Method for leaching platinum, palladium and rhodium from spent ternary catalyst

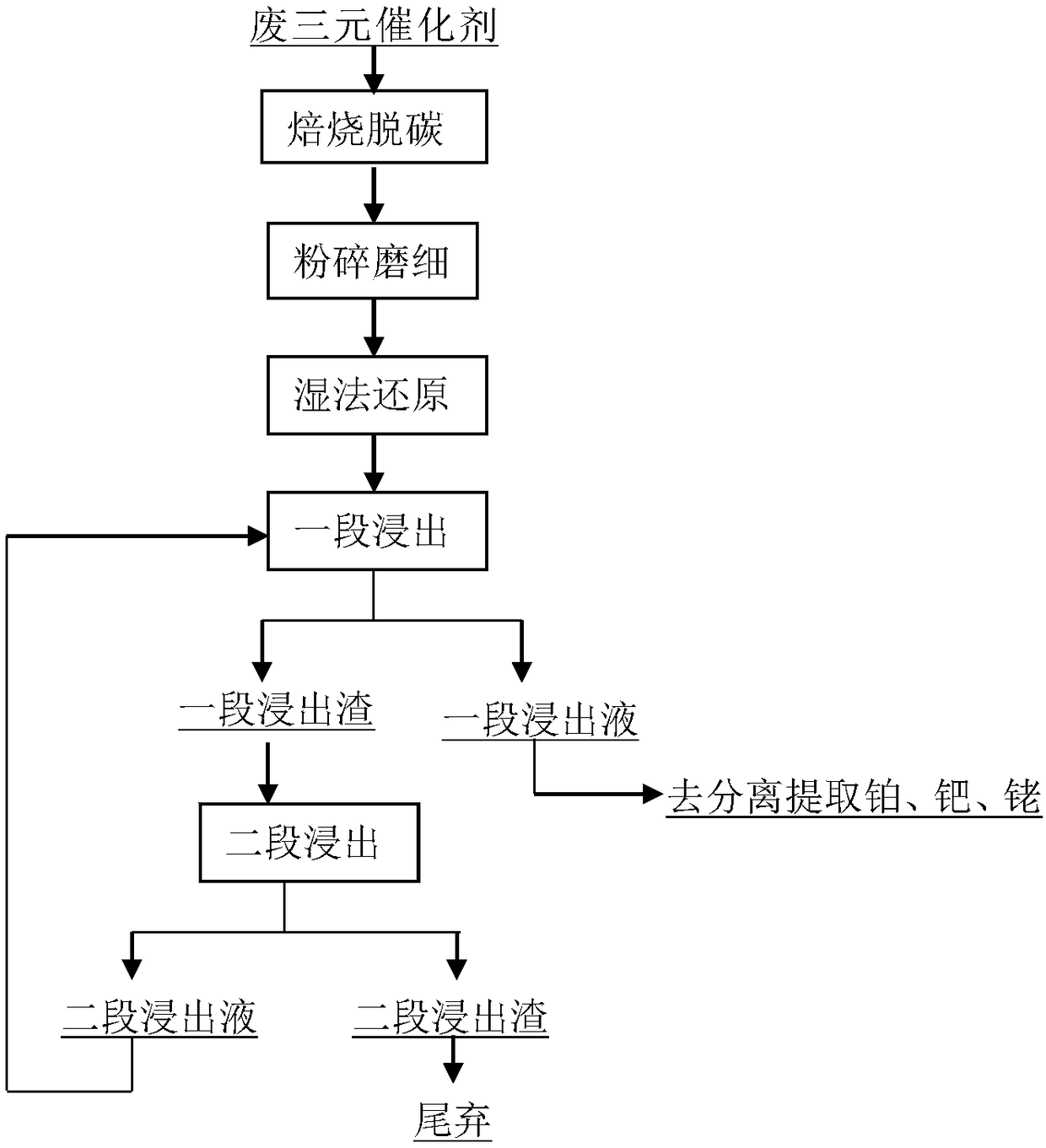

A three-way catalyst and waste catalyst technology, which is applied in the leaching of palladium and rhodium, and the field of platinum in waste three-way catalysts, can solve the problems of difficult separation of metal and slag, high viscosity of slag, difficult process, etc., and achieves good applicability and excellent treatment The effect of low cost and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of leaching method of platinum, palladium, rhodium in spent three-way catalyst comprises the following steps:

[0033] S1: Roasting the spent three-way catalyst, the calcination temperature is controlled at 300°C, and the calcination time is 2h;

[0034] S2: Crushing and grinding the roasted three-way spent catalyst, and controlling the particle size to 10 mesh after grinding;

[0035]S3: Reduce and transform the oxidized noble metal in the ground three-way waste catalyst into a single substance state. The process conditions for reduction and transformation are: temperature 60°C, liquid-solid ratio 3 / 1, time 3h;

[0036] S4: The three-way spent catalyst is made of cordierite 2MgO·2Al 2 o 3 ·5SiO2 2 As the substrate, an alumina active coating is used to coat it, and the active components contained in the catalyst are concentrated in the alumina coating; the alumina coating on the surface of the three-way waste catalyst carrier is dissolved with sulfuric acid, a...

Embodiment 2

[0046] A kind of leaching method of platinum, palladium, rhodium in spent three-way catalyst comprises the following steps:

[0047] S1: Roasting the spent three-way catalyst, the calcination temperature is controlled at 900°C, and the calcination time is 8h;

[0048] S2: Crushing and grinding the roasted three-way waste catalyst, and controlling the particle size to 200 mesh after grinding;

[0049] S3: Reductively transform the oxidized noble metal in the finely ground three-way spent catalyst into a single substance state. The process conditions for the reduction transformation are: temperature 90°C, liquid-solid ratio 3 / 1, time 3h;

[0050] S4: The three-way spent catalyst is made of cordierite 2MgO·2Al 2 o 3 ·5SiO2 2 As the substrate, an alumina active coating is used to coat it, and the active components contained in the catalyst are concentrated in the alumina coating; the alumina coating on the surface of the three-way waste catalyst carrier is dissolved with sulfur...

Embodiment 3

[0060] 600g of an automobile three-way waste catalyst, containing 0.064% of Pt, 0.136% of Pd, and 0.016% of Rh. The catalyst is based on cordierite (2MgO·2Al 2 o 3 ·5SiO2 2 ) is a carrier in the shape of a honeycomb cylinder, with carbon deposits on the surface and partly sintered. The X-ray fluorescence semi-quantitative full analysis results are shown in Table 1

[0061] Table 1 X-fluorescence semi-quantitative analysis results

[0062] Element

Al 2 o 3

SiO 2

MgO

CeO 2

P 2 o 5

Fe 2 o 3

ZrO 2

BaO

SO 3

content%

41.6

32.4

7.8

4.7

1.6

1.5

0.78

0.767

0.61

[0063] 600g of spent three-way catalyst was first calcined at 700°C for 4 hours, then crushed and ground to -100 mesh, and 1800ml of water was added to a 5-liter beaker, and the finely ground catalyst was added while stirring. After the temperature was raised to 60°C, 30ml of hydrazine hydrate was added for For reduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com