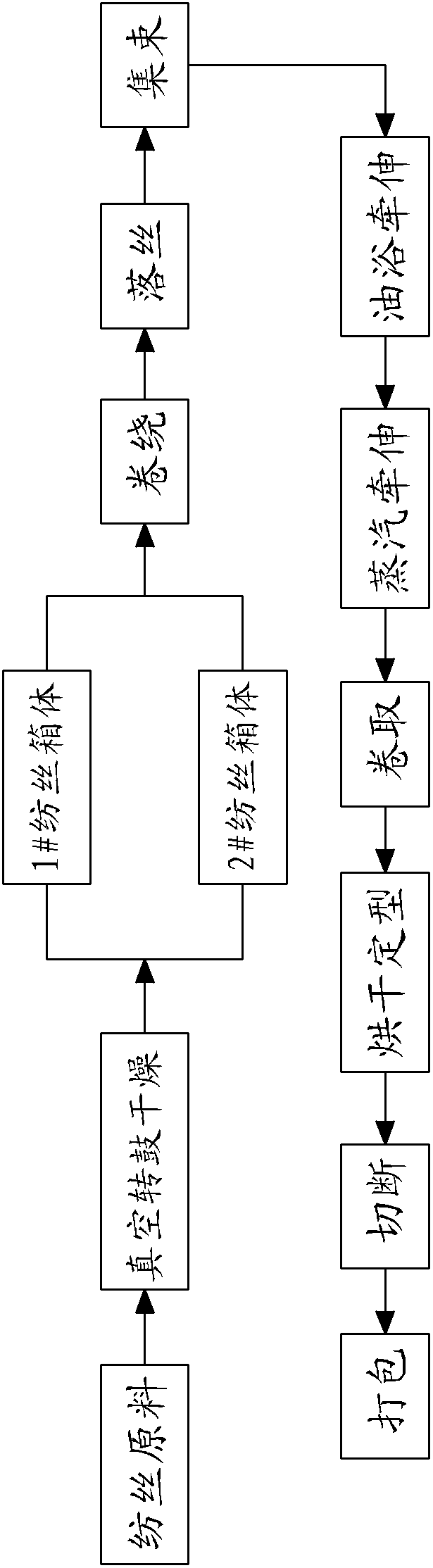

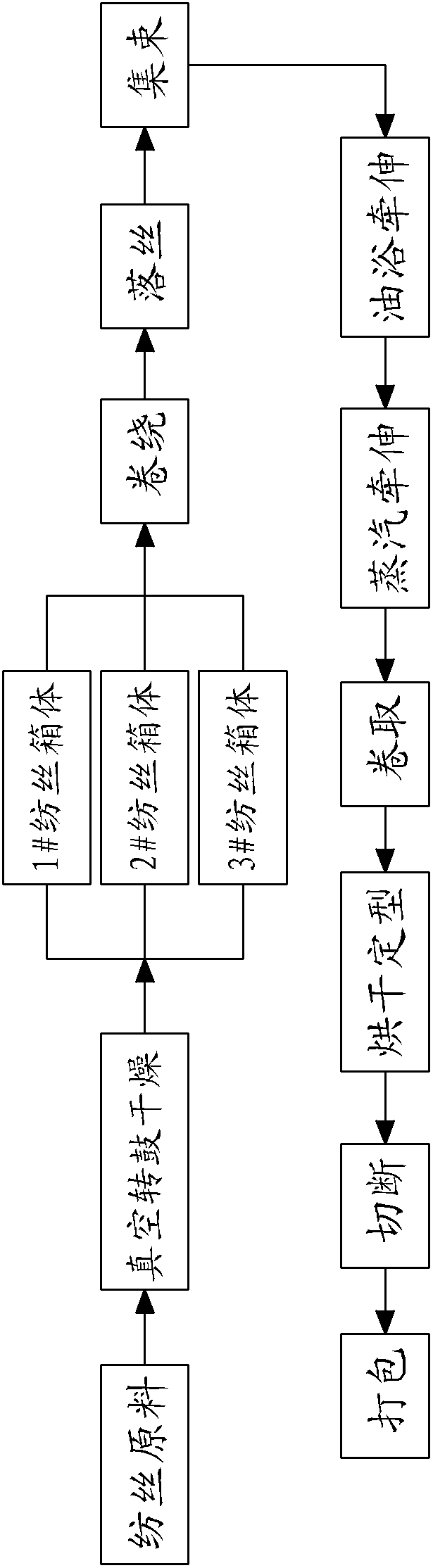

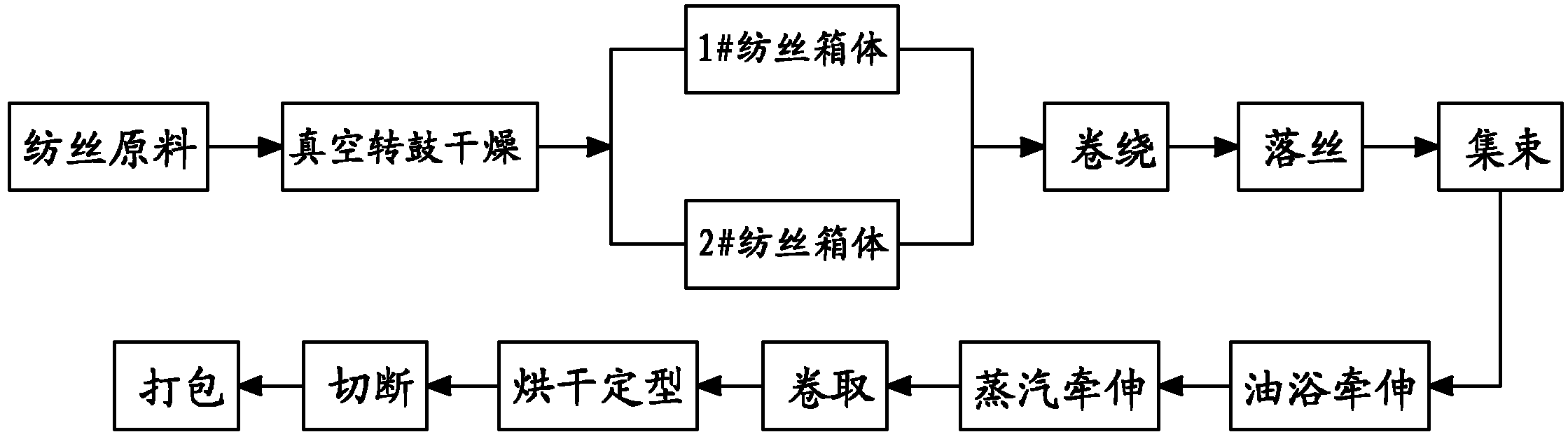

The invention discloses a method for preparing mixed regenerated polyester fibers special for a non-woven material. The method comprises the following steps of: mixing spinning raw materials such as bottle flakes, a chemical fiber friction material, a bubble material and a fluorescent brightener, drying by using a vacuum drum dryer, and performing melt spinning to obtain as-spun fibers with two or more kinds of fineness through two or more spinning box bodies of melt spinning equipment; winding, doffing and bundling the as-spun fibers in turn; drawing in an oil bath, drawing in steam, and reeling; and performing heat setting to prepare the mixed regenerated polyester fibers special for the non-woven material. Compared with the prior art, the method has the advantages that: the fibers produced by the method have two or more kinds of fineness, the raw materials are stably proportioned and uniformly mixed, the non-woven material can have good opening and mixing effects, and the technical index of the non-woven material can be effectively improved. The mixed fibers can be used for producing different styles of non-woven materials, work efficiency is improved, and production cost is reduced.

Owner:福建鑫华股份有限公司

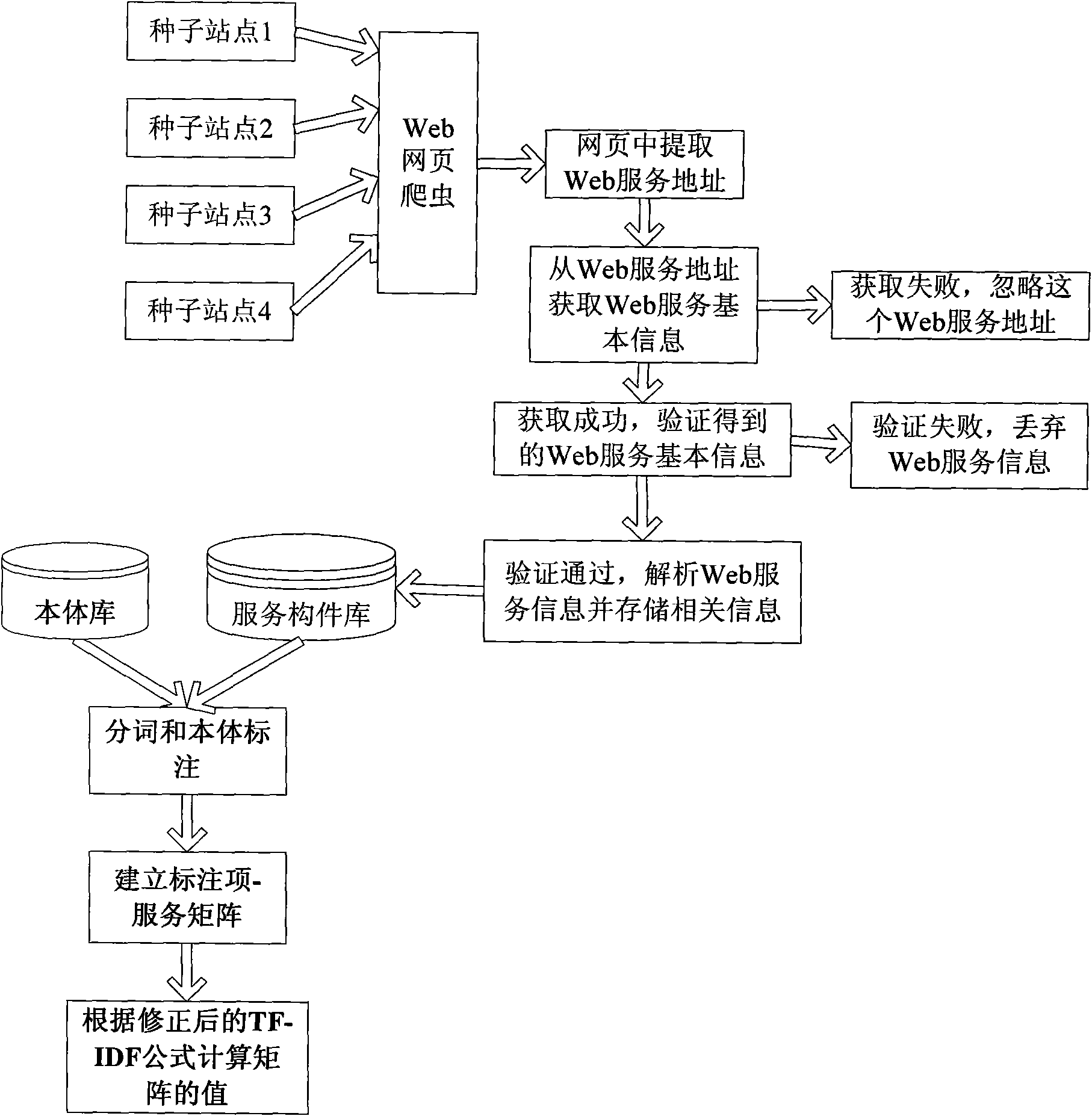

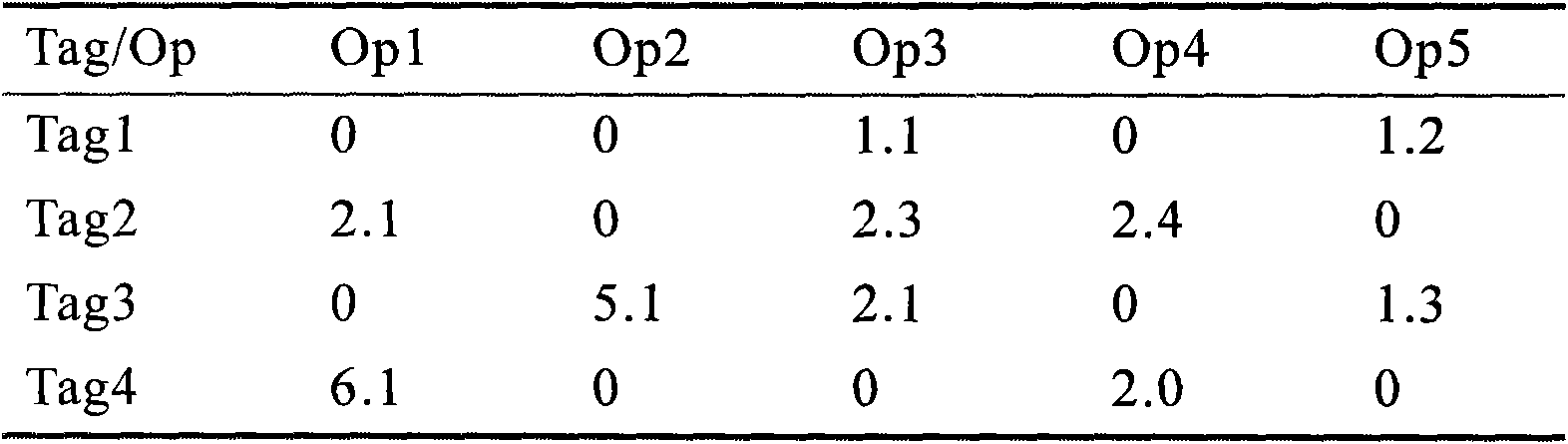

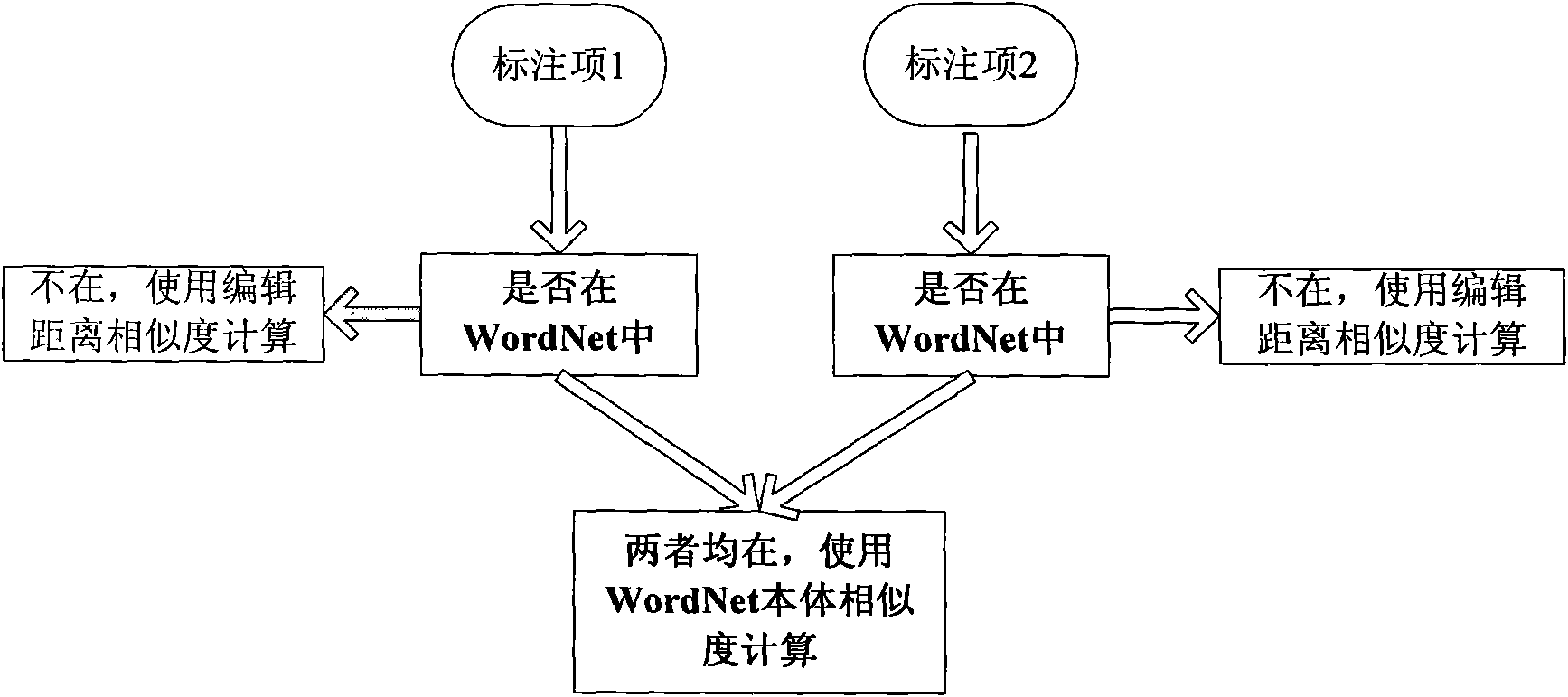

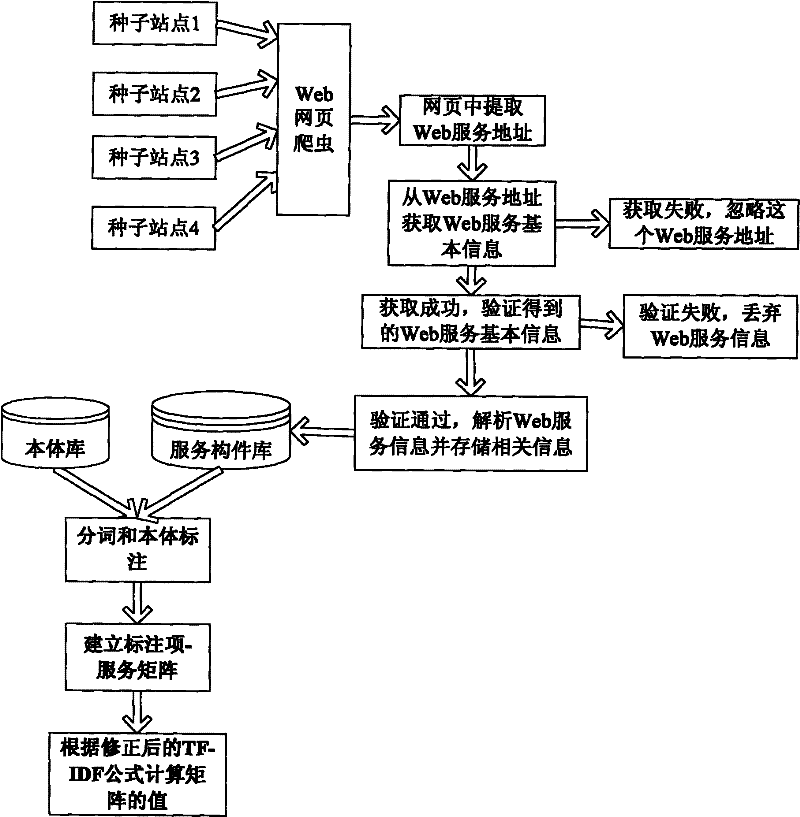

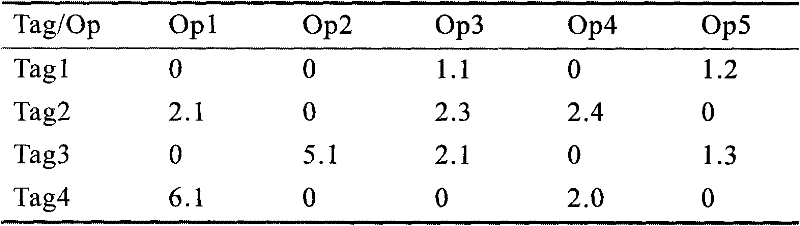

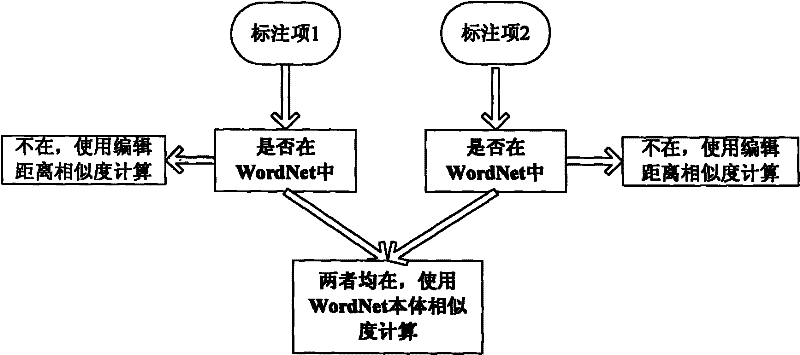

Dynamic construction method for Web service component library and service search method thereof

InactiveCN101650729AImproved technical indicatorsSpecial data processing applicationsWeb serviceSemantic matching

The invention provides a dynamic construction method for a Web service component library, which realizes the search based on potential semantic matching by semantically marking a Web service description document. At the same time, the invention also provides a service search method designed according to the construction method. Because the comparison obtained by the construction method for the Webservice component library and the search method thereof is based on the semantic similarity of words and phrases, the problems such as polysemy, synonyms, singular and plural words, misspelling, etc.are solved to a certain extent. Thus, all the technical targets of the Web service search method are improved.

