Patents

Literature

78results about How to "Technical indicators are stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkyl silicone continuous production system and production method

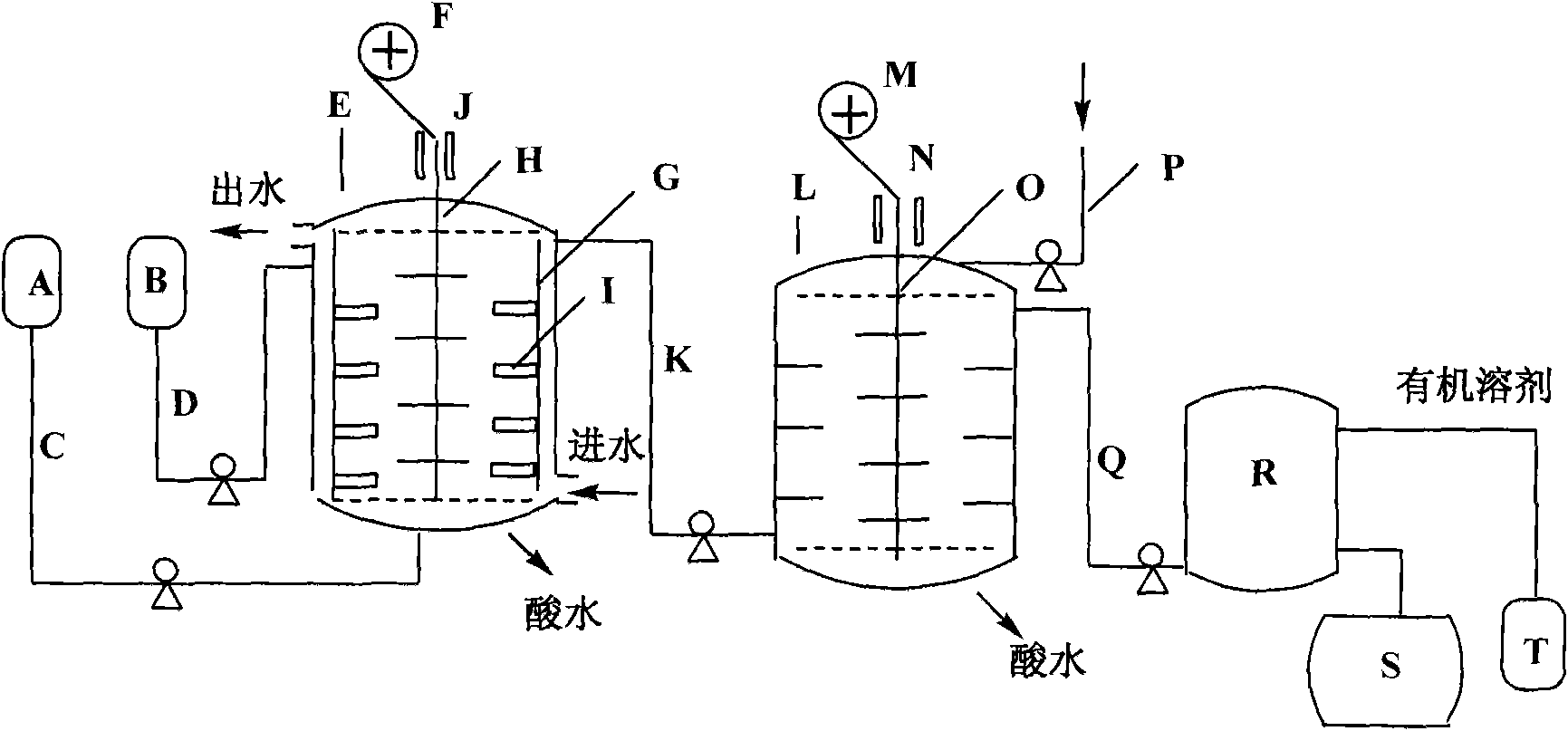

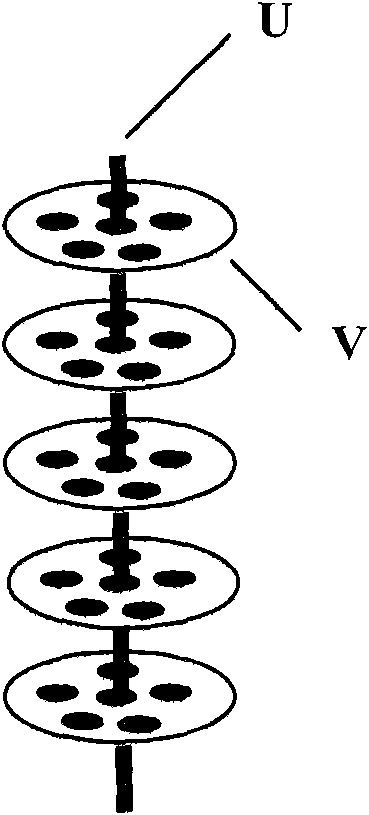

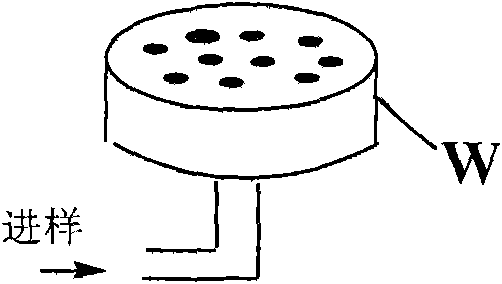

The invention relates to an alkyl silicone continuous production system and a production method thereof. The production system comprises a reaction still and a washer; a first reciprocating sieve plate and a second reciprocating sieve plate are respectively arranged in the reaction still and the washer and driven to reciprocate by a motor and an eccenter; a conduit is connected between the reaction still and the washer, a tap water input conduit is arranged on the top of the washer and a water outlet is arranged at the bottom of the washer; alkylsilanol solution flows into the bottom of the washer through a conduit, and a conduit is arranged between the washer and a vacuum distillation tower; the vacuum distillation tower is communicated with a product storage pot through a conduit. The production method includes that alkylchlorosilane reactant solution and hydrolysate are prepared; alkylchlorosilane is hydrolyzed under 1-25 DEG C, the hydrolyzed silanol solution is separated from a settling chamber on the top of the washer, washed in the washer and conducted to the washer bottom through a flowmeter by 0.1-1.0 cubic meters per hour; water is sent in from the washer top through the flowmeter by 0.2-5.0 cubic meters per hour; the silanol solution is washed in countercurrent until the pH value is 6.5-7 and then condensed in vacuum to become alkyl silicone.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

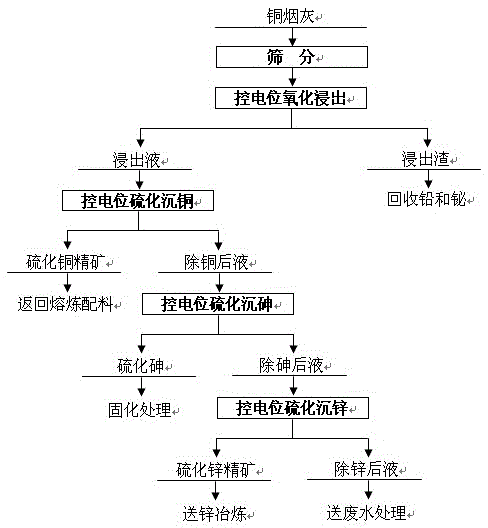

Method for potential controlled selection separation of copper refinery ash

InactiveCN105567984AIncrease sedimentation rateEasy to separateProcess efficiency improvementSlurryCopper sulfide

The invention relates to a method for potential controlled selection separation of copper refinery ash. The copper refinery ash is screened and then subjected to oxidizing leaching in a sulfuric acid system. An oxidizing agent is added to control the metal ion mixed potential of slurry, copper, arsenic, zinc and other metal are dissolved into a solution, and lead, bismuth and other metal precipitate and enter leaching residues. The metal ion mixed potential and the pH value of a leachate are simultaneously controlled, so that copper sulfide concentrate is produced through precipitation. The metal ion mixed potential and the pH value of copper-removed liquid are simultaneously controlled, so that arsenic sulfide products are produced through precipitation. The metal ion mixed potential and the pH value of arsenic-removed liquid are simultaneously controlled, so that zinc sulfide concentrate is produced through precipitation. Zinc-removed liquid is subjected to wastewater treatment and then discharged after reaching the standard. According to the method, the potential controlled oxidizing leaching and potential controlled sulfide precipitation ways are simultaneously adopted for recovering valuable metal step by step, the selection separation effect, which cannot be achieved by independently using the ways, of the valuable metal in the copper refinery ash is achieved, and the leaching rates of copper, arsenic and zinc are larger than 98.0%.

Owner:CENT SOUTH UNIV

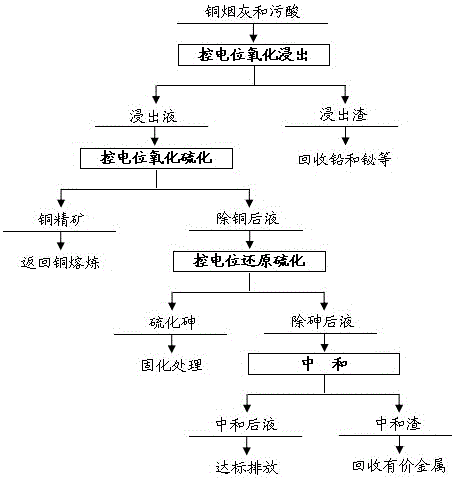

Combined treatment method for copper smelting soot and polluted acid

InactiveCN105950874AEasy to separateAvoid consumptionProcess efficiency improvementCopper sulfideSoot

The invention discloses a combined treatment method for copper smelting soot and polluted acid. The method includes the steps that after the copper smelting soot and the polluted acid are mixed for pulp conditioning, an oxidizing agent is added for controlled-potential oxidization leaching, so that copper, arsenic, zinc and other metal in the copper soot are dissolved to enter leachate, and lead, bismuth and other metal are precipitated to enter a reaching residue; then an oxidizing agent is added into the leachate so that As(III) in the solution can be completely oxidized into As(V); afterwards, sodium sulphide is added, so that the copper in the solution is precipitated in the form of copper sulphide to produce copper concentrate, and a reducing agent is added into the copper-removed solution so that the As(V) in the solution can be completely reduced into As (III); then sodium sulphide is added so that the arsenic in the solution can be precipitated in the form of arsenic sulfide; and finally the arsenic-removed solution is neutralized with alkaline and then is discharged after reaching the standard. By the adoption of the combined treatment method, controlled-potential oxidization leaching, controlled-potential oxidization sulfurization and reduction sulfurization are simultaneously combined to be used for step-by-step separation and recovery of valuable metal in the copper smelting soot and polluted acid, and therefore waste in the system can be recycled, and the purpose of using waste to treat waste is achieved.

Owner:CENT SOUTH UNIV

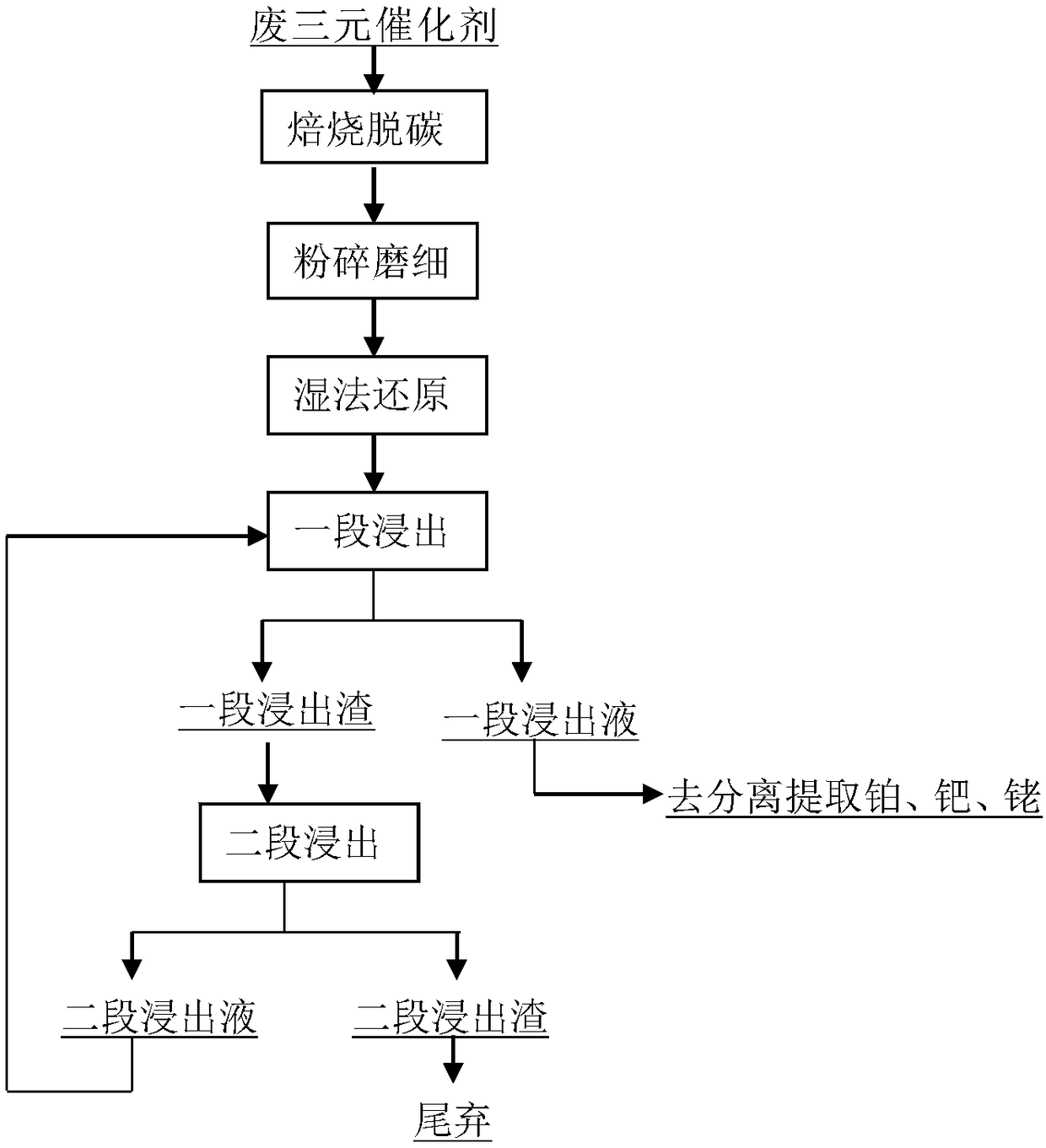

Method for leaching platinum, palladium and rhodium from spent ternary catalyst

InactiveCN108265180AImprove leaching rateImprove applicabilityProcess efficiency improvementPlatinumMetallurgy

