Method for inhibiting sand return of preserved fruits

A technology of preserved fruit and sand returning, applied in food science, food ingredients as coating agent, application, etc., can solve the problems of sand returning of candied fruit, surface sand returning, flowing sugar, etc., so as to reduce the phenomenon of sand returning and prevent Surface sand return, good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

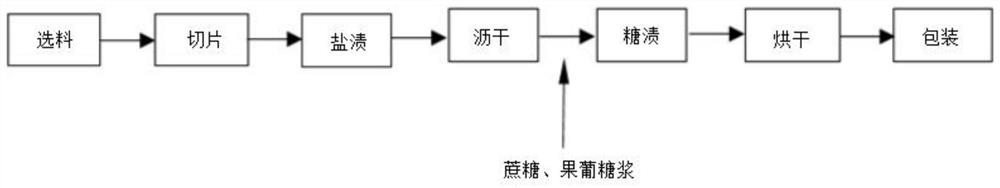

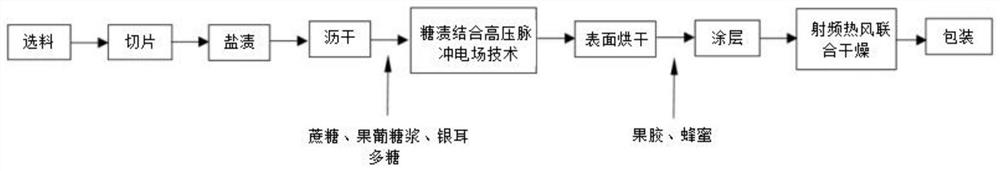

Method used

Image

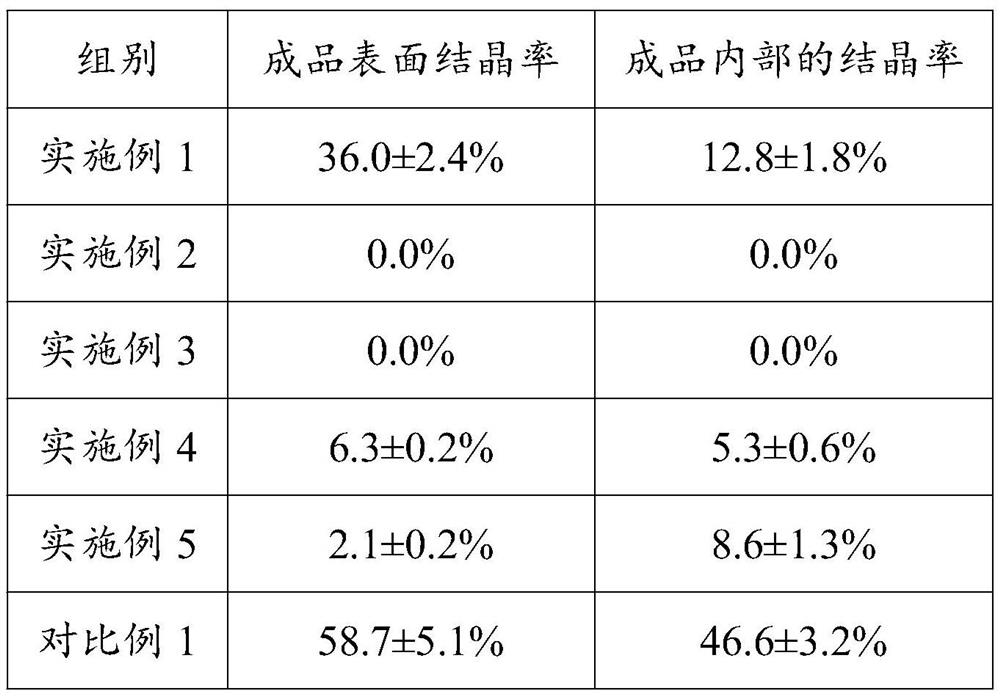

Examples

Embodiment 1

[0034] Example 1: Containing 50-70kDa white fungus polysaccharide sugar liquid sugar pickling & pulse treatment

[0035] (1) Material selection and cutting: select high-quality walnuts (purchased from Lianhua Supermarket), wash them with clean water, and cut them after trimming, with a thickness of 2cm;

[0036] (2) Salting: salt the fruit with the same block shape for 20 hours with 3 times the volume of saline solution, the salt content in the saline is 2wt%, remove it after immersion, rinse with water 2 to 3 times, and then drain;

[0037] (3) Sugar stain: sucrose (purchased from Shanghai Yichuan Sugar Technology Co., Ltd.), fructose syrup (purchased from Zhejiang Zhongtuan Biotechnology Co., Ltd.), 50-70kDa tremella polysaccharide (purchased from Zhejiang Baishanzu Biotechnology Co., Ltd. Company) is dissolved in water according to the mass ratio of 12:5:2 to form 55wt% sugar solution, and the drained fruit is poured into the sugar solution according to the mass ratio of fr...

Embodiment 2

[0040] Example 2: Containing 50-70kDa white fungus polysaccharide sugar liquid sugar stain & pulse treatment + coating & radio frequency hot air combined drying

[0041] (1) Material selection and cutting: select high-quality fresh walnuts (purchased from Lianhua Supermarket), wash them with clean water, trim them and cut them into pieces, with a thickness of 2cm;

[0042] (2) Salting: salt the fruit of the same size with 3 times the quality of salt water for 20 hours. The salt content in the salt water is 2wt%. After the dipping is completed, take it out, rinse it with water for 2 to 3 times, and then drain it;

[0043] (3) Sugar stain: sucrose (purchased from Shanghai Yichuan Sugar Technology Co., Ltd.), fructose syrup (purchased from Zhejiang Zhongtuan Biotechnology Co., Ltd.), 50-70kDa tremella polysaccharide (purchased from Zhejiang Baishanzu Biotechnology Co., Ltd. Company) is dissolved in water according to the mass ratio of 12:5:2 to prepare 55wt% sugar solution, and t...

Embodiment 3

[0048]Embodiment 3: Containing 50~70kDa white fungus polysaccharide sugar liquid candied & pulse treatment+coating & radio frequency hot air combined drying

[0049] (1) Material selection and cutting: select high-quality fresh walnuts (purchased from Lianhua Supermarket), wash them with clean water, trim them and cut them into pieces, with a thickness of 2cm;

[0050] (2) Salting: salt the fruit of the same size with 3 times the quality of salt water for 20 hours. The salt content in the salt water is 2wt%. After the dipping is completed, take it out, rinse it with water for 2 to 3 times, and then drain it;

[0051] (3) Sugar stain: sucrose (purchased from Shanghai Yichuan Sugar Technology Co., Ltd.), fructose syrup (purchased from Zhejiang Zhongtuan Biotechnology Co., Ltd.), 50-70kDa tremella polysaccharide (purchased from Zhejiang Baishanzu Biotechnology Co., Ltd. Company) is dissolved in water according to the mass ratio of 13:5:2 to prepare 55wt% sugar solution, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com