Screw sand washer with wear resistant composite bearing

A composite bearing and sand washing machine technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of reducing work efficiency, large amount of returned sand, affecting output, etc., to improve production efficiency and reduce maintenance. Cost and effect of reducing economic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

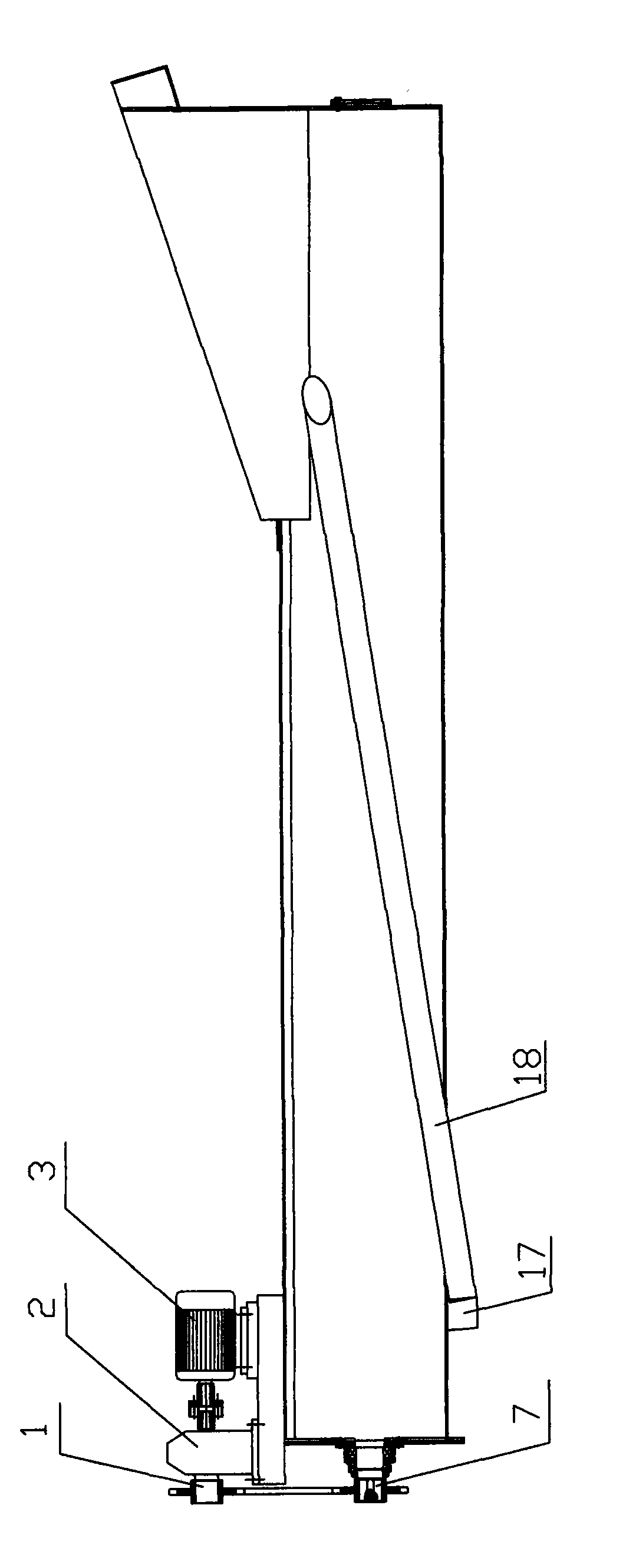

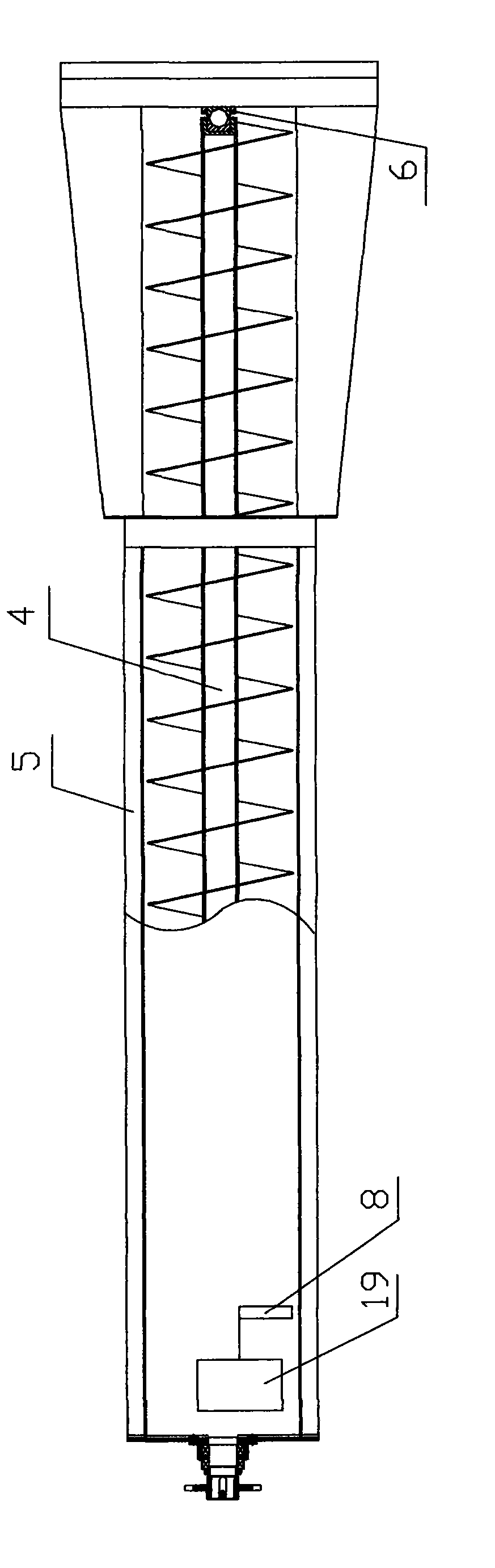

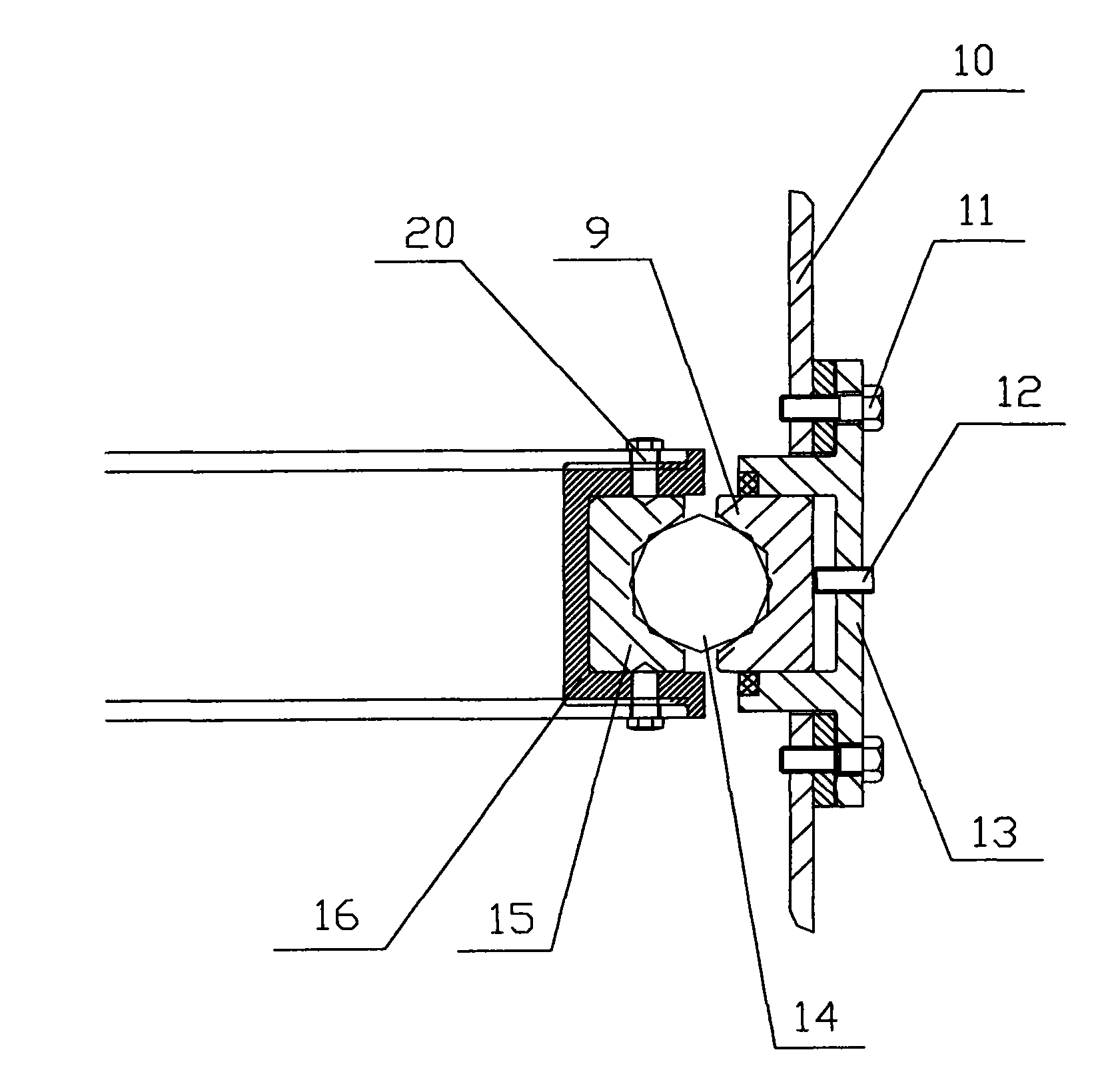

[0026] A spiral sand washing machine using wear-resistant composite bearings, including a transmission device, a housing 5 and a spindle system fixed in the housing 5, the front end of the housing 5 is provided with a discharge port 19, and the housing 5 The rear end is the sand washing tank. The end of the discharge port 19 away from