The invention relates to a method for leaching precious metals from a spent catalyst. The method is suitable for leaching platinum, palladium and rhodium from an automobile spent ternary tail gas catalyst. The method comprises the following steps: performing calcination decarburization at a proper temperature, crushing and grinding the obtained catalyst, performing reducing conversion, and performing two-stage countercurrent dissolving to leach the platinum, palladium and rhodium. The method for leaching the platinum, palladium and rhodium from the ternary tail gas catalyst through adopting awet process has the advantages of short process, low treatment cost and high precious metal leaching rate, and allows the platinum leaching rate to reach 96.5%, the palladium leaching rate to reach 98.4% and the rhodium leaching rate to reach 91.1%.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

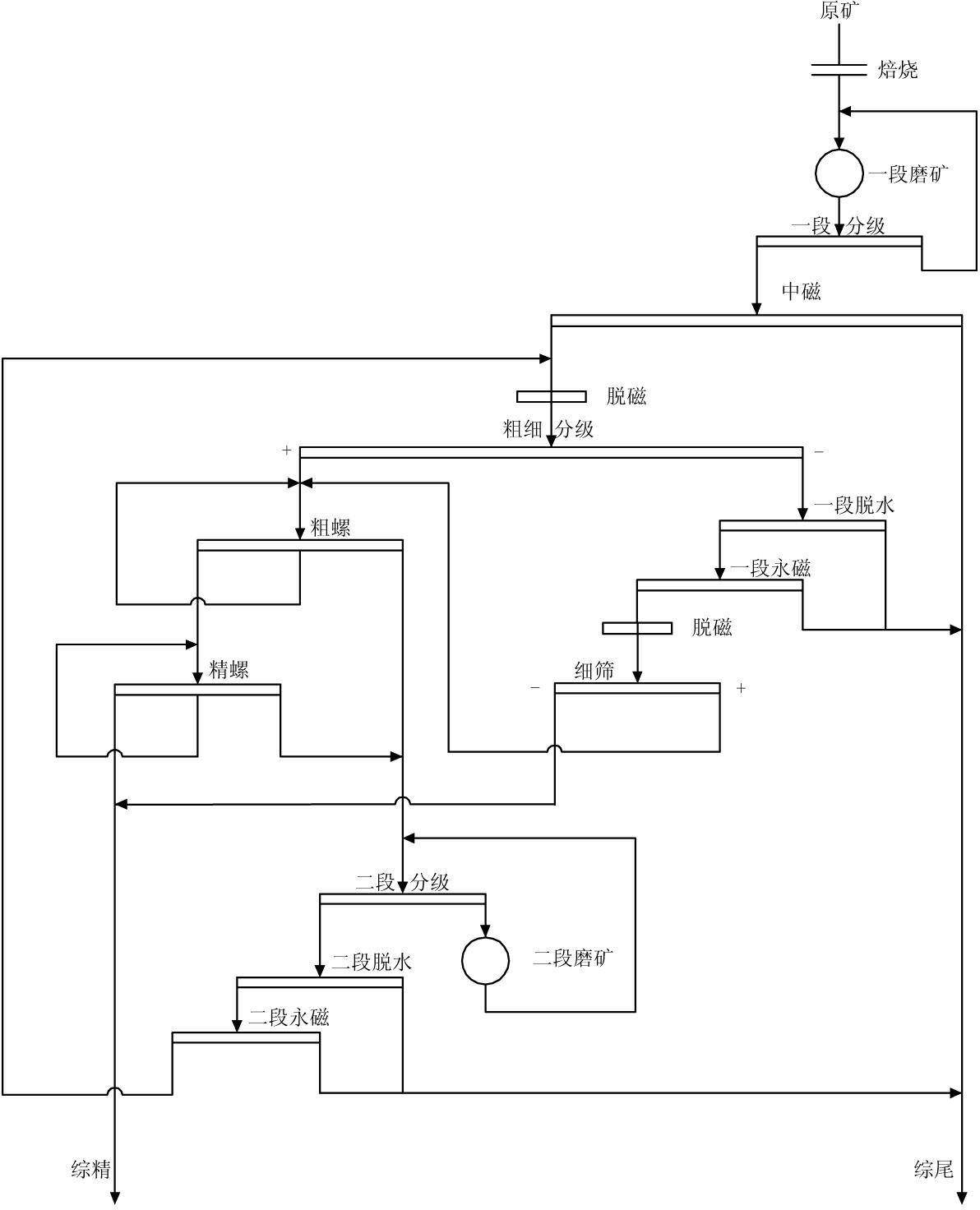

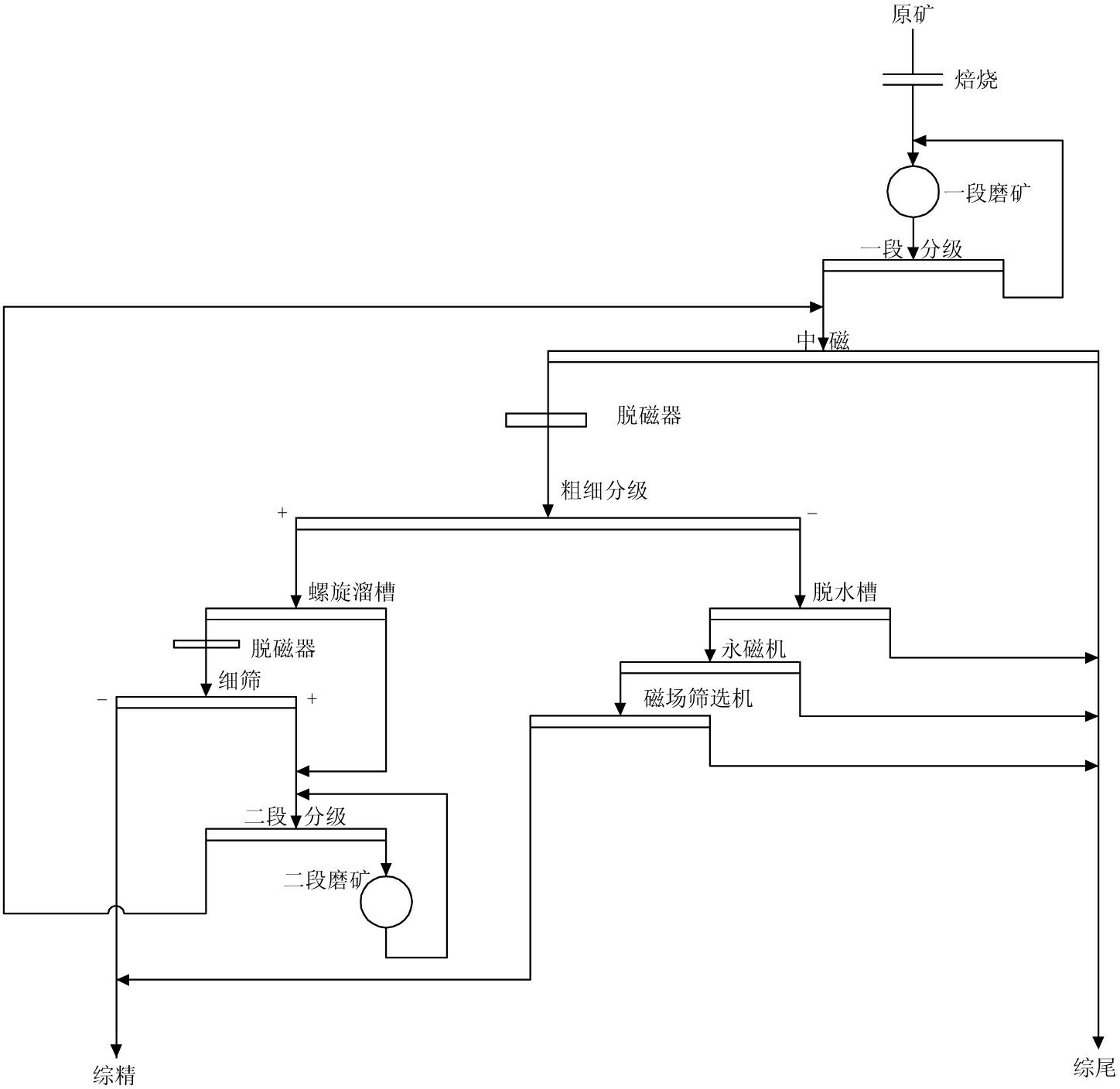

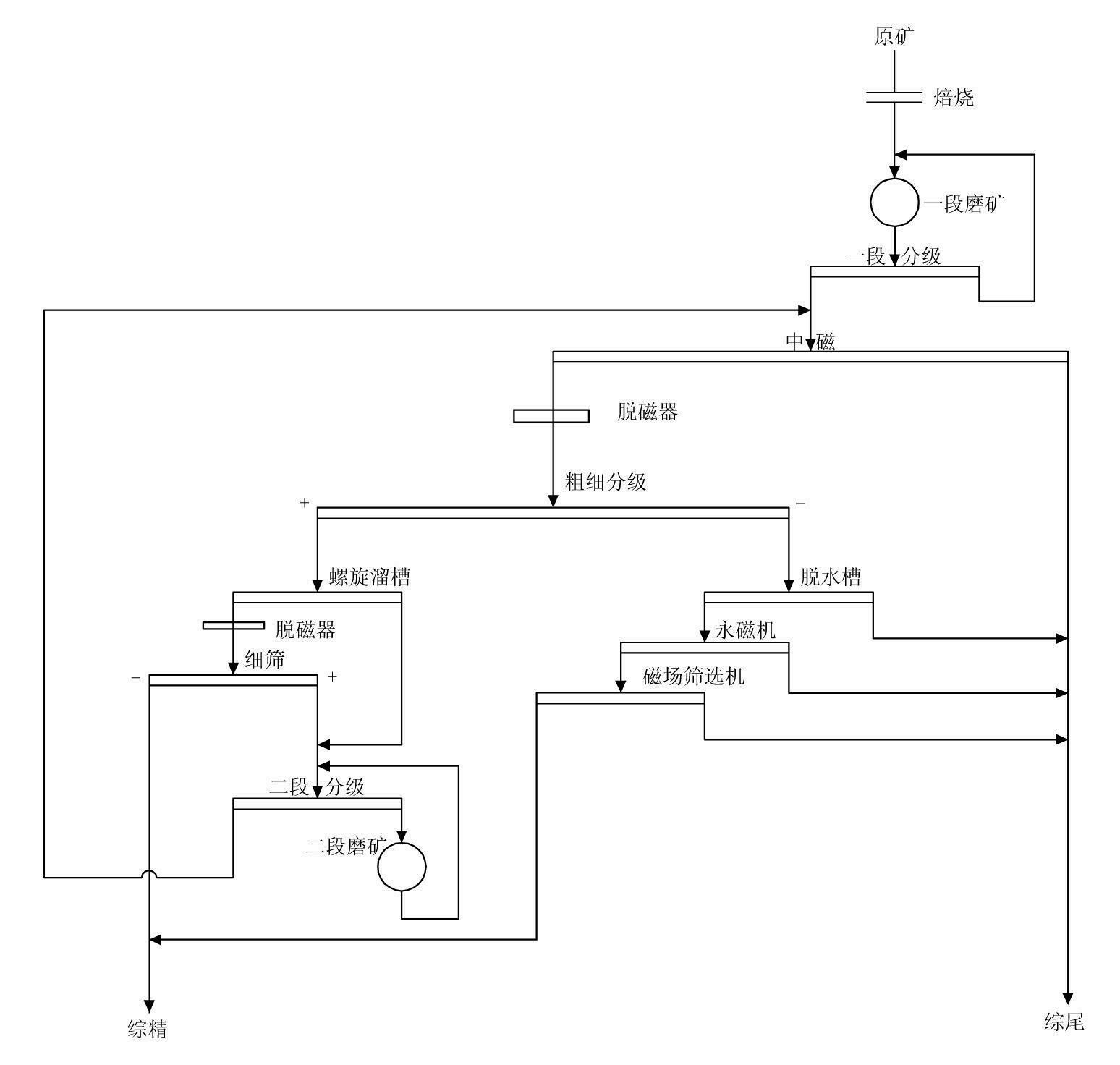

Hematite roasting, stage grinding, intermediate magnetic separation, fineness classifying, gravity concentration-magnetic separation technique

ActiveCN102631984AImprove sorting efficiencyImproved technical indicatorsWet separationScreening proceduresClosed loop

The invention belongs to the technical field of iron ore grading and especially relates to a hematite roasting, stage grinding, intermediate magnetic separation, fineness classifying, gravity concentration-magnetic separation technique, comprising raw ore roasting, first segment of closed loop grinding, primary grading, intermediate magnetic separation, fineness classifying and gravity concentration-magnetic separation. The technique is characterized by feeding the intermediate magnetic separation concentrate in a demagnetizer, grading the concentrate through fineness classifying, grading the material into rough granule level product and fine granule level product, feeding the rough granule level product in the fineness classifying procedure in a helical chute, demagnetizing the concentrate in the helical chute and performing screening procedure on the concentrate, serving the tailings in the helical chute and the oversize product in the screening procedure as middlings, performing secondary grading and second segment of closed loop grinding procedures on the middlings, and feeding the fine granule parts in the fineness classifying procedure in a dehydration tank, a permanent magnetic machine and a magnetic field screening machine to perform magnetic separation procedure. The comprehensive concentrate is composed of screening concentrate and magnetic field screening machine concentrate, and the compressive tailings are composed of intermediate magnetic separation tailings, dehydration tank tailings, permanent magnetic machine tailings and magnetic field screening machine tailings. The technique has the advantages that the sorting efficiency of the whole procedure is improved, the screening concentrate in rough granule procedure and the magnetic field screening machine concentrate in fine granule procedure can reach 65-67%, the level of the comprehensive concentrate is higher than 65-67%, and the level of the compressive tailings is reduced to 8-10%.

