Down-flow preselection spiral classifier

A technology of spiral classifier and pre-separator, which is applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of reducing the recovery rate of magnetic minerals, wasting grinding energy consumption, reducing concentrate grade and recovery rate, etc. Achieve the effect of improving the recovery rate of magnetic minerals, improving the classification efficiency, and reducing the energy consumption of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

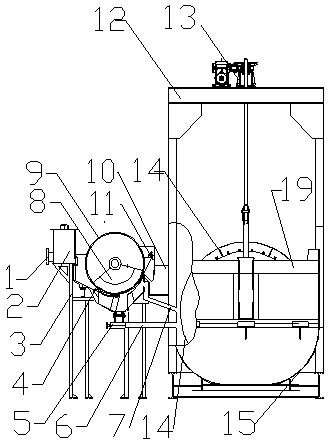

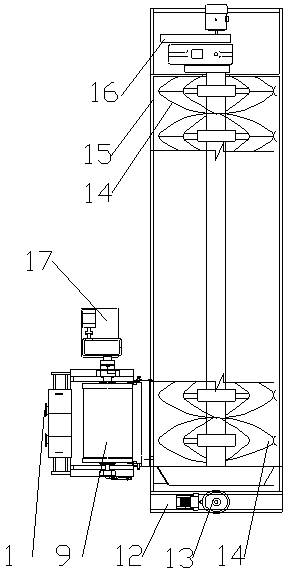

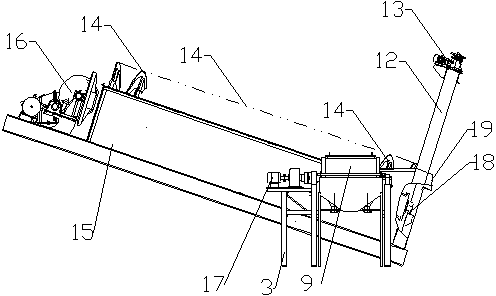

[0022] In order to further describe the present invention, a downstream pre-selection spiral classifier of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] Depend on figure 1 The front elevation schematic diagram of a kind of downstream pre-selection spiral classifier of the present invention shown and combined figure 2 and image 3 It can be seen that a downstream preselection spiral classifier of the present invention is composed of a downstream magnetic separation preselector and a spiral classifier organically:

[0024] The downstream magnetic separation pre-selector is composed of an ore feeding port 1, an ore feeding box 2, a frame 3, a sorting tank 4, an ore discharge valve 5, an ore discharge pipe 6, an overflow pipe 7, a magnetic system 8, a circular The cylinder 9, the concentrate tank 10, the flushing water pipe 11, and the cylinder driving mechanism 17 are combined; the ore feeding port 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com