Inorganic foam cement thermal insulation material for outer wall

A technology of inorganic foam and thermal insulation materials, applied in the field of thermal insulation materials, can solve the problems of inorganic fireproof thermal insulation materials such as heavy weight, low mechanical strength, and high water absorption rate, and achieve the effect of reducing self-weight, reducing water absorption rate, and improving cement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

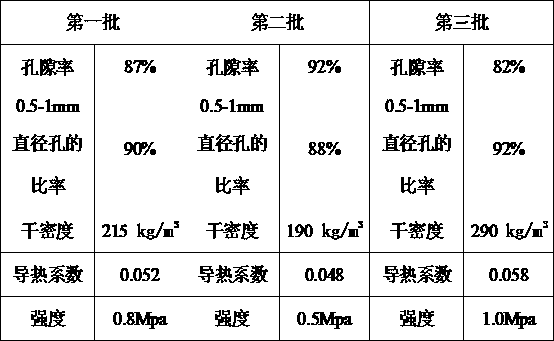

Embodiment 1

[0034] (1) Preparation of cement slurry: Take 170g of sulfoaluminate cement and 75g of water, mix and stir for 2-4 minutes until uniform, then add 0.3g of silicone waterproofing agent, 0.3g of water reducing agent, and stir for 1-2 minutes until uniform , and finally add fiber 1.2g slowly and stir for 1-3 minutes.

[0035] (2) Foam preparation: Take 1kg of foaming agent, 0.005kg of foam stabilizer and 25kg of water, mix them evenly, move them into a foaming machine, and prepare uniform and stable foams in the foaming machine.

[0036] (3) Stir the cement paste and foam in a mixer for 3-10 minutes at a volume ratio of 0.17:0.83 until evenly mixed.

[0037] (4) Pouring the prepared foam cement into the mold made of insulation board, covering the mold with insulation board after pouring, removing the mold after 12 hours, cutting, heat preservation and maintenance.

[0038] The water temperature of the water used in the preparation of the insulation material is 25°C.

Embodiment 2

[0040] (1) Preparation of cement slurry: Take 150g of sulfoaluminate cement and 60g of water, mix and stir for 2-4 minutes until uniform, then add 0.2g of silicone waterproofing agent, 0.2g of water reducing agent, and stir for 1-2 minutes until uniform , and finally slowly add 2.0 g of fiber and stir for 1-3 minutes.

[0041] (2) Foam preparation: Take 1g of foaming agent, 0.007g of foam stabilizer and 28g of water, mix them evenly, transfer them into a foaming machine, and prepare a uniform and stable foam in the foaming machine.

[0042] (3) Mix the cement paste and foam in a mixer for 3-10 minutes at a volume ratio of 0.1:0.9 until evenly mixed.

[0043] (4) Pouring the prepared foam cement into a mold made of insulation board, covering the mold with insulation board after pouring, removing the mold after 8 hours, cutting, heat preservation and maintenance.

[0044] The water temperature of the water used in the preparation of the insulation material is 27°C.

Embodiment 3

[0046] (1) Preparation of cement slurry: Take 230g of sulfoaluminate cement and 95g of water, mix and stir for 2-4 minutes until uniform, then add 0.4g of silicone waterproofing agent, 0.4g of water reducing agent, and stir for 1-2 minutes until uniform , and finally slowly add 2.8g of fiber and stir for 1-3 minutes.

[0047] (2) Foam preparation: Mix 1kg of foaming agent, 0.008kg of foam stabilizer and 24kg of water according to the stated proportions, transfer them into a foaming machine, and prepare uniform and stable foams in the foaming machine.

[0048] (3) Stir the cement paste and foam in a mixer for 3-10 minutes at a volume ratio of 0.2:0.8 until evenly mixed.

[0049] (4) Pouring the prepared foam cement into the mold made of insulation board, covering the mold with insulation board after pouring, removing the mold after 30 hours, cutting, heat preservation and maintenance.

[0050] The water temperature of the water used in the preparation of the insulation materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com