Owner:ANSTEEL GRP MINING CO LTD

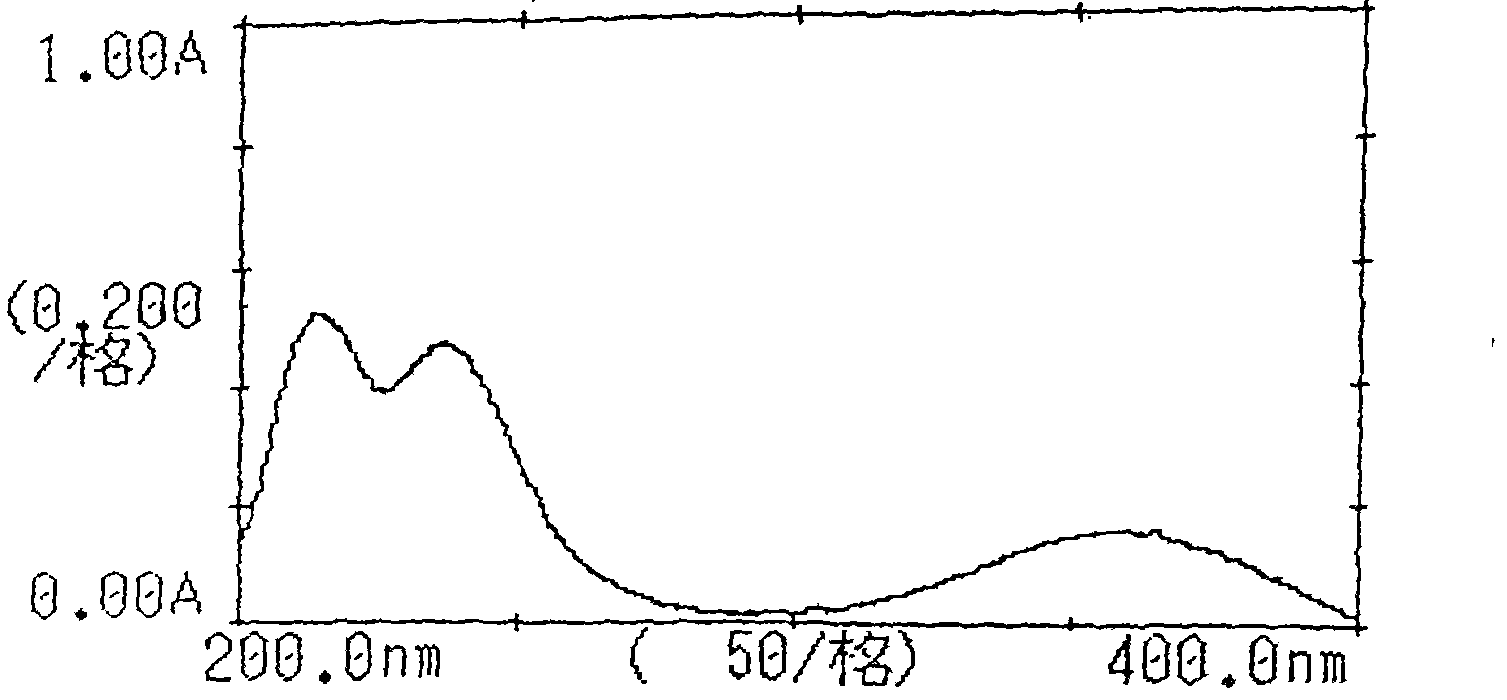

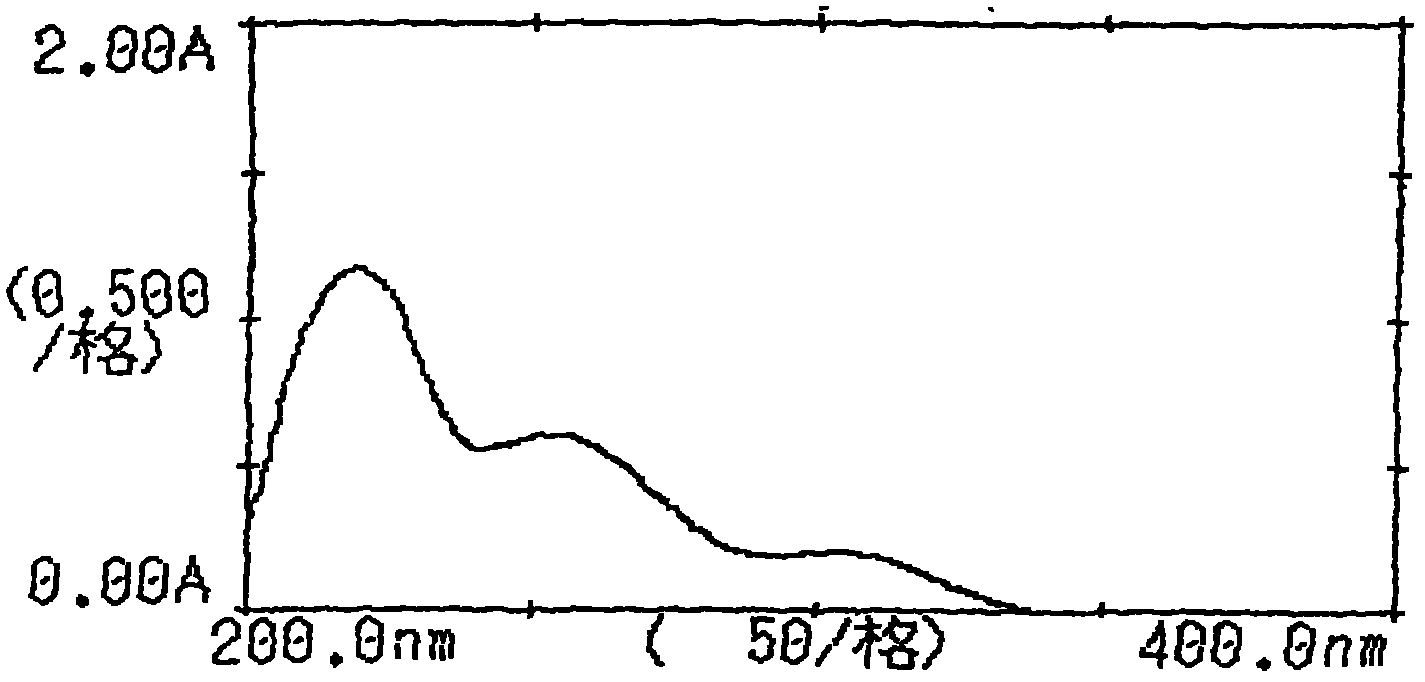

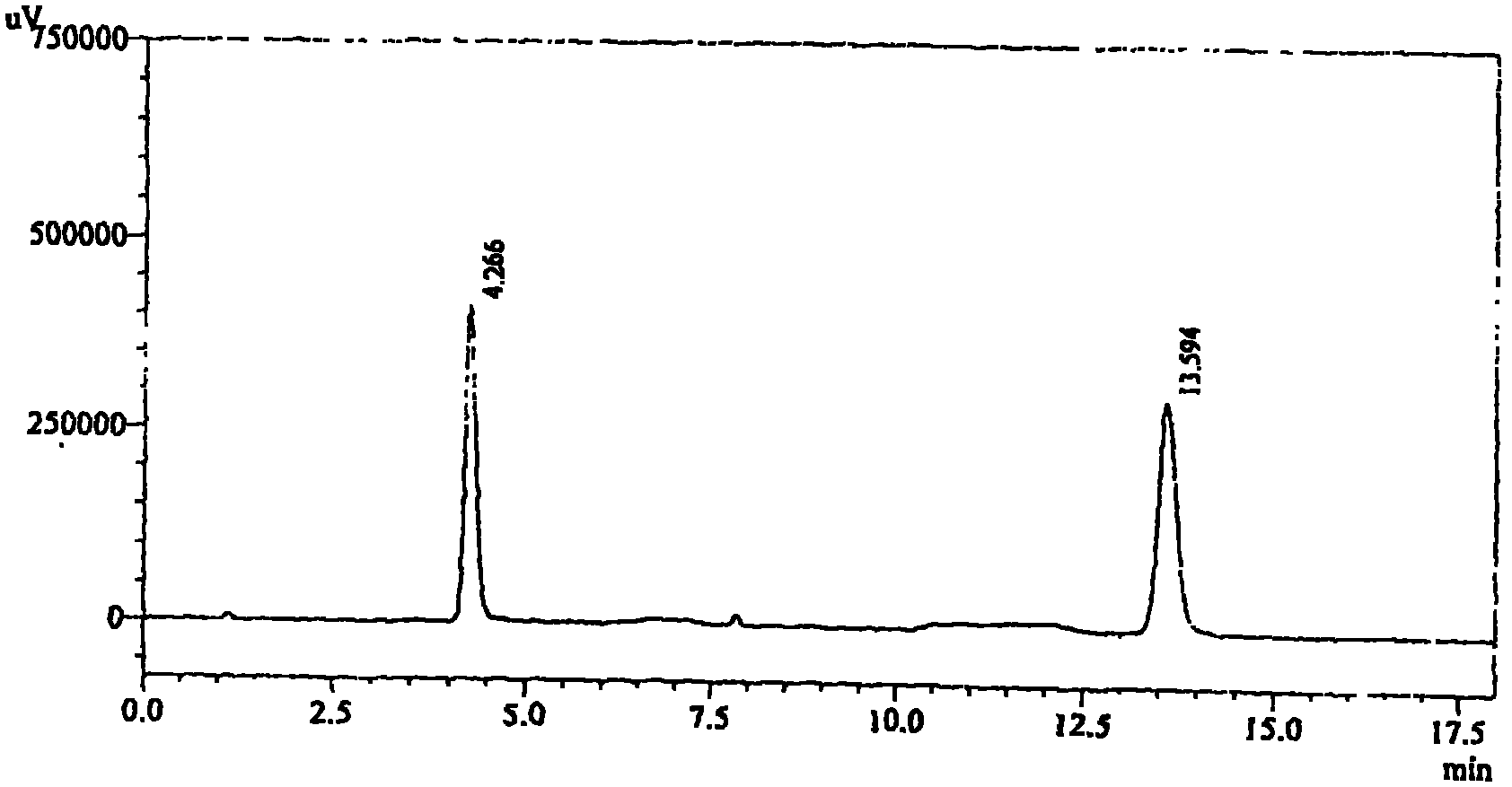

Composition containing candesartan and amlodipine, preparation process, testing process and application thereof

ActiveCN102670604AUnique formulaReduce manufacturing costOrganic active ingredientsComponent separationCandesartanAngina

The invention relates to a composition and a preparation process, a testing process and an application thereof. The composition comprises a therapeutically effective amount of candesartan or pharmaceutically acceptable ester or salt, a therapeutically effective amount of amlodipine or other pharmaceutically acceptable salt, 70-150 parts of mannitol or lactose, 2-5 parts of croscarmellose sodium or cross-calcium carboxymethyl cellulose and 5-40 parts of microcrystalline cellulose or corn starch. The composition is easy to prepare, low in production cost, utilizes accessories of unique prescription, and the like, can be prepared into oral preparation in forms of tablets, capsules, granules and the like by means of pharmaceutics, can be checked by different checking processes, has high quality, has functions of treating hypertension, angina pectoris and kidney diseases and has effect of myocardial protection.