Owner:北京赛柏科技有限责任公司

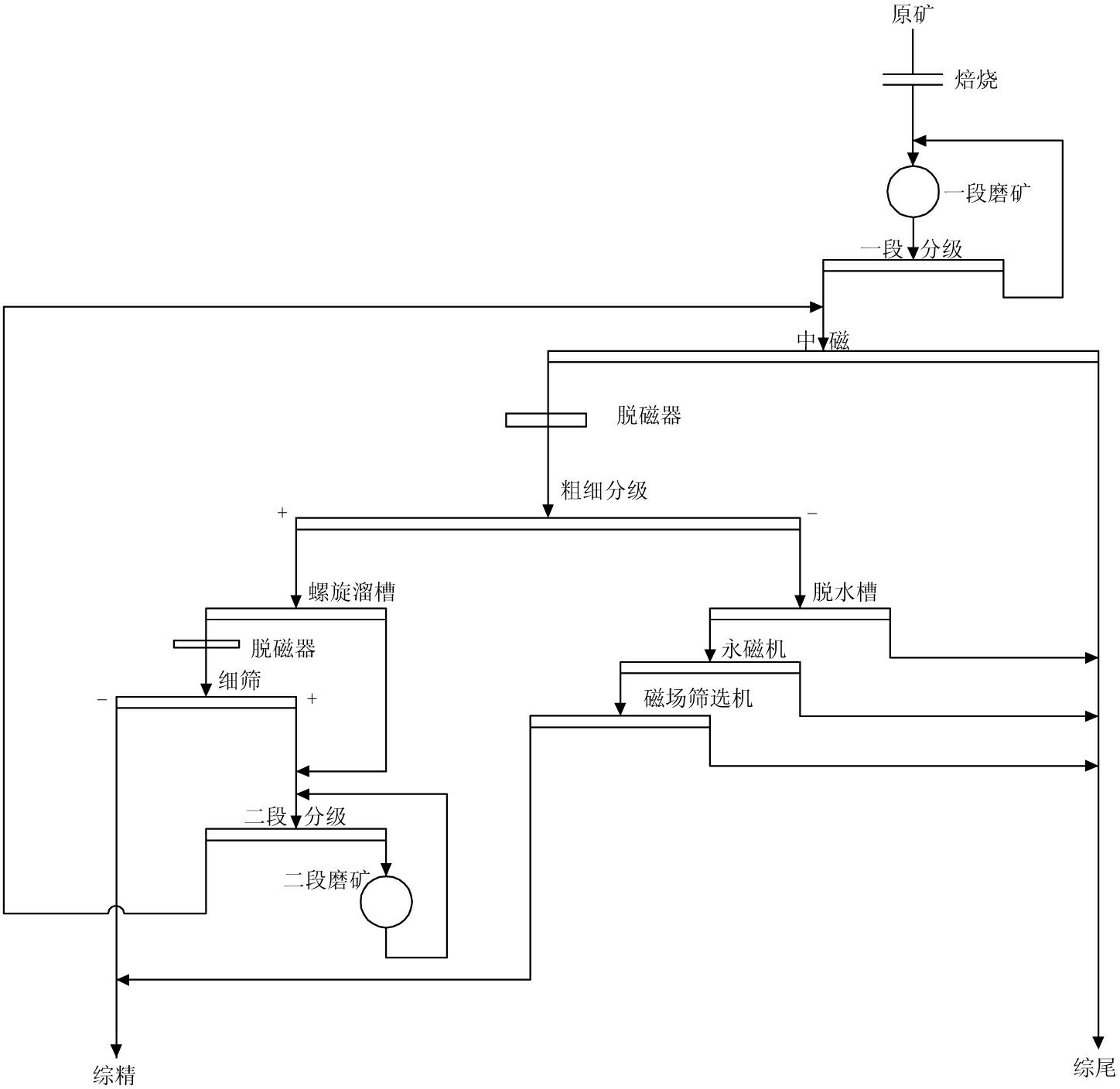

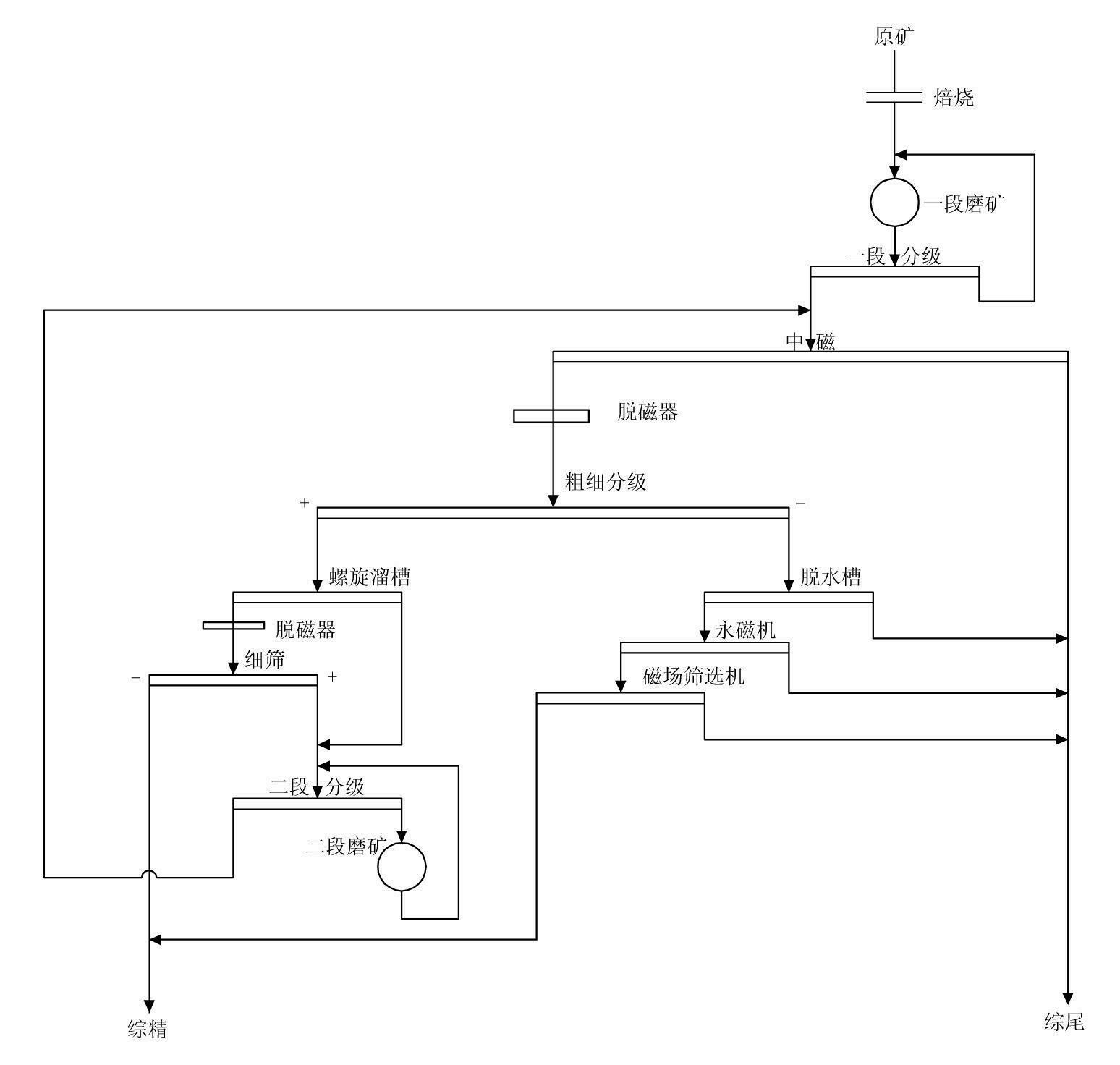

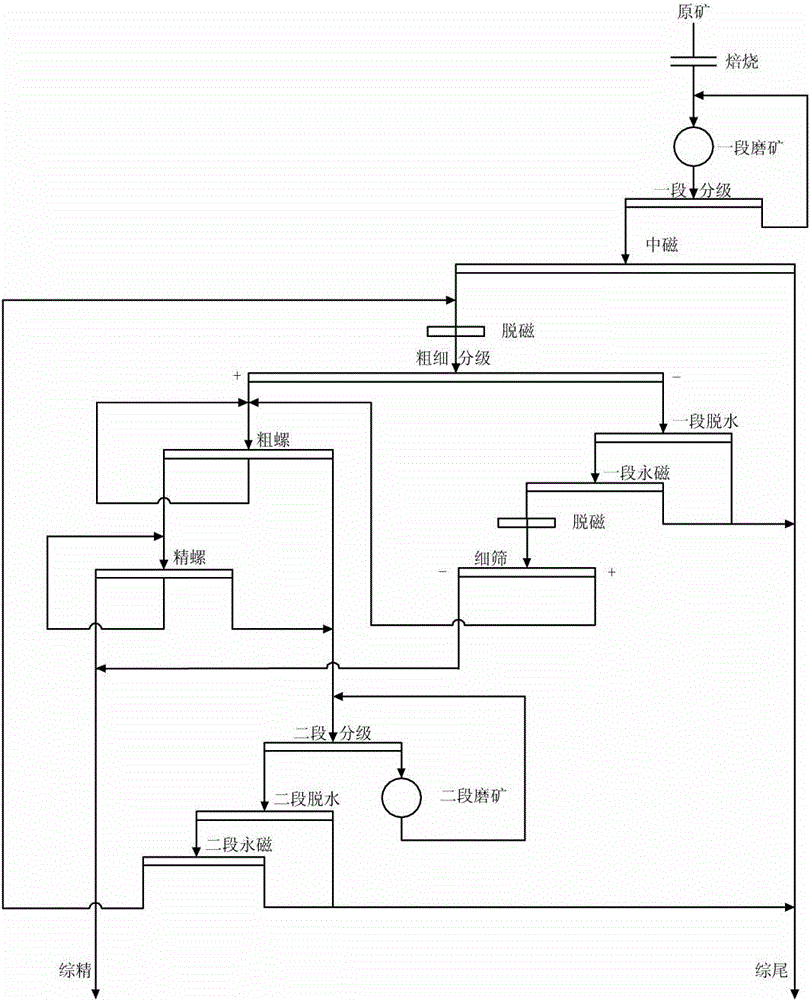

Hematite roasting, stage grinding, intermediate magnetic separation, fineness classifying, gravity concentration-magnetic separation technique

ActiveCN102631984AImprove sorting efficiencyImproved technical indicatorsWet separationScreening proceduresClosed loop

The invention belongs to the technical field of iron ore grading and especially relates to a hematite roasting, stage grinding, intermediate magnetic separation, fineness classifying, gravity concentration-magnetic separation technique, comprising raw ore roasting, first segment of closed loop grinding, primary grading, intermediate magnetic separation, fineness classifying and gravity concentration-magnetic separation. The technique is characterized by feeding the intermediate magnetic separation concentrate in a demagnetizer, grading the concentrate through fineness classifying, grading the material into rough granule level product and fine granule level product, feeding the rough granule level product in the fineness classifying procedure in a helical chute, demagnetizing the concentrate in the helical chute and performing screening procedure on the concentrate, serving the tailings in the helical chute and the oversize product in the screening procedure as middlings, performing secondary grading and second segment of closed loop grinding procedures on the middlings, and feeding the fine granule parts in the fineness classifying procedure in a dehydration tank, a permanent magnetic machine and a magnetic field screening machine to perform magnetic separation procedure. The comprehensive concentrate is composed of screening concentrate and magnetic field screening machine concentrate, and the compressive tailings are composed of intermediate magnetic separation tailings, dehydration tank tailings, permanent magnetic machine tailings and magnetic field screening machine tailings. The technique has the advantages that the sorting efficiency of the whole procedure is improved, the screening concentrate in rough granule procedure and the magnetic field screening machine concentrate in fine granule procedure can reach 65-67%, the level of the comprehensive concentrate is higher than 65-67%, and the level of the compressive tailings is reduced to 8-10%.

