Bauxite grinding technology and apparatus thereof

A bauxite and equipment technology, applied in the field of bauxite grinding process and equipment, can solve the problems of complex process, long process and high consumption, and achieve the effect of short process, reduced maintenance and reduced operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

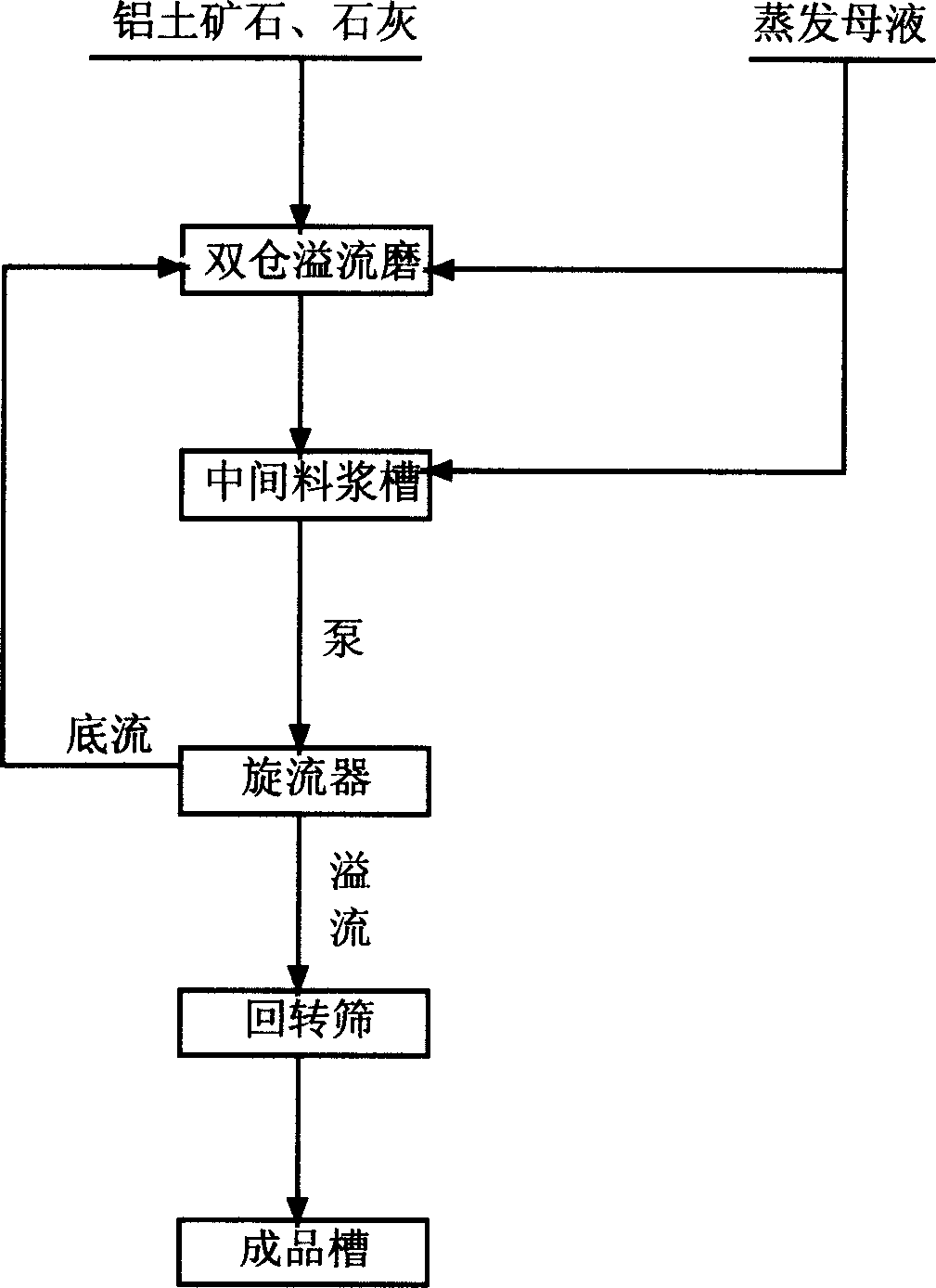

Method used

Image

Examples

Embodiment Construction

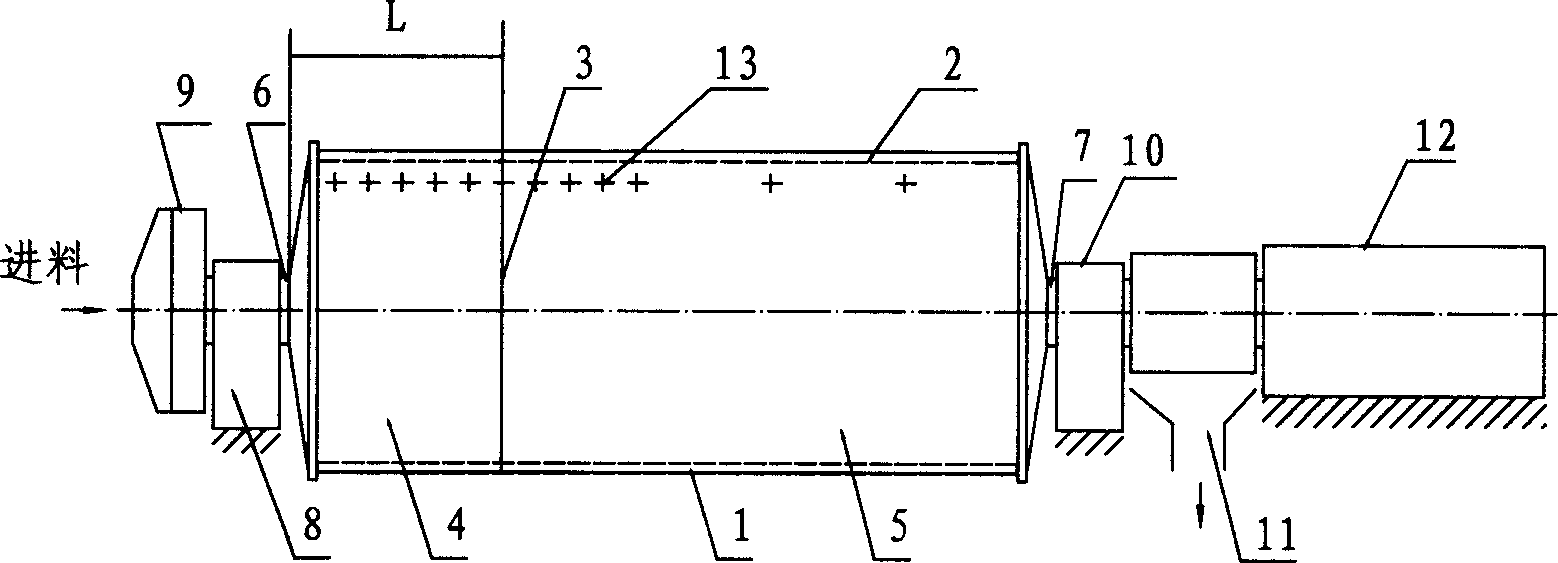

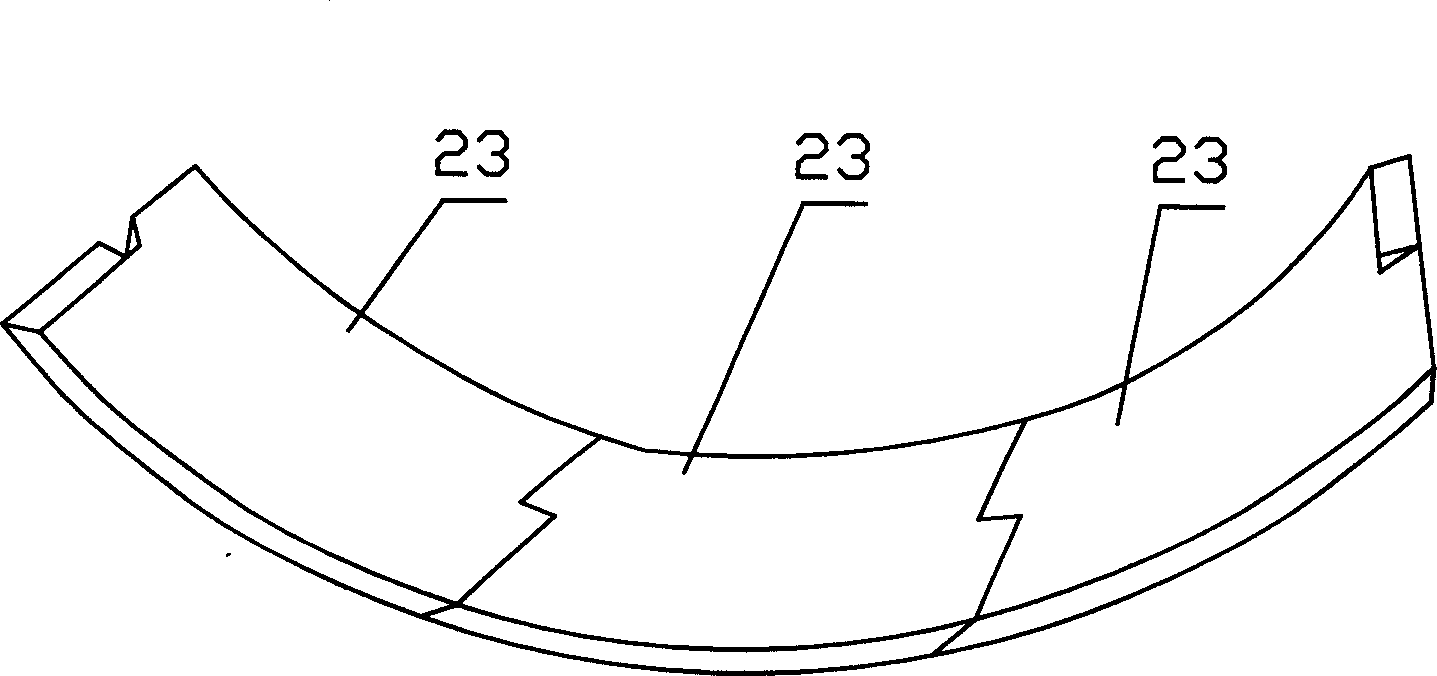

[0030]Embodiments of the present invention: as shown in the accompanying drawings, the grinding mill of the present invention comprises a circular cylinder (1), and a liner (2) is installed on the inner wall of the cylinder (1), and the liner (2) In order to connect the liner without bolts, the liner (2) is inlaid by several arc-shaped plates (23), and wedge joints (21) and wedge joints (22) are arranged at both ends of each plate body (23). ), the plates (23) are inlaid with each other by wedge joints (21) and wedge joints (22). A partition board (3) is fixed inside the cylinder body (1) with bolts (13), and the partition board (3) separates the cylinder body (1) into two independent coarse material bins (4) and fine material bins ( 5); where the compartment plate (3) is made of cast steel material, for the convenience of installation, the compartment plate (3) is assembled by several fan-shaped plates (14); meanwhile, for the convenience of the coarse feed bin (4 ) can ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com