Owner:SICHUAN SUNNYHOPE PHARM CO LTD

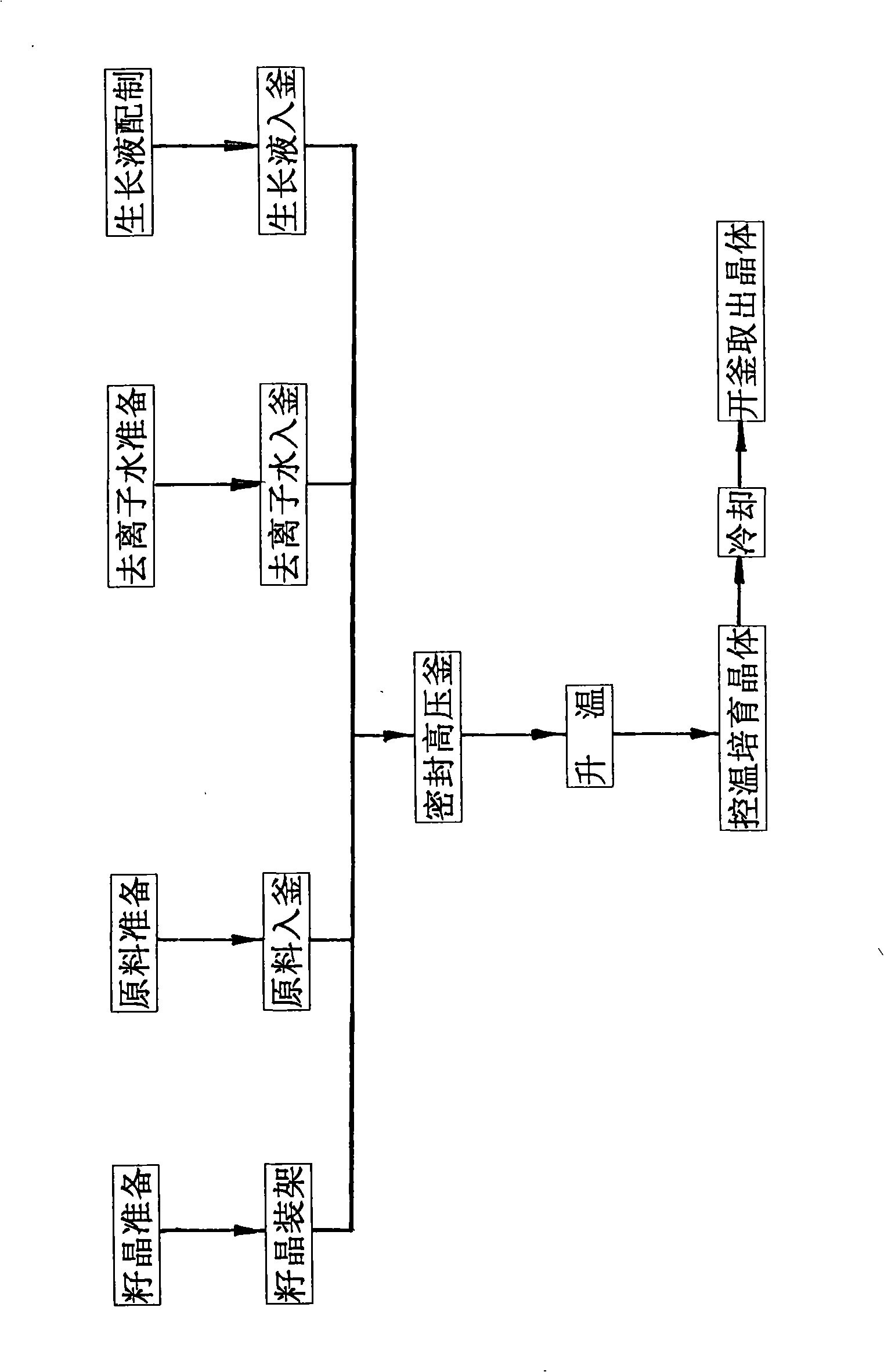

Optical-level quartz crystal temperature-variable temperature difference method growth technique

InactiveCN101319375AGuaranteed pulse indexGuarantee indicatorPolycrystalline material growthFrom normal temperature solutionsChannel densityGrowth promoting

The invention discloses an optical level quartz crystal temperature-changing temperature differential method growth technology, comprising the following steps that: firstly, raw materials of seed crystal and quartzite are washed, deionized water and a growth-promoting media are prepared, and a high-pressure autoclave is washed by ionized water and is drained off by a membrane pump; secondly, a raw material basket holding the quartzite is put in the washed autoclave, the prepared grow-promoting media and a seed crystal bracket hung with the seed crystal are poured into the autoclave, the liquid level is measured, and the autoclave opening is sealed; thirdly, a temperature control system is started, the high-pressure autoclave is heated, the parameters of temperature, pressure and time of the sealed high-pressure autoclave are adjusted so that the quartz crystal is grown and formed. The optical level quartz crystal temperature-changing temperature differential method growth technology is characterized by determining the lineage grade of the seed crystal, the a equivalent concentration of the grow-promoting media, the parameter of a filling degree of the autoclave, the temperature changing and differential parameter and the pressure parameter of the heated high-pressure autoclave. According to the quartz crystal produced by the technology, the lineage index is more than the grade A, the etch channel density is less than 10 strips per centimeter<2>, the value of Q is more than or equal to 3.0x10<6>, an inclusion is higher than the Ia type, the optical uniformity delta n is less than or equal to 5x10<-6>, and the spectrum transmission ratio is more than 95 percent when the wavelength is between 800 and 2, 500 nanometers.

Owner:刘盛浦

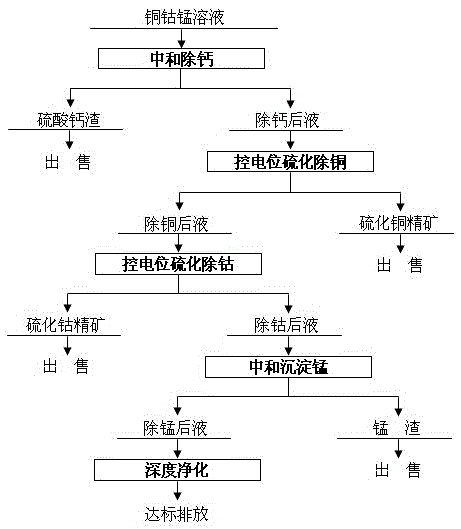

Method for vulcanizing and separating valuable metal in solution through controlled potential

InactiveCN105648214AHigh recovery rateAchieve recyclingRotary drum furnacesCrucible furnacesSlagManganese

The invention discloses a method for vulcanizing and separating valuable metal in a solution through controlled potential. The method comprises the steps that 1, alkali and sulfate are simultaneously added into the copper-cobalt-manganese solution to remove calcium in the solution; 2, sodium sulphide is added into the calcium removed solution to enable the mixed potential of metal ions in the solution to be controlled to be a required value, and meanwhile hydrochloric acid is added to adjust the pH value of the solution; 3, after the solution potential is stabilized and continuously stirred, filtering and copper removing are conducted; 4, after coppering removing is completed, the sodium sulphide is added to enable the mixed potential of the metal ions in the solution to be controlled to be the required value, and the hydrochloric acid is added to adjust the pH value; 5, after the solution potential is stabilized and continuously stirred, filtering is conducted; and 6, the pH value of the cobalt removed solution is neutralized through the alkali to reach a required value, the solution is filtered after being stirred, deposited manganese slag is obtained, and selective step-by-step separation of the valuable metal in the solution is achieved. According to the method for vulcanizing and separating the valuable metal in the solution through the controlled potential, selective separation of the valuable metal in the solution is achieved by controlling the mixed potential of the metal ions in the solution and the pH value at the same time; selective separation of the valuable metal in the solution is achieved, and the deposition rate of copper, the deposition rate of cobalt and the deposition rate of manganese are all 99.0% or above.

Owner:CENT SOUTH UNIV

Method for treating lead anode slime

InactiveCN103205576ASuitable for handlingEasy to usePhotography auxillary processesProcess efficiency improvementArsenic pollutionEnergy conservation

The invention discloses a method for treating lead anode slime. The method has the advantages that preparation procedures for oxidization and state transition, fine grinding and the like are omitted, and the method is applicable to treating freshly produced anode slime; hydrogen peroxide solution is used as a leached oxidant and can be used safely and conveniently; the reaction speed and the production efficiency are high, and the method is suitable for batch production; reagents can be recycled, discharge of waste water containing heavy metal is prevented, and the direct yield and the recovery rate are high; precious metal and base metal which are separated from each other by a wet process can react at a low temperature, the direct gold yield and the direct silver yield are high, and an operation environment is good; interfering ions are omitted, process conditions are easy to control, and technical indexes are stable; and the method is thorough in comprehensive recovery performance and is obvious in merits of energy conservation and environmental protection, and particularly, arsenic pollution can be prevented.

Owner:ANHUI TONGGUAN NONFERROUS METALS (CHIZHOU) CO LTD

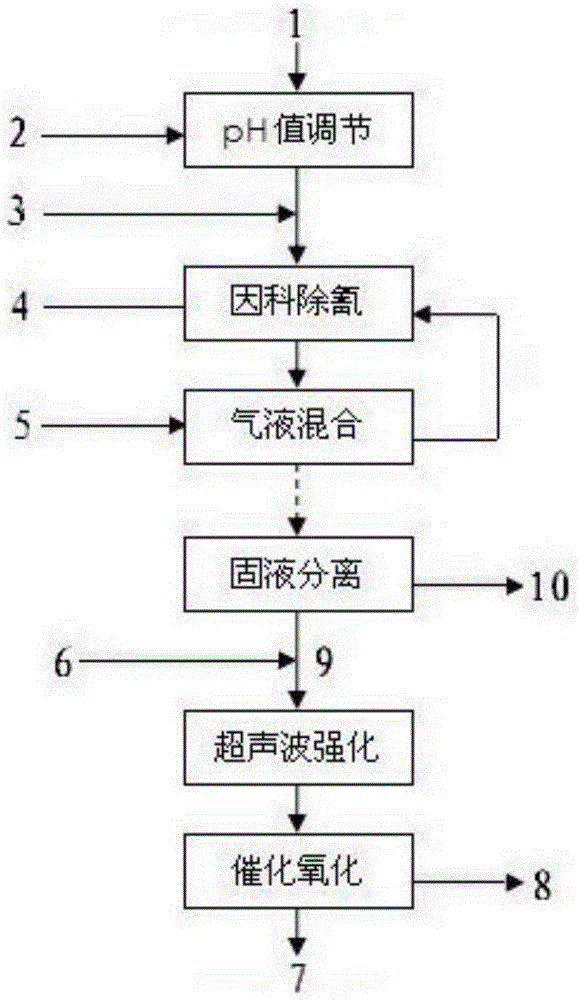

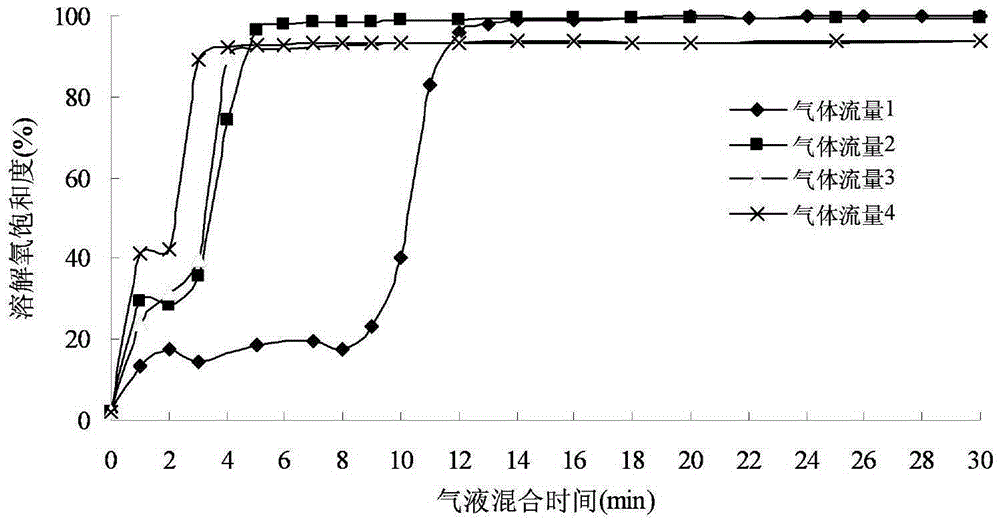

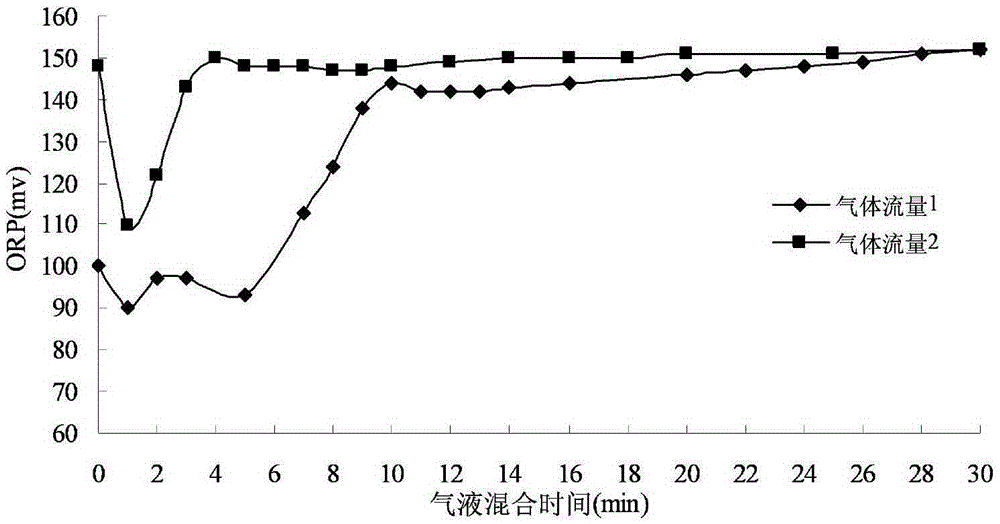

Treatment method for copper-containing gold ore cyaniding waste water

ActiveCN105399237AReaction is easy to controlStrong resistance to hydraulic shock loadWaste water treatment from quariesWater contaminantsChemical reactionSulfite salt

The invention relates to a treatment method for copper-containing gold ore cyaniding waste water. The treatment method comprises the following steps under the following conditions: pH value adjustment: adjusting the pH value of the cyaniding waste water to 8.0 to 11.5; cyanogen removal in an INCO method (sulfur dioxide-air oxidation method): adding sodium sulfite into the cyaniding waste water with pH value well adjusted, uniformly mixing, mixing air and the cyaniding mixed solution, and monitoring the value by using a DO or ORP monitor; solid-liquid separation: performing solid-liquid separation for the waste water reaching a set value by adopting a coagulating sedimentation method, and separating a precipitate product dominant on copper hydroxide and supernatant; oxidation strengthening: adding an oxidant into the supernatant, and carrying out ultrasonic strengthening and induced oxidization; and catalytic oxidation: performing active carbon physical and chemical reactions for the ultrasonically-strengthened solution to obtain pure water and gold-loaded carbon. The method has the advantages that technological advantages are complementary and unified, the reaction is relatively easy to control, the hydraulic impact load resistant capability is high, the pH value of water is not required to be maintained, the operation is simple, the power consumption is small, the consumption of the oxidant and the expense of chemicals are low, the purified water quality is good, the recovery rate of valuable metals is high, and the like; and the method is suitable for treating the copper-containing gold ore cyaniding waste water.

