Method for vulcanizing and separating valuable metal in solution through controlled potential

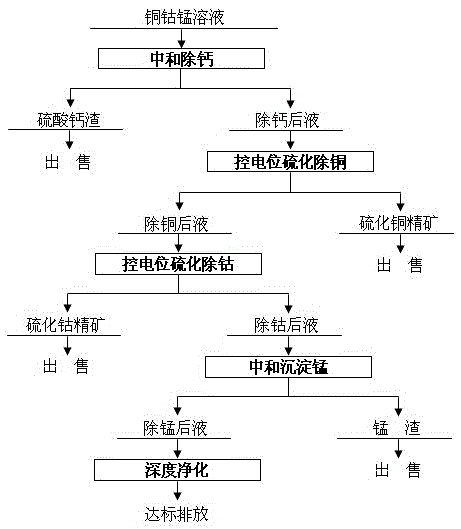

A valuable metal and solution technology, applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc., can solve problems such as solution treatment difficulties, solution system changes, and wastewater treatment difficulties, so as to eliminate environmental pollution, simple process and low production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The copper-cobalt-manganese solution of the cobalt smelting system of a domestic enterprise in the P204 stripping and impurity removal process has a main composition range (g / L): Cu42.0, Co2.8, Zn6.4, Ca6.0, Mn110.0, Cl180 .0 and H18.0. The mass percentage of industrial grade sodium sulfide is greater than 60.0%, and the mass percentage of industrial grade hydrochloric acid is not less than 31.0%. to 10m 3 Add 220Kg of industrial-grade sodium sulfate to the copper-cobalt-manganese solution, then add solid sodium carbonate to adjust the pH of the solution to 0.95, keep the temperature at 50°C and the speed at 120r / min, stir for 60 minutes, and use plate and frame filter press to achieve solid-liquid separation. The weight of slag is 254Kg, and the calcium content in the liquid after decalcification is 0.01g / L. Keep the temperature of the decalcified solution at 50°C and the speed at 120r / min, add sodium sulfide solution with a concentration of 312.0g / L, and add industr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com