Owner:ANSTEEL GRP MINING CO LTD

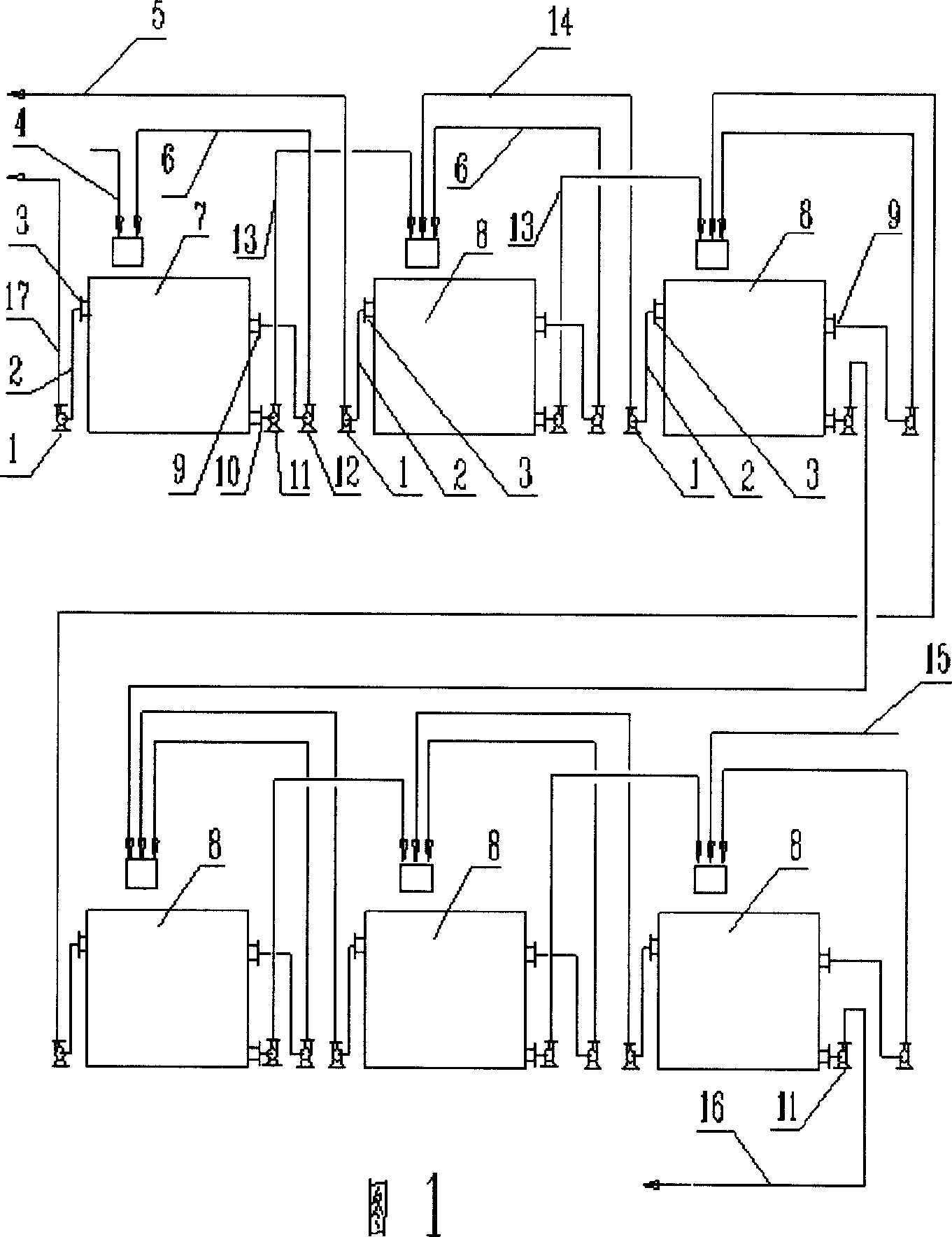

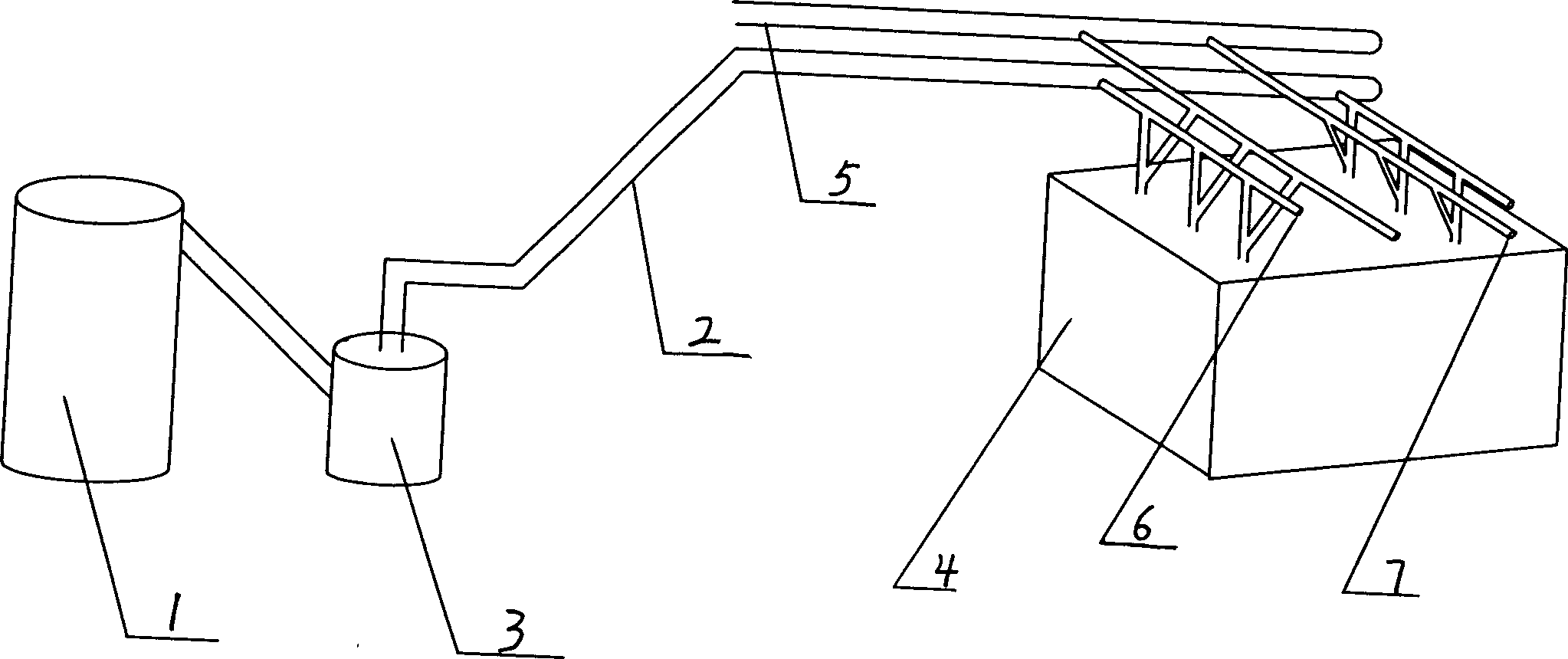

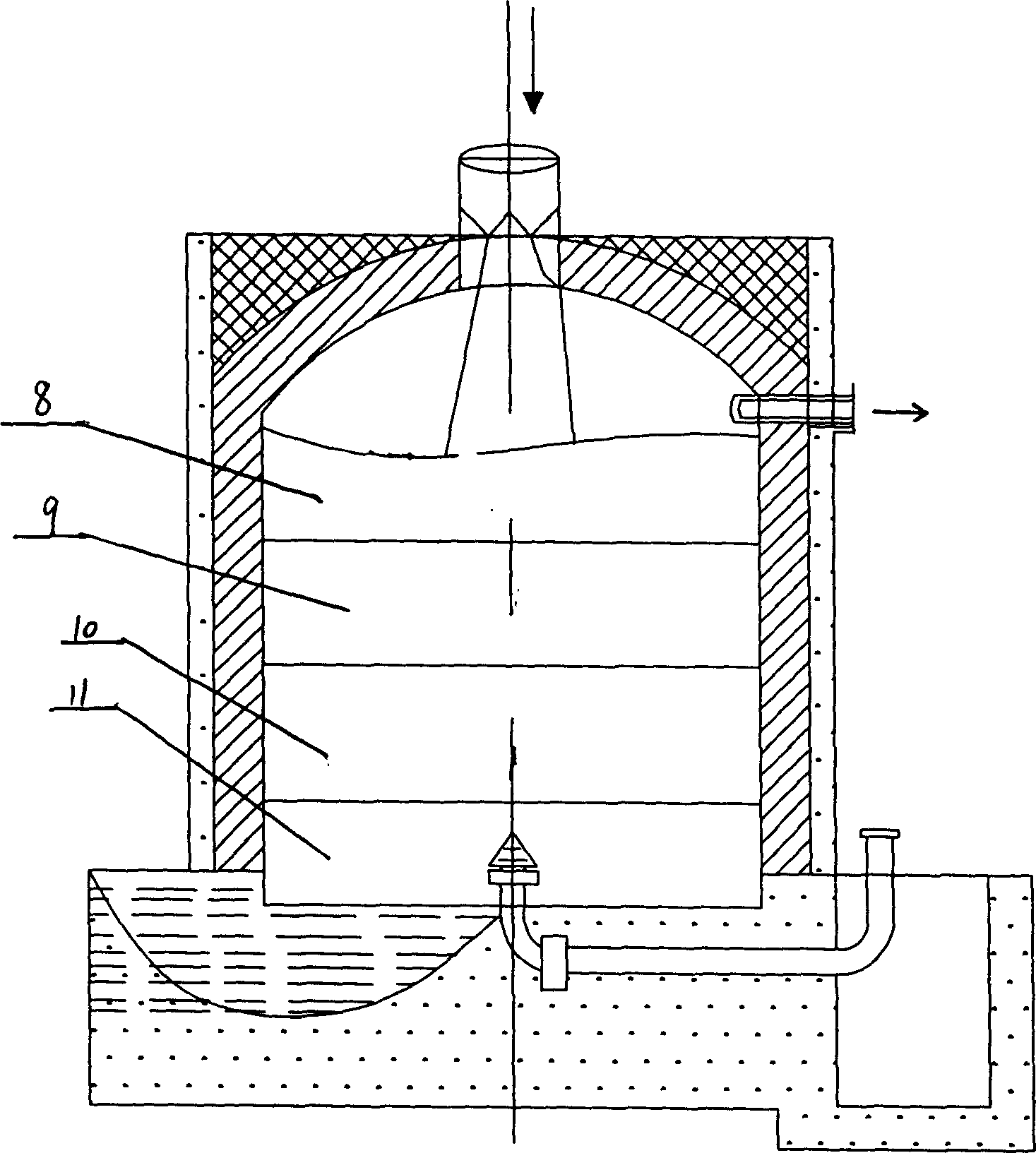

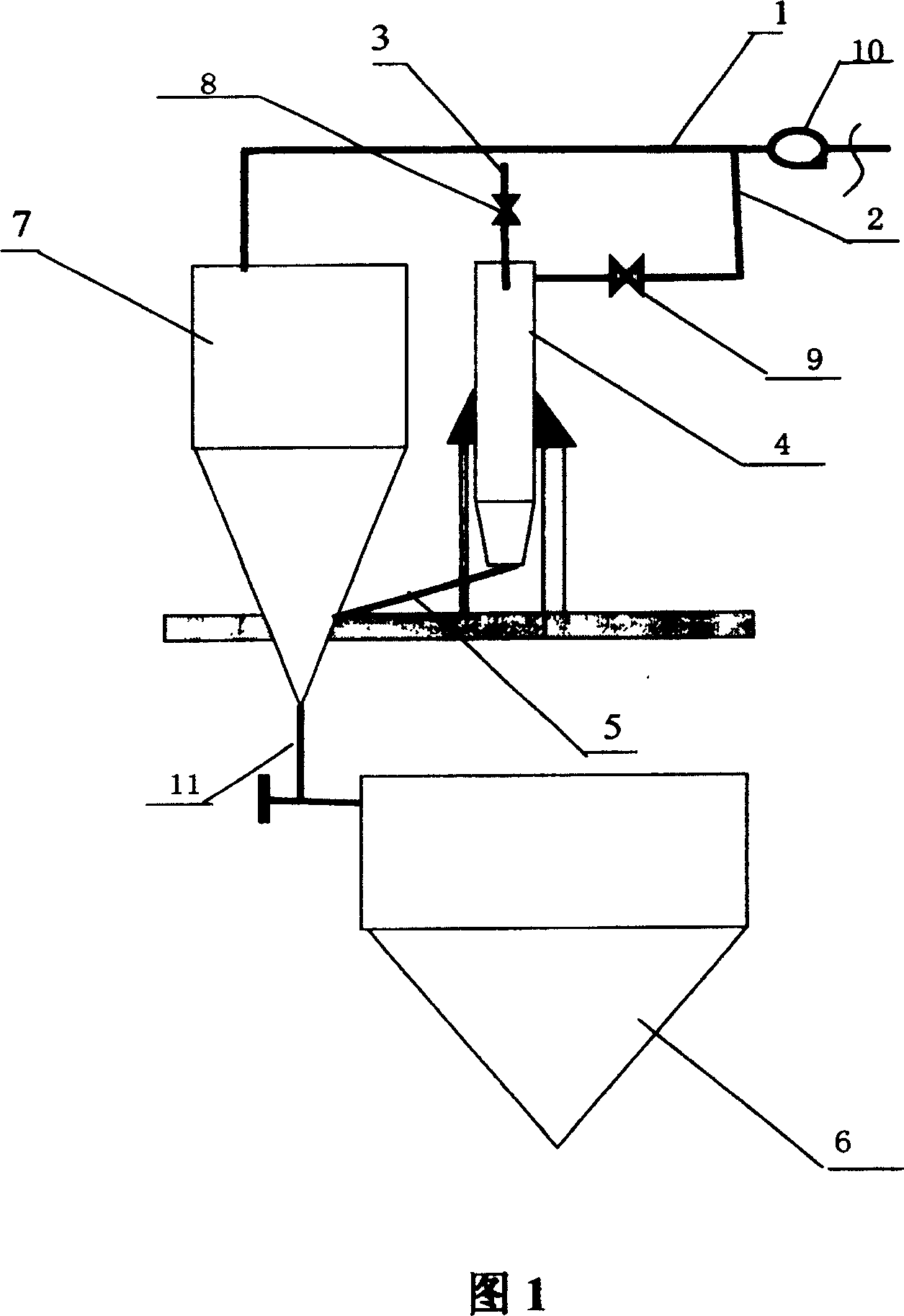

Red mud separating washing technology with self circulation and its device

InactiveCN1868879AReduce the amount of washing water addedSolve washing problemsAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxides/hydroxidesRed mudCirculating pump

A red mud washing-separating process and apparatus with self circulation features that a solution outlet is additionally made at the upper-middle part of each separating settling bath and each washing settling bath, each settling bath has a circulating pump at its bottom for circulating 10-60% of the solution in the bath itself, all the washing settling baths are cascaded for serially transferring te bottom flow from this one to next one, and final red mud is filtered.

Owner:GUIYANG AL-MG DESIGN & RES INST

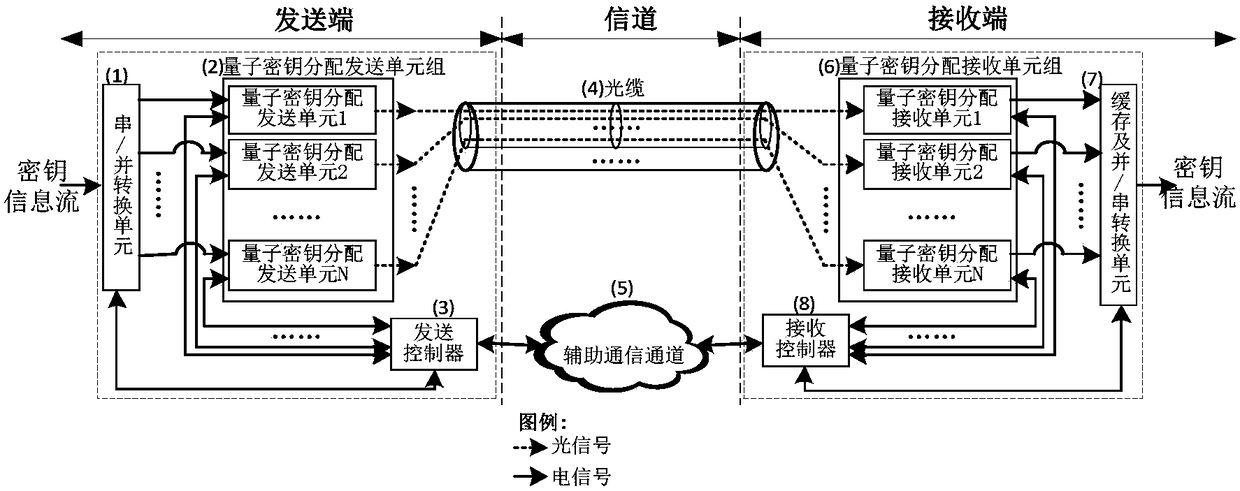

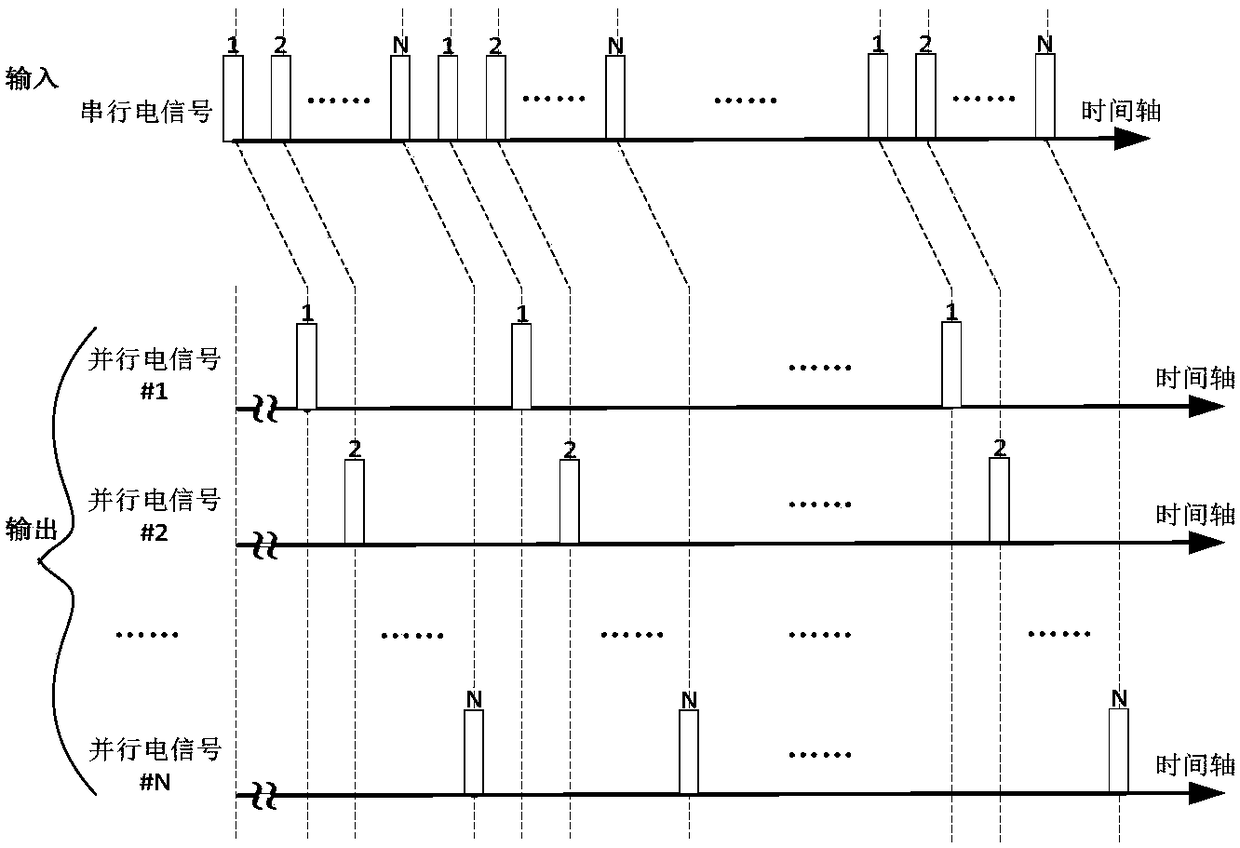

Optical fiber quantum key distribution system and control method

InactiveCN108259167AIncrease spawn rateImprove performanceKey distribution for secure communicationPhotonic quantum communicationEngineeringUnit group

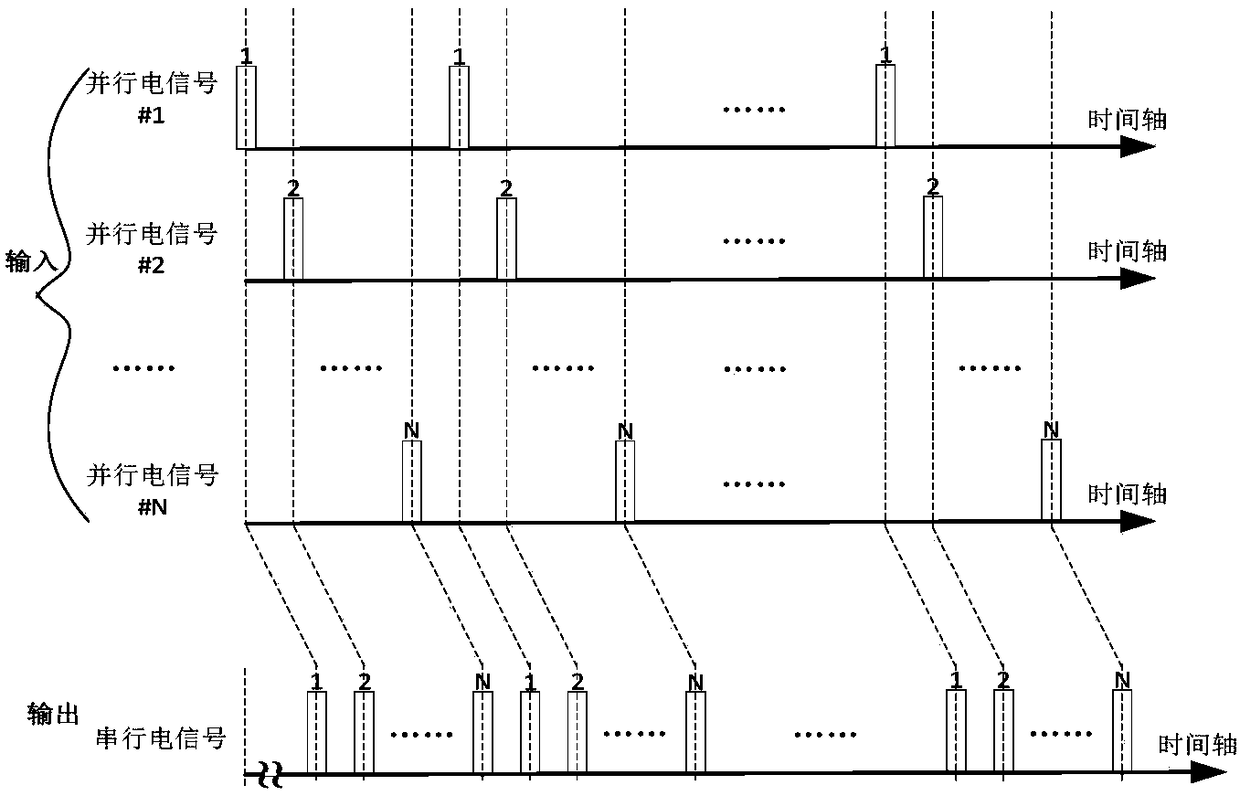

The invention relates to an optical fiber quantum key distribution system and a control method thereof. The system comprises a transmitting end, a channel and a receiving end, which are sequentially connected, the transmitting end comprises a serial / parallel conversion unit, a quantum key distribution transmitting unit group and a transmission controller, the channel comprises an optical cable andan auxiliary communication channel, the receiving end comprises an quantum key distribution receiving unit group, a buffer, a parallel / serial conversion unit and a receiving controller, which are connected with each other; and the parallel work of N quantum key distribution transmitting units having the same performance, transmission media, quantum key distribution receiving units are controlledby the corresponding controllers, thereby overcoming the limitation problems of technical and cost factors, stably improving the output rate of secure keys of the optical fiber quantum key distribution system without reducing the non-relay transmission distance, and improving the technical performance and practicability of quantum cryptography communication.