Owner:ZIJIN MINING GROUP

Production and preparation process for fulvic acid

The invention relates to the field of chemical product production, in particular to a production and preparation process for fulvic acid. The production and preparation process is characterized in that a raw material lignite for preparing the fulvic acid is smashed into 80 mesh and added into warm water at the temperature of 49 DEG C to 51 DEG C, and the ratio of the dry weight of the lignite powder to the weight of the water is 1:(18-22), H2O2 is slowly added in a stirring state, the adding rate of H2O2 is limited by the reaction temperature lower than 65 DEG C, and the mass ratio of the lignite powder to H2O2 is 1:(0.68-0.72); after lignite is subjected to an oxydrolysis reaction, the mixture is subjected to solid-liquid separation and dried, and a fulvic acid product is obtained. The production and preparation process has the advantages that the leonardite is adopted as the raw material, so that the production cost is low; hydrogen peroxide is adopted as an oxidizing agent, so that environmental friendliness is achieved, and pollution is avoided; adopted equipment is simple, the production conditions are easy to control, the process route is feasible, the technical index is stable, the production and preparation process is suitable for large-scale industrial production, and the fulvic acid is high in yield and purity; compared with an imported product, the cost is greatly reduced, and conditions are created for full utilization of low-quality coal resources and substituting for imported goods.

Owner:王墨林

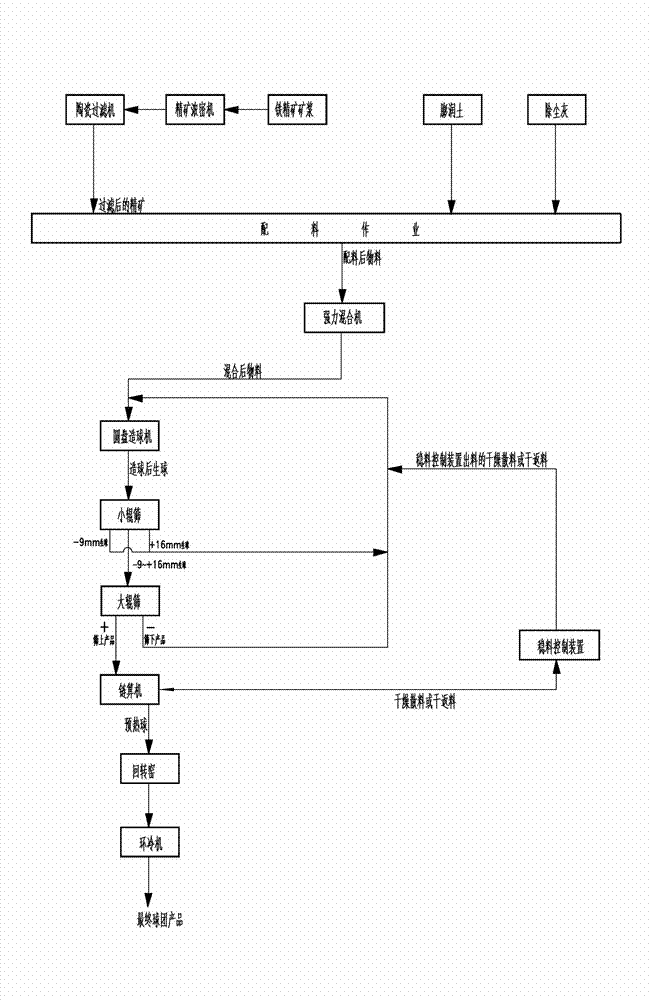

Novel energy-saving technology for producing pellets with fine-grained iron ore concentrates

ActiveCN102925676ASimple production processReduce concentrate moistureEnergy conservationMaterials science

The invention discloses a novel energy-saving technology for producing pellets with fine-grained iron ore concentrates, which is characterized in that the novel energy-saving technology comprises the following steps that pulp of the iron ore concentrates is fed to an ore concentrate thickening machine to be thickened, fed to a ceramic filtering machine, subjected to batching, mixed by an intensive mixing machine, and pelletized by a disc pelletizer; then fresh pellets after being pelletized are fed to a small roll screen for screening; after the fresh pellets are treated by the small roll screen, the fresh pellets in unqualified grain sizes are return to the pelletizing process for pelletizing again, while the fresh pellets in qualified grain sizes are fed to a large roll screen for secondary screening; undersized products screened by the large roll screen return to the pelletizing process; the products on the large roll screen are fed to a chain grate; and after being fed to the chain grate, the qualified fresh pellets are dried and preheated by the chain grate, and then fed to a rotary kiln to be calcined and cooled to be qualified pellet products. The novel energy-saving technology has the advantages that on the premise that the product quality of the pellets is ensured, energy conservation and emission reduction are realized by optimizing the production technology and improving the production flow.

Owner:ANSTEEL GRP MINING CO LTD

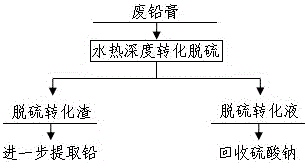

Hydrothermal deep conversion desulfurization method for waste lead plaster of lead-acid storage battery

ActiveCN105950870AReduce consumptionAchieve removalProcess efficiency improvementSulfate radicalsPhysical chemistry

The invention discloses a hydrothermal deep conversion desulfurization method for waste lead plaster of a lead-acid storage battery. The method includes the steps that the waste lead plaster and aqueous alkali are mixed and then added into a high pressure reactor, and reacting is carried out under the required temperature and nitrogen partial pressure, so that lead sulfate is completely reacted with alkali to remove sulfate radicals; and solid-liquid separation is conducted after the requirement for reaction time is met, sodium sulfate is recovered from desulfuration conversion liquid, and lead is further extracted from desulfuration conversion slug. By the adoption of the hydrothermal mode, the alkaline conversion desulfuration process of the waste lead plaster is strengthened, the sulfate radicals in the waste lead plaster can be removed completely, the consumption of alkaline only accounts for 1.0-1.05 times of the theoretical dose, the desulfurization degree is above 99.0%, and therefore advantage conditions are created for subsequent extraction of lead from the conversion slag.

Owner:CENT SOUTH UNIV

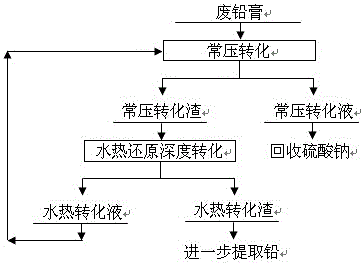

Waste lead-acid battery diachylon hydrothermal reduction dual conversion method

ActiveCN105950872AEasy to operateTechnical indicators are stableWaste accumulators reclaimingProcess efficiency improvementLead dioxideSulfate radicals

The invention discloses a waste lead-acid battery diachylon hydrothermal reduction dual conversion method. Waste diachylon and alkali solution are firstly converted under normal pressure to remove most sulfate radicals; normal-pressure conversion liquid is fed to recover sodium sulfate; normal-pressure conversion slag and the alkali solution are pulped to feed into a reducing agent to add in a high-pressure reaction kettle for reaction under requested temperature and nitrogen partial pressure, so that residual lead sulfate in the normal-pressure conversion slag is reacted with alkali to deeply remove the sulfate radicals; meanwhile, lead dioxide is reduced as lead monoxide; after the reaction time is reached, the solid-liquid separation is performed; hydrothermal conversion liquid is returned into the normal-pressure conversion process; and lead is further extracted from the hydrothermal conversion slag. The essence of the method is to realize dual purposes of deep conversion desulfurization and reduction conversion of the waste diachylon by using a water heat and reduction combined mode; the desulfurization rate and the lead dioxide reduction rate both reach above 99.0%; and advantageous conditions are created for subsequent lead extraction from conversion slag.

Owner:CENT SOUTH UNIV

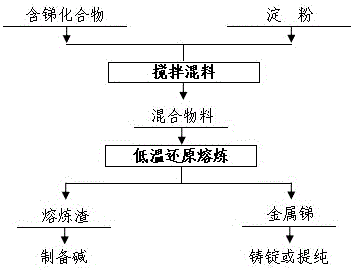

Low-temperature reduction smelting method of stibium-containing compound

The invention discloses a low-temperature reduction smelting method of a stibium-containing compound. The low-temperature reduction smelting method of the stibium-containing compound comprises the following steps: simultaneously adding the stibium-containing compound and starch into a conical mixer, stirring and mixing; continuously conveying the mixed material to an indirect heating smelting pot; then heating to the required temperature and smelting; and further treating produced stibium. Under the condition of indirect heating, the starch is used as a reducing agent, the purpose of producing the stibium by low-temperature reduction smelting of the stibium-containing compound is achieved, reduction smelting temperature is reduced to be 800-850 DEG C, and the direct recovery rate of the stibium reaches 90.0% or above.

Owner:CENT SOUTH UNIV

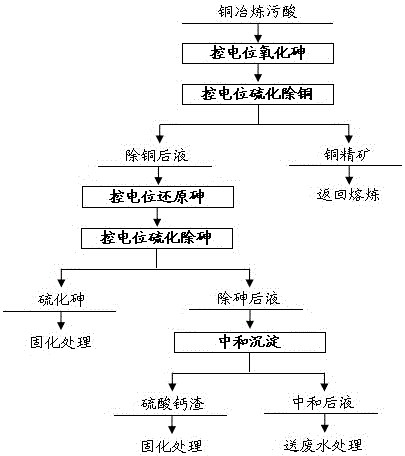

Potential-control selective separation method of copper smelting acidic wastewater

InactiveCN106045140AEasy to separateLess investmentWater contaminantsWaste water treatment from metallurgical processSlagArsenic sulfide

The invention relates to a potential-control selective separation method of copper smelting acidic wastewater. The method comprises the following steps: adding a potential-control oxidizer into copper smelting acidic wastewater to completely oxidize As (III) into As (V), and adding potential-control sodium sulfide to precipitate copper in the solution in the form of cupric sulfide so as to generate a copper concentrate; adding a potential-control reducer into the decoppered solution to completely reduce the As (V) in the solution into As (III), adding potential-control sodium sulfide to precipitate arsenic in the solution in the form of arsenic sulfide, and neutralizing the dearsenified solution with lime to generate gypsum slag; and sending the neutralization solution to wastewater treatment, and discharging after reaching the standard. The method avoids the idea of traditional neutralizing treatment on copper smelting acidic wastewater by using gypsum, selectively implements fractional precipitation of valuable metals, implements fractional precipitation of copper and arsenic in the acidic wastewater, and has the advantages of favorable copper and arsenic separating effects and low reagent consumption.

Owner:CENT SOUTH UNIV

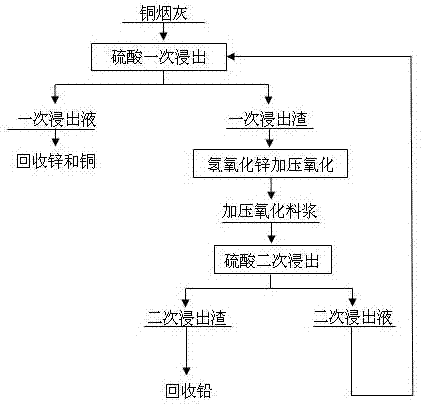

Method for pressurizing and strengthening leaching of copper smelting dust

InactiveCN107502748ALow PH value of slurryEfficient leachingProcess efficiency improvementZinc hydroxidePregnant leach solution

Provided is a method for pressurizing and strengthening leaching of copper smelting dust. After being subjected to screening, the copper smelting dust is leached at a time in a sulfuric acid system, so that oxide and sulfate in soot are dissolved to enter a primary leaching agent, therefore metal sulfide and the like are left in primary leaching residues, zinc and copper are recycled from the primary leaching agent, the primary leaching residues are then added into zinc hydroxide to be subjected to pressurized oxidation, the metal sulfide is oxidized and enters pressurized oxidation slurry, the pressurized oxidation slurry is refilled with sulfuric acid to subjected to secondary leaching, a sulfuric acid secondary leaching agent returns to a sulfuric acid primary leaching process, and lead is recycled by sulfuric acid secondary leaching residues. According to the method for pressurizing and strengthening leaching of the copper smelting dust, the leaching rate of copper and zinc in the copper smelting dust is improved by adopting a zinc hydroxide pressurized oxidation mode, the leaching rate of each of the copper and the zinc reaches 92% or over, current metal phase complexity can be effectively handled, and particularly the copper smelting dust with the high sulfide content can be handled.