the front end of the housing 5 is provided with a water return port 8, and the water return port 8 is connected to one end of the water return pipe 18 through the water diversion groove 17 arranged at its lower part, and the other end of the water return pipe 18 is connected to the water return pipe 18. The sand washing tank is connected. The main shaft system includes a main shaft 4 with helical blades; the transmission device includes a motor 3, the motor 3 is connected to the driving wheel 1 through a reducer 2, and the driving wheel 1 is connected to the driven wheel 7 through a chain. The driven wheel 7 is connected with the main shaft 4 . ...

Embodiment 2

[0029] A spiral sand washing machine using wear-resistant composite bearings, including a transmission device, a housing 5 and a spindle system fixed in the housing 5, the front end of the housing 5 is provided with a discharge port 19, and the housing 5 The rear end is the sand washing tank. The end of the discharge port 19 away from the front end of the housing 5 is provided with a water return port 8, and the water return port 8 is connected to one end of the water return pipe 18 through the water diversion groove 17 arranged at its lower part, and the other end of the water return pipe 18 is connected to the water return pipe 18. The sand washing tank is connected. The main shaft system includes a main shaft 4 with helical blades; the transmission device includes a motor 3, the motor 3 is connected to the driving wheel 1 through a reducer 2, and the driving wheel 1 is connected to the driven wheel 7 through a chain. The driven wheel 7 is connected with the main shaft 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com