Owner:STATE GRID CORP OF CHINA +1

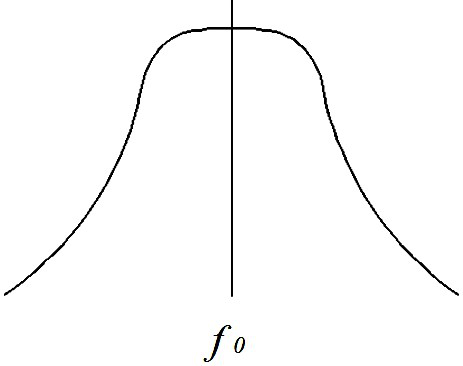

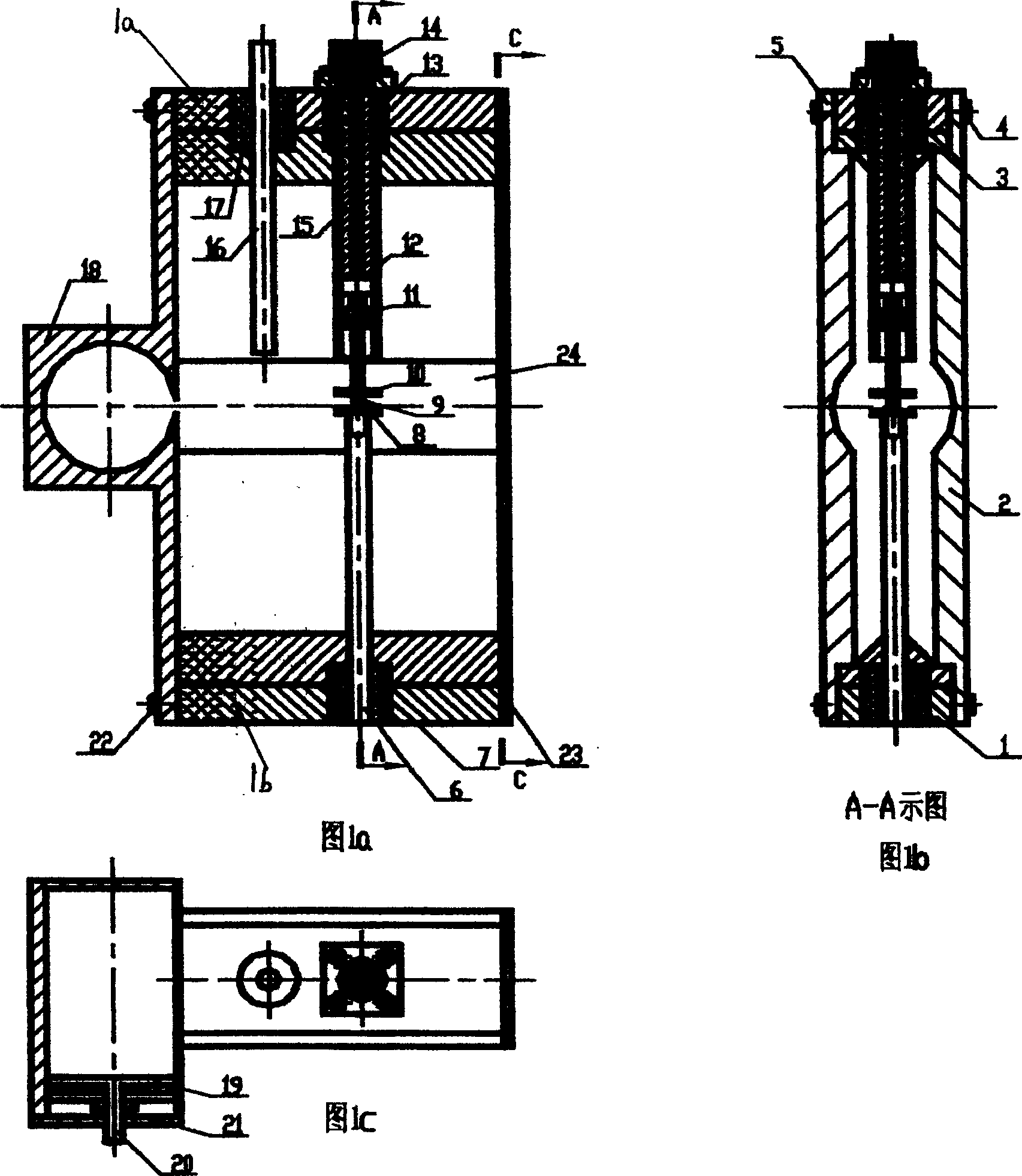

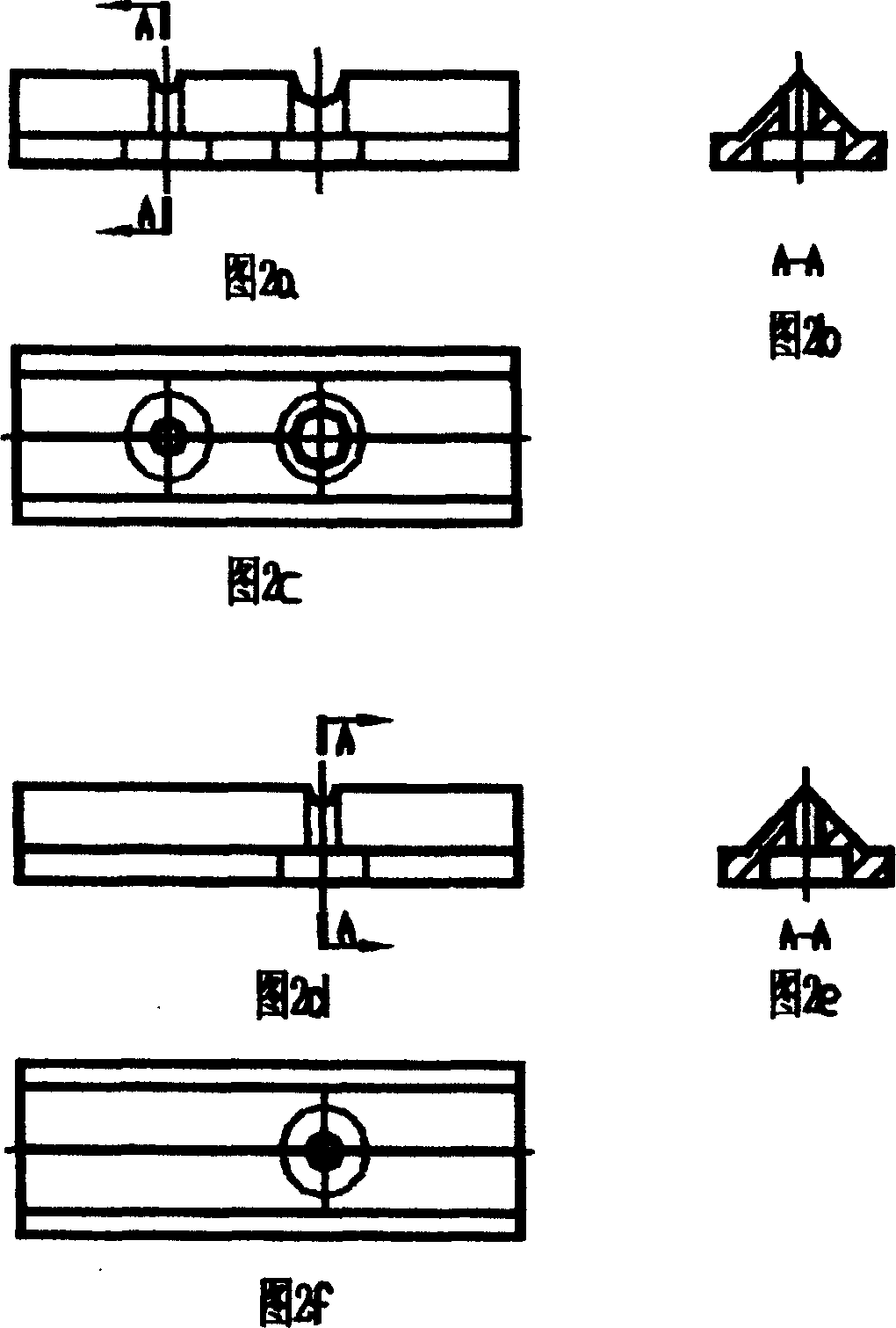

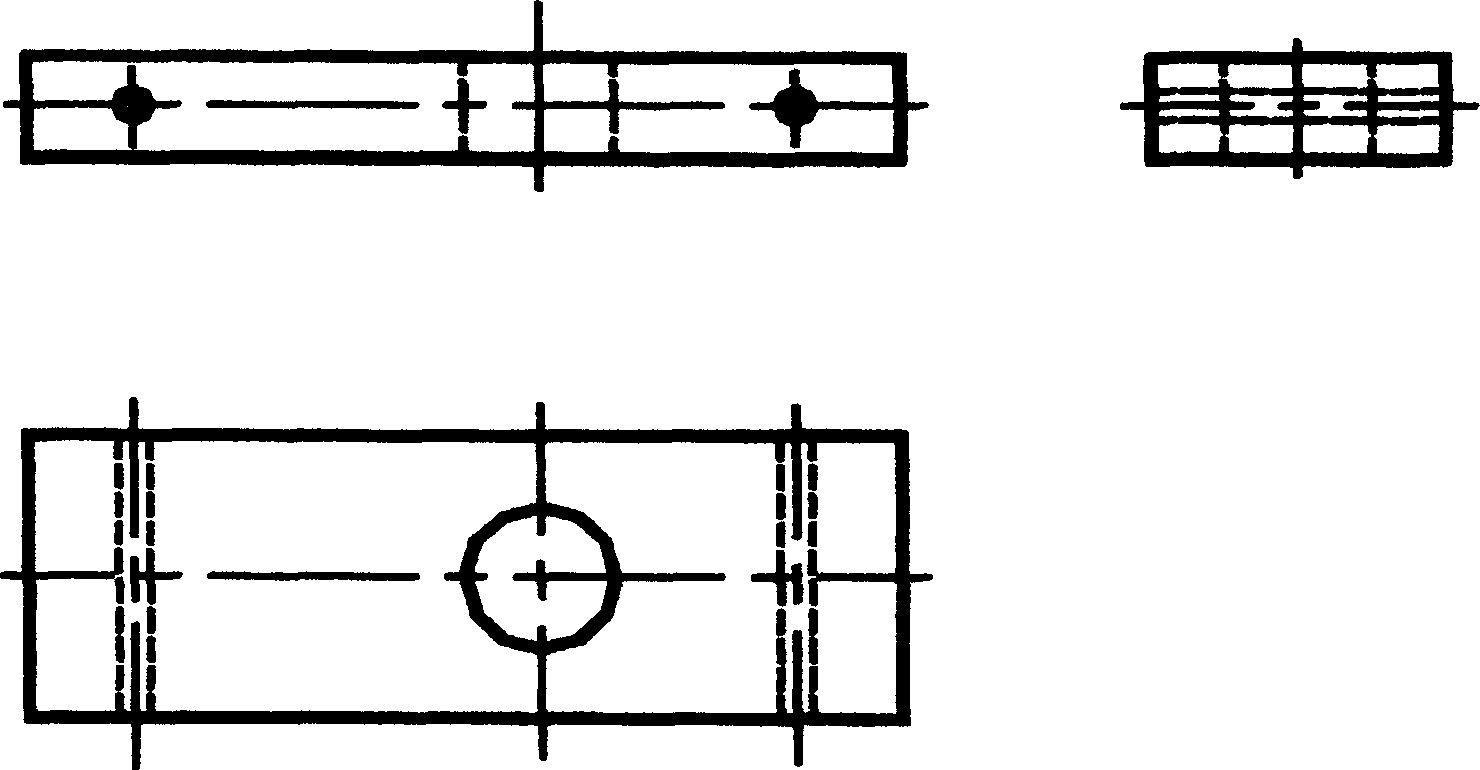

Circular recess wave guide chamber stable oscillator

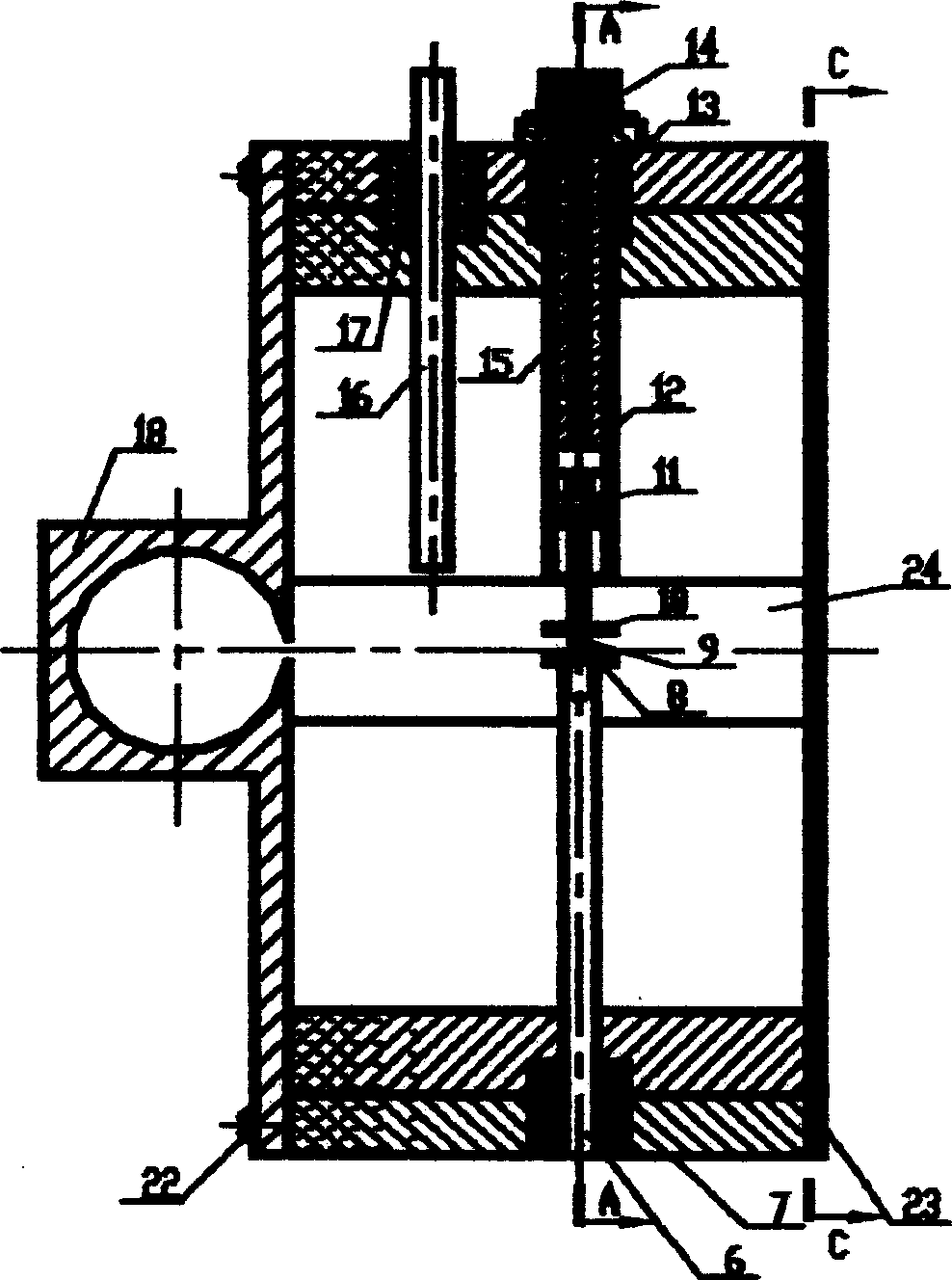

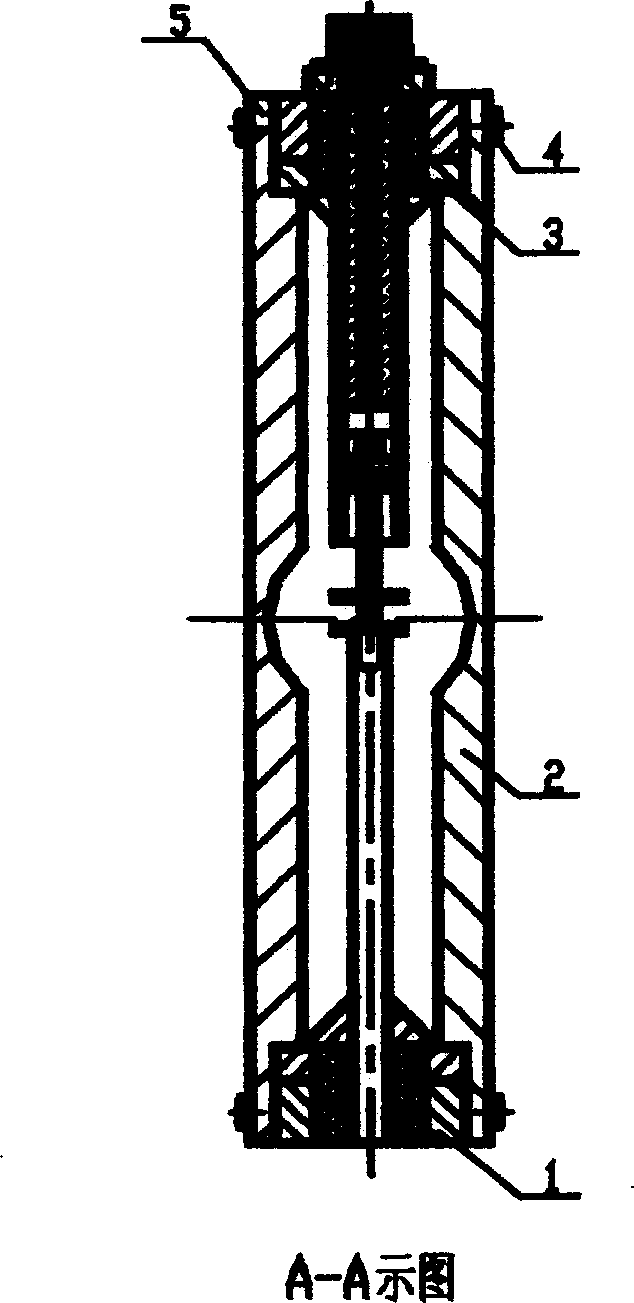

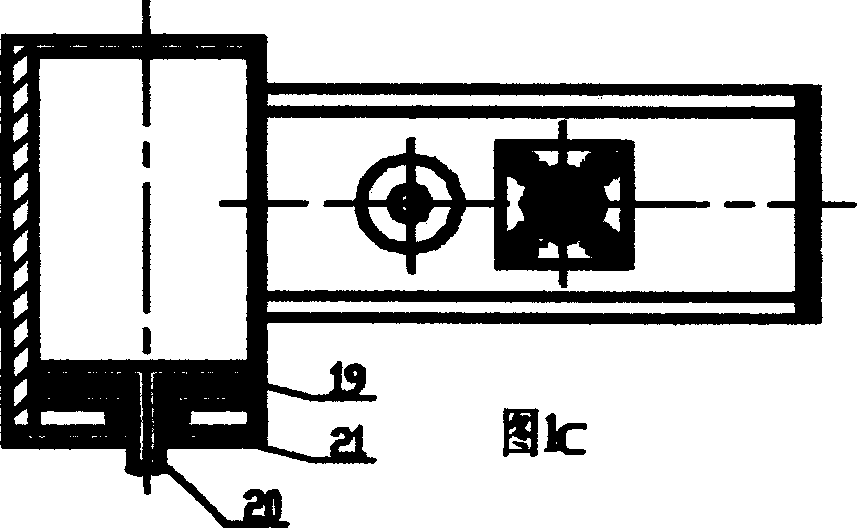

InactiveCN1588690ASmall sizeIncreased power capacityResonatorsOscillations generatorsResonant cavityCircular waveguide