Owner:CENT SOUTH UNIV

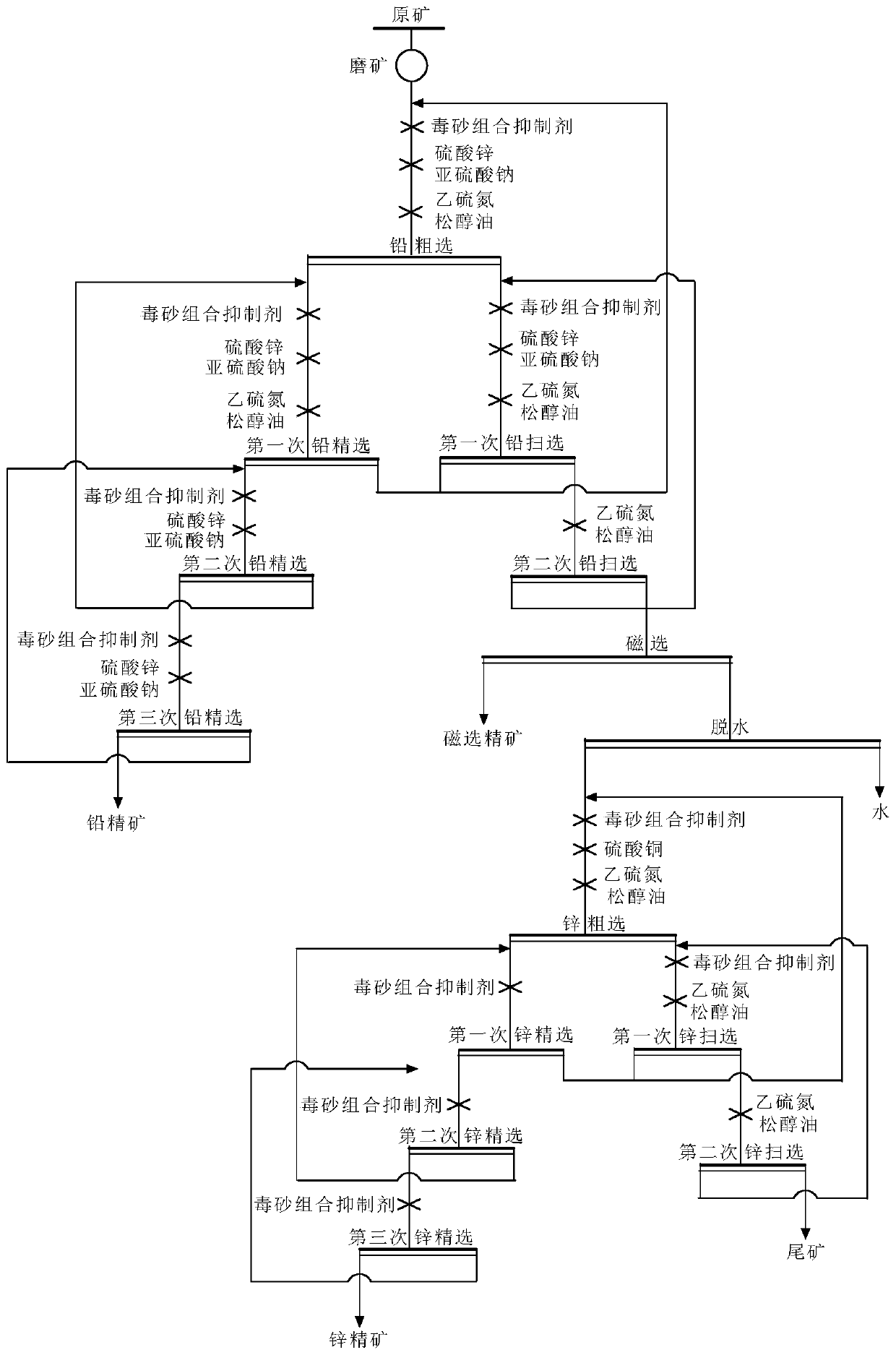

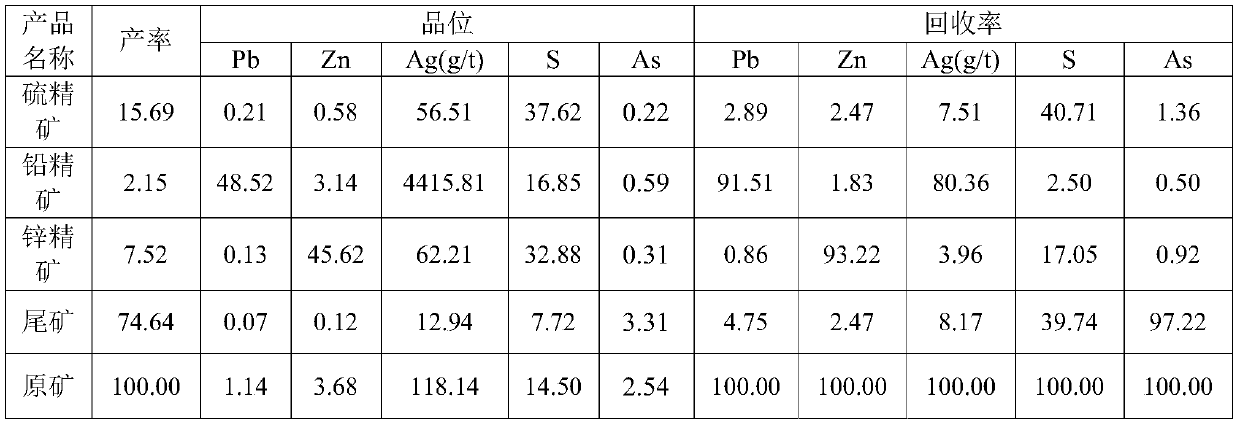

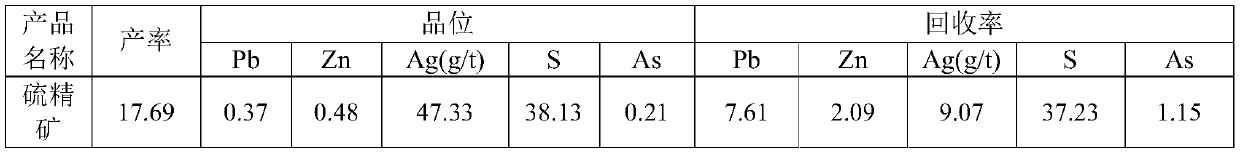

Toxic sand combined inhibitor and high-sulfur high-arsenic lead-zinc-silver ore beneficiation method

InactiveCN111250270AEfficient separationEfficient recyclingFlotationWet separationCalcium hypochloriteMagnetic separation

The invention discloses a toxic sand combined inhibitor and a high-sulfur high-arsenic lead-zinc-silver ore beneficiation method, the toxic sand combined inhibitor is formed by mixing lime, calcium hypochlorite and sodium humate, and the mass ratio of the lime to the calcium hypochlorite to the sodium humate is (4.0-8.0): (2.0-4.0): (1.0-2.0). The lead-zinc-silver ore beneficiation method comprises the following steps that a toxic sand combined inhibitor is added into raw ore pulp for lead roughing, and lead roughing concentrate and lead roughing tailings are obtained; lead scavenging is conducted on the lead roughing tailings at least once, and lead scavenging tailings are obtained; the lead roughing concentrate is subjected to at least one time of lead concentration, and lead concentrateis obtained; magnetic separation is carried out on the lead scavenging tailings to obtain magnetic separation tailings; concentrating and dehydrating are carried out on the magnetic separation tailings to obtain concentrated ore pulp, and the toxic sand combined inhibitor is added into the concentrated ore pulp for zinc flotation to obtain zinc concentrate. The method can effectively separate thelead-zinc-silver minerals from pyrrhotite and poisonous sand, and is simple, easy to implement, efficient and environmentally friendly.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Method for producing high-vanadium low-silicon high-quality vanadium slag and low-silicon-sulfur high-quality molten iron

The invention belongs to the field of molten iron pretreatment in the metallurgical industry, and particularly discloses a method for producing high-vanadium low-silicon high-quality vanadium slag andlow-silicon-sulfur high-quality molten iron. A desilication desulfuration agent is added into a vanadium-contained molten iron, and is promoted to be decomposed at the high temperature to generate gas CO2 and solid CaO, through the gas CO2, silicon and sulphur in the molten iron are subjected to oxidation to generate gas SiO and SO2 to be escaped and removed, at the same time, continuously-introduced CO2 and CaO have a reaction with residual silicon and sulphur in the molten iron to generate SiO2 and CaS to enter a slag phase to be removed, the content of vanadium in the molten iron is hardlychanged, and the low-silicon-sulfur high-vanadium high-quality molten iron is obtained; furthermore, oxygen is used for blowing the low-silicon-sulfur high-vanadium high-quality molten iron, and twooptimized products of high-vanadium low-silicon vanadium slag and low-silicon low-sulfur molten iron are obtained. In the molten iron treatment process, slagging off is carried out for two times, SiO2and CaS slag are subjected to slagging off, and first-time slag and iron separation is achieved; after oxygen blowing, vanadium slag is subjected to slagging off, and second-time slag and iron separation is achieved; and the molten iron and vanadium slag product quality can be improved from the sources of vanadium-contained molten iron vanadium slag blowing and steel smelting, cost is low, implementation is easy and convenient, and efficiency is high.

Owner:NORTHEASTERN UNIV

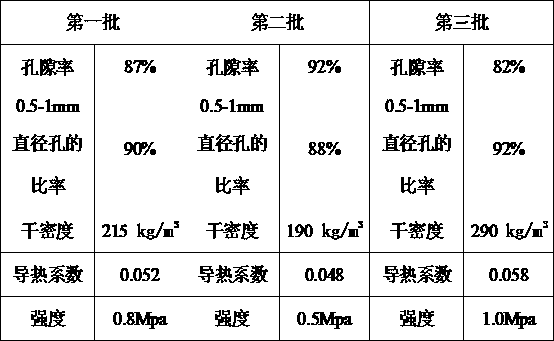

Inorganic foam cement thermal insulation material for outer wall

The invention provides an inorganic foam cement thermal insulation material for an outer wall and a manufacturing method thereof. The inorganic foam cement thermal insulation material has simple components, so that the manufacturing process is easy to control and the properties of a product can be kept stable; by using a physical foaming method, the foam uniformity is improved, the foam damage degree is reduced, and the thermal insulation property is improved; and meanwhile, the defects that the conventional organic fire-resistant thermal insulation material has large weight, high water absorption, low mechanical strength and the like can be overcome.

Owner:管振忠

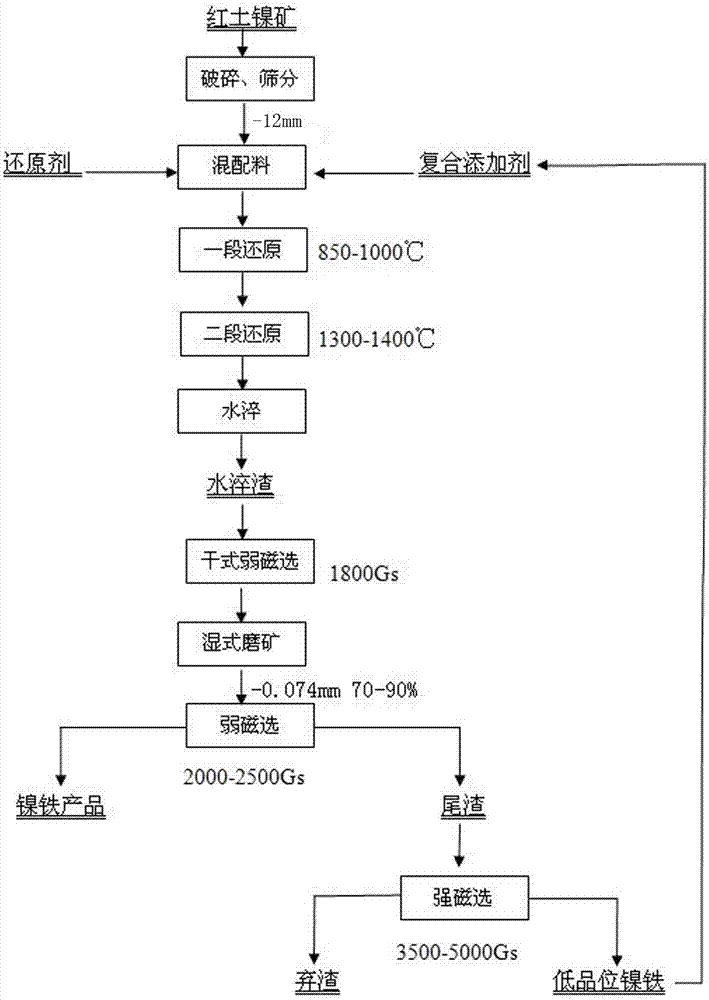

Method for producing ferronickel through nickel-laterite ore direct reduction and ore-dressing enrichment method

ActiveCN107267776ATechnical indicators are stableImprove work rateRotary drum furnacesGrain treatmentsEnrichment methodsEconomic benefits

The invention belongs to the technical field of nonferrous metallurgy and particularly relates to a method for producing ferronickel through a nickel-laterite ore direct reduction and ore-dressing enrichment method. According to the method, two rotary kilns are adopted for reduction roasting to avoid the rotary kiln ring formation temperature intervals. By means of the method, the serious technical problems existing in an existing direct reduction and ore-dressing enrichment method are solved; continuous production and smooth running can be guaranteed; good economic benefits can be obtained. The technology can be applied and popularized in production and especially has more practical significance in development of nickel-laterite ore resources in areas lacking electric power facilities.

Owner:SHENYANG RES INST OF NONFERROUS METALS

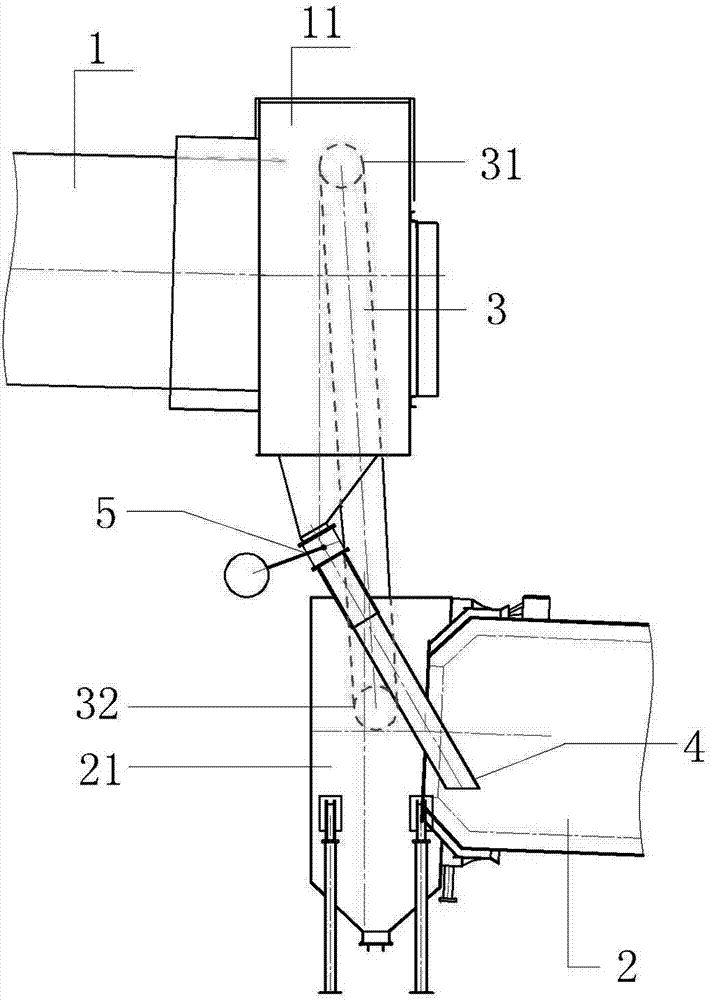

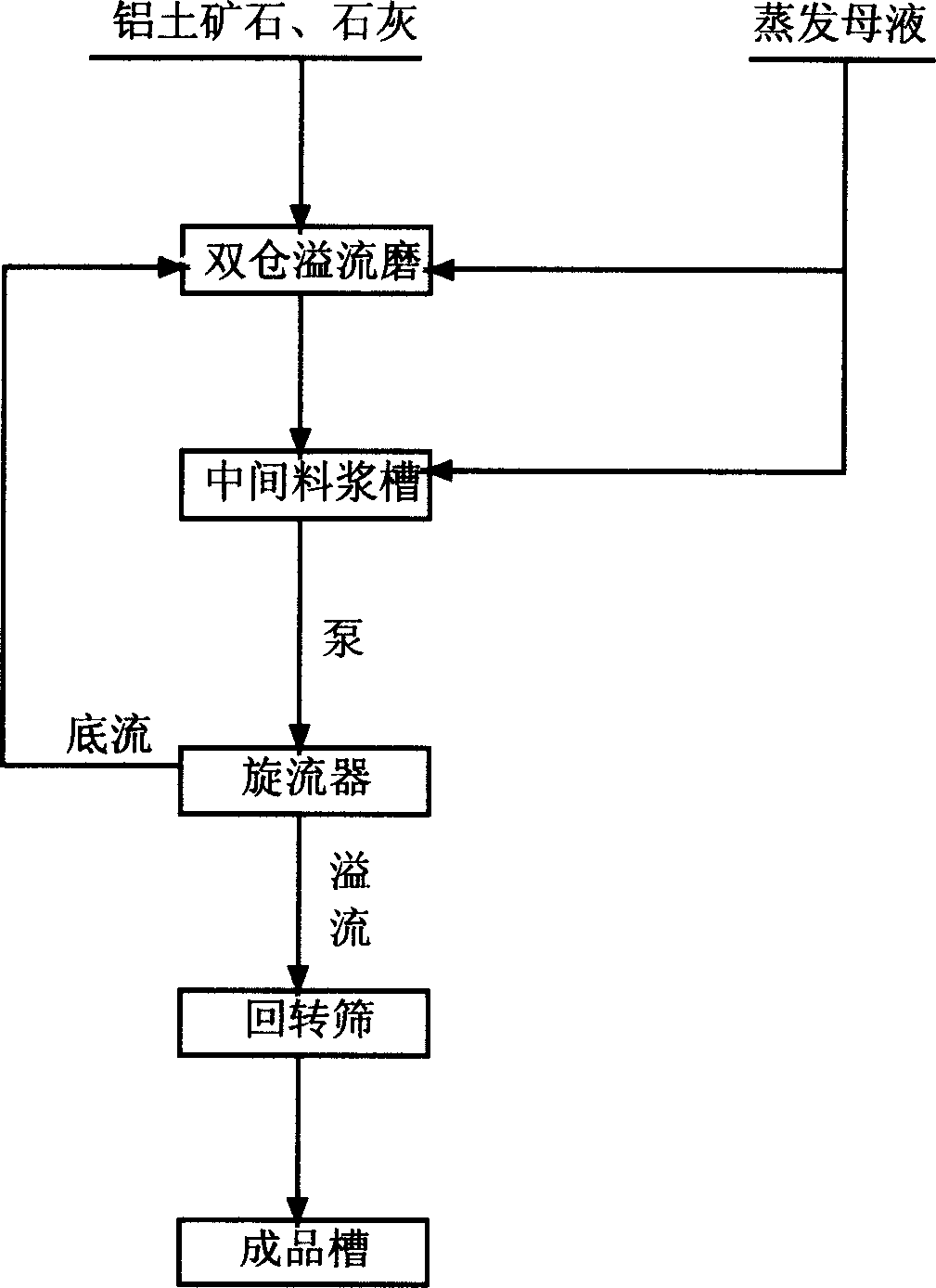

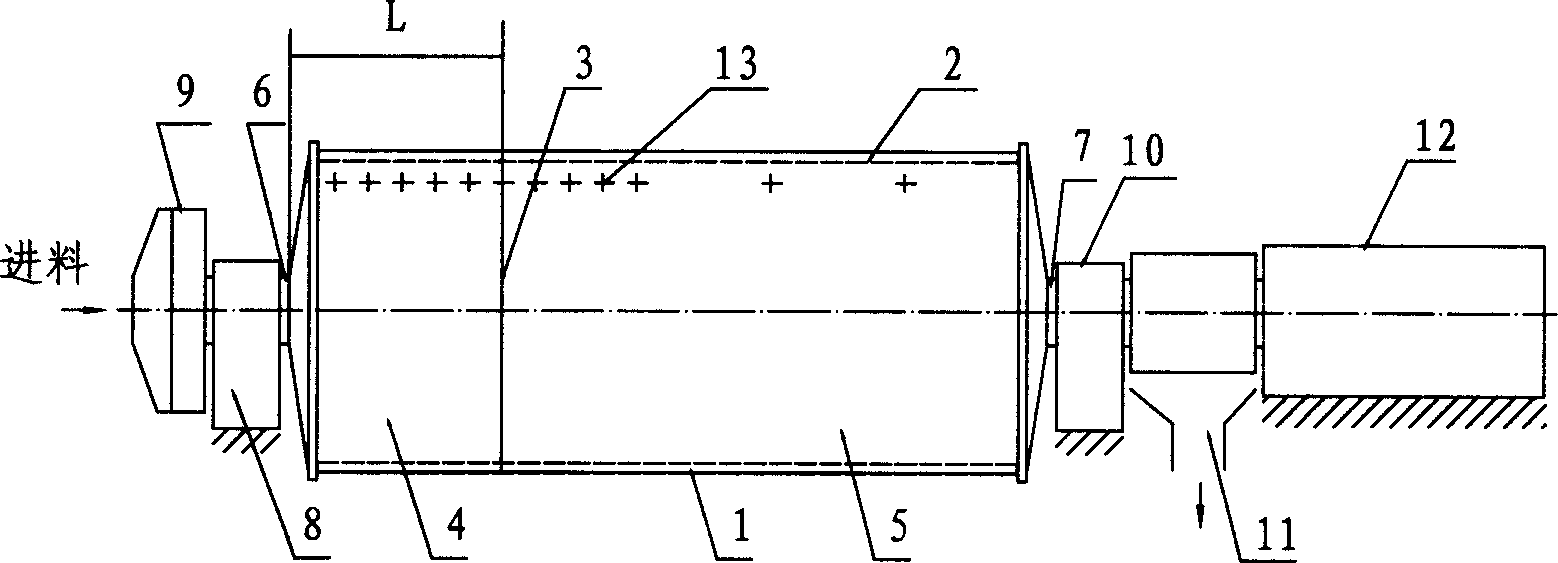

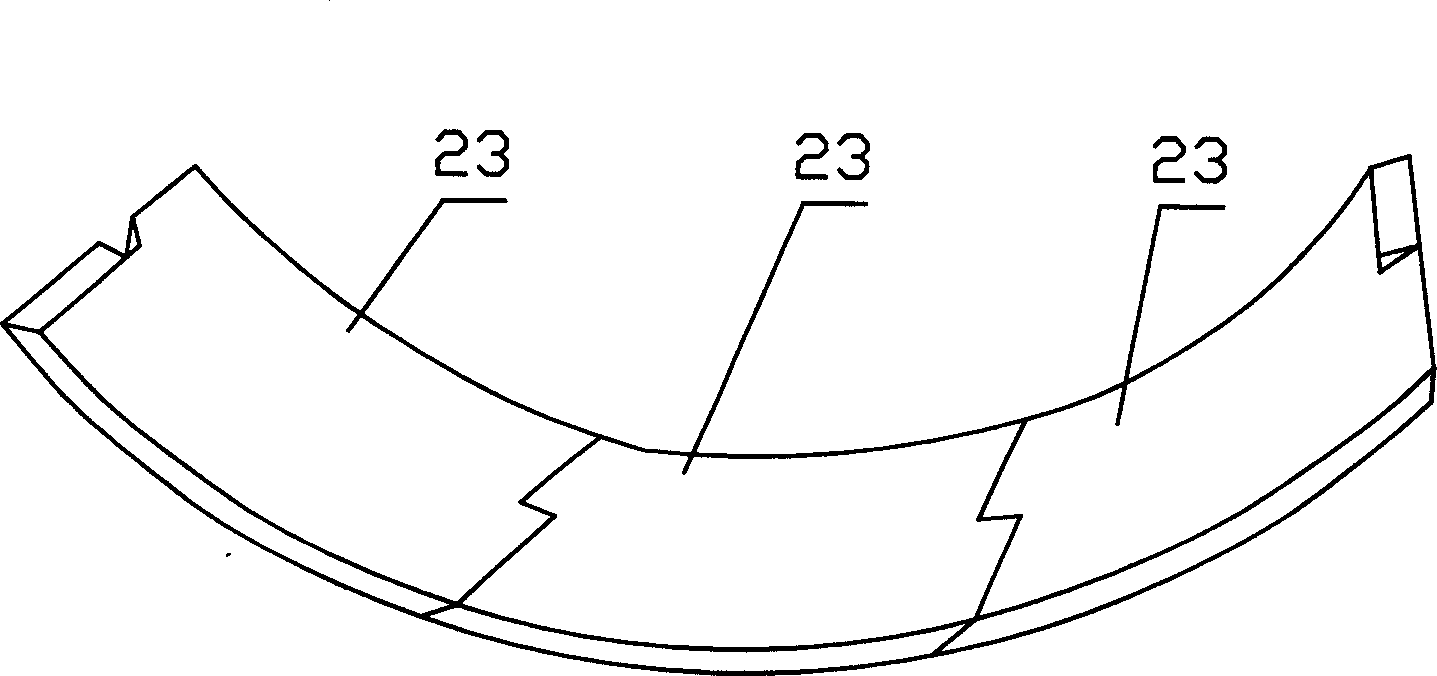

Bauxite grinding technology and apparatus thereof

The bauxite grinding process includes the following steps: feeding bauxite ore, lime and evaporation mother liquor into two-bin overflow grinding mill, breaking, coarse grinding, fine grinding, overflow discharging the ground ore slurry and feeding the ore slurry into intermediate slurry groove, then pumping the ore slurry into cyclone separator, sorting, discharging coarse granules slurry out from bottom outlet of cyclone separator and back returning the coarse granules slurry into two-bin overflow grinding mill and further grinding, screening fine granules slurry and feeding the fine granules slurry into finished product groove to make storage.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

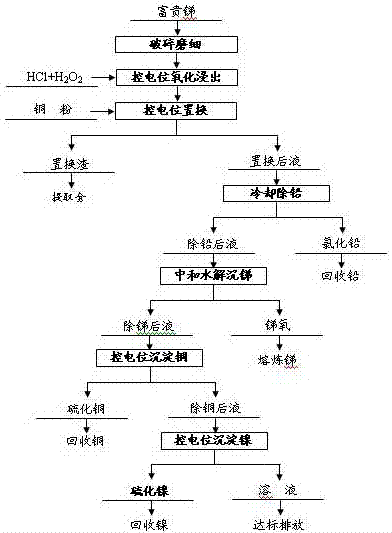

Method for potential-controlled separation and recovery of base metals in precious antimony

ActiveCN107447107AEasy to separateAvoid distractionProcess efficiency improvementSlurryNickel sulfide

The invention relates to a method for potential-controlled separation and recovery of base metals in precious antimony. The method comprises the steps of smashing and grinding the precious antimony to a required particle size; adding hydrogen peroxide into a pure hydrochloric acid system and carrying out potential-controlled oxidation leaching; adding copper powder into slurry and carrying out potential-controlled replacement; cooling the replaced liquid, crystallizing and separating out lead chloride; simultaneously adding sodium hydroxide and water into the lead-removed liquid and carrying out neutralization-hydrolysis to separate out antimony oxide; adding sodium sulfide into the antimony-removed liquid and carrying out potential-controlled copper precipitation to separate out copper sulfide; adding the sodium hydroxide and the sodium sulfide into the copper-removed liquid and carrying out potential-controlled nickel precipitation to separate out nickel sulfide; and discharging the up-to-standard nickel-removed liquid. The essence of method disclosed by the invention is that the effective removing and stepwise recovery of the base metals in the precious antimony are realized in the potential controlling way; and the purpose that the four processes of oxidation leaching, replacement, copper precipitation and nickel precipitation are adjustable and controllable is realized. The method has the advantages that the technical index in the technical processes is stable; the labour intensity is low; the production cost is low and the like.