Circular recess waveguide cavity steady oscillator is suitable for microwave, millimeter wave and submillimetre wave. In the circular recess waveguide cavity steady oscillator, an upper insulating bar and a lower insulating bar are fit on inside of front metal plate and rear metal plate to separate them separately, wedging shape matched dry loads are fit on inside of upper and lower insulating bars separately, a circular through-hole with diameter D along length direction of the plates at symmetrical center of end surface of two metal plates to form circular recess waveguid; a transistor base, a coaxial low pass filter and tuning screw are fit in space between two metal plates, the transistor base and coaxial low pass filter are in a same axis, the tuning screw and coaxial low pass filter are parallel, a high Q cylinder adjustable resonant cavity is fit on one end of circular recess waveguide, the axis of the cavity and the circular through hole are vertical.

Owner:SOUTHEAST UNIV

Grind grading technique for aluminum oxide raw material - monohydrallite

The invention relates to a grading process technology containing two procedures of grinding ore and grading in processing monohydrallite. Grinding equipment adopts two-bin overflow ball mill and grading equipment adopts hydraulic cyclone group, which cooperate with each other to form closed-circuit grading flow process. Two-bin overflow ball mill equips compartment board that can be adjusted to separate mill into two bins. The invention simplifies procedure and makes the operation convenient.

Owner:GUIYANG AL-MG DESIGN & RES INST

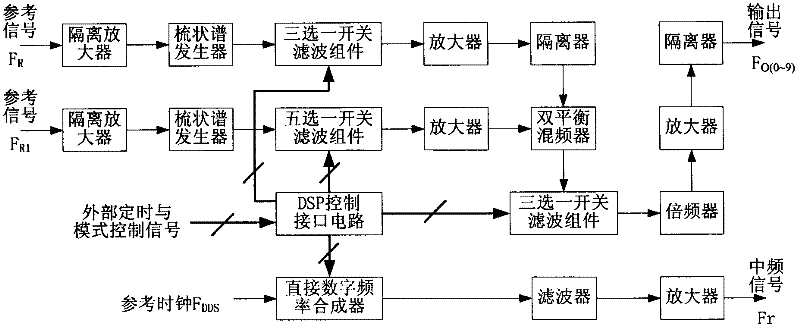

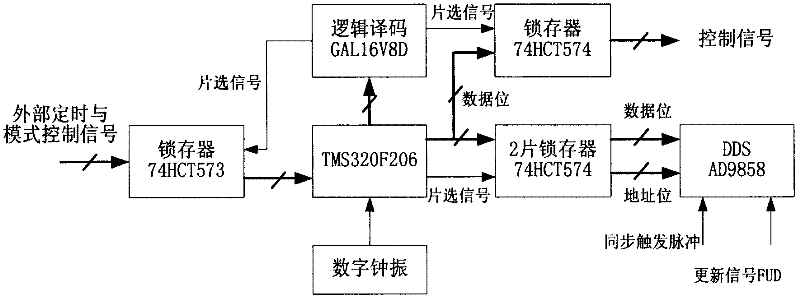

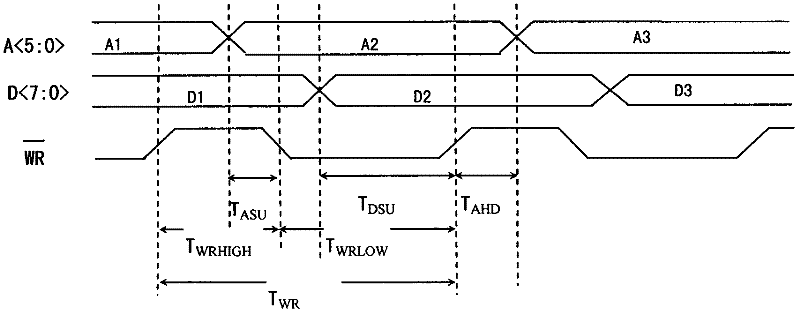

Frequency agility synthesis method compatible with microwave large band width and mid-frequency small stepping and device thereof

InactiveCN102394645AImproved technical indicatorsImprove scalabilityProgramme controlPulse automatic controlIntermediate frequencySynthesis methods

The invention relates to a frequency agility synthesis method compatible with microwave large band width and mid-frequency small step and a device thereof. The invention is characterized in that direct simulation type frequency synthesis, direct digital frequency synthesis, and DSP(digital signal processor) technology are combined to perform frequency synthesis, so as to make the best of the advantages of the mentioned technologies, avoid technical defects, realize the optimization of all technical indexes of the frequency synthesizer, has a better expandability on the design of frequency band width and at the same time is compatible with large band width microwave frequency agility and mid-frequency small stepping frequency agility signal functions.

Owner:中国兵器工业第二〇六研究所

Freon-free slagging agent for rotating furnace

The invention discloses a freon-free slagging agent for a rotating furnace, mainly comprising the following materials in parts by weight: 5-30 parts of manganese (Mn), 0-20 parts of silicon dioxide (SiO2) and 10-50 parts of total iron (TFe). The freon-free slagging agent is prepared into 5-50mm particles and the adding amount thereof is determined according to the silicon content in molten iron and is controlled to be within 5-7kg / t steel. The freon-free slagging agent has the advantages of prolonging the service life of a rotating furnace body, reducing the wastage rate of fettling material, accelerating the joint concentration of steelmaking of the rotating furnace, and reducing the time of daily maintenance and overhauling. Under the condition that the materials and the status of equipment are not changed, after the rotating furnace is added with the freon-free slagging agent, the technical indexes are all improved with different degrees, also the blowing is stable, the slagging is good, the phenomenon that the slag is re-dried is avoided, the operating conditions of steelmaking of the rotating furnace are improved, certain main consumption indexes of the rotating furnace take on downward trend, and the effects of dephosphorization and desulfurization are superior to that of other slagging agents.

Owner:郑州市鑫磊冶金材料有限公司

Hydrophobic modified antimicrobial cashmere fiber and manufacturing method of hydrophobic modified antimicrobial cashmere fiber

InactiveCN105088768ANot easy to fall offLow costFibre treatmentConjugated cellulose/protein artificial filamentsPolyesterCarbon nanotube

The invention discloses hydrophobic modified antimicrobial cashmere fiber. Chitosan fiber and cashmere are creatively blended, so that chitosan is uniformly distributed, cannot easily fall off and can be combined with saliva of bacterial microbe phospholipids; the chitosan is permeated and enters cell bodies to be adsorbed; the normal physiological activities of cells are disturbed, so that bacteria are killed; the bactericidal effect is durable; in addition, bamboo charcoal polyester fiber is adopted for replacing the partial cashmere fiber; the cost is reduced; various technical indexes of cashmere are also improved; added carbon nanotubes generate carboxyl and hydroxyl groups after being subjected to mixed acid oxidation modification; after the carboxyl and hydroxyl groups are added into raw materials, good dispersibility and good stability are realized. The prepared cashmere fiber adopts methacrylamide as a grafting monomer for surface grafting decoration modification; the prepared cashmere fiber has a hydrophobic antibiosis function, a far infrared function and a negative ion functions; the hand feeling of fabrics is soft; the heat insulation and comfort functions are good; the cashmere fiber is suitable for being made into casual clothes and underwears.

Owner:ANHUI TIANWEI CASHMERE PROD

Calcining method for belt sintering machine

InactiveCN1776337ALow costIncreased sintering throughputFurnace typesGaseous fuel burnerSmall footprintEngineering

Under stable supply, coal gas is fired to burn materiel on lead sinter machine. Through gas pipe, coal gas generated from gas generator is entered to cyclone dust collector. Through gas pipe, dust removed coal gas is entered to branch pipe. Through air pipe, comburant air enters into branch pipe. After branch pipe for coal gas and branch pipe for comburant air are connected to each other, and led to burner, where gas and air are mixed fully in volume ration being about 1:1. Through the burner, mixed gas burns in firebox of ignition furnace. Advantages are: lowering cost by using gas to replace heavy oil, better controlling fire behavior, and good effect for baking materiel.

Owner:HENAN YUGUANG GOLD & LEAD

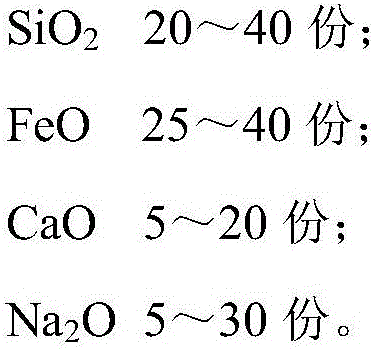

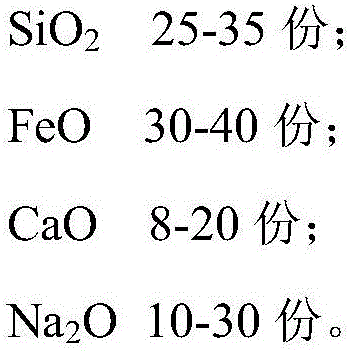

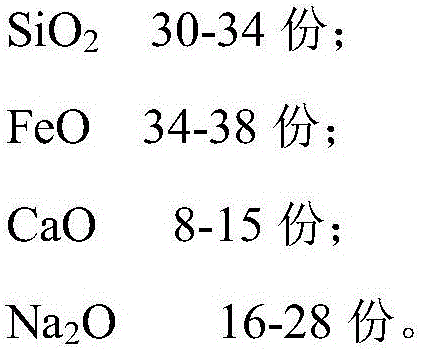

Reduction smelting slag and application of reduction smelting slag to reduction smelting of coarse antimony oxide

The invention relates to reduction smelting slag and application of the reduction smelting slag to reduction smelting of coarse antimony oxide, and belongs to the field of nonferrous metallurgy. The designed reduction smelting slag comprises, by mass, 20-40 parts of SiO2, 20-40 parts of FeO, 5-20 parts of CaO and 5-25 parts of Na2O. During reduction smelting of the coarse antimony oxide, the set reduction smelting slag is supplemented, the temperature ranging from 900 DEG C to 1,200 DEG C is kept for 30-120 min, coarse antimony, glass slag, smoke and flue gas can be generated, the coarse antimony and the slag are independently discharged after settling separation, the smoke is subjected to powder returning treatment, and the flue gas is exhausted after being purified. The design technology has the beneficial effects that the smelting temperature is low, the antimony content of the slag is small, the antimony direct recovery rate is high, and the powder returning amount is small; and large-scale industrial application is facilitated.

Owner:CENT SOUTH UNIV

Lead blowing-furnace oxygen-rich smelting process

InactiveCN1775970AImproving the reduction smelting processIncrease throughputSmelting processEconomic benefits

The invention relates to lead blast furnace oxygen enrichment smelting technology that adding oxygen into air supplied to blast furnace by blower fan to improve the oxygen concentration to 20-30%. Thus, the reducing atmosphere of the furnace is improved and the processing quantity is increased. The technology index is sharply increased, and the social and economic benefits are notable.