Owner:CENT SOUTH UNIV

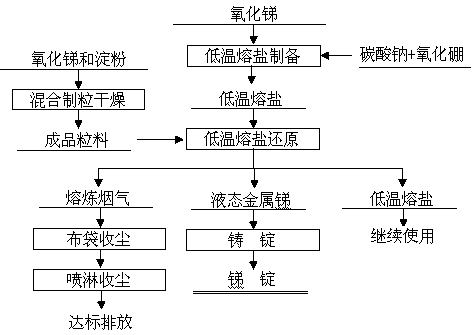

Method of using starch to reduce antimony oxide in low temperature molten salt

The invention relates to a method of using starch to reduce antimony oxide in low temperature molten salt. According to the method, antimony oxide and starch are mixed, granulated, and dried, then granules are reduced in low temperature molten salt to produce antimony, and the method mainly comprises three phases: mixing-granulating-drying, low temperature molten salt preparation, and low temperature molten salt reduction. In low temperature molten salt, starch is used to reduced antimony oxide, the energy consumption of reduction melting is largely reduced, the temperature of reduction melting is reduced to 600-750 DEG C; at the same time, antimony oxide is mixed with starch, the mixture is granulated, dried, and added into low temperature molten salt, the starch loss during the combustion process is effectively prevented, and the utilization rate of starch is greatly increased.

Owner:CENT SOUTH UNIV

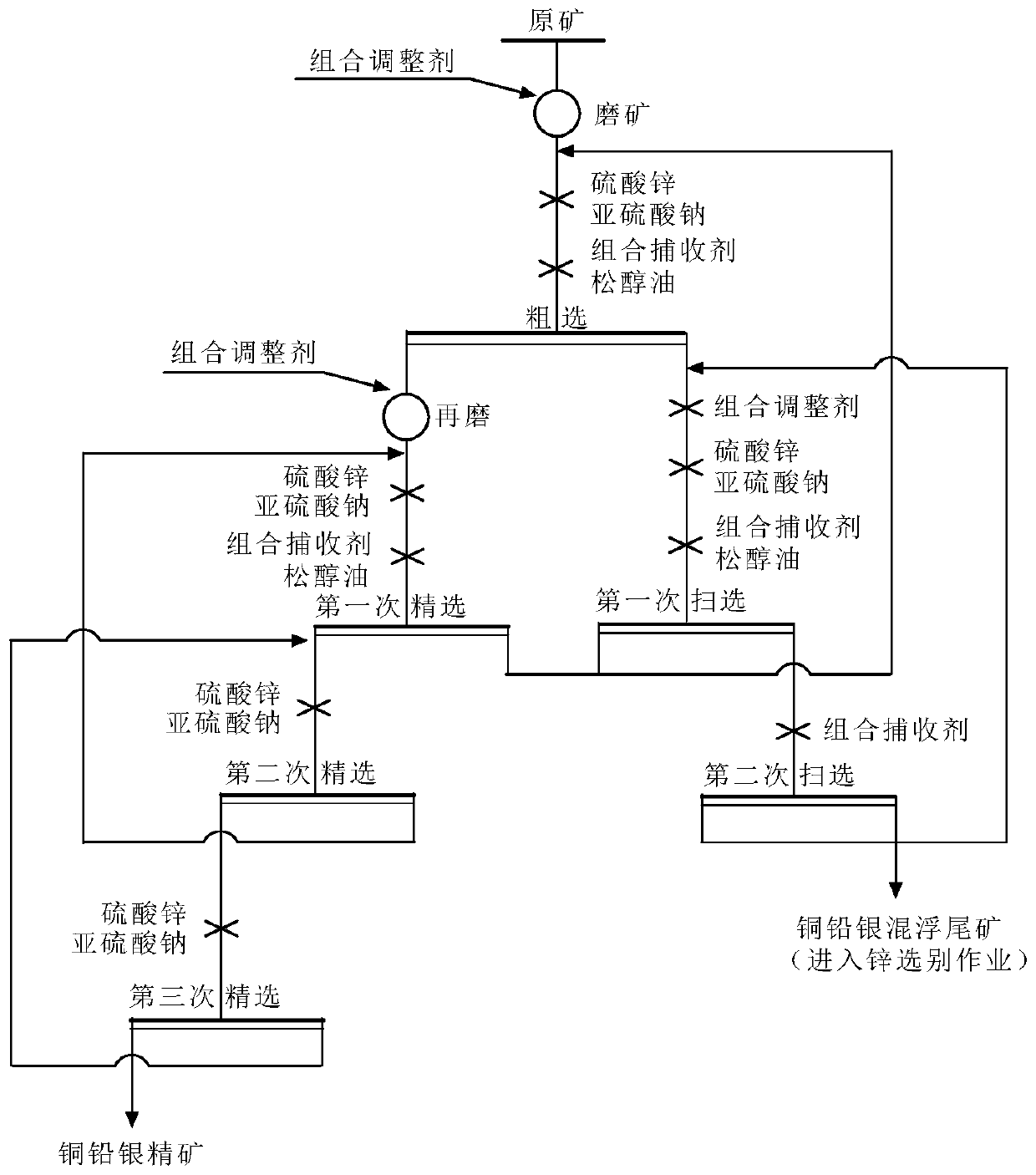

Combined collecting agent and beneficiation method for recovering copper, lead and silver from copper lead zinc and silver polymetallic ore

The invention discloses a combined collecting agent and a beneficiation method for recovering copper, lead and silver from copper lead zinc and silver polymetallic ore. The combined collecting agent is prepared by mixing dianilinodithiophosphoric acid, sodium carbonate and ethyl thio carbamate in a mass ratio of (3.0 to 5.0):(2.0 to 3.0):(1.0 to 2.0). The beneficiation method comprises the steps that a combined regulator is added into raw ore for grinding to prepare raw ore slurry; zinc sulfate, sodium sulfite, the combined collecting agent and terpineol oil are added into the raw ore slurry in turn for rough separation to obtain copper-lead mixed coarse concentrate; the copper-lead mixed coarse concentrate is subjected to thickening and dewatering, and then the combined regulator is addedfor grinding to prepare regrinding slurry; and the zinc sulfate, the sodium sulfite, the combined collecting agent and the terpineol oil are added into the regrinding slurry in turn, then fine separation is conducted, and thus copper-lead-silver mixed concentrate is obtained. According to the combined collecting agent and the beneficiation method for recovering the copper, the lead and the silverfrom the copper lead zinc and silver polymetallic ore, copper lead silver mineral in the high sulfur high arsenic copper lead zinc and silver polymetallic ore can be efficiently recovered.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Method for leaching and recycling valuable elements of copper smelting smoke dust

ActiveCN113444886AEasy to handleHigh recovery rateProcess efficiency improvementLead smeltingHydrometallurgy

The invention discloses a method for leaching and recycling valuable elements of copper smelting smoke dust, and belongs to the technical field of hydrometallurgy. The method comprises the following steps of mixing smoke dust and concentrated sulfuric acid according to a certain acid-dust ratio for pretreatment; carrying out dilute sulfuric acid leaching on the smoke dust, carrying out solid-liquid separation to obtain a primary leachate and primary leaching residues, and feeding the leaching residues to a lead smelting system for recycling; adding an alkaline reagent into the primary leachate, so that arsenic in the solution is removed in a stable arsenate solid form; recovering valuable metals such as copper, cadmium and the like by a replacement method, adding zinc powder into the solution after arsenic precipitation, and precipitating and recovering the valuable metals such as copper and the like from the solution in the form of sponge copper at a certain temperature for a certain time; and concentrating, crystallizing and recovering zinc, purifying the solution subjected to copper deposition, and concentrating and crystallizing to obtain a zinc sulfate heptahydrate product. The method is suitable for leaching smoke dust generated by smelting and blowing processes in the copper smelting process, the application range of the method is wide, the treatment effect on elements such as copper, lead, zinc and arsenic is good, economic benefits are high, and the method is suitable for industrial application.

Owner:NORTHEASTERN UNIV LIAONING

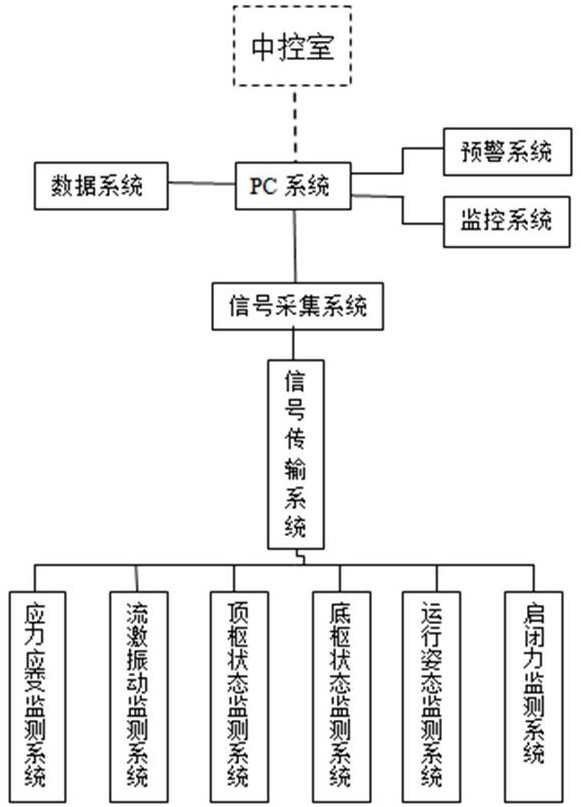

Ship lock miter gate and hoist health state real-time online monitoring system

PendingCN111897270AEasy to buyReal-time grasp of operating statusProgramme controlMeasurement devicesEarly warning systemControl engineering

The invention discloses a ship lock miter gate and hoist health state real-time online monitoring system. The system comprises a stress-strain monitoring system, a flow-induced vibration monitoring system, a top pivot state monitoring system, a bottom pivot state monitoring system, a gate operation posture monitoring system, an opening and closing force monitoring system, a signal transmission system, a signal acquisition system, a monitoring system, an early warning system, a data system and a PC system. According to the invention, the system is scientific in principle , simple in structure,convenient to purchase adopted components, easy to operate during construction, capable of guaranteeing the monitoring effect and mastering the operation conditions of large metal structure equipmentsuch as a ship lock miter gate and a hoist in real time, and easy to widely popularize in metal structure engineering of domestic harbor and navigation channel engineering due to the fact that the overall construction cost is controllable.

Owner:郑州金闸测控技术有限公司

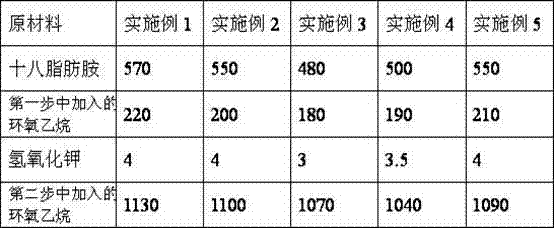

Method for preparing octadecyl amine polyoxyethylene ether

The invention relates to a method for preparing octadecyl amine polyoxyethylene ether. The octadecyl amine polyoxyethylene ether is prepared by adding ethylene oxide and a catalyst into octadecyl amine which is taken as a raw material, and performing polymerization reaction. The method is characterized in that the reaction comprises the following two steps of: 1, adding the octadecyl amine into a spray reaction kettle, raising the temperature to 160 to 170 DEG C during vacuumization until the pressure in the kettle is 0.2 to 0.3MPa, sucking the material in the kettle out from the reaction kettle, spraying from the upper part of the reaction kettle, spraying the ethylene oxide into the kettle at the same time, and pre-reacting; and 2, adding the catalyst, namely potassium hydroxide, and spraying the residual ethylene oxide into the kettle at the same time. The reaction time is short, the reaction is complete, and the compatibility is high when the octadecyl amine polyoxyethylene ether is compounded.

Owner:吴金海

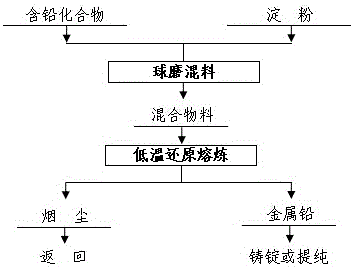

Low-temperature reduction smelting method for lead-containing compound

ActiveCN106048229AReduce energy consumptionReduce manufacturing costProcess efficiency improvementBall millEnergy consumption

Disclosed is a low-temperature reduction smelting method for a lead-containing compound. The lead-containing compound and starch are added into a ball mill simultaneously to be subjected to ball milling and mixing. The mixed materials are continuously conveyed into a smelting pot for indirect heating and are smelted after being heated to a required temperature. Produced wet lead is subjected to electrolytic refining treatment. The essence of the technical scheme is that the starch serves as a reducing agent under an indirect heating condition, and the purpose of producing the wet lead from the lead-containing compound through reducing smelting is realized. The direct recovery rate of the lead can reach 96.0% or above. The starch serves as the reducing agent, the reducing smelting temperature is lowered to 800-850 DEG C, and the energy consumption of low-temperature reducing smelting of the lead-containing compound is greatly lowered.

Owner:CENT SOUTH UNIV

Method for reducing enzyme usage amount in process of producing acrylamide by virtue of microbiological method

ActiveCN106467921AReduce consumptionReduce the number of storage devicesFermentationHydration reactionMicroorganism

The invention provides a method for reducing a nitrile hydratase usage amount in a process of producing acrylamide by virtue of a microbiological method. In a process of producing the acrylamide by catalyzing a hydration reaction in the microbiological method, the quality of the acrylamide is optimized when a fermentation broth storage time of nitrile hydratase cells is 96-240h; and when the storage time is longer than or equal to 240h, the activity of the nitrile hydratase in a fermentation broth drops, the usage amount of the fermentation broth is increased and the quality of the obtained acrylamide is reduced. According to the method provided by the invention, by mixing the nitrile hydratase cell fermentation broth with the storage time shorter than or equal to 24h and the nitrile hydratase cell fermentation broth with the storage time longer than or equal to 240h, the activity and the quality of the nitrile hydratase are improved, so that the method for reducing the usage amount of the nitrile hydratase is achieved. With the application of the method provided by the invention, the usage amount of the nitrile hydratase in the production process is reduced, the consumption of raw materials of a fermentation medium is relieved and the stability of the quality of an acrylamide solution is improved, and the method is conducive to the subsequent production of the acrylamide. When the method provided by the invention is applied to the industrial production of the acrylamide by virtue of the microbiological method, the finished product is stable in various technical indicators.

Owner:SICHUAN GUANGYA POLYMER CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com