Owner:HENAN YUGUANG GOLD & LEAD

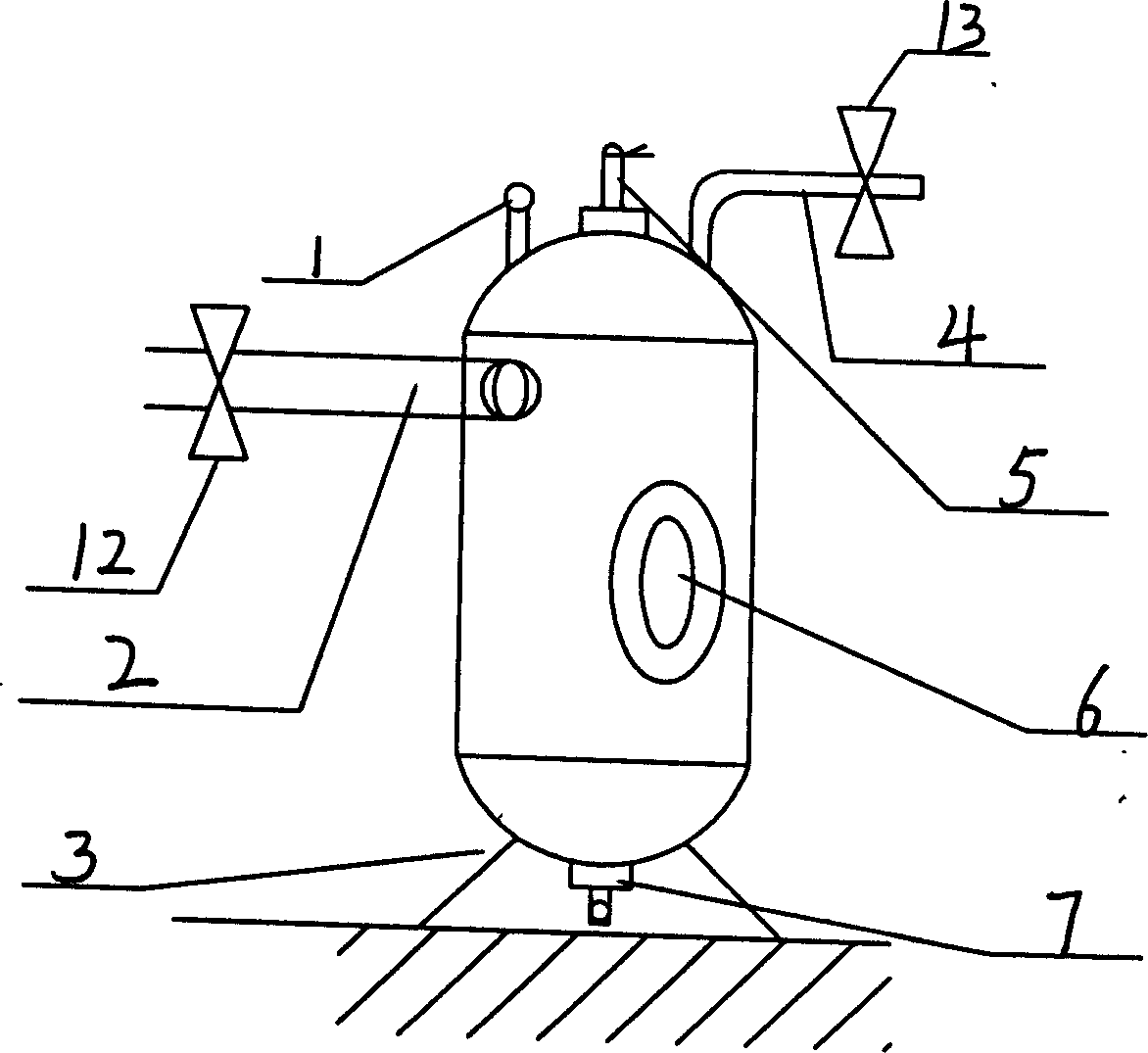

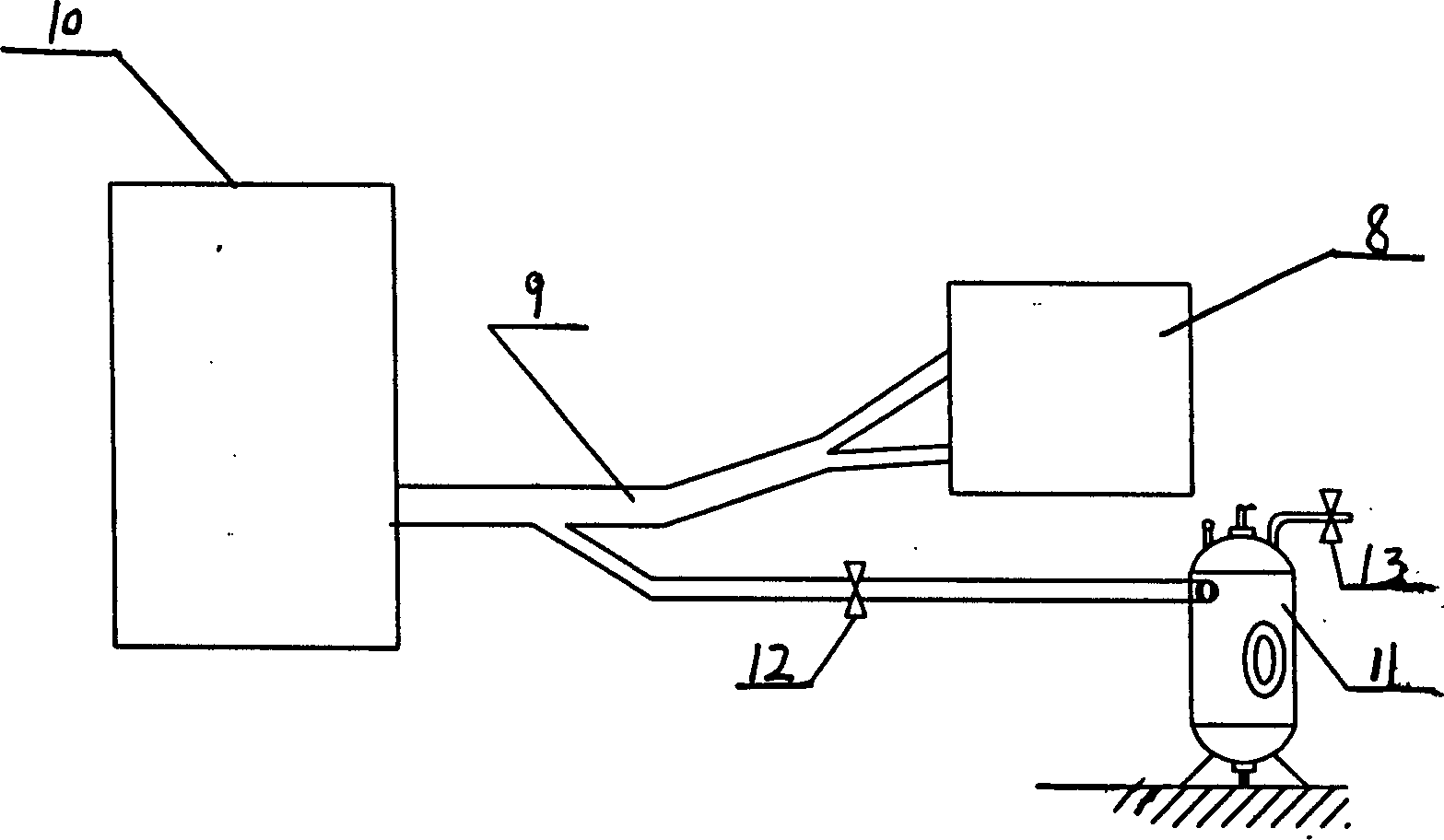

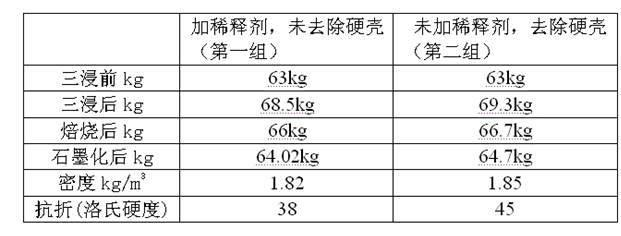

Soaking method for high-purity graphite multi-immersed product

The invention relates to the production field of the graphite material, in particular to a soaking method for a high-purity graphite multi-immersed product, which can completely soak a roasted carbon product. The roasted carbon product is put into a shot blasting machine to remove a surface shell; then the processed carbon product is preheated in a preheating furnace; the preheated carbon productis taken out to put into an impregnating tank and the impregnating tank is vacuumized; then, coal tar pitch is added into the impregnating tank; under the condition of certain pressure, the carbon product is kept for certain time; then, the carbon product is hoisted out and is cooled in a cooling pool at certain temperature for certain time; then the carbon product is hoisted out to remove surface pitch, and is roasted; according to the requirement, the processes of removing the shell, impregnating and roasting are carried out for 1-3 times; the carbon product can be soaked without adding anydiluent; and therefore, each performance index of the high-purity graphite product can be drastically improved.

Owner:FIVE STAR NEW MATERIAL TECH CO LTD

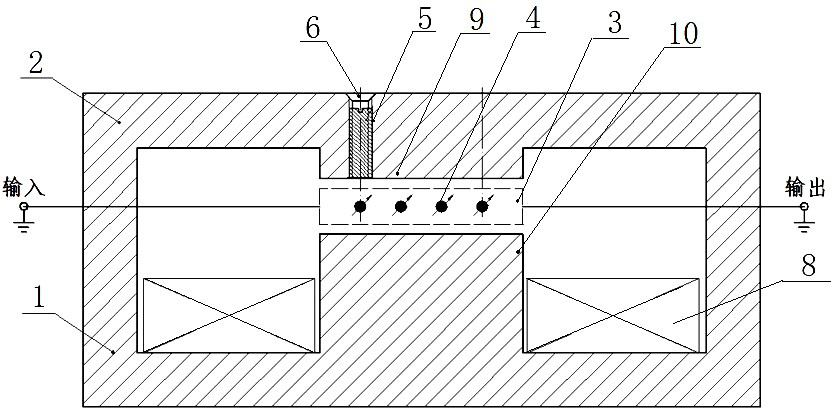

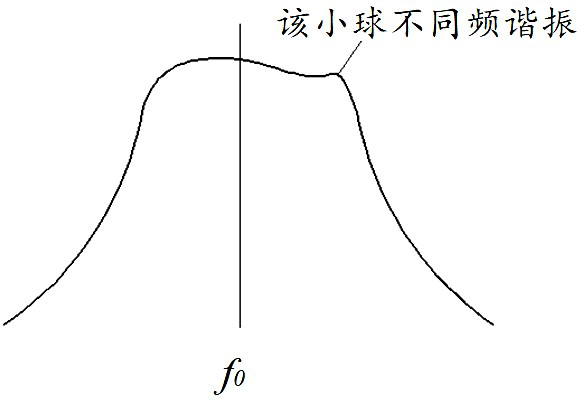

Magnetic tuned filter with magnetic circuit air gap field fine tuning structure and debugging method

ActiveCN114696052ASolve the problem of inconsistent resonance frequencyImproving Magnetic Tuning Filter SpecificationsWaveguide type devicesResonanceHemt circuits

The invention discloses a magnetic tuning filter with a magnetic circuit air gap field fine tuning structure and a debugging method, the filter comprises an upper magnetic circuit, a lower magnetic circuit, a working air gap and a resonant circuit, the resonant circuit comprises a plurality of coupled small resonant balls, one side of each small resonant ball is provided with a ball adjusting rod, and when the number of the small resonant balls is three, the upper magnetic circuit corresponds to the interstage small ball, and the lower magnetic circuit corresponds to the interstage small ball. When the number of the small resonance balls is larger than three, the positions, corresponding to the small input and output balls, of the upper magnetic circuit are each vertically provided with a through screw hole, and a fine adjustment screw is arranged in each through screw hole. According to the invention, the debugging mode is simple, the local magnetic field of the individual small ball is adjusted through the fine tuning screw, and the fixed frequency difference of the individual small ball is adjusted by combining the small ball adjusting rod, so that the frequency of the harmonic oscillator and the frequencies of other harmonic oscillators coincide in a wide frequency range. The problems of filter response waveform deformation and index deterioration caused by frequency asynchronism of the small resonant balls during broadband tuning are solved, and the production efficiency is improved.

Owner:SOUTHWEST INST OF APPLIED MAGNETICS

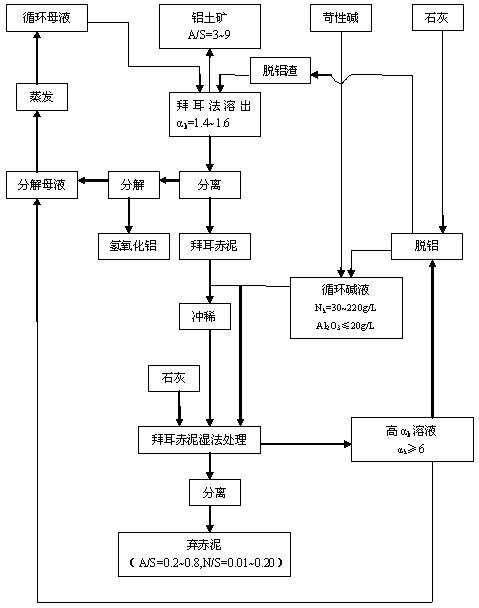

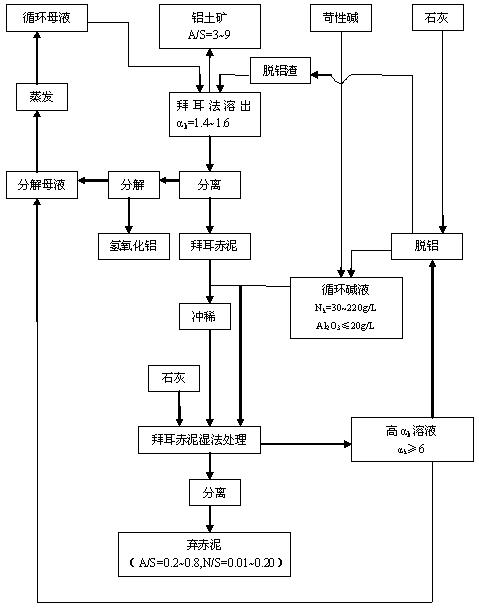

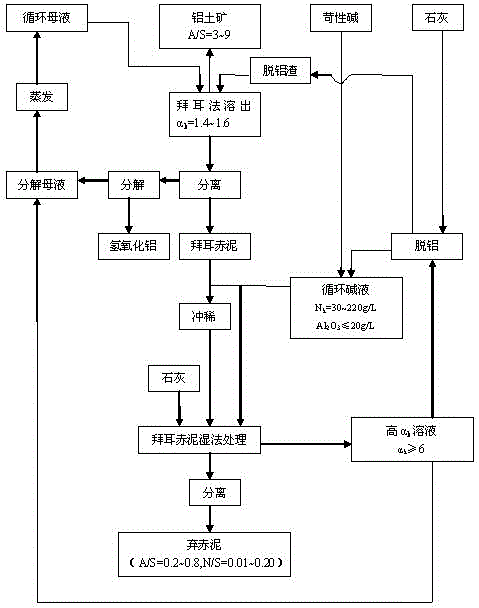

Improved method for producing aluminium oxide by medium-low-grade bauxite

ActiveCN102070166AHigh recovery rateReduce the amount addedAluminium oxides/hydroxidesRed mudAluminium recycling

The invention relates to an improved method for producing aluminium oxide by medium-low-grade bauxite, which is characterized in that the production process comprises two-time dissolution processes, i.e. (1) dealuminizing slag is added into the bauxite for carrying out Bayer-process dissolution, and carrying out Bayer-process production of the aluminium oxide; and (2) adding Bayer-process dissolved red mud obtained in the step (1) into alkali liquor, carrying out wet-process dissolution treatment, recovering alkali and aluminium oxide in the Bayer-process red mud. In the method disclosed by the invention, the process of the Bayer process mainly recovers the aluminium oxide in the bauxite, and a wet-process red mud treatment system mainly recovers alkali in the Bayer-process red mud. Dissolved liquor obtained in the Bayer-process part is diluted and purified to remove seed crystal for decomposition, lime is added into the dissolved liquor by wet-process treatment of the Bayer-process red mud to dealuminize, the obtained high-molecular-proportion dealuminized mother liquor is then used for dissolving the Bayer-process red mud, solid-phase dealuminizing slag replacing the lime is added into a Bayer-process system. In the method disclosed by the invention, the process is simple, the energy consumption is low, alkali consumption is low, the recovery ratio of the aluminium oxide is high, the method is suitable for treating the medium-low-grade bauxite mainly in China, the resource utilization ratio is high, the discharged red mud amount is less, and the red mud is easy to be utilized comprehensively.

Owner:河南华慧有色工程设计有限公司 +1

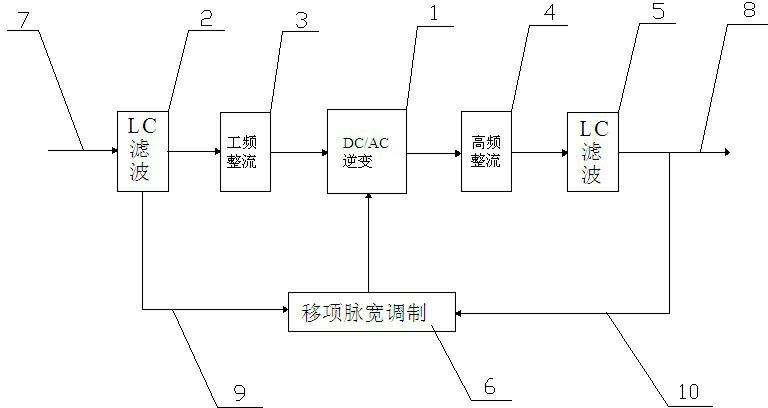

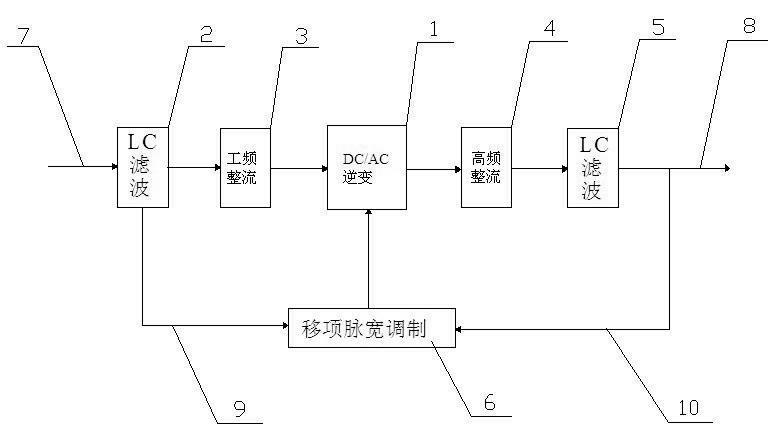

High frequency soft-switching technology switching power supply

InactiveCN102629830AReduce pollutionAccurate identificationEfficient power electronics conversionDc-dc conversionLow noiseSoft switching

The invention discloses a high frequency soft-switching technology switching power supply which is mainly for direct current switching power supply designed for the structure of a hybrid maglev system and comprises a DC / AC inverter control module, a first LC filtering module, a power frequency rectifier module, a high frequency rectifier module, a second LC filtering module and a transposition pulse width modulation module. Through the connection of the above modules, the switching power supply has the advantages of small volume, light weight, low noise, improved work efficiency and power density, less pollution to grid, fast dynamic response, stable output, and easy examination and repair.

Owner:江苏王牌电机制造有限公司

Circular recess wave guide chamber stable oscillator

InactiveCN1300896CSmall sizeIncreased power capacityResonatorsOscillations generatorsResonant cavityMicrowave

Circular recess waveguide cavity steady oscillator is suitable for microwave, millimeter wave and submillimetre wave. In the circular recess waveguide cavity steady oscillator, an upper insulating bar and a lower insulating bar are fit on inside of front metal plate and rear metal plate to separate them separately, wedging shape matched dry loads are fit on inside of upper and lower insulating bars separately, a circular through-hole with diameter D along length direction of the plates at symmetrical center of end surface of two metal plates to form circular recess waveguid; a transistor base, a coaxial low pass filter and tuning screw are fit in space between two metal plates, the transistor base and coaxial low pass filter are in a same axis, the tuning screw and coaxial low pass filter are parallel, a high Q cylinder adjustable resonant cavity is fit on one end of circular recess waveguide, the axis of the cavity and the circular through hole are vertical.

Owner:SOUTHEAST UNIV

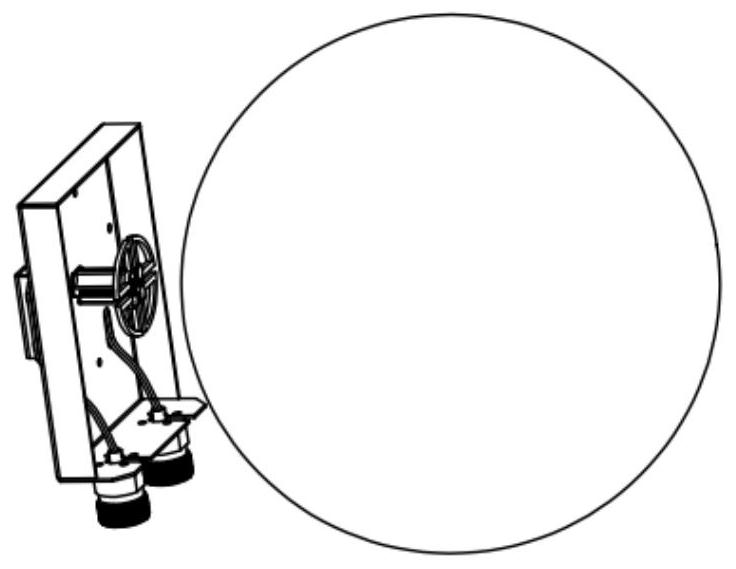

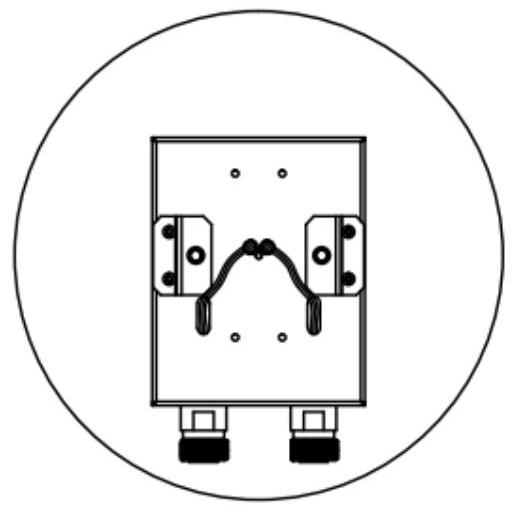

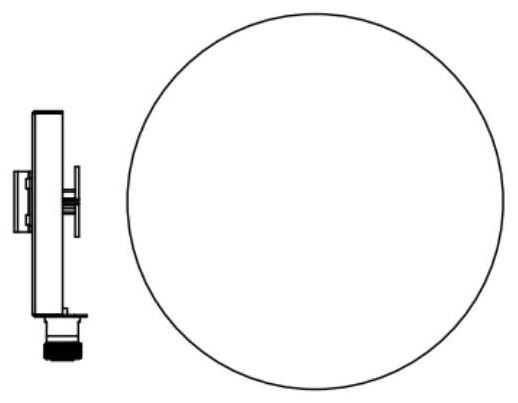

A kind of manufacturing method of artificial dielectric multi-layer ball lens

Owner:XIAN HAITIAN ANTENNA TECH CO LTD

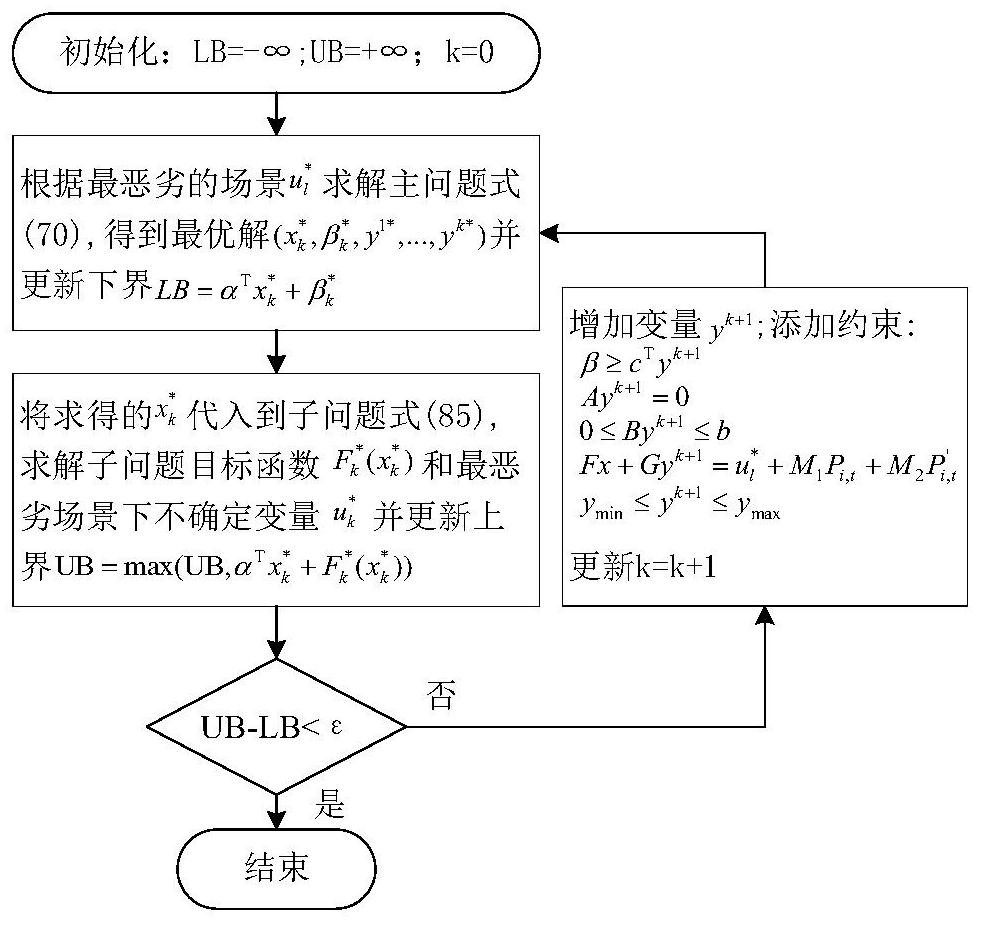

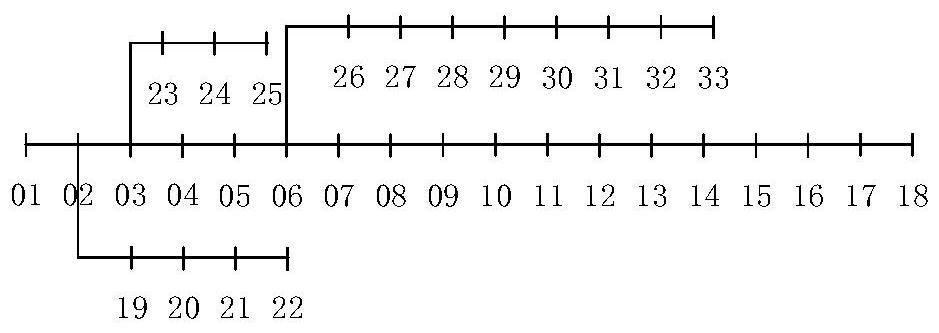

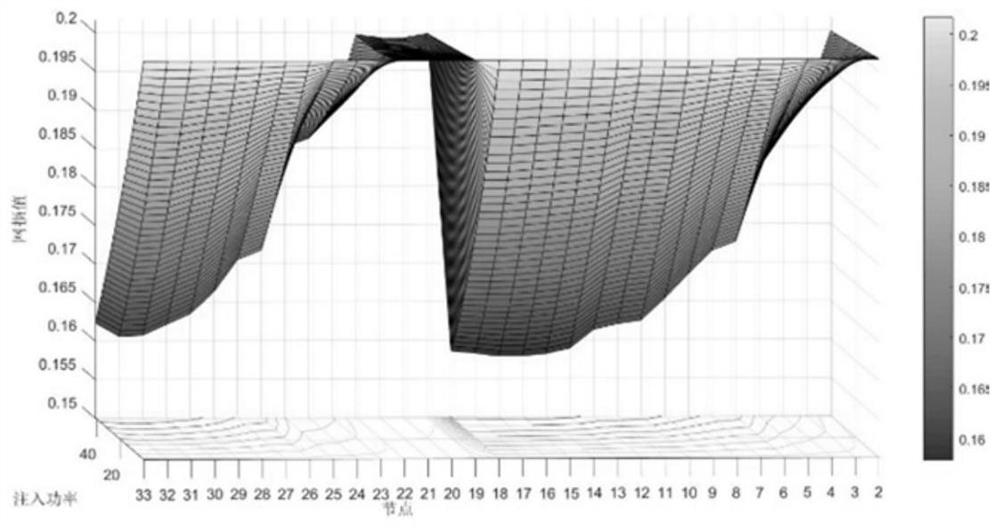

Microgrid group multi-stage optimization planning method considering load uncertainty

PendingCN112952806AImproved technical indicatorsTo achieve coordinated developmentLoad forecast in ac networkSingle network parallel feeding arrangementsMathematical modelControl engineering

The invention relates to a microgrid group multi-stage optimization planning method considering load uncertainty, and the method comprises the steps: constructing a two-stage robust optimization double-layer mathematical model, wherein the upper layer of the two-stage robust optimization double-layer mathematical model is a cost model of a power distribution network, and the lower layer of the two-stage robust optimization double-layer mathematical model is a cost model of a microgrid group; carrying out power interaction between the upper layer and the lower layer through PCC points to form coupling of the double-layer model; when the two-stage robust optimization double-layer mathematical model is solved, carrying out KKT equilibrium constraint on constraint conditions of the cost model of the microgrid group, and then linearizing the constraint conditions by using a large M method; and finally, solving the two-stage robust optimization double-layer mathematical model by adopting a column constraint generation decoupling algorithm. Compared with the prior art, the optimal planning construction scheme can be provided for the micro-grid group, the income equalization of a plurality of benefit subjects is realized, the utilization rate of renewable energy sources is improved, the technical indexes of the power distribution network are improved, and the coordinated development of the power distribution network and the micro-grid is effectively realized.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

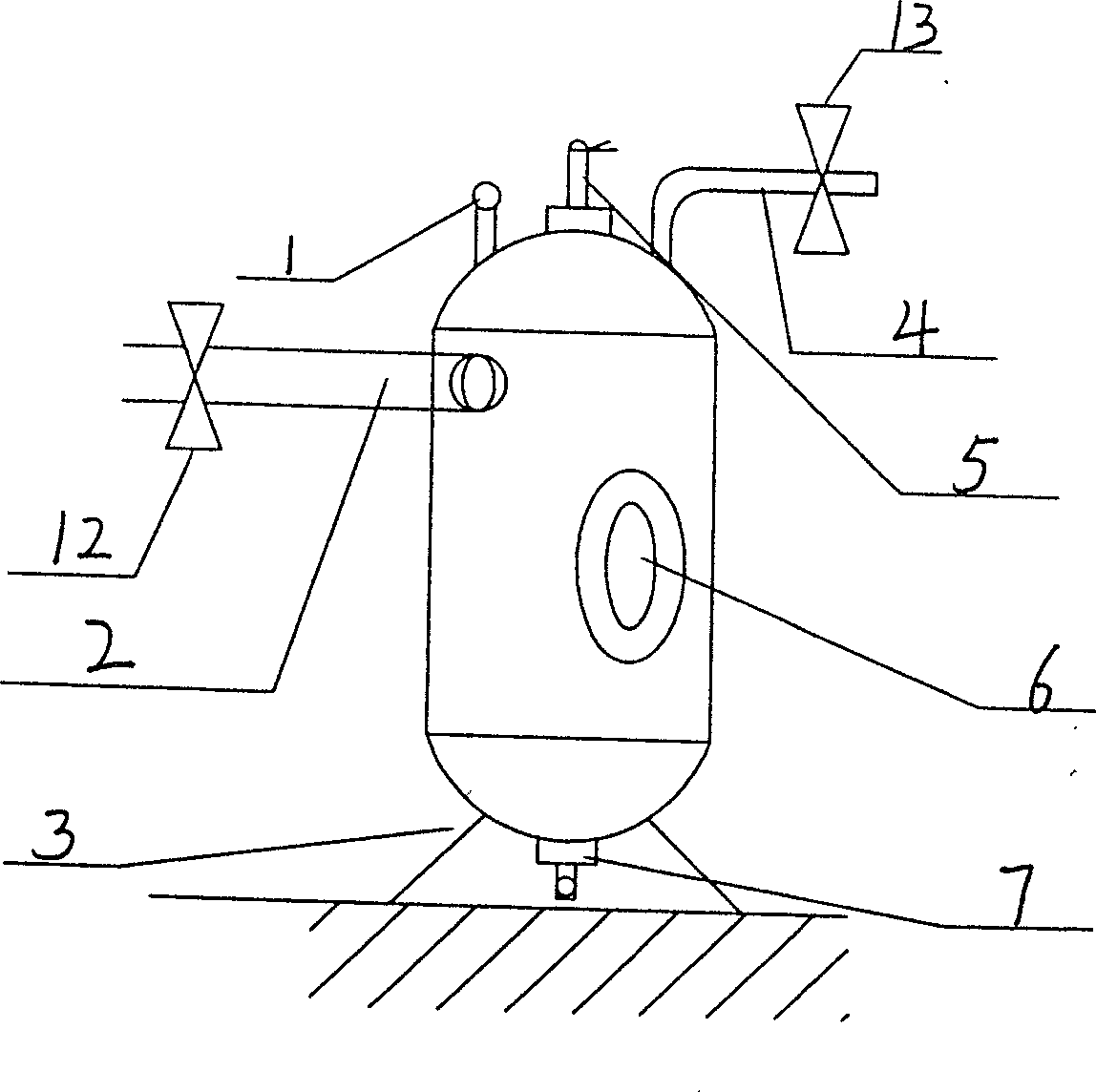

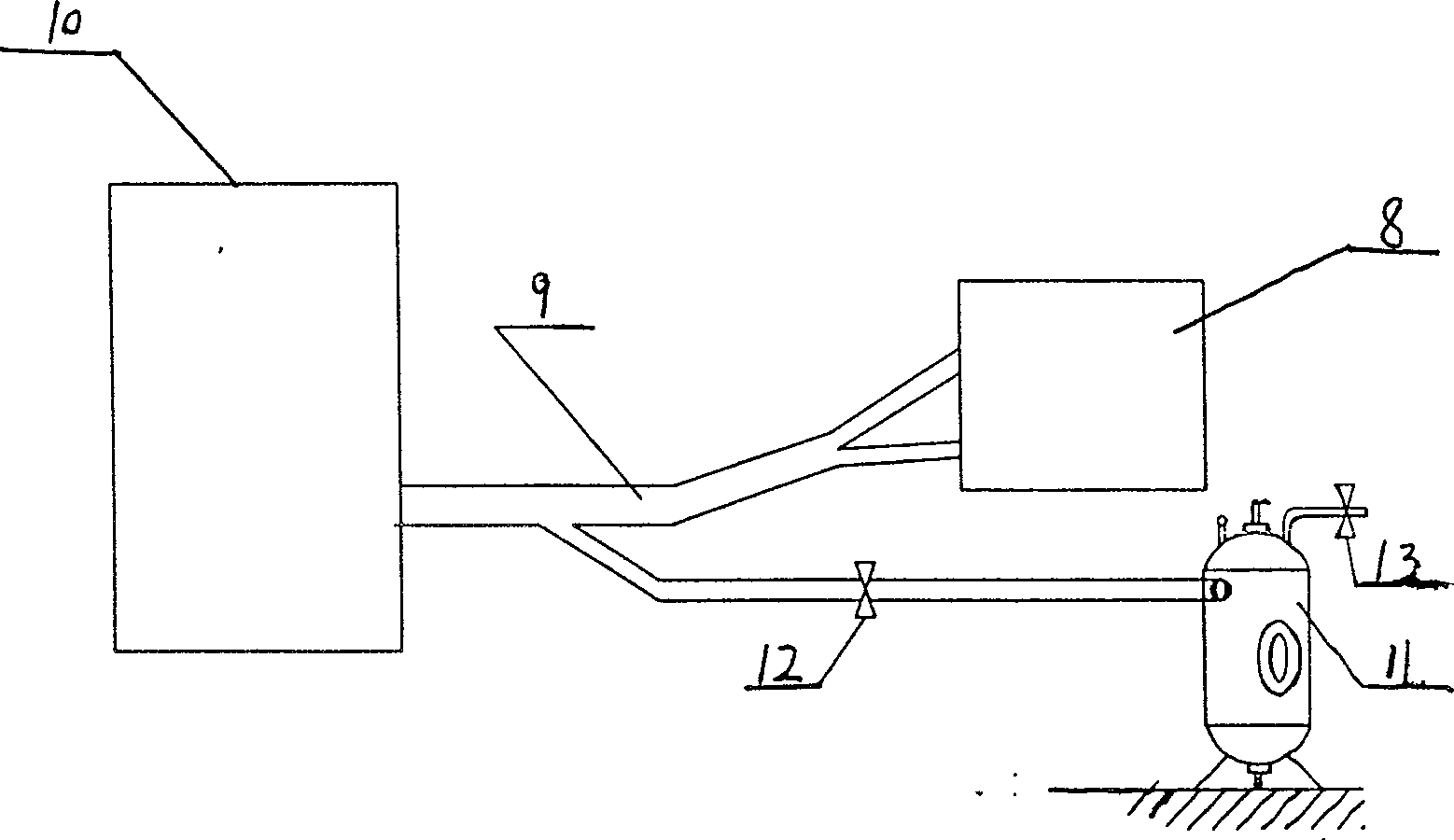

Red mud slurry heating method and apparatus for alumina production

ActiveCN1329297CImprove efficiencyImprove controllabilityChemical industryAluminium oxides/hydroxidesRed mudProcess engineering

The present invention discloses red mud slurry heating method and apparatus for alumina production. The red mud slurry is partially heated before entering the washing and depositing tank to reach the technological process required temperature, and this can improve the deposition performance and washing effect of red mud slurry and ensure the stable and high output running of the washing and depositing tank. At the same time, material is conveyed with bottom pump and steam enters the heater by means of self pressure, so that two kinds of material contact fully to exchange heat, resulting in fast heating, easy operation and saving in energy.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Improved method for producing aluminium oxide by medium-low-grade bauxite

ActiveCN102070166BSimple processImproved technical indicatorsAluminium oxides/hydroxidesRed mudAluminium recycling

The invention relates to an improved method for producing aluminium oxide by medium-low-grade bauxite, which is characterized in that the production process comprises two-time dissolution processes, i.e. (1) dealuminizing slag is added into the bauxite for carrying out Bayer-process dissolution, and carrying out Bayer-process production of the aluminium oxide; and (2) adding Bayer-process dissolved red mud obtained in the step (1) into alkali liquor, carrying out wet-process dissolution treatment, recovering alkali and aluminium oxide in the Bayer-process red mud. In the method disclosed by the invention, the process of the Bayer process mainly recovers the aluminium oxide in the bauxite, and a wet-process red mud treatment system mainly recovers alkali in the Bayer-process red mud. Dissolved liquor obtained in the Bayer-process part is diluted and purified to remove seed crystal for decomposition, lime is added into the dissolved liquor by wet-process treatment of the Bayer-process red mud to dealuminize, the obtained high-molecular-proportion dealuminized mother liquor is then used for dissolving the Bayer-process red mud, solid-phase dealuminizing slag replacing the lime is added into a Bayer-process system. In the method disclosed by the invention, the process is simple, the energy consumption is low, alkali consumption is low, the recovery ratio of the aluminium oxide is high, the method is suitable for treating the medium-low-grade bauxite mainly in China, the resource utilization ratio is high, the discharged red mud amount is less, and the red mud is easy to be utilized comprehensively.

Owner:河南华慧有色工程设计有限公司 +1

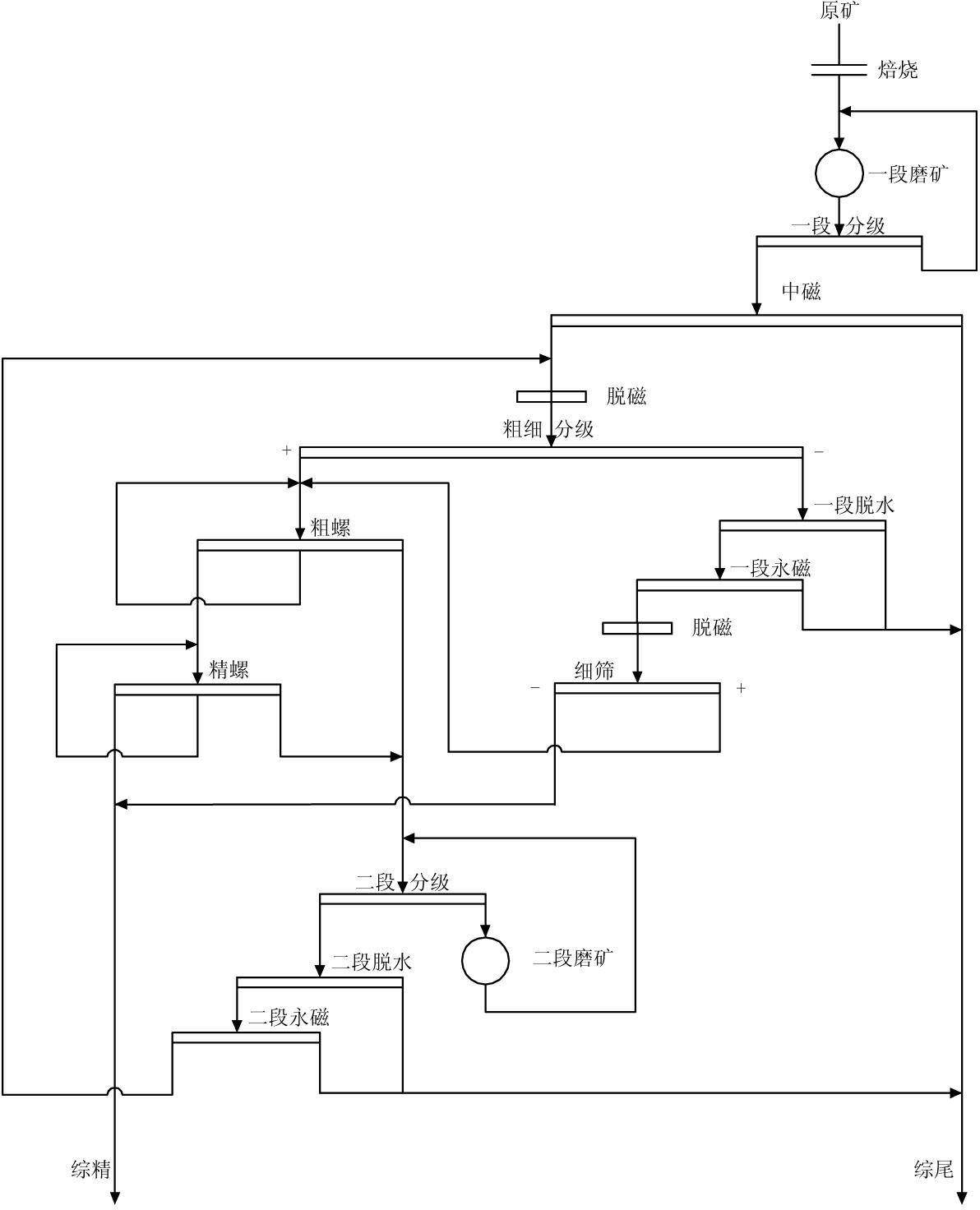

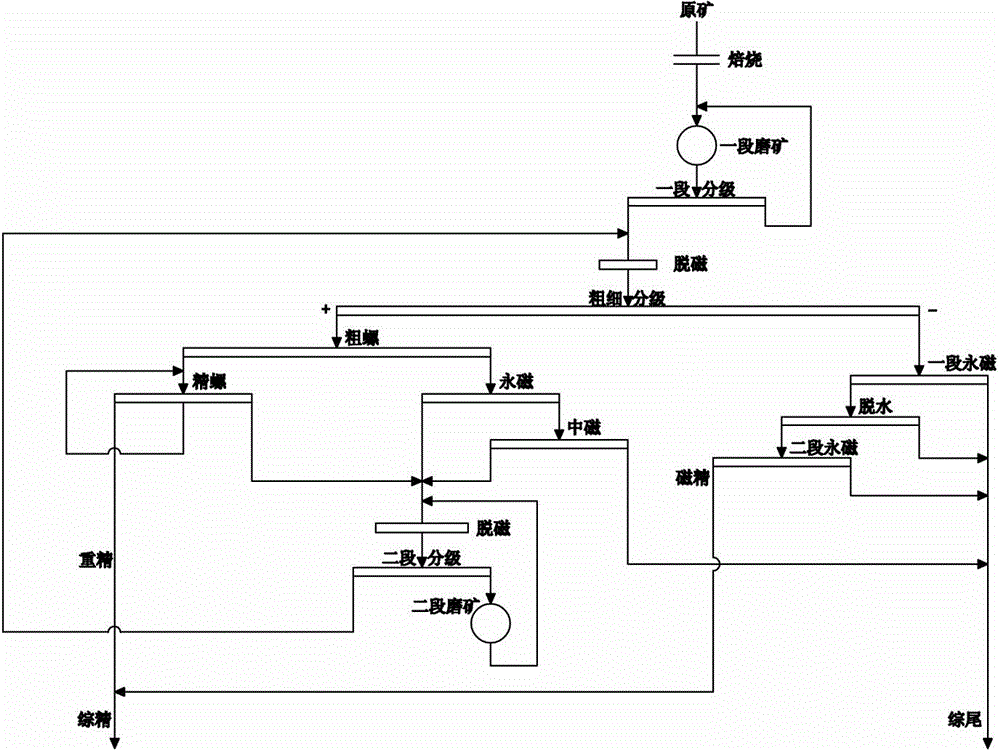

Process for roasting, stage grinding, coarse-fine grading and reselection-magnetic separation of hematite

ActiveCN102284359BImprove sorting efficiencyImproved technical indicatorsMagnetic separationEngineeringMagnetic separation

The invention relates to a process for the roasting, stage grinding, coarse-fine grading and reselection-magnetic separation of hematite. The process is characterized by comprising the following steps of: demagnetizing effusion subjected to first-section grading, and performing coarse-fine grading; performing coarse screwing on coarse grains, and performing first-section permanent magnetism on fine grains; performing fine screwing on concentrates subjected to the coarse screwing, and performing the permanent magnetism on tailings subjected to the coarse screwing; returning middlings subjectedto the fine screwing to a fine screwing process, and performing second-section demagnetizing on tailings subjected to the fine screwing; performing the second-section demagnetizing on concentrates subjected to the permanent magnetism, and performing middle magnetic separation on tailings subjected to the permanent magnetism; performing the second-section demagnetizing on concentrates subjected tothe middle magnetic separation to enter a second-section grading process, returning effusion subjected to second-section grading to the coarse-fine grading process, and performing second-section grinding on silt subjected to the second-section grading; returning products subjected to the second-section grinding to a second-section demagnetizing process; dewatering concentrates subjected to first-section demagnetizing, and performing second-section permanent magnetism on the dewatered concentrates; and mixing the concentrates subjected to the second-section permanent magnetism and concentratessubjected to the fine screwing to form final concentrates, and mixing tailings subjected to the first-section permanent magnetism, dewatered tailings, tailings subjected to the second-section permanent magnetism and tailings subjected to the middle magnetic separation to form final tailings and discarding. The process has a simple flow, and is convenient to control and stable in technical indexes.

Owner:ANSTEEL GRP MINING CO LTD

Lead blowing-furnace oxygen-rich smelting process

InactiveCN100491550CImproving the reduction smelting processIncrease throughputSmelting processEconomic benefits

Owner:HENAN YUGUANG GOLD & LEAD

Method for preparing mixed regenerated polyester fibers special for non-woven material

ActiveCN102505177BStable ratioWell mixedArtificial filament heat treatmentMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention discloses a method for preparing mixed regenerated polyester fibers special for a non-woven material. The method comprises the following steps of: mixing spinning raw materials such as bottle flakes, a chemical fiber friction material, a bubble material and a fluorescent brightener, drying by using a vacuum drum dryer, and performing melt spinning to obtain as-spun fibers with two or more kinds of fineness through two or more spinning box bodies of melt spinning equipment; winding, doffing and bundling the as-spun fibers in turn; drawing in an oil bath, drawing in steam, and reeling; and performing heat setting to prepare the mixed regenerated polyester fibers special for the non-woven material. Compared with the prior art, the method has the advantages that: the fibers produced by the method have two or more kinds of fineness, the raw materials are stably proportioned and uniformly mixed, the non-woven material can have good opening and mixing effects, and the technical index of the non-woven material can be effectively improved. The mixed fibers can be used for producing different styles of non-woven materials, work efficiency is improved, and production cost is reduced.

Owner:福建鑫华股份有限公司

Meat duck feed

The invention discloses a meat duck feed. The meat duck feed is prepared from the following raw materials in parts by weight: 4-11 parts of malts, 6-15 parts of sweet potato starch, 4-17 parts of spiral seaweeds, 9-14 parts of mulberry leaf powder, and 11-20 parts of siberian cocklebur flowers. The feed is beneficial for growth of meat ducks; traditional Chinese medicine additives can improve digestive ability of the meat ducks in a growth process, also can improve production performance of the meat ducks, further improves technical indexes of the meat duck bodies, meets high-quality needs ofpeople on food, and brings better economic benefits for the vast farmers.

Owner:俞一成

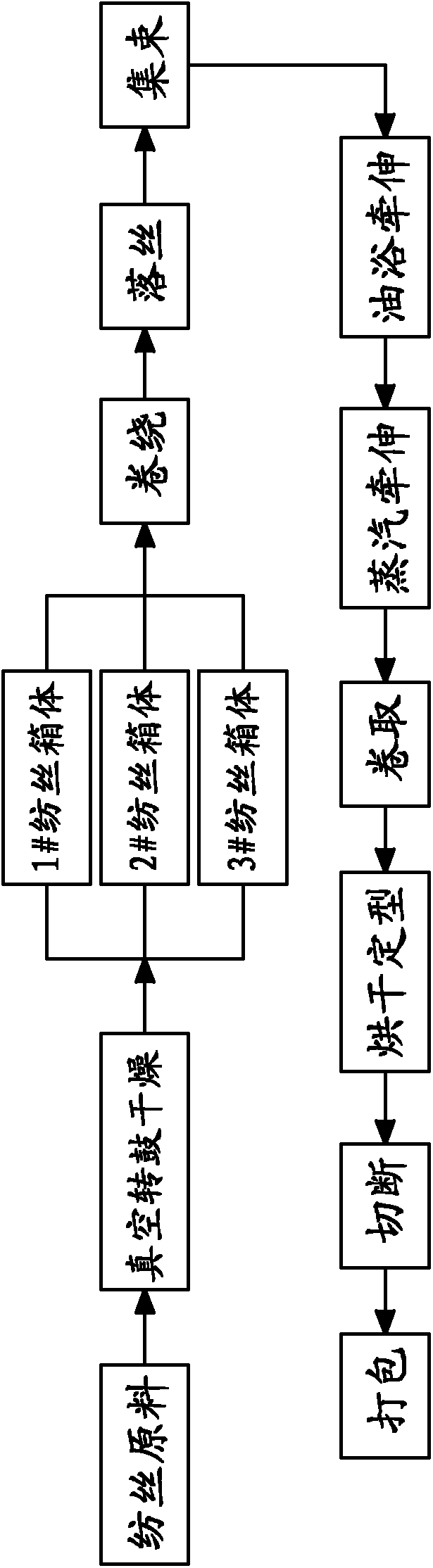

A sorting process for processing magnetic red mixed ore based on iron mineral embedding particle size

ActiveCN109351467BEfficient sorting processReduce energy consumptionSolid separationMagnetiteMagnetic separation

The invention relates to a separation process for magnetic red mixed ore based on iron material disseminated particle size treatment. The process comprises the operation of feeding the mixed ore withthe grade of 27%-29% and with magnetite as a main raw material into first-section closed circuit ore grinding operation to obtain a primary grading overflow product, and is characterized by further comprising first-section weak magnetic and strong magnetic operation, fine screening operation, first-section magnetic separation and first-section washing magnetic separation operation, second-sectionclosed circuits ore grinding operation, second-section weak magnetic strong magnetic operation, second-section magnetic separation and washing magnetic separation operation, third-section closed circuit ore grinding, third-section weak magnetic strong magnetic operation and reverse flotation operation. The final concentrate with the grade of 66%-66.5% is obtained through the operation. Compared with the prior art, the separation process has the advantages that 1) an efficient separation process which is characterized in that the concentrate can be obtained once dissociation is achieved and segmented ore grinding, segmented concentrate taking and segmented tailings discharging are achieved is provided for the magnetic red mixed ore with the non-uniform iron material disseminated particle sizes, so that overgrinding is reduced, and energy conservation and consumption reduction are achieved; 2) magnetic separation equipment is adopted for upgrading, and three sections of ore grinding is carried out by adopting vertical mills; and 3) the process is simple in structure, free of middling circulation, easy to implement on site and easy to produce and manage.

Owner:ANSTEEL GRP MINING CO LTD

Dynamic construction method for Web service component library and service search method thereof

InactiveCN101650729BImproved technical indicatorsSpecial data processing applicationsWeb serviceSemantic matching

Owner:北京赛柏科技有限责任公司

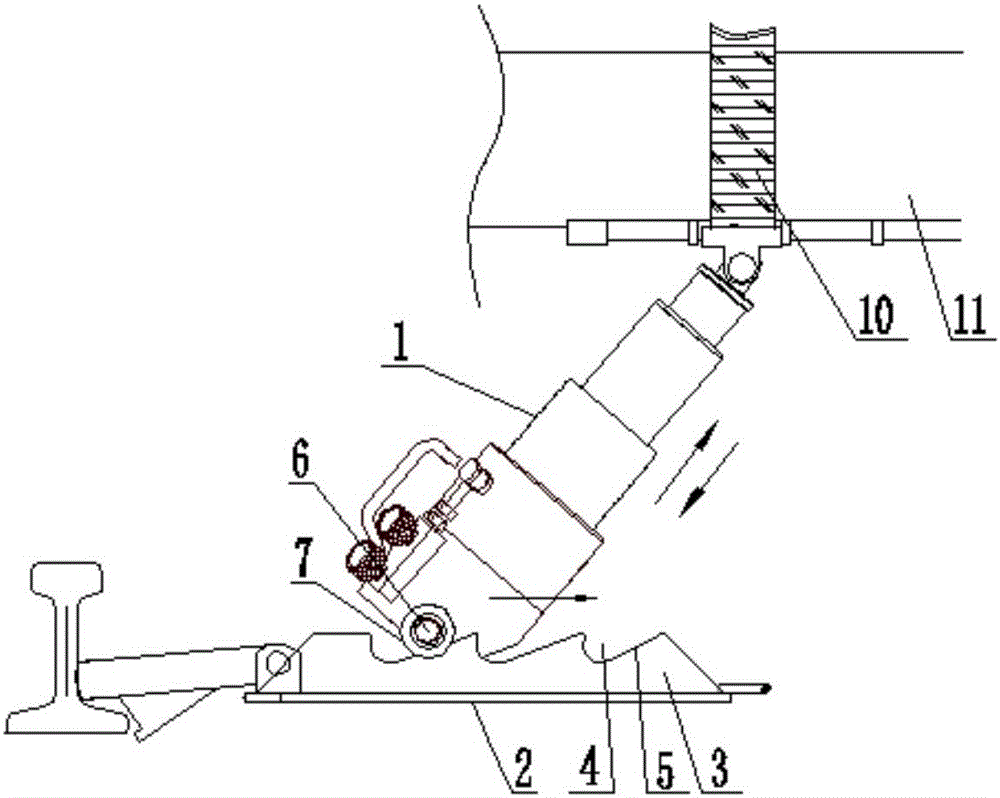

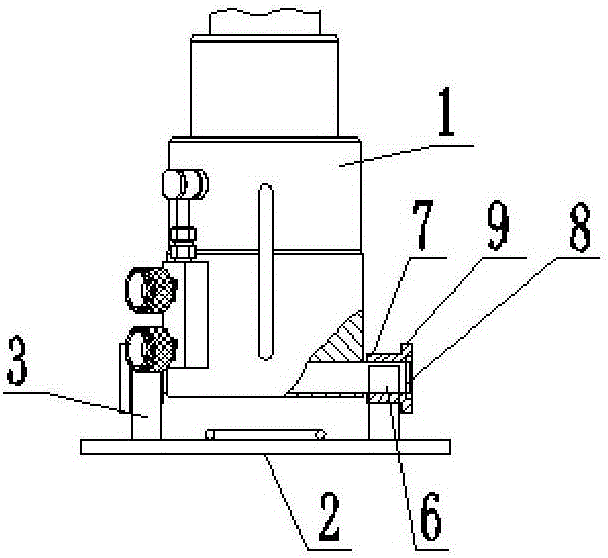

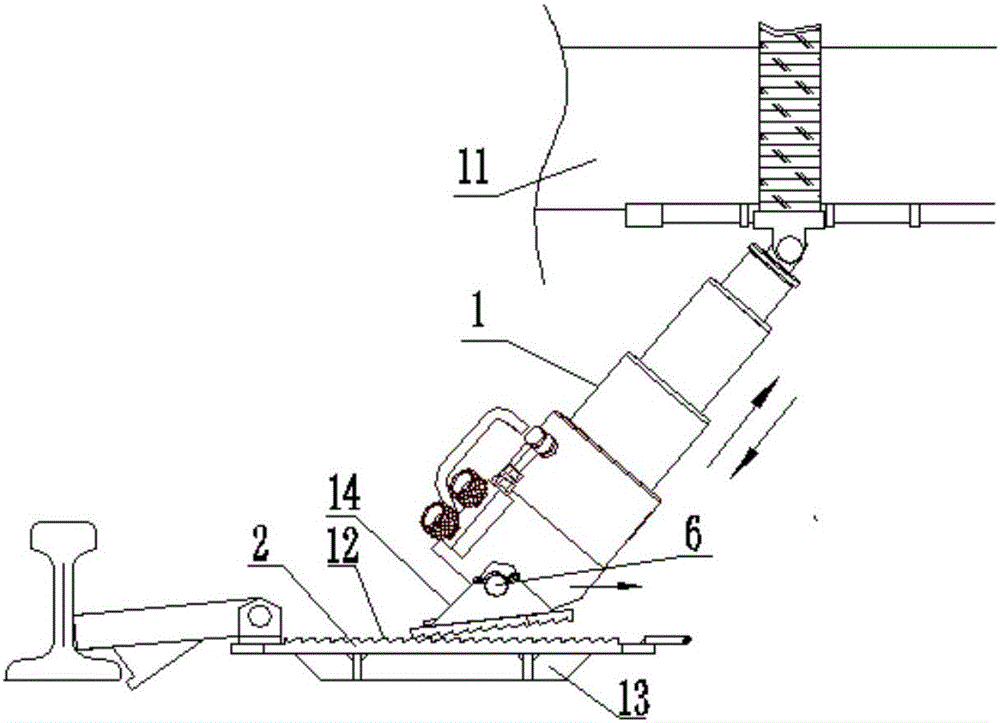

Adjusting device for transverse movement of positions of holes of titling type oil cylinder

InactiveCN106335521AUndisturbedSimple shape and structureRailway auxillary equipmentEngineeringSupport point

The invention provides an adjusting device for transverse movement of the positions of holes of a titling type oil cylinder and belongs to the technical field of auxiliary equipment for railways. The adjusting device comprises a lifting and returning oil cylinder arranged obliquely, wherein a bearing bottom plate is arranged under the lifting and returning oil cylinder; two hole brackets are longitudinally welded on the bearing bottom plate; a plurality of rotary shaft holes are symmetrically formed in the hole brackets and are forwards opened; an obliquely-upward small-slope oblique plane is arranged between every two adjacent rotary shaft holes; a rotary shaft penetrates through the bottom part of the lifting and returning cylinder; the two ends of the rotary shaft are respectively provided with a roller; the rollers are arranged in the rotary shaft holes; and when the position of the lifting and returning oil cylinder is adjusted, the rollers can roll easily into next rotary shaft hole from the oblique plane. The adjusting device provided by the invention has the advantages that the appearance and the structure are simple; the surface of the bearing bottom plate does not need to be cut by a machine tool; the requirement for the whole processing accuracy is reduced; the working conditions of supporting points are not interfered by the external environment; the adjustment for position movement of the lifting and returning oil cylinder is stable and reliable; and numerous problems in the existing device are solved.

Owner:天